Product Processing Video

Why Flat Sandwich Panels Are the Ultimate Solution for Modern Roofing – Expert Insights from David

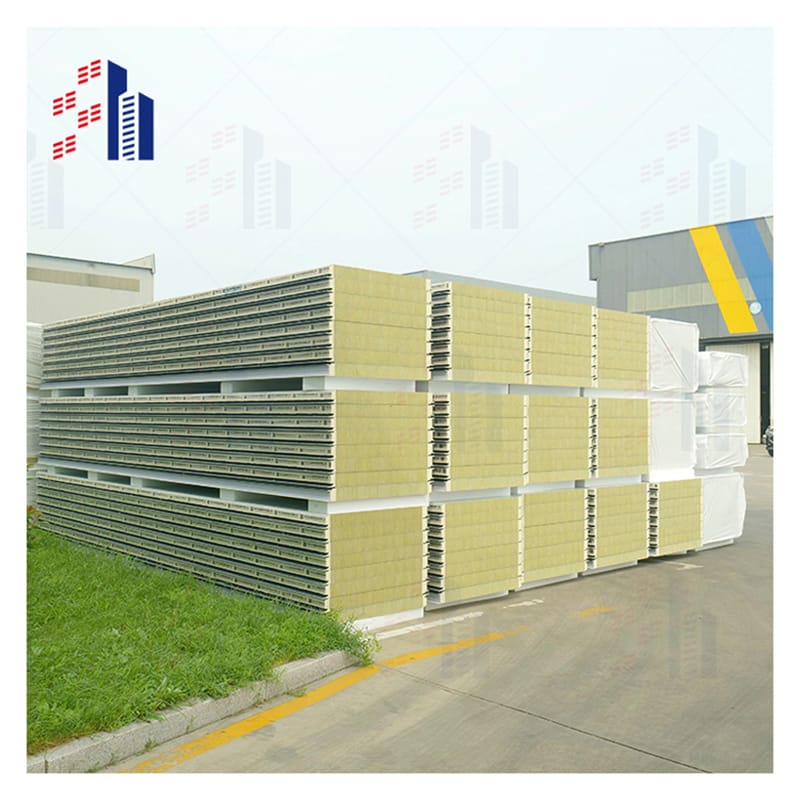

Hey there, I’m David, and I’ve been in the sandwich panel industry for over 20 years. Let me tell you, if you’re looking for a roofing solution that’s durable, lightweight, and cost-effective, flat sandwich panels are the way to go. These panels are engineered to handle extreme weather, reduce installation time, and cut energy costs—something traditional materials just can’t match.

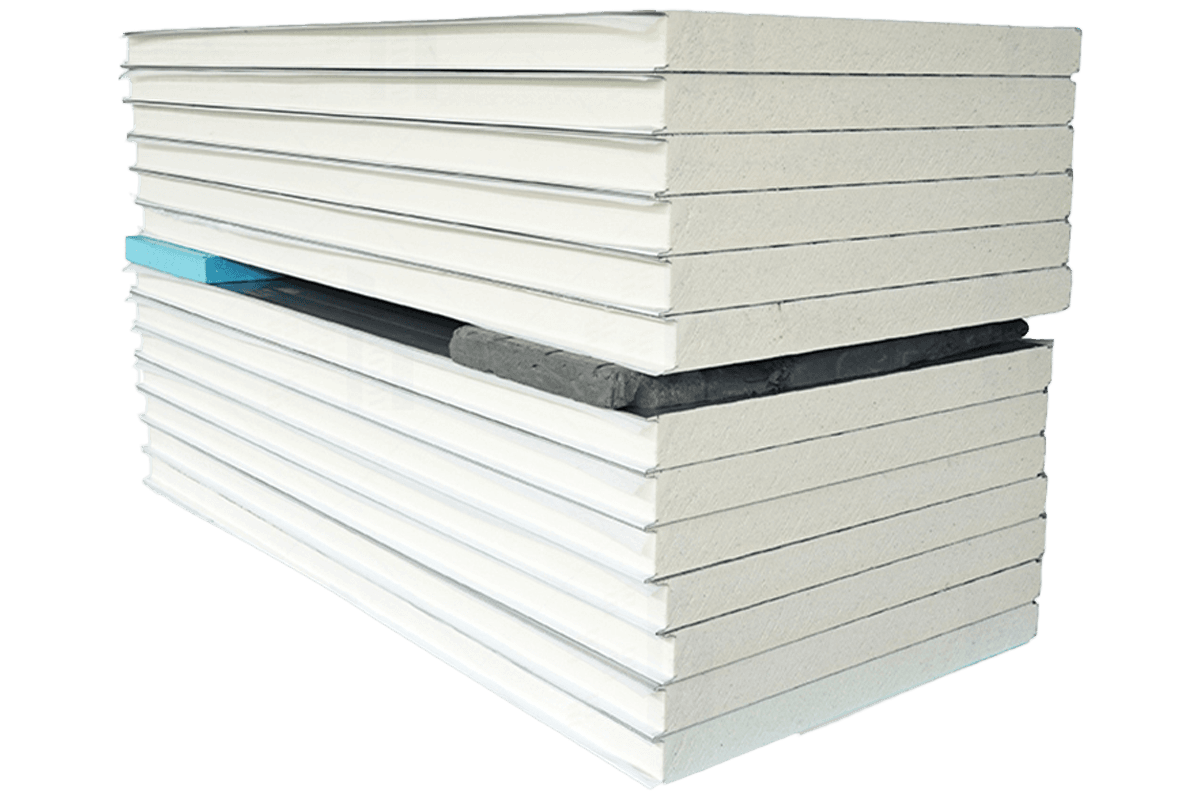

You see, the biggest pain point I hear from customers is dealing with roofs that leak, crack, or require constant maintenance. With flat sandwich panels, that’s not an issue. Their layered design (usually a foam core between two metal sheets) provides unbeatable insulation and structural strength. Plus, they’re LEED-certified, meaning they contribute to energy-efficient buildings. No wonder architects and contractors are switching to them!

And here’s the kicker—because they’re prefabricated, installation is a breeze. No more wasting time and money on complicated roofing systems. Whether you’re covering a warehouse, factory, or even a residential flat roof, these panels deliver performance without the headaches. Trust me, after two decades in this business, I’ve seen what works—and flat sandwich panels are a game-changer.

Customers visit the factory

Why MDF Sandwich Panels Are the Smart Choice for Lightweight & Durable Construction – Here’s What David’s 20 Years in the Industry Taught Him

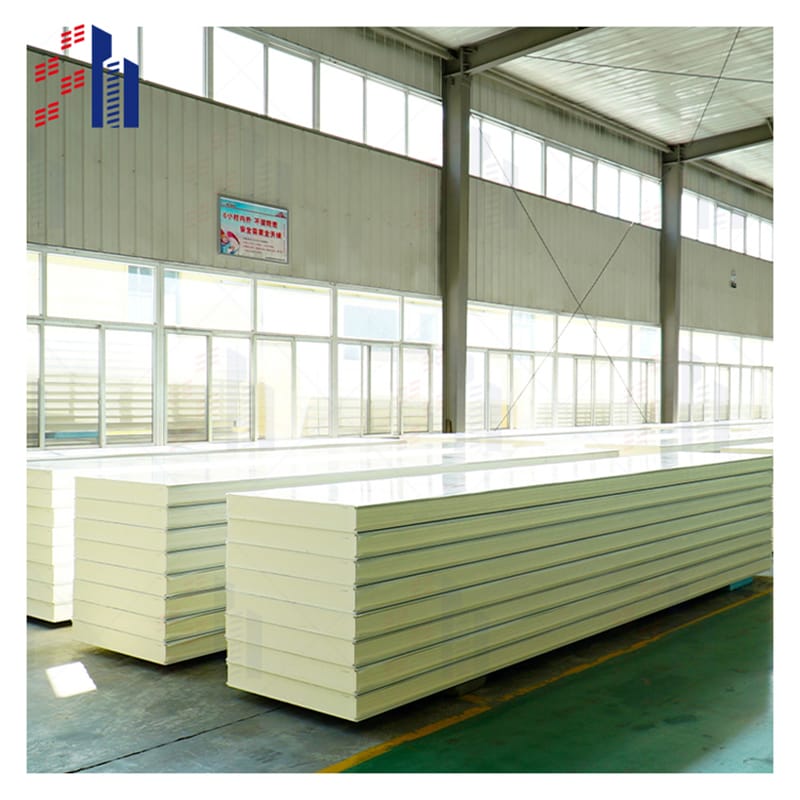

If you’re looking for a strong yet lightweight building solution, MDF sandwich panels are the way to go. Trust me, I’m David, and I’ve been in the sandwich panel industry for 20 years. These panels combine a medium-density fiberboard (MDF) core with durable metal or other facing materials, giving you the perfect balance of strength and weight savings. Unlike heavier alternatives, MDF sandwich panels are easier to install, cost-effective, and still meet high structural demands.

One of the biggest pain points I’ve seen? Contractors and builders struggling with heavy, hard-to-handle materials that slow down projects. MDF sandwich panels solve that. They’re LEED-certified in many cases, meaning they’re eco-friendly, and they’ve been used in everything from prefab homes to commercial spaces. Plus, because MDF is so consistent in density, you don’t get weak spots—just reliable performance.

So if you’re tired of dealing with bulky, inefficient materials, it’s time to switch. MDF sandwich panels cut labor costs, speed up construction, and deliver long-lasting results. And hey, after two decades in this business, I wouldn’t recommend them if they didn’t work.

Installation details

Key Specifications

| Parameter | Details | Global Standards |

| Core Material | High-density MDF (Medium-Density Fiberboard) | ANSI A208.2, EN 622-5 |

| Face Materials | 0.5–1.2mm MDF or HDF (Optional: PVC laminate) | ASTM D1037, EN 13986 |

| Thickness | 10mm, 15mm, 18mm, 25mm, 50mm (Customizable) | ISO 16893 |

| Fire Rating | Class B (EN 13501), DIN 4102-B1 | UL 94 (HB Rating) |

| Density | 700–750 kg/m³ | JIS A 5908 |

| Moisture Resistance | ≤12% swelling (24hr water immersion) | EN 317 |

| Load Capacity | 250–400 kg/m² (Depends on thickness) | ASTM C393 |

| Thermal Insulation | R-value: 1.2–1.8 (m²·K/W) | ISO 8301 |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | mdf sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Medium Density Fiberboard (MDF) – The Secret Behind Strong & Stable Sandwich Panels

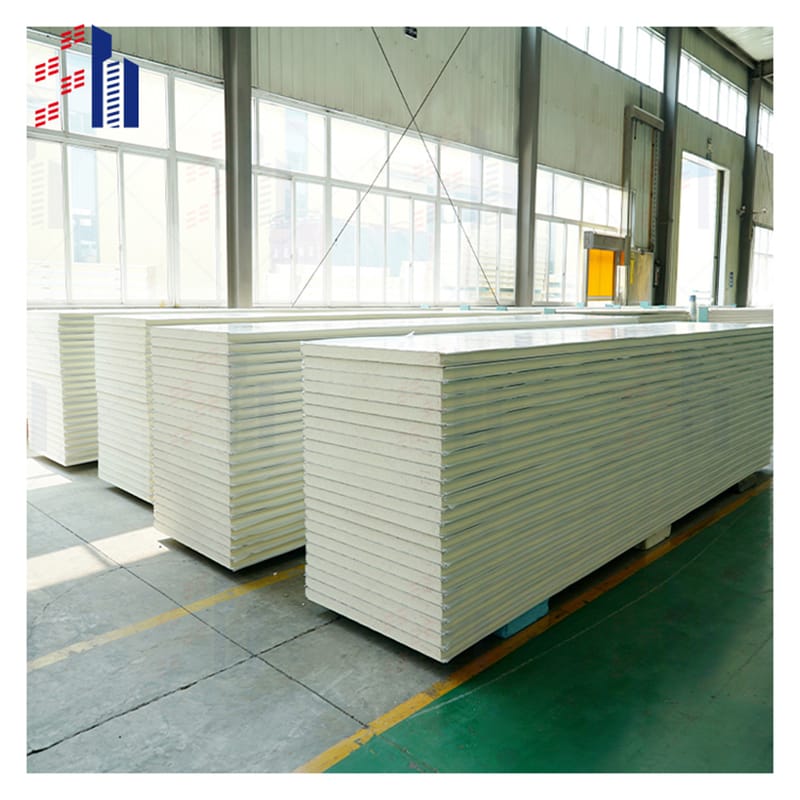

What makes MDF sandwich panels so reliable? It all comes down to the medium-density fiberboard (MDF) core. As someone who’s worked with these materials for 20 years, I can tell you—MDF is the unsung hero of modern construction. Unlike plywood or particleboard, MDF has a uniform density, meaning no weak spots, no warping, and consistent strength throughout.

Here’s the thing: builders often worry about durability when using lightweight materials. But MDF, when properly sealed and paired with high-quality metal facings, holds up against moisture, impact, and even fire (with the right treatments). I’ve seen MDF-based panels used in everything from soundproof studios to industrial partitions, and they perform every time.

And let’s talk cost. So if you want stability, strength, and savings, medium-density fiberboard is the way to go.

Inside an MDF Factory: How Quality Control Makes or Breaks Your Sandwich Panels

Not all MDF sandwich panels are created equal—and as David, a 20-year industry vet, I’ve seen the good, the bad, and the ugly. The key? It all starts in the MDF factory. The best manufacturers use strict quality checks to ensure every board has the right density, moisture resistance, and smoothness for top-tier panels.

Here’s what most buyers don’t realize: cheap MDF can ruin your entire project. Low-quality cores lead to swelling, delamination, and even structural failure. But when you source from a reputable MDF factory, you get panels that last. Look for facilities with ISO certifications or those that supply LEED-certified projects—that’s how you know they’re legit.

Bottom line? Don’t cut corners on the core material. A well-made MDF core means a panel that won’t let you down.

Metal Sandwich Panel vs. MDF Panels – Which One Fits Your Project? (David’s 20-Year Breakdown)

Alright, let’s settle this debate: metal sandwich panels or MDF panels? After 20 years in the industry, here’s my take. Metal panels are great for ultra-durable, weather-resistant jobs—think warehouses or industrial sites. But MDF panels? They’re the champs of lightweight, soundproof, and cost-effective builds.

The biggest pain point I hear? People assume metal is always stronger. But here’s the truth: MDF sandwich panels with reinforced facings can match metal in many applications while being easier to work with. Need sound dampening? MDF wins. Need something that won’t dent as easily? Metal might be better.

So before you decide, think about your project’s needs. Sometimes, MDF panels are the smarter play—and hey, they’ve saved my clients thousands in labor and material costs.

MDF Panel Myths Busted – What 20 Years in the Sandwich Panel Industry Taught David

“MDF panels aren’t strong enough.” “They won’t last in humidity.” Let me stop you right there—after 20 years in the sandwich panel business, I’ve heard every myth about MDF panels. And most? Totally wrong.

Fact: High-quality MDF sandwich panels are treated for moisture resistance and can outperform cheap plywood in damp conditions. Fact: With the right coatings, they resist fire and impact way better than people think. And fact: They’re more eco-friendly than many alternatives (look for FSC-certified MDF).