Are you searching for the perfect 80cm sandwich panel to take your construction projects to the next level? Choosing the right panel size can make a huge difference—not just in how quickly you install but also in the insulation performance and long-term durability of your buildings.

In this guide, you’ll discover everything about 80cm sandwich panels—from their key specifications and material benefits to practical applications and installation tips you don’t want to miss. Whether you’re an architect, contractor, or DIY enthusiast, understanding why the 80cm width is preferred can save you time and money.

Ready to explore the advantages of these panels and find out why shanghe is a trusted name in quality sandwich panels? Let’s jump right in!

What Is an 80cm Sandwich Panel

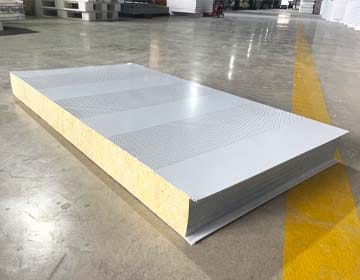

When you hear about an 80cm sandwich panel, it refers to a type of construction panel widely used for walls, roofs, and insulation purposes. Sandwich panels are composite structures made of two rigid outer layers bonded to a lightweight core material, offering strength, insulation, and durability all in one product.

Definition and Core Structure of Sandwich Panels

A sandwich panel consists of:

- Outer layers: Usually metal sheets like galvanized steel or aluminum, providing protection and mechanical strength.

- Core material: The insulating heart of the panel, made from materials such as polyurethane (PU), polyisocyanurate (PIR), rock wool, or expanded polystyrene (EPS). Each core material affects insulation, fire resistance, and mechanical properties differently.

This structure delivers excellent thermal insulation, fire resistance, and load-bearing capability, making sandwich panels ideal for various construction projects.

Why the 80cm Width Matters

The 80cm width of sandwich panels is a widely accepted standard for many building applications, especially in the US market. Here’s why this width matters:

- Offers a balanced coverage area that reduces the number of joints, helping improve insulation and avoid energy loss.

- Fits well with modular construction systems and common framing dimensions.

- Simplifies transportation and installation because the panel size is easy to handle without compromising coverage efficiency.

This width is especially popular in industrial buildings, cold storage rooms, and commercial facilities.

Typical Thickness and Materials

The thickness of 80cm sandwich panels usually ranges between 40mm and 200mm, depending on insulation requirements and load needs.

Common core materials include:

- Polyurethane (PU): Provides excellent thermal insulation with low heat conductivity.

- Polyisocyanurate (PIR): Similar to PU but with enhanced fire-resistant properties.

- Rock wool: Offers superior fire resistance and soundproofing, suitable for heavy-duty applications.

- Expanded polystyrene (EPS): Cost-effective insulation, widely used in less fire-sensitive projects.

Standard Sizes and Panel Structure

While the width is fixed at 80cm, lengths vary widely, generally from 2 meters up to 12 meters or more, making it easy to customize for different building dimensions. The panel’s layered structure includes:

- External metal sheets, available in different thicknesses and coatings for durability.

- The core insulating material providing thermal and fire-resistant qualities.

- Often a sealed edge system to ensure moisture and air tightness.

Together, these features ensure that 80cm sandwich panels deliver a high-performance, versatile solution for roofing, walls, and insulation, meeting both technical and practical needs efficiently.

Technical Specifications of 80cm Sandwich Panels

Dimensions and Sizes

The 80cm sandwich panel refers to panels with a standard width of 800mm, which is a popular size for efficient coverage and installation. Lengths typically vary from 2 meters up to 12 meters or more based on project needs. Thickness options usually range from 40mm to 200mm, allowing for customization depending on insulation and structural requirements.

Material Composition and Core Types

These panels feature a sandwich structure consisting of two strong outer metal sheets—often galvanized steel or aluminum—and an insulating core. Common core materials include:

- PU (Polyurethane) foam: Excellent thermal insulation with low thermal conductivity.

- PIR (Polyisocyanurate) foam: Offers better fire resistance while maintaining strong insulation.

- Rock wool: Known for fire resistance and sound insulation.

- EPS (Expanded Polystyrene): Cost-effective, good insulation for less demanding applications.

The choice of core affects overall thermal performance, fire resistance, and weight.

Thermal Properties and Insulation Performance

The thermal insulation of 80cm sandwich panels is a key selling point. Due to their wider width and quality insulation cores, these panels achieve low U-values, meaning less heat passes through. For example:

- PU cores can reach thermal conductivity as low as 0.022 W/m·K.

- PIR cores also perform well with values around 0.023 W/m·K.

This makes the 80cm sandwich panel ideal for energy-efficient buildings, significantly reducing heating and cooling costs.

Fire Resistance and Safety Standards

Fire safety is a major consideration. Depending on the core:

- PIR and rock wool cores provide strong fire resistance, meeting ASTM E84 and other key fire safety standards.

- PU and EPS cores have varying fire ratings and may require additional treatments or certifications for strict building codes.

Manufacturers typically certify these panels according to local US fire safety regulations to ensure compliance.

Load Bearing and Mechanical Strength

The outer metal layers combined with the core thickness give these panels good structural strength. Key features include:

- High load-bearing capacity to withstand wind, snow, or other loads.

- Adequate mechanical strength for wall and roofing applications.

- Resistance to deformation while maintaining thermal isolation.

This makes 80cm sandwich panels suitable for industrial and commercial construction where durability is critical.

Compliance and Quality Standards

Reliable panels come with certifications ensuring they meet ANSI, ASTM, and local building codes in the US. This includes:

- Thermal performance verification.

- Fire resistance certifications.

- Structural integrity testing.

Choosing panels that comply with these standards guarantees safety, efficiency, and long service life in US construction projects.

Advantages of Choosing 80cm Sandwich Panels for Thermal Insulation and Structure

When you pick 80cm sandwich panels, you’re opting for a smart balance of size, insulation, and ease that fits many construction needs here in the US. This panel width is becoming popular for good reasons, especially in industrial and commercial builds.

Enhanced Thermal Insulation Efficiency

The 80cm width provides an optimal thermal barrier with less heat transfer compared to narrower panels. Thanks to thicker insulation cores like PU (polyurethane), PIR, rock wool, or EPS packed inside, these panels trap heat better, making them ideal for cold storage, warehouses, and energy-efficient buildings. This size helps maintain consistent indoor temperatures, reducing HVAC load and cutting energy bills.

Cost Effectiveness in Design and Installation

Using wider 80cm sandwich panels means fewer panels are needed to cover the same area. This translates to:

- Lower labor costs because installation is quicker

- Reduced material waste thanks to fewer cuts and joints

- Streamlined logistics with less handling and packaging

Overall, these panels help keep project budgets tighter without compromising quality.

Faster and Easier Installation Process

Thanks to their large panel width, 80cm panels cover more surface area per unit, speeding up installation on walls and roofs. The panel’s design, with interlocking edges and consistent dimensions, supports:

- Simple fastening techniques

- Fewer onsite adjustments

- Less likelihood of mistakes during assembly

This efficiency reduces downtime and labor hours, which is a big plus on tight US project schedules.

Improved Structural Stability and Longevity

The sandwich panel’s rigid outer layers combined with strong insulation cores result in high mechanical strength. The 80cm width enhances this by offering a sturdy bite against:

- Wind loads

- Weather exposure

- Impact resistance

This strength translates into longer-lasting structures that withstand harsh US weather conditions, from coastal humidity to northern cold snaps.

Energy Savings and Environmental Benefits

With superior insulation properties, 80cm sandwich panels help buildings use less energy for heating and cooling. The reduced demand on HVAC systems cuts power usage, lowering carbon footprints and utility bills. Plus, many cores like PIR or rock wool are eco-friendlier materials, aligning with green building standards common in the US market.

In , 80cm sandwich panels deliver a sweet spot of insulation, cost savings, quick install, and durability — a practical choice for many US builders aiming for efficient and reliable construction.

Common Applications of 80cm Sandwich Panels in Construction

80cm sandwich panels are highly versatile and well-suited for a range of building projects across the U.S. Their specific width and insulation features make them a top choice for industries that demand efficiency, durability, and quick installation.

Industrial Buildings and Warehouses

One of the most frequent uses of industrial sandwich panels 80cm wide is in large-scale industrial buildings and warehouses. These panels offer:

- Superior thermal insulation to regulate internal temperatures.

- Fire-resistant options ideal for safety compliance.

- Easy to install wide panels that speed up construction time.

Their strength and insulation make them perfect for facilities storing sensitive materials or requiring temperature control.

Cold Storage Rooms

For cold storage, PU sandwich panel 80cm thickness options help maintain consistent low temperatures, critical for food and pharmaceuticals. The large panel width reduces the number of joints, lowering risks of thermal bridging and leaks, enhancing energy efficiency.

Residential Roofing and Wall Construction

In residential settings, roofing sandwich panel 80cm width works well for both exterior walls and roofs. Benefits include:

- Efficient insulation, reducing energy costs.

- Lightweight panels that simplify installation on homes.

- Aesthetic finishes that fit modern building designs.

Commercial Facilities and Modular Buildings

Commercial buildings and modular constructions get a big boost with 80cm panels thanks to:

- Modular-friendly panel sizes compatible with building systems.

- Faster assembly reducing downtime.

- Improved load-bearing capacity supporting multi-story designs.

These panels fit well for retail stores, offices, and even temporary structures.

Ideal Use Cases for 80cm Width Panels

The 80cm width stands out because:

- It balances material waste and installation speed better than wider or narrower options.

- Perfect for projects where thermal performance and structural strength must align.

- Works well in both low-rise and medium-height constructions.

In short, if you’re looking at projects that need both insulation and durability with a cost-effective installation process, 80cm sandwich panels are a solid choice in the U.S. market.

Installation Tips for 80cm Sandwich Panels

Installing 80cm sandwich panels correctly is key to getting the best performance, durability, and insulation out of your project. Here’s what you need to know to keep things smooth and efficient.

Preparation and Surface Requirements

- Ensure the base is clean, dry, and level. Any dirt, moisture, or uneven surfaces can affect panel stability and sealing.

- Check for proper structural support aligned with panel dimensions—80cm width panels need consistent support at joints to avoid sagging or gaps.

- Measure carefully to account for panel length and thickness. Accurate measurements reduce cutting waste and speed up installation.

Fastening Methods Suitable for 80cm Panels

- Use self-drilling screws with sealing washers specifically designed for sandwich panels. These provide tight, secure fastening without damaging the core.

- Install fasteners along the panel’s support framework, usually spaced between 300mm to 500mm, depending on load requirements.

- Avoid over-tightening screws—a snug fit prevents panel deformation while maintaining an airtight seal.

Sealants and Jointing Techniques

- Use high-quality polyurethane or silicone-based sealants suitable for panel materials to fill gaps and improve weatherproofing.

- For joining panels, apply sealant evenly on the edges before overlapping or interlocking panels to create a tight, continuous barrier against air and moisture.

- Pay extra attention to vertical and horizontal joints, especially in wall sandwich panel installations, to maintain insulation effectiveness.

Handling and Transportation Advice

- Handle panels with care to avoid dents or damage to the outer layers—use lifting equipment or suction cups for large panels.

- Transport panels flat and supported along their length; avoid resting them on edges, which may cause bending or twisting.

- Protect panels from extreme temperature changes during transport, as sudden shifts can affect core materials like PU or PIR.

Common Installation Mistakes to Avoid

- Skipping surface preparation: Leads to poor adhesion and panel settling.

- Wrong fastener type or placement: Can cause panel damage or weak points prone to leaks.

- Ignoring thermal expansion gaps: Sandwich panels expand and contract with temperature changes—no gaps cause buckling or warping.

- Inadequate sealing of joints: Water infiltration and heat loss occur without proper sealants.

- Rushing handling and transport: Damaged panels lower insulation and structural performance.

Following these guidelines will help you get maximum value and lifespan from your sandwich panel 80cm width installations, whether for walls, roofing, or industrial buildings.

Cost Considerations and Purchasing Tips for 80cm Sandwich Panels

When budgeting for 80cm sandwich panels, several factors affect the overall cost. Understanding these will help you make smarter choices without compromising quality or performance.

Price Factors Affecting 80cm Sandwich Panel Costs

- Core material type: PU (Polyurethane) and PIR cores generally cost more but offer superior insulation and fire resistance. EPS and rock wool cores tend to be more affordable but may vary in thermal performance.

- Panel thickness: Thicker panels provide better insulation and structural strength but increase the price. Typical thicknesses range from 40mm up to 150mm depending on your insulation needs.

- Surface material: Outer layers like galvanized steel, aluminum, or coated metal influence durability and price.

- Length and order size: Custom lengths or small orders can raise costs per panel compared to standard sizes and bulk purchases.

- Fire rating and certifications: Panels with enhanced fire-resistant features and those compliant with local building codes usually come at a premium.

Choosing the Right Thickness and Core Material for Your Budget and Needs

- If energy efficiency is your priority, PU or PIR cores with 80cm width panels are worth the investment.

- For cost-sensitive projects, EPS core panels offer a good balance of price and basic insulation.

- Consider the climate — colder regions benefit from thicker panels like 100mm or more for better thermal retention.

- For industrial or heavy-duty use, rock wool cores provide excellent fire resistance and soundproofing but may come at a higher cost.

Where to Buy Quality 80cm Sandwich Panels in the US

Shanghe is a trusted supplier offering a wide selection of 80cm sandwich panels in various materials and thicknesses. Their products are known for reliability, certified quality, and consistent thermal performance. You can explore options like PU foam sandwich panels or check out their range of metal and composite panels suited for roofing or walls.

Warranty Maintenance and After-Sale Services

- Look for panels that come with manufacturer warranties, typically covering defects and structural integrity for several years.

- Ask about maintenance requirements, though sandwich panels usually need minimal upkeep.

- Choose suppliers like Shanghe that offer after-sale support, including installation guidance and replacement services if needed.

By balancing your budget with your project needs and sourcing from reputable manufacturers, you can secure the best 80cm sandwich panel solution for your building’s insulation and structural demands.

Why Choose Shanghe’s 80cm Sandwich Panels

When it comes to reliable 80cm sandwich panels, Shanghe stands out with a strong focus on quality, customization, and customer support. Here’s why choosing Shanghe makes sense for your project:

Trusted Brand with High Manufacturing Standards

Shanghe has built a solid reputation in the U.S. market for producing thermal insulation sandwich panels that meet strict industry standards. Their 80cm sandwich panels undergo rigorous quality checks ensuring consistent performance in fire resistance, insulation, and structural strength. This means you get panels that are durable, safe, and up to code for a variety of buildings—from warehouses to residential walls.

Wide Customization Options

Not every project is the same, so Shanghe offers flexible options for panel thickness, core material (PU, PIR, rock wool, EPS), and surface finish. Whether you’re looking for panels optimized for cold storage, industrial roofing, or commercial wall cladding, they customize your 80cm sandwich panel size and specifications. This tailored approach helps you balance budget, performance, and installation speed perfectly.

Proven Customer Success and Case Studies

Many businesses across the U.S. have successfully used Shanghe’s panels in their facilities. From energy-efficient industrial warehouses to modular commercial buildings, customer feedback highlights ease of installation, thermal efficiency, and long-term durability. These case studies provide practical proof that Shanghe delivers on its promises, especially when you need reliable performance in demanding environments.

Easy Ordering and Responsive Support

Ordering Shanghe’s 80cm sandwich panels is straightforward. They offer clear guidance on selecting the right panel type and thickness, plus fast shipping options to keep your project on track. Their U.S.-based customer service is ready to assist with technical questions, installation tips, and warranty info—making it easy to find exactly what you need and get it when you need it.

By choosing Shanghe, you’re not just buying a panel—you’re investing in a tested product backed by a manufacturer that understands local building codes, climate challenges, and the need for efficient, cost-effective solutions in the U.S. market.

Frequently Asked Questions About 80cm Sandwich Panels

What Makes 80cm Sandwich Panels Better Than Other Widths

The 80cm width hits a sweet spot between efficiency and ease of installation. Compared to wider panels like 100cm, 80cm panels are easier to handle on-site, reducing labor time and cuts down on waste. This size also provides consistent thermal insulation because the joints are minimized, improving overall energy efficiency. Many builders prefer 80cm sandwich panels because they offer a balanced combination of structural strength, thermal performance, and cost-effectiveness for typical U.S. construction projects.

Can These Panels Be Used in Extreme Weather Conditions

Absolutely, 80cm sandwich panels are designed to perform well in a variety of climates, including harsh U.S. winters and hot summers. Their core materials—commonly PU (polyurethane), PIR (polyisocyanurate), rock wool, or EPS—offer excellent thermal insulation and fire resistance. Properly installed panels help prevent air leaks and moisture infiltration, which means they maintain comfort and durability in rain, snow, wind, or heat. Always check for local building code compliance and consider additional protective coatings for extreme environments.

How Long Do 80cm Sandwich Panels Last

When you invest in a quality 80cm sandwich panel, you can expect a service life of 25 to 40 years or more depending on maintenance and environmental exposure. The outer metal layers are typically coated to resist rust and corrosion, while the insulated core maintains its properties over time. Regular inspections and proper care, like keeping drainage clear and avoiding physical damage during installation and use, will extend the lifespan. Choosing panels from trusted U.S. manufacturers with warranties adds peace of mind.

How Do 80cm Sandwich Panels Impact Energy Efficiency

The size and materials of 80cm sandwich panels strongly contribute to energy savings by offering superior thermal insulation. The reduced number of joints in wider panels means fewer gaps where heat can escape or enter, improving the building’s energy performance. The core materials, especially PU and PIR, have high R-values, which means better resistance to heat flow. Using these panels can lower heating and cooling costs significantly, making them a smart choice for industrial buildings, cold storage, and even residential structures focused on sustainability and lower utility bills.