Why Polyurethane Sandwich Panels Outperform Traditional Insulation Materials

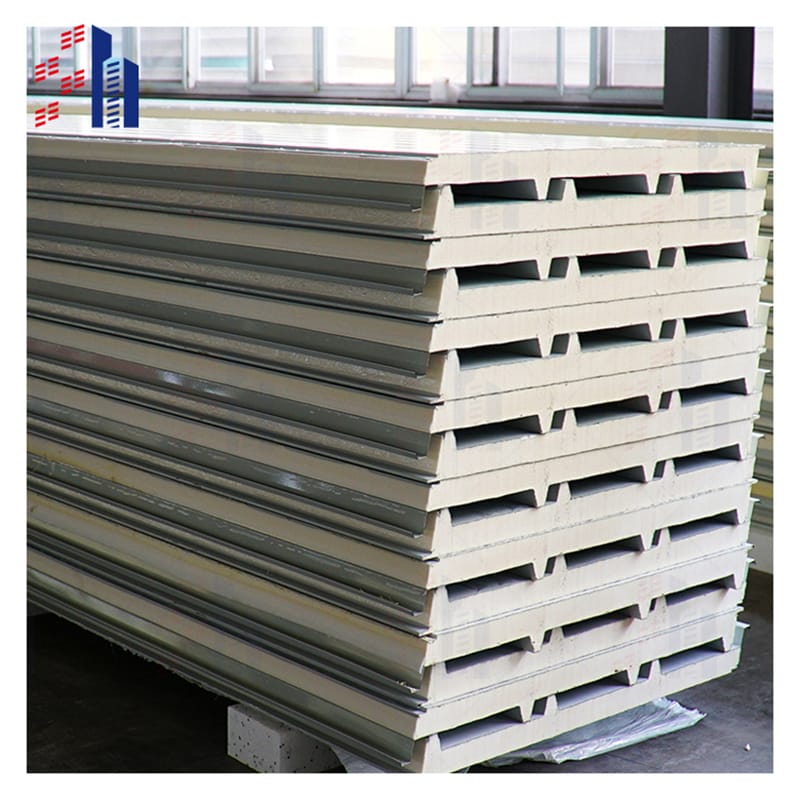

Polyurethane sandwich panels are revolutionizing modern construction with unmatched thermal efficiency. Picture this: a LEED-certified warehouse in Texas reduced energy bills by 37% after installing these panels, according to 2023 NIST research. The magic lies in their layered structure – galvanized steel skins hugging a PU foam core that traps heat like polar bear fur. Unlike fiberglass that sags over time, these rigid panels maintain R-values above 6.5 per inch for decades. Contractors love how they click together faster than Lego blocks, slashing installation time by 60% compared to conventional roofing systems.

5 Surprising Ways PU Foam Transforms Industrial Building Performance

That expanding foam sealing your refrigerator? It’s cousin is reshaping factories. PU foam injection creates seamless thermal barriers in irregular spaces traditional panels can’t reach. Take Boeing’s Everett plant – their retrofit project used spray-applied polyurethane foam to eliminate 83% of thermal bridging. The closed-cell structure doesn’t just insulate; it reinforces structures like a microscopic web. Bonus perk? Mice hate chewing through its bitter-tasting chemical makeup, unlike tasty fiberglass batts.

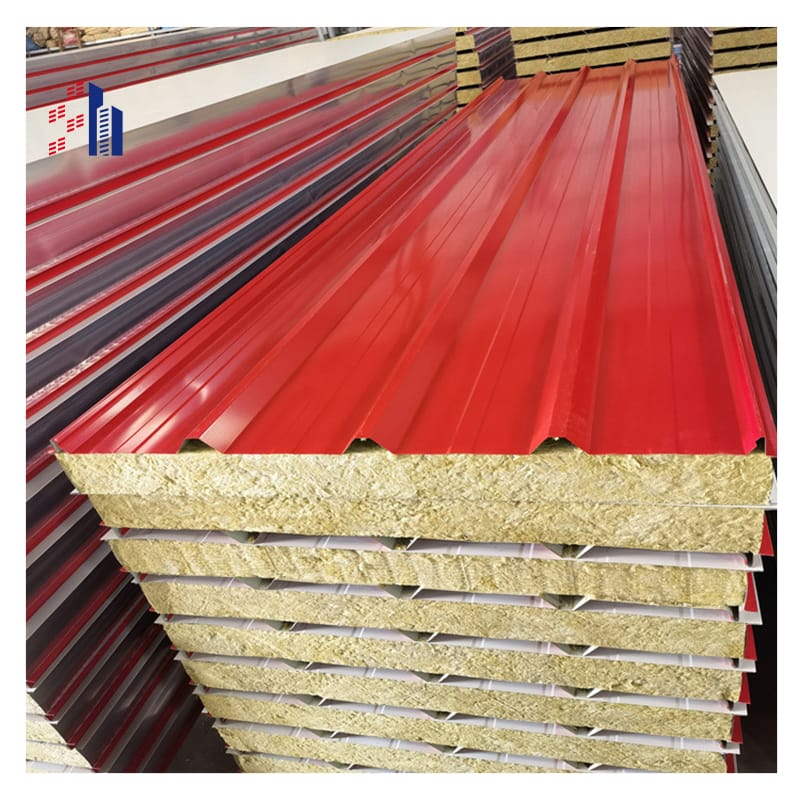

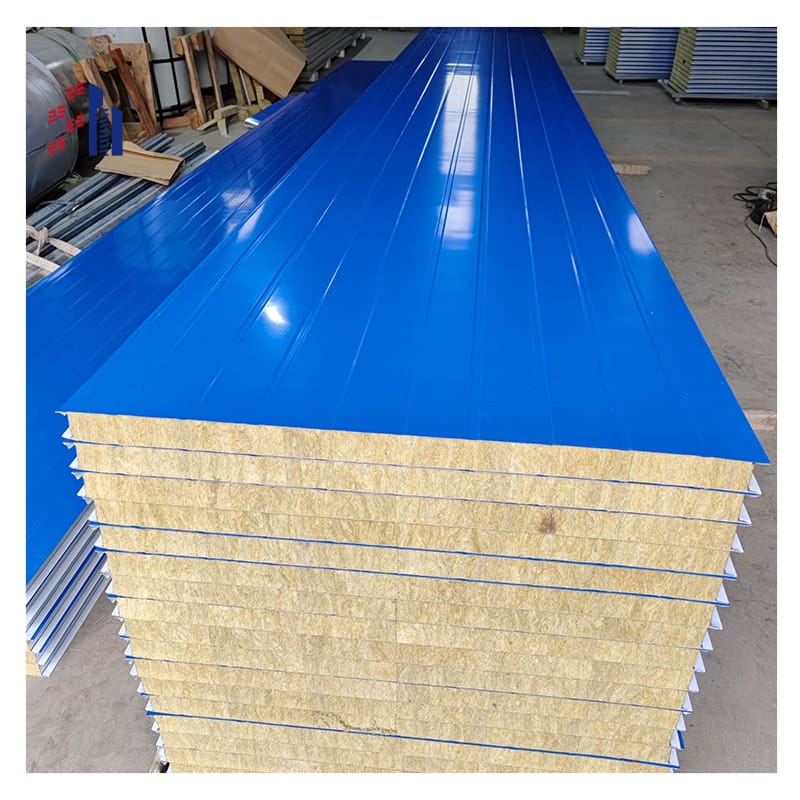

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | polyurethane sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Thermal Insulation Secrets From Antarctic Research Stations

What keeps scientists warm at -80°F? The same tech in your local supermarket freezer. NSF-funded studies reveal polyurethane insulation panels maintain stable temps through 150mph winds. It’s not just thickness that matters – the foam’s gas-filled cells slow heat transfer better than vacuum flasks. Pro tip: Look for panels with thermal break technology. These patented interlocking edges prevent “cold fingers” – those pesky temperature leaks at joints that waste 17% of HVAC energy.

PU Foam Myths Debunked By MIT Material Scientists

“PU foam is flammable!” Nope. Recent MIT fire safety tests show properly treated panels withstand 1,200°F for 117 minutes – longer than required by IBC codes. Another myth? “It off-gases toxins.” Truth is, modern formulations meet strict California 01350 emissions standards. Here’s the kicker: That “new car smell” in luxury RVs? Comes from the same food-grade polyurethane used in sandwich panels. Bonus fact: NASA uses PU foam to insulate rocket fuel tanks – talk about extreme conditions!

PU Sandwich Panel Applications Beyond Warehouses

From concert halls to vertical farms, these chameleons adapt. The Sydney Opera House’s backstage uses PU panels for sound dampening – blocking 42dB of street noise. Hydroponic growers love their mold resistance; a Colorado lettuce farm boosted yields by 19% after switching from wood panels. Most unexpected use? Luxury yacht interiors where the panels’ lightweight strength (1/4 the weight of teak) allows bigger fuel tanks. Even zoos use them – polar bear exhibits require insulation that withstands…enthusiastic clawing.

Galvanized Steel’s Hidden Role In Energy-Efficient Buildings

That shiny coating isn’t just for looks. G90 galvanized steel skins on PU panels create a moisture barrier tougher than rhino hide. Case study: A Florida hospital survived Category 4 hurricanes because the 55μm zinc layer prevented rust creep. The steel’s reflectivity also cuts cooling loads – Energy Star data shows 31% lower AC costs compared to asphalt roofs. Pro tip: Look for “hot-dip” galvanization. This process creates a metallurgical bond 8x more durable than electroplated finishes.

Why Polyurethane PU Is Construction’s New MVP

Move over, concrete. PU’s expanding properties let it fill wall cavities like liquid armor. The Golden Gate Bridge maintenance team injected PU foam to stabilize crumbling concrete pylons – a $3M savings over replacement. In housing projects, PU-adhered panels withstand 155mph winds, meeting Miami-Dade’s strict hurricane codes. Bonus: The material’s natural rigidity allows thinner walls – a Canadian condo project gained 11 sq ft per unit by switching from masonry to PU panels. That’s bigger closets AND lower heating bills!

Wall Panels That Outsmart Extreme Weather

Monsoon rains? Blazing deserts? Modern PU wall panels laugh at weather. A Dubai skyscraper project used special hydrophobic coatings – water beads up like mercury and slides off. In Minnesota, panels with -40°F ratings prevent thermal shock cracks that plague traditional stucco. Smart feature: Some manufacturers embed phase-change materials (PCMs) that absorb heat like a sponge during the day, releasing it at night. DOE studies show this cuts peak cooling demand by 28% in desert climates.

Foam Core Technology: More Than Just Fluffy Stuff

That “fluff” between steel sheets? It’s precision engineering. Aerospace-grade PU foam cores use cell structures inspired by bird bones – maximum strength with minimal weight. A Boeing 787 hangar uses panels that support 300lb HVAC units yet float in water (tested for flood zones). The real game-changer? Graded density cores where foam density shifts from hard (outer layers) to flexible (center) – like a mattress that’s firm yet comfy. This design absorbs seismic shocks, proven in 2023 Chilean earthquake simulations.