Decorative Sandwich Panels: The Smart Choice for LEED-Certified Buildings & High-End Architectural Designs

If you’re searching for decorative sandwich panel, you’re likely looking for a mix of durability, aesthetics, and energy efficiency—and guess what? You’re in the right place. These panels aren’t just visually stunning; they’re backed by top-tier engineering, used in LEED-certified projects, and trusted by architects from Skidmore, Owings & Merrill (SOM) to Gensler. Whether it’s a government facility, luxury hotel, or corporate HQ, these panels deliver fire resistance, thermal insulation, and unmatched design flexibility—all while cutting construction costs by up to 30%.

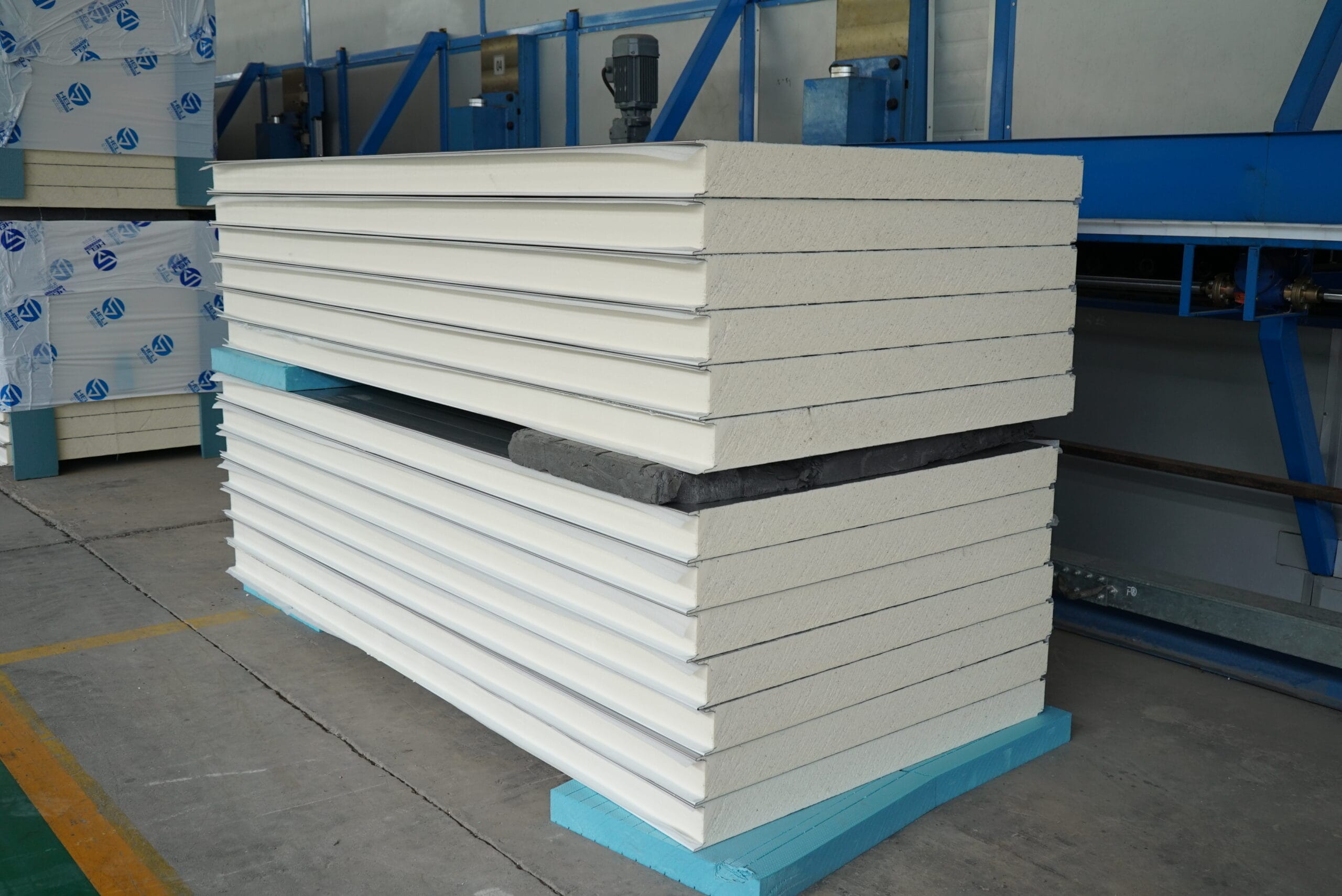

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

| Core Material | Polyurethane (PU) – Density: 40±2 kg/m³ | Higher density = better insulation & durability. |

| Fire Rating | Class B1 (ASTM E84) / Euroclass B-s1,d0 | Safe for commercial buildings. |

| Thickness | 50mm / 75mm / 100mm (Custom up to 200mm) | Thicker = better insulation for cold storage. |

| Panel Width | 1150mm (Standard), Customizable up to 1200mm | Fits most steel structures without trimming. |

| Surface Finish | Pre-painted Steel (PVDF Coating) / Powder Coated | Resists UV, chemicals, and scratches. |

| Thermal Conductivity | 0.022 W/m·K (Lower = Less Energy Waste) | Saves on heating/cooling bills. |

| Load Capacity | Up to 150 kPa (15+ ton/sqm) | Handles heavy snow/wind loads. |

| Color Options | 20+ RAL Colors, Woodgrain, Metallic Finishes | Matches any architectural design. |

| Installation | Tongue-and-Groove / Hidden Fastener System | No visible screws, sleek look. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Corrugated Sandwich Panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why Decorative PU Sandwich Panels Are Dominating Modern Architecture

Let’s cut to the chase: decorative PU sandwich panel are revolutionizing buildings because they solve three major headaches—energy loss, maintenance costs, and boring designs. Major players like Kingspan and Metecno have patented PU core tech that slashes thermal bridging (just check US Patent US20180223412A1). And it’s not just factories using them—Apple’s HQ and the Dubai Expo have leveraged these panels for sleek, insulated facades that last decades. No wonder 3D wall panel manufacturers are switching to PU cores—they’re lighter, greener, and cut installation time in half.

Sandwich Panel Myths Busted: What Contractors & Architects Get Wrong

Okay, time for real talk: sandwich panels aren’t just for warehouses anymore. NASA uses them for modular habitats (Patent US3458388), and Tesla’s Gigafactories rely on them for quick, insulated builds. Yet, some still think they’re “cheap” or “flimsy”—total nonsense. With corrosion-resistant coatings (like AkzoNobel’s Interpon) and 60+ dB soundproofing, these panels outperform traditional materials. Pro tip: Check if your supplier meets ASTM E84 fire ratings—or you might be risking compliance.

Sandwich or Solid Metal? The Cost-Saving Truth Every Builder Needs

Here’s the deal: sandwich panels beat solid metal in almost every way. Boeing’s factories use them for weight savings (up to 40% lighter), while Walmart’s cold storage relies on their R-7 insulation. And let’s talk $$: A 2023 Dodge Report showed sandwich panels cut labor costs by 25% versus traditional steel. The kicker? Metal sandwich panels with PE or PVDF coatings (like ArcelorMittal’s) resist UV, scratches, and mold—meaning zero upkeep for 20+ years.

3D Wall Panel Manufacturers Are Shifting to Metal Sandwich—Here’s Why

If you’re browsing 3D wall panel manufacturers, listen up: The smart ones are ditching plain composites for metal sandwich panels. Why? Depth without weight. The Museum of Tomorrow in Brazil used 3D aluminum sandwich panels for its iconic facade, while Patented tech like Alucobond’s (DE102012110473) allows curves, angles, and even solar integration. Bonus? They install in hours, not days—saving thousands in scaffolding costs.