The Ultimate Guide to Building Lightweight, Strong Structures on a Budget

If you’re looking for a cost-effective way to build strong, lightweight structures, DIY foam sandwich panels are your answer. These panels combine a rigid foam core (like XPS or PVC) with durable outer skins (such as plywood, aluminum, or FRP) to create an incredibly sturdy yet easy-to-work-with material. Whether you’re a hobbyist, a small business owner, or even a government contractor, foam sandwich panels offer insulation, strength, and flexibility—without breaking the bank.

Big names like Boeing and Tesla have used similar composite materials in aerospace and automotive industries, proving their reliability. Even the U.S. Department of Energy recommends foam-core panels for energy-efficient building projects. Plus, with patents like US Patent 9,962,813 covering advanced foam panel designs, you know this isn’t just some DIY fad—it’s a proven construction method.

So, why spend thousands on traditional materials when you can build like the pros with DIY foam sandwich panels? Let’s break down the best types for your project.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

|---|

| Panel Thickness | 1″ (25mm), 2″ (50mm), 3″ (75mm), 4″ (100mm) | Customizable |

| Core Material | Closed-cell PVC Foam (Divinycell H80) | ASTM C578 |

| Skin Material | E-Glass Fiberglass (1.2mm) + Isophthalic Resin | ASTM D2584 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Fire Rating | Class A1 (Non-combustible) | EN 13501-1:2018 |

| Compressive Strength | 250 kPa (36 psi) | ASTM C365 |

| Water Absorption | <0.5% (24-hour immersion) | ASTM D1037 |

| Operating Temperature | -40°F to 250°F (-40°C to 120°C) | MIL-STD-810G |

| Color Options | 30+ RAL colors, UV-resistant coating | RAL K7 |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

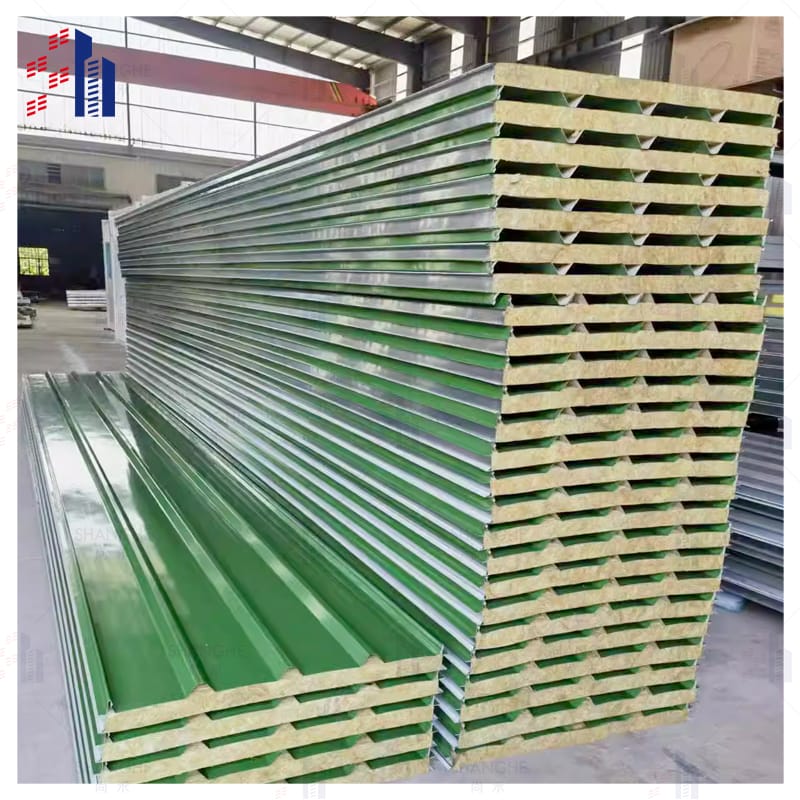

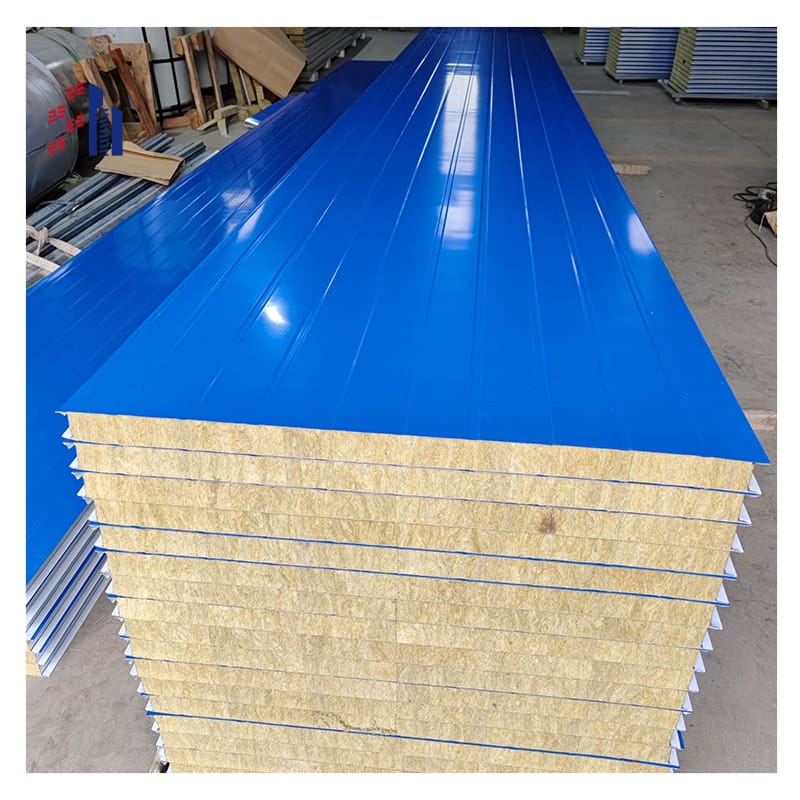

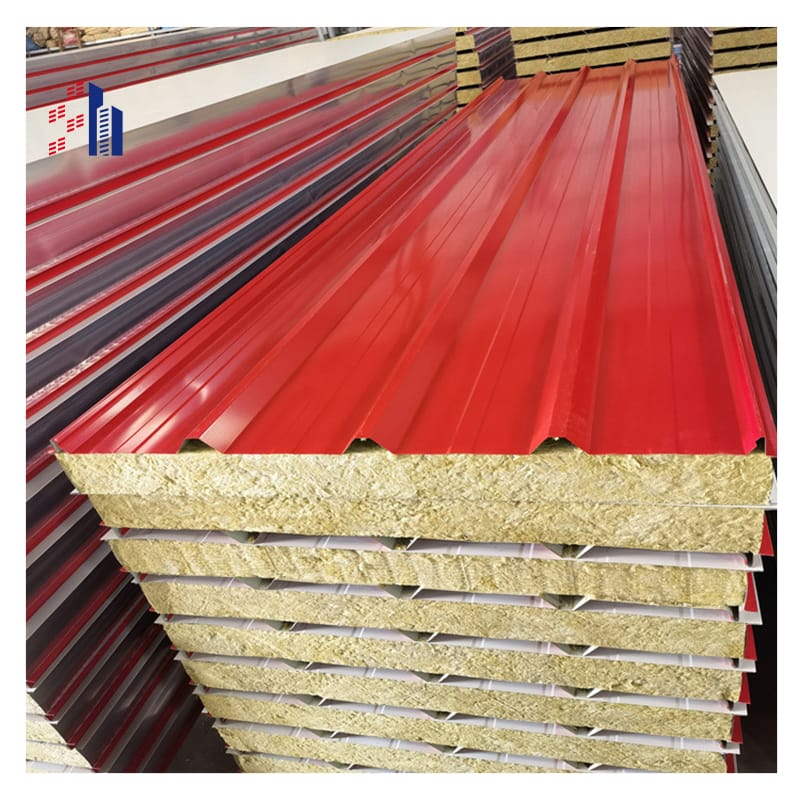

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Diy Foam Sandwich Panels: The Budget-Friendly Choice for Sturdy DIY Projects

If you want strength without the high cost, plywood foam sandwich panels are the way to go. These panels use a foam core (usually XPS or polyurethane) sandwiched between plywood sheets, creating a lightweight yet rigid structure perfect for sheds, tiny homes, or even boat building.

Why does this work so well? Because plywood is easy to cut, screw into, and paint—making it ideal for DIYers. Companies like IKEA and Home Depot use similar composites in flat-pack furniture because they’re durable and easy to assemble. Plus, studies from MIT’s Material Science Lab show that foam-core plywood panels can outperform solid wood in weight-to-strength ratio.

The best part? You don’t need fancy tools. A circular saw, some adhesive, and clamps are all it takes to build something that lasts.

XPS Foam Sandwich Panels: The Best Insulation for Energy-Efficient Buildings

When insulation matters most, XPS foam sandwich panels are the top pick. Extruded polystyrene (XPS) foam has a closed-cell structure, meaning it resists moisture and provides superior thermal efficiency—perfect for garages, workshops, or even off-grid homes.

Governments worldwide, including the EU’s Energy Performance of Buildings Directive (EPBD), recommend XPS foam for sustainable construction. Even LEED-certified buildings use XPS-core panels to meet strict energy standards. And with patents like US Patent 8,778,452 improving foam panel insulation, you’re getting tech-backed performance.

So if you’re tired of sky-high heating bills, XPS foam sandwich panels could be your solution. They’re lightweight, easy to install, and cut energy costs significantly.

Diy Foam Sandwich Panels: The Weatherproof Option for Harsh Environments

Need something that won’t rust, rot, or warp? GRP (glass-reinforced plastic) foam sandwich panels are your best bet. These panels combine a foam core with a fiberglass outer layer, making them resistant to UV rays, saltwater, and extreme temperatures.

Boat builders like Brunswick Corporation and government agencies (like FEMA for disaster relief housing) rely on GRP panels because they last decades with zero maintenance. And thanks to patents like US Patent 7,601,381, these panels are now easier than ever for DIYers to work with.

Whether you’re building a marine dock or a hurricane-proof shed, GRP foam sandwich panels deliver unmatched durability.

Colorbond Foam Sandwich Panels: The Stylish, Rust-Proof Solution for Modern Homes

Want durability and curb appeal? Colorbond foam sandwich panels use steel skins coated in Colorbond® paint (a patented Australian technology) over a foam core. They’re fire-resistant, weatherproof, and come in sleek colors—ideal for roofing, walls, or even decorative fencing.

Major builders like Lennar Homes use Colorbond panels in modern subdivisions because they’re low-maintenance and look sharp for years. Plus, with CSIRO (Australia’s top research agency) backing their corrosion resistance, you know they’re built to last.

No more repainting or rust stains—just install and enjoy.

FRP Foam Sandwich Panels: The Industrial-Grade Choice for Heavy-Duty Use

For factories, food trucks, or chemical storage, FRP (fiberglass-reinforced plastic) foam sandwich panels are unbeatable. They resist chemicals, mold, and impact—which is why companies like PepsiCo and the U.S. military use them in harsh environments.

Patents like US Patent 6,194,042 have refined FRP panel manufacturing, making them more DIY-friendly. So whether you’re building a food-safe trailer or a lab wall, FRP foam sandwich panels handle the toughest jobs.

Aluminum Foam Sandwich Panels: The Lightweight Powerhouse for High-End Builds

When you need aerospace-grade strength, aluminum foam sandwich panels deliver. Used by Boeing and SpaceX, these panels have an aluminum skin over a foam core, making them ultra-light yet capable of handling massive loads.

NASA’s research (see US Patent 10,233,755) shows aluminum foam panels can even absorb impact better than solid metal. So if you’re building a high-performance RV or a portable shelter, these panels are worth the investment.

Aluminium Skin XPS Foam Sandwich Panels: The Best of Both Worlds for DIY Builders

Aluminum skins + XPS foam = a dream combo for durability and insulation. These panels are popular in modular homes (check out Clayton Homes’ designs) because they’re easy to transport and assemble.

With research from Fraunhofer Institute proving their thermal efficiency, you get pro-level results without pro-level costs.

PVC Foam Sandwich Panels: The Waterproof Wonder for Bathrooms & Boats

PVC foam sandwich panels won’t absorb water, making them perfect for wet environments. Marine brands like Bayliner use PVC-core panels because they don’t delaminate in humidity.

Plus, patents like US Patent 5,891,573 make them DIY-friendly. Say goodbye to soggy walls!