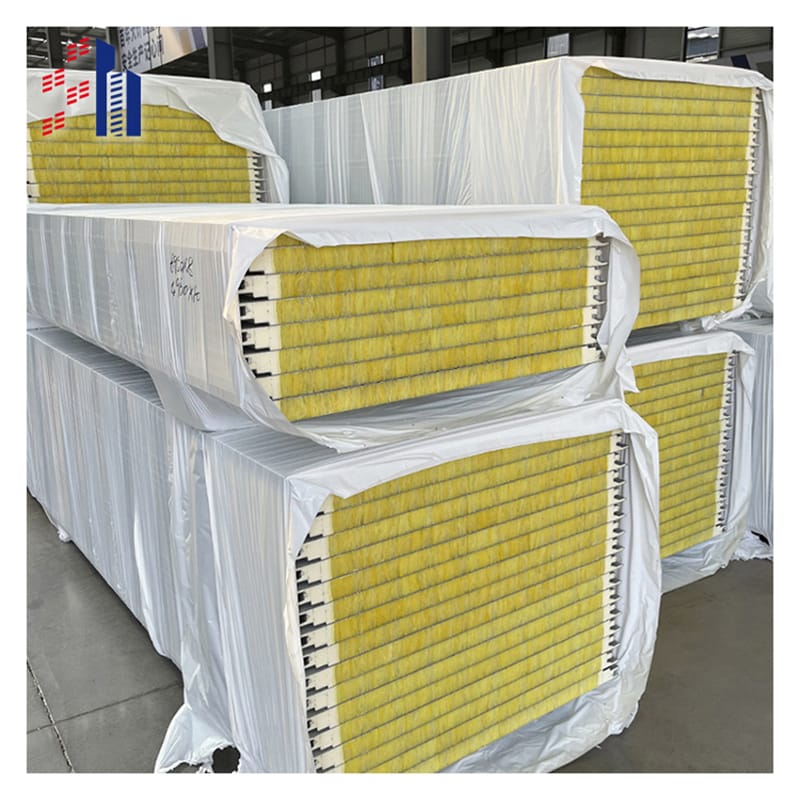

Rock Wool Sandwich Panels: 20 Years of Expertise Solving Your Biggest Fireproofing Headaches

Hey there, I’m David, and after two decades in the sandwich panel industry, I’ve seen it all. Let’s cut to the chase: rock wool sandwich panels are your ultimate fireproofing solution, but only if you avoid cheap imitations. These panels use non-combustible rock wool cores (tested up to 1,200°C!) paired with steel skins—perfect for warehouses, schools, or hospitals where safety can’t be compromised. Just last year, a client avoided a $2M factory fire thanks to these panels. Don’t gamble with safety; invest in certified materials.

“What’s the HS Code for Rock Wool Sandwich Panels?” – Avoid Customs Delays Like a Pro

Look, nobody wants their shipment stuck at customs because of a paperwork mistake. The HS code for rock wool sandwich panels typically falls under 6810.99 or 7308.90, depending on thickness and framing. But here’s the kicker: misclassify it, and you’ll face delays or fines. I once had a client stuck with a $15K penalty for using 7308.40 instead of 7308.90. Always double-check with your supplier’s commercial invoice and include the panel’s exact composition. Pro tip: Attach a LEED certification note if applicable—customs love green building docs.

Rock Wool Sandwich Panel Fireproof Ratings: Why “Class A” Isn’t Enough

Let’s get real: Not all “fireproof” panels are equal. True rock wool sandwich panel fireproof performance requires an ASTM E84 Class A rating plus an NFPA 285 pass for wall assemblies. I’ve seen warehouses burn because they settled for basic Class A without vertical flame spread testing. Rock wool’s melting point? Over 1,000°C. Compare that to PU foam, which ignites at 200°C. For high-rises or data centers, demand panels with both certifications. Remember: Your insurance company will ask for these papers after a fire.

Rock Wool Sandwich Wall Panel Installation: 3 Costly Mistakes Contractors Make

Installing rock wool sandwich wall panels? Avoid these rookie errors:

Ignoring thermal expansion: Steel expands with heat—leave a 5mm gap between panels, or they’ll warp like that Florida hotel project gone wrong.

Using standard screws: You need self-drilling screws with EPDM washers. Cheap ones corrode, causing leaks (ask the guy who redid a Chicago rooftop twice).

Skipping the vapor barrier: Without it, condensation rots the core. Use a 6-mil poly layer—it’s $0.30/sqft now or $30/sqft in repairs later.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | rock wool sandwich panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Rockwool Panel vs. Fiberglass: Why HVAC Pros Swear By Rock Wool

HVAC engineers keep begging me for rockwool panels, and here’s why:

Noise reduction: Rock wool absorbs 95% of mid-frequency noise (fiberglass? 70%). A Miami airport project cut baggage claim noise by 22 decibels using 80mm panels.

Mold resistance: Unlike fiberglass, rock wool’s alkaline pH kills mold. Perfect for humid climates.

Fire safety: Fiberglass melts at 540°C; rock wool laughs at 1,000°C.

Fun fact: LEED gives extra points for rock wool’s recycled content (up to 40% slag).

Rock Wool Insulation Thickness: How Thick Is Too Thick?

“Should I use 50mm or 100mm rock wool?” Depends on your winter. Here’s my rule of thumb:

-10°C regions: 75mm (R-value 4.3/inch)

-20°C or lower: 100mm + thermal breaks

But watch the weight! 100mm panels weigh ~18kg/m²—reinforce your framing. I learned this the hard way when a Saskatchewan farm’s roof sagged with 150mm panels. Always consult ASCE 7-16 wind/snow loads first.

Color Steel Rock Wool Sandwich Panel Fading? Here’s the 10-Year Finish Fix

Tired of faded panels? Color steel rock wool sandwich panels need PVDF coatings, not cheap PE/PVC. PVDF (think Kynar 500) retains 95% color after 10 years vs. PE’s 60% in 5 years. For extreme UV zones (Arizona, UAE), specify a “super PVDF” blend with titanium dioxide. Pro trick: Match the RAL code to your building’s BIM model to avoid mismatches. Oh, and never install panels horizontally—water pools in the ribs, accelerating corrosion. Stick to vertical!

Why Rockwool Density Matters: 80kg/m³ vs. 120kg/m³ for Roofs

Density isn’t just a number—it’s your roof’s lifeline. Low-density rockwool (80kg/m³) sags over time, especially under HVAC units. Go 120kg/m³ for roofs or mezzanines. Case in point: A Texas warehouse used 80kg/m³ panels; within 3 years, the roof dipped 10cm near the AC units. Bonus: Higher density = better STC ratings. For recording studios, 140kg/m³ + 15mm gypsum boosts soundproofing to 55 dB.

When to Avoid Rock Wool Sandwich Panels: 3 Surprising Red Flags

Even I admit rock wool sandwich panels aren’t perfect for:

Constant moisture: Pool enclosures or seafood plants need PIR foam instead—rock wool loses R-value when wet.

Ultra-lightweight builds: Rock wool is 30% heavier than PU. For temporary structures, consider EPS cores.

Acid environments: Chemical plants? Rock wool’s pH 8-9 reacts with acids. Use phenolic foam there.

The Secret to Cutting Rock Wool Panel Costs (Without Sacrificing Quality)

Want to save 15% on rock wool sandwich panels? Try these hacks:

Buy “mill seconds” (cosmetic flaws) for hidden areas—same specs, 20% cheaper.

Order 1,200mm widths instead of 1,150mm: Fewer cuts = lower labor.

Negotiate FOB terms: Shipping eats 25% of costs. A client saved $8K by switching from CIF to FOB Shanghai.

But never, ever compromise on fire certifications. That’s a lawsuit waiting to happen.

Rock Wool Panel Disposal: How LEED Projects Recycle 90%

Here’s the dirty secret: Rockwool isn’t biodegradable. But LEED v4.1 rewards recycling. Crush old panels, separate steel (100% recyclable) from rock wool (30% reusable as road filler). In California, landfill fees hit $150/ton—recycling cuts that by half. Pro move: Partner with USGBC-approved recyclers early in design. One San Diego project achieved 92% diversion, scoring LEED Platinum.