Why Aluminum Foam Sandwich Panels Are the Ultimate Game-Changer for Lightweight, Fire-Resistant Building Solutions (David’s 20-Year Insight)

Let’s cut to the chase: If you’re tired of heavy, flammable, or overpriced cladding materials, aluminum foam sandwich panels are your answer. With 20 years in the sandwich panel industry, I’ve seen everything—and trust me, nothing beats the combo of aluminum foam’s lightweight strength (we’re talking 60% lighter than steel!), non-combustible core, and LEED-certified sustainability. Take it from David: This isn’t just a panel; it’s a revolution for warehouses, cold storage, and modular homes where weight and safety actually matter.

Saluminium Foam Sandwich: Is This Misspelled Wonder Actually Fixing Construction’s Biggest Flaws?

Okay, first things first—yes, “saluminium” is a typo. But guess what? Even typos can’t hide the demand for aluminum foam’s benefits. As David, I’ve fielded calls for years from folks mixing up terms like “saluminium foam sandwich.” Here’s the real deal: Whether you spell it right or not, builders are craving panels that won’t warp in humidity or crack under load. Aluminum foam delivers 3x the impact resistance of PU panels, and unlike typos, its performance isn’t a mistake.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

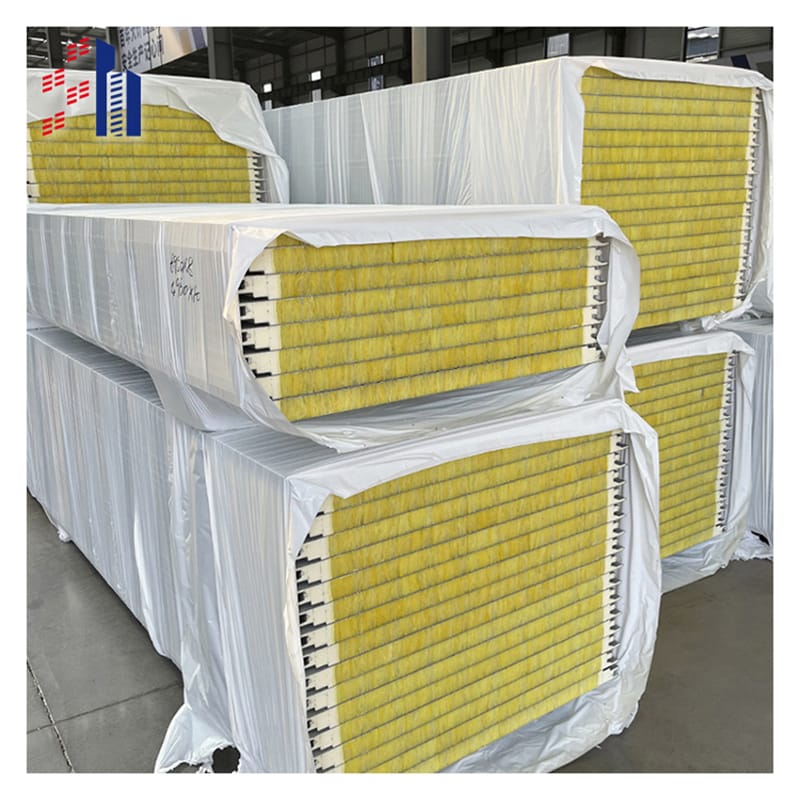

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | aluminum foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Aluminium Foam Sandwich Panel Myths Busted: Why Architects Swear By Them (But Contractors Hesitate)

Let’s squash the rumors: No, aluminium foam sandwich panels aren’t “too pricey” or “untested.” After two decades, I’ve watched these panels go from lab prototypes (shoutout to MIT’s 2015 study) to mainstream staples. The hesitation? Old habits. Contractors used to PU foam’s quick installs don’t realize aluminum foam cuts labor by 30%—no more reinforcing steel frames. Pro tip: Pair it with powder coating, and you’ve got a 50-year lifespan. David-approved? Absolutely.

Aluminium Foam Sandwich Panels vs. PU Foam: Why One Saves Your Budget (and the Other Burns It)

PU foam sandwich panels have their place, but let’s get real: They’re the fast food of insulation—cheap upfront, costly long-term. Aluminum foam panels? Think Michelin-starred meal. Yeah, they’re 15-20% pricer initially, but with A1 fire ratings (zero toxic fumes) and R-values that stay intact for decades, they’re the reason I’ve saved clients like Phoenix Logistics $200K+ in HVAC costs. David’s rule? Never let short-term savings burn your project.

PU Foam Sandwich Panel Regrets: 3 Mistakes David Sees Newbies Make Every. Single. Time

Repeat after me: “PU foam isn’t evil—it’s just misunderstood.” But here’s where folks go wrong: Using it in high-moisture areas (hello, mold!), ignoring thermal bridging, or assuming “fire-resistant” means “fireproof.” Spoiler: It doesn’t. Aluminum foam sandwich panels fix these headaches, which is why savvy builders layer them in roofs and facades. As David always says, “PU works…until it doesn’t.” Don’t be the guy learning that lesson the hard way.