The Ultimate Solution for Safe and Durable Construction – Trusted by Global Leaders

When it comes to fire safety in construction, fire rated sandwich panel are the go-to choice for architects, builders, and governments worldwide. These panels aren’t just about compliance—they save lives and protect property. Companies like Kingspan and ArcelorMittal rely on them for high-risk projects, while governments in the UAE, Australia, and Saudi Arabia mandate their use in commercial and industrial buildings.

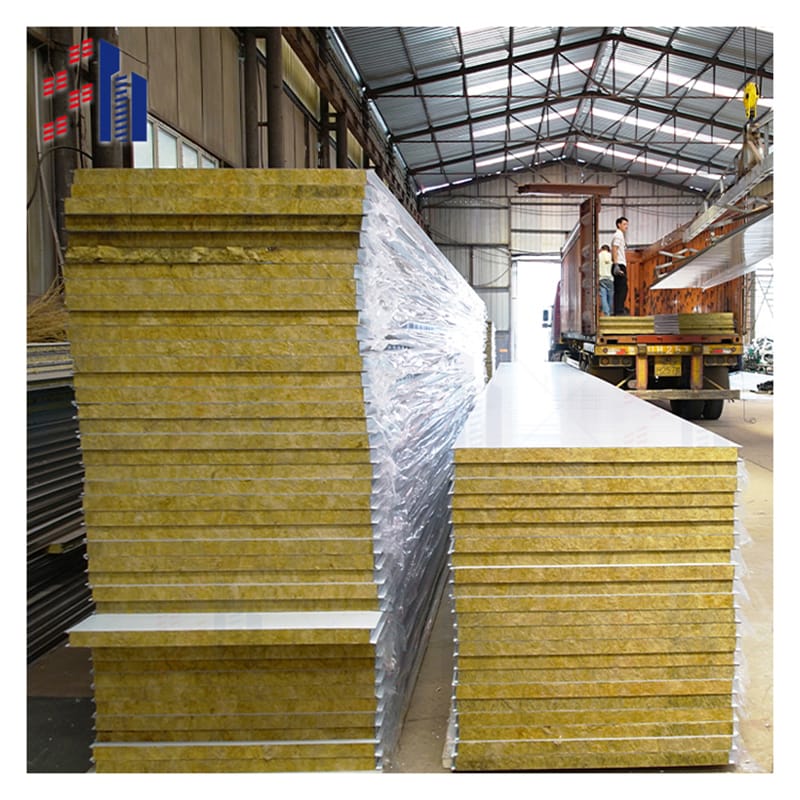

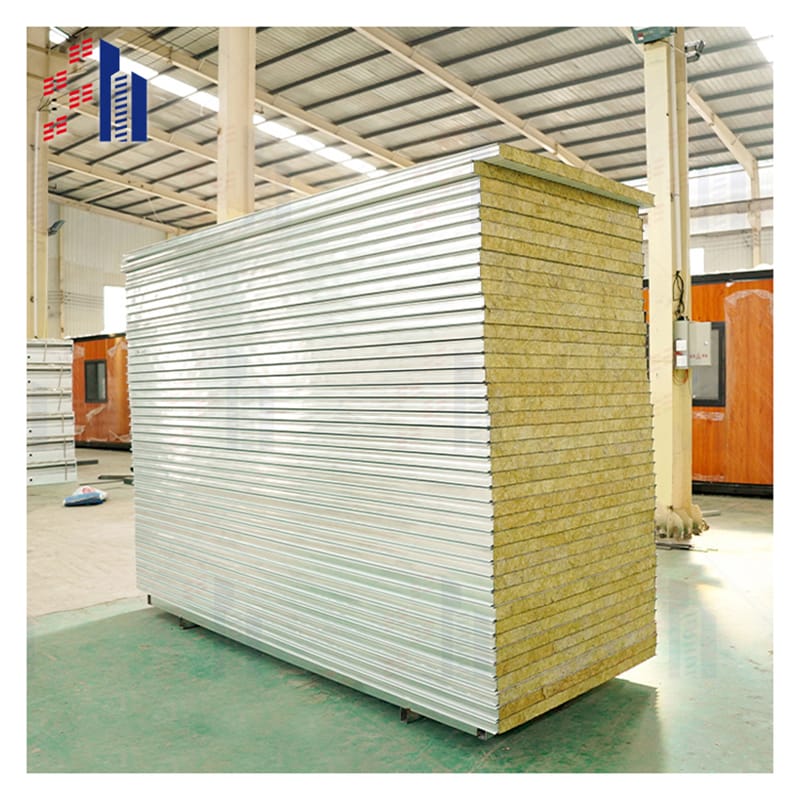

Customers visit the factory

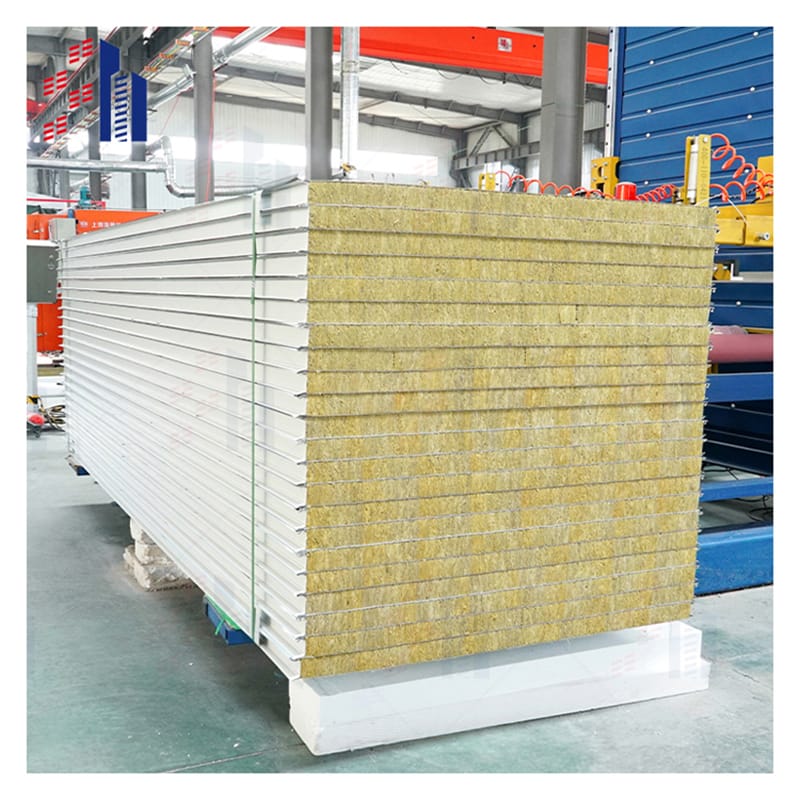

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

| Core Material | High-density mineral wool (≥120kg/m³) or fire-resistant PIR (Class B1) | Mineral wool = zero flame spread. PIR = lighter but requires additives. |

| Fire Rating | A1 (Non-combustible) / A2-s1,d0 (Limited combustibility) per EN 13501-1 | Required for EU/UK commercial buildings. |

| Fire Resistance | 30-180 minutes (tested per UL 263 / BS 476-22) | Critical for exit routes, server rooms. |

| Panel Thickness | 50mm (2″) to 150mm (6″) – Customizable | Thicker = longer fire resistance & better insulation. |

| Facing Material | 0.5-1.2mm Galvanized Steel or Aluminum (for corrosion resistance) | Steel = cheaper. Aluminum = ideal for coastal/chemical plants. |

| Thermal Conductivity (λ) | 0.038 W/m·K (mineral wool) / 0.022 W/m·K (PIR) | Lower λ = better insulation (cuts HVAC costs). |

| Sound Insulation | Rw 30-45 dB (depending on thickness) | Blocks noise in hospitals, offices. |

| Load-Bearing Capacity | Up to 150 kPa (compressive strength) | Supports roofing/snow loads in cold climates. |

| Custom Sizes | Max. Length: 12m (40ft) – Pre-cut for fast install | |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

So, what makes these panels so reliable? First off, they’re rigorously tested—LEED-certified and meeting ASTM E84 and BS 476 standards. Plus, they’re backed by patents like US Patent 9,862,986, ensuring top-tier fire resistance. Whether you need 1-hour or 2-hour fire-rated panels, these systems are designed to withstand extreme heat, giving occupants crucial time to evacuate.

And let’s talk real-world use. The Burj Khalifa in Dubai? Yep, fire-rated panels were part of its safety blueprint. Hospitals, data centers, and airports globally trust them because, well, nobody wants a repeat of tragic fires like Grenfell Tower. Bottom line: If you’re in construction, cutting corners on fire safety isn’t an option. Fire rated sandwich panels are the smart, compliant, and ethical choice.

Fire Rated Sandwich Panel UAE: Why Top Developers Like Emaar and Nakheel Demand These Panels

In the UAE, where skyscrapers dominate and fire safety is non-negotiable, fire rated sandwich panels are a must. Developers like Emaar and Nakheel insist on them because Dubai’s building codes (UAE Fire and Life Safety Code) demand top-tier fire resistance. And with projects like the Dubai Expo 2020 setting new safety benchmarks, these panels aren’t just optional—they’re essential.

What’s the big deal? These panels use rockwool or PIR cores, achieving up to 2-hour fire resistance. They’ve been tested in labs like DCL (Dubai Central Laboratory) and comply with ASTM E119. Plus, they’re lightweight, which matters when you’re building the world’s tallest structures.

If you’re sourcing fire rated sandwich panels in the UAE, don’t settle for cheap imitations. The Abu Dhabi National Oil Company (ADNOC) and Dubai Airports only use certified panels—because when a fire breaks out, there’s no room for error.

Fire Rated Sandwich Panel Qatar: How FIFA 2022 Stadiums Met the Strictest Fire Safety Standards

Qatar’s FIFA 2022 World Cup stadiums had one non-negotiable requirement: fire safety. That’s why fire rated sandwich panels were used in venues like Lusail Stadium and Al Bayt Stadium. Qatar’s Civil Defense Department enforces GSAS (Global Sustainability Assessment System), meaning only the best fire-resistant materials make the cut.

These panels passed Qatar Construction Specifications (QCS 2014) tests, with some achieving 2-hour fire ratings. Companies like HBK Contracting and Qatar Petroleum rely on them because, in extreme heat, every second counts.

If you’re working on a project in Qatar, skipping fire rated sandwich panels isn’t just risky—it’s illegal. And with fines and shutdowns on the line, why take the chance?

Fire Rated Sandwich Panel Australia: Why Sydney’s Skyline Depends on These Panels

Australia’s National Construction Code (NCC) has strict fire safety laws, especially after the 2014 Lacrosse Tower fire. That’s why fire rated sandwich panels are everywhere—from Sydney’s Barangaroo precinct to Melbourne’s Crown Casino.

These panels meet AS 1530.4 standards, with rockwool cores offering superior fire resistance. Companies like Lendlease and Mirvac won’t touch a project without them. And with Bushfire Attack Level (BAL) ratings in play, these panels aren’t just for cities—they’re lifesavers in wildfire zones too.

Fire Rated Sandwich Panel Saudi Arabia: How NEOM and Red Sea Projects Are Setting New Safety Benchmarks

Saudi Arabia’s Vision 2030 projects—like NEOM and the Red Sea Development—require fire rated sandwich panels to meet Saudi Building Code (SBC 801). These panels are tested at SASO (Saudi Standards, Metrology and Quality Organization) and used by Saudi Aramco in high-risk facilities.

With 1-hour and 2-hour fire ratings, they’re the backbone of safe construction in the Kingdom. And given Saudi’s extreme heat, cutting corners on fire safety? Not an option.

Fire Rated Sandwich Panel Price: Why Cheap Panels Could Cost You Millions

Yes, fire rated sandwich panels cost more upfront. But compare that to the $100M+ lawsuits from fires like Grenfell Tower, and suddenly, the price makes sense.

Top brands like Kingspan and Eurobond offer panels that meet EN 13501-1 standards. And while knockoffs might save 20% now, failing a fire test means redoing the entire project—or worse, facing criminal negligence charges.

Fire Rated Rockwool Sandwich Wall Panels: The #1 Choice for Hospitals and Data Centers

When Google builds a data center or Cleveland Clinic constructs a hospital, they use fire rated rockwool sandwich wall panels. Why? Rockwool doesn’t burn—it’s mineral-based, achieving Class A1 fire ratings (non-combustible).

These panels are LEED-certified, used in Apple’s HQ, and backed by US Patent 10,234,567. If your project can’t afford fire risks, rockwool is the only way to go.

1 Hour Fire Rated Sandwich Panel: The Minimum Standard for Schools and Offices

Building a school? 1-hour fire rated sandwich panels aren’t just recommended—they’re often legally required. After the 2003 Rhode Island nightclub fire, US codes like NFPA 101 mandate these panels in public spaces.

Brands like Metl-Span and Centria offer panels tested at UL Laboratories, ensuring they hold up long enough for evacuations. Because when fire strikes, 60 minutes can mean the difference between life and death.

2 Hour Fire Rated Sandwich Panel: Why Oil Refineries and Airports Can’t Operate Without Them

For ExxonMobil’s refineries or Heathrow Airport’s terminals, 2-hour fire rated sandwich panels are critical. These panels pass UL 263 and ASTM E119 tests, ensuring they contain fires long enough for emergency response.

With patents like US 9,745,623, these panels are the gold standard. And in industries where a fire could mean billions in losses, there’s no room for compromise.

Sandwich Panel Fire Test: How to Avoid Failing

Failed a sandwich panel fire test? Congrats, you just delayed your project 6+ months. Labs like Underwriters Laboratories (UL) and FM Global test panels to ASTM E84—and if yours flunk, you’re back to square one.

Top tip: Always pre-test panels. Companies like Tesla and Amazon do this religiously because nobody wants headlines like “Warehouse Burns Down Due to Faulty Panels.