Why Top Architects Like Norman Foster Choose Them for Lightweight, High-Strength Designs

If you’re looking for a building material that’s both lightweight and incredibly strong, foam core sandwich panels are the answer. These panels, used by renowned architects like Norman Foster in projects like The Gherkin in London, combine a lightweight foam core with durable outer skins—often aluminum or fiberglass—to create structures that are easy to handle yet can withstand extreme loads. The secret? The foam core distributes stress evenly, making these panels a favorite in aerospace, marine, and high-end construction. Companies like 3A Composites and Alucobond have patented advanced versions, while government projects, like military shelters, rely on them for rapid deployment.

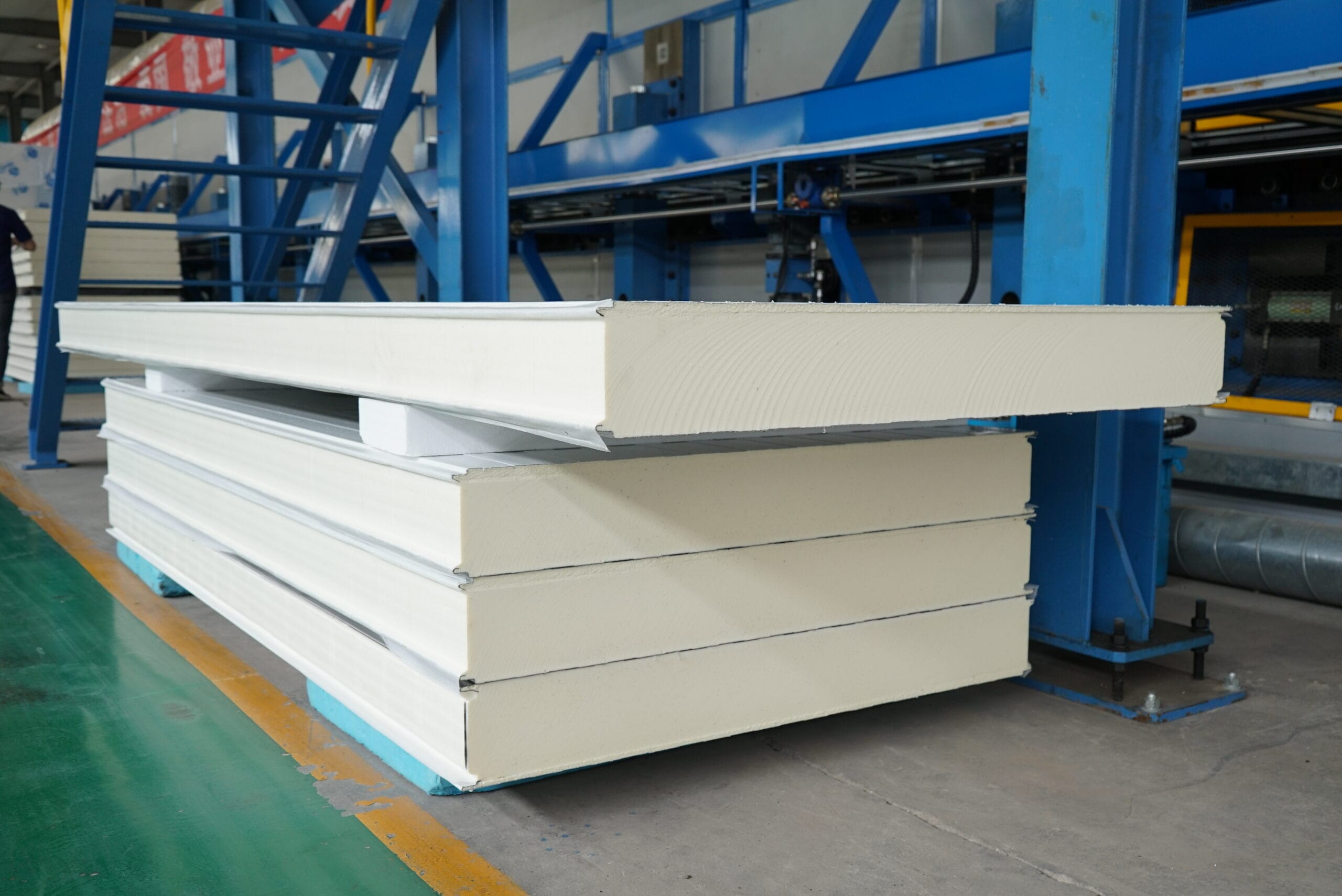

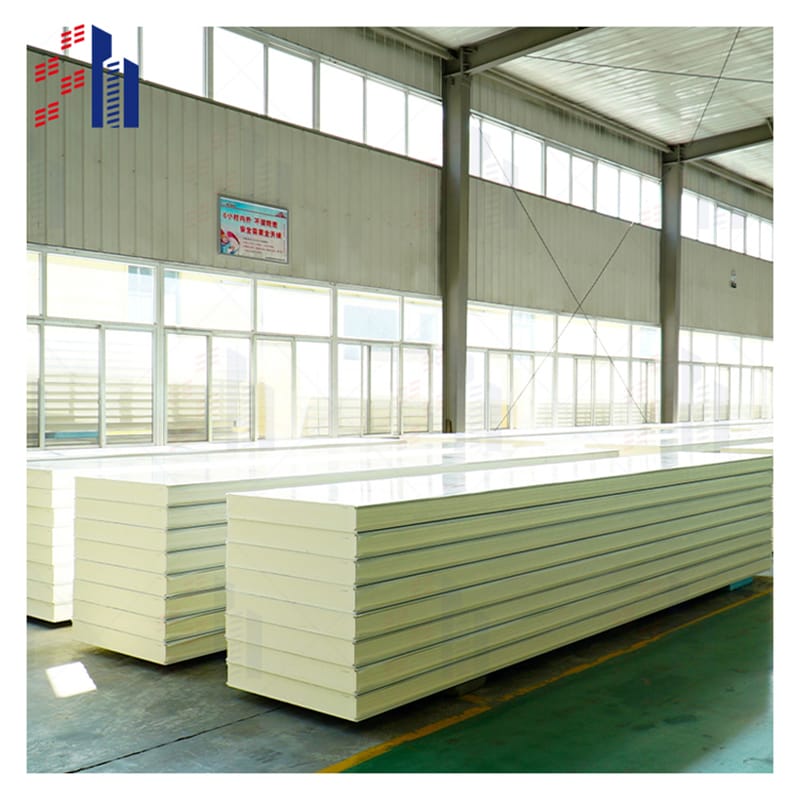

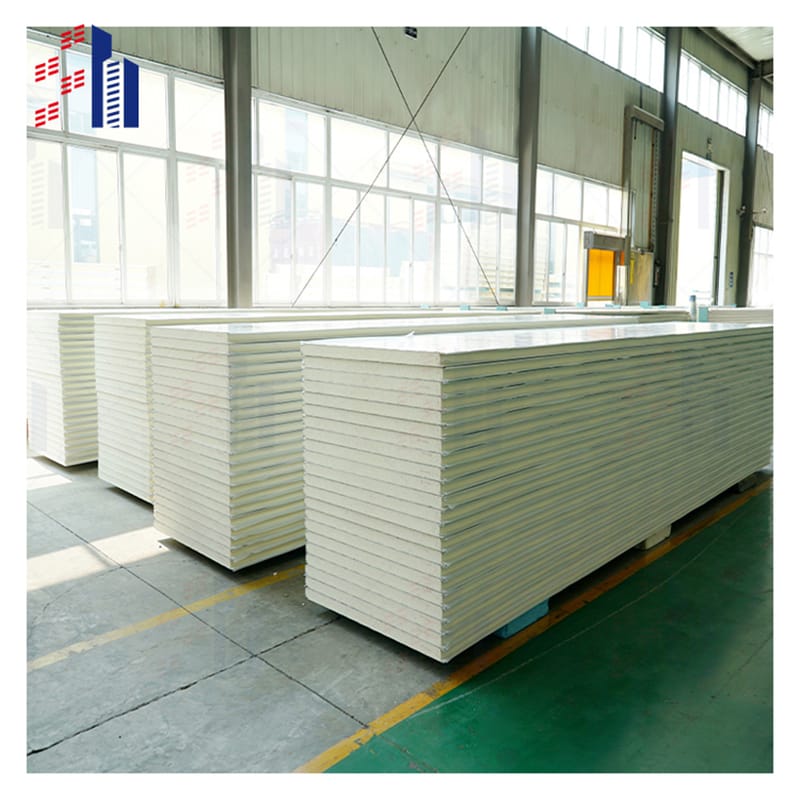

Customers visit the factory

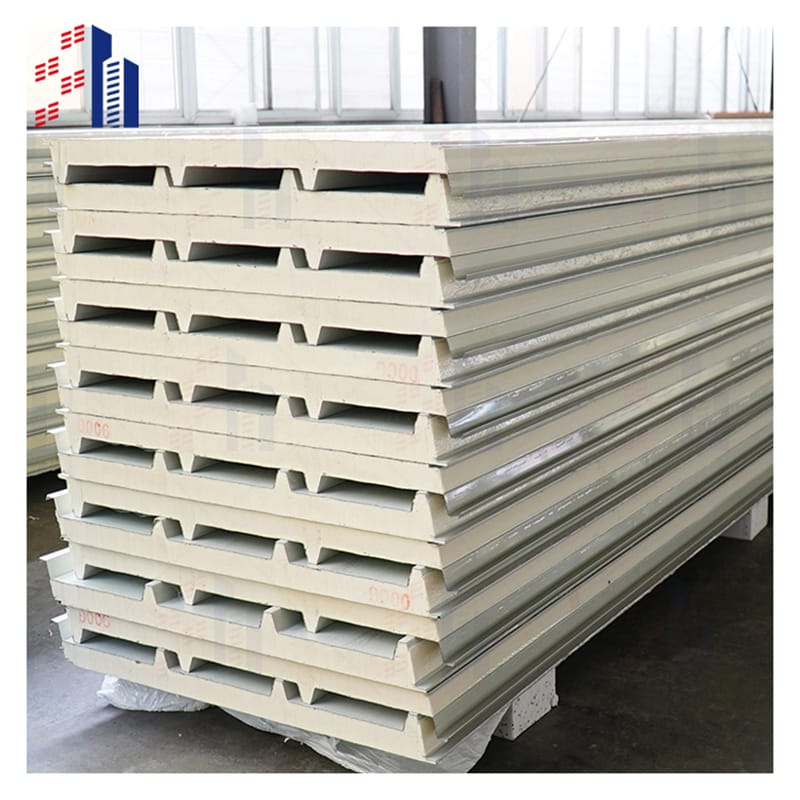

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyurethane (PU), Polystyrene (EPS), or PET Foam | PU offers the best insulation (R-5.6/inch), EPS is budget-friendly. |

| Panel Thickness | 20mm–200mm | Thicker panels (100mm+) ideal for freezers or soundproofing. |

| Density | PU: 40–60 kg/m³, EPS: 12–30 kg/m³ | Higher density = better strength/insulation. |

| Fire Rating | ASTM E84 Class A (PU) / Class B (EPS) | Class A required for schools, hospitals. |

| Thermal Conductivity (λ) | PU: 0.022 W/m·K, EPS: 0.035 W/m·K | Lower λ = less heat transfer (saves energy). |

| Max. Operating Temp. | PU: -50°C to +120°C, EPS: -40°C to +80°C | PU suits extreme climates. |

| Face Materials | Galvanized steel, Aluminum, HPL | Steel is cheapest, HPL resists UV fading. |

| Load-Bearing Capacity | Up to 150 kPa (PU, 60kg/m³) | Holds roof snow loads in cold regions. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

But why does this matter to you? Well, if you’re tired of heavy, cumbersome materials that drive up labor costs and slow down projects, foam core sandwich panels cut installation time in half. Plus, they’re LEED-certified, meaning better energy efficiency—something corporations like Apple prioritize in their campuses. Whether it’s reducing weight in aircraft (Boeing uses them) or speeding up modular construction, these panels solve real-world problems. So, if you want a material that’s strong, light, and backed by top-tier engineering, this is it.

Foam Core Panels: The Secret Behind Faster, Cheaper Construction (And Why Contractors Love Them)

Let’s cut to the chase: foam core panels are revolutionizing construction because they slash both time and costs. How? Unlike traditional materials, these panels are pre-fabricated, meaning contractors can install walls or roofs in hours, not days. Big names like Kingspan and Owens Corning have invested heavily in this tech, and even the U.S. military uses them for quick-assembly structures.

The foam core—usually PVC, PU, or aluminum—acts as insulation, so you’re also saving on HVAC costs. That’s why companies like Amazon use them in warehouses. And here’s the kicker: they’re fire-resistant (tested to ASTM E84 standards) and won’t rot or warp. So, if you’re sick of delays from weather or labor shortages, foam core panels are the fix.

Foamboard in Architecture: How Zaha Hadid’s Firm Uses It for Stunning, Lightweight Designs

Ever wonder how avant-garde firms like Zaha Hadid Architects create those gravity-defying curves? One word: foamboard. This ultra-light yet rigid material lets designers experiment freely without worrying about weight constraints. Universities like MIT even use it for prototyping.

For builders, the appeal is simple: it’s easy to cut, doesn’t require heavy machinery, and pairs perfectly with composites. Plus, it’s moisture-resistant—a must for coastal projects. So, if you want to push design limits without blowing the budget, foamboard is your go-to.

Aluminium Foam Core Sandwich Panels: The Military-Grade Material Going Mainstream

Originally developed for armored vehicles, aluminum foam core sandwich panels are now hitting commercial construction. Why? They’re bulletproof, fireproof, and weigh 60% less than steel. The European Space Agency uses them for satellite housings, and Tesla’s Cybertruck reportedly incorporates similar tech.

For architects, this means sleek, thin profiles without sacrificing safety. And since they’re recyclable, they’re a hit with eco-conscious developers. Bottom line? If security and sustainability are priorities, this material’s a game-changer.

PVC Foam Core Sandwich Panels: The Boat Builder’s Best-Kept Secret

Boat manufacturers from Brunswick to Sunseeker swear by PVC foam core sandwich panels—and here’s why. They don’t absorb water (bye-bye, rot), resist salt corrosion, and are so lightweight they boost fuel efficiency by up to 20%.

Landlubbers benefit too: these panels are popping up in flood-prone homes and poolside cabanas. So whether you’re battling waves or just Florida humidity, PVC foam core has your back.

PU Foam Sandwich Panels: The Insulation Powerhouse Cutting Energy Bills by 30%

PU foam sandwich panels are the unsung heroes of energy efficiency. With R-values topping 8 per inch, they outperform fiberglass by a mile. Walmart uses them in cold storage, and LEED-certified buildings love them for slashing HVAC costs.

Plus, they self-extinguish in fires (UL94-rated) and dampen sound—perfect for schools and hospitals. If you’re tired of sky-high utility bills, PU foam is the fix.

Sandwich Panels 101: What Boeing, BMW, and Your Local Hospital Have in Common

From airplane wings (Airbus A380) to MRI rooms, sandwich panels are everywhere. Their secret? Customizability. Need soundproofing? Add a thicker core. Need bullet resistance? Switch to aluminum foam.

With patents from companies like Hexcel and Gurit, this isn’t some niche tech—it’s the future of manufacturing. And it’s probably already in your neighborhood.

Sandwich Panel Manufacturing: How Automation Is Cutting Costs for Giants Like Toyota

Robotic arms don’t get tired, and that’s why Toyota uses them to mass-produce sandwich panels with zero defects. Automated lines from firms like Henkel can spit out a panel every 30 seconds—all while keeping tolerances under 1mm.

For small shops, this tech is now affordable thanks to startups like Paneltec. Translation? You don’t need to be a Fortune 500 company to compete.