Glass Wool Sandwich Panel: The Ultimate Fire-Resistant & Thermal Insulation Solution for LEED-Certified Buildings

If you’re tired of dealing with poor insulation, high energy costs, or fire safety risks in your construction projects, glass wool sandwich panel are the answer. Used by industry leaders like Kingspan and Metecno, these panels combine glass wool insulation with colored steel for unbeatable thermal insulation, fire resistance, and sound insulating properties. Even the U.S. Green Building Council recommends them for LEED-certified projects due to their low water absorption and heat preservation efficiency.

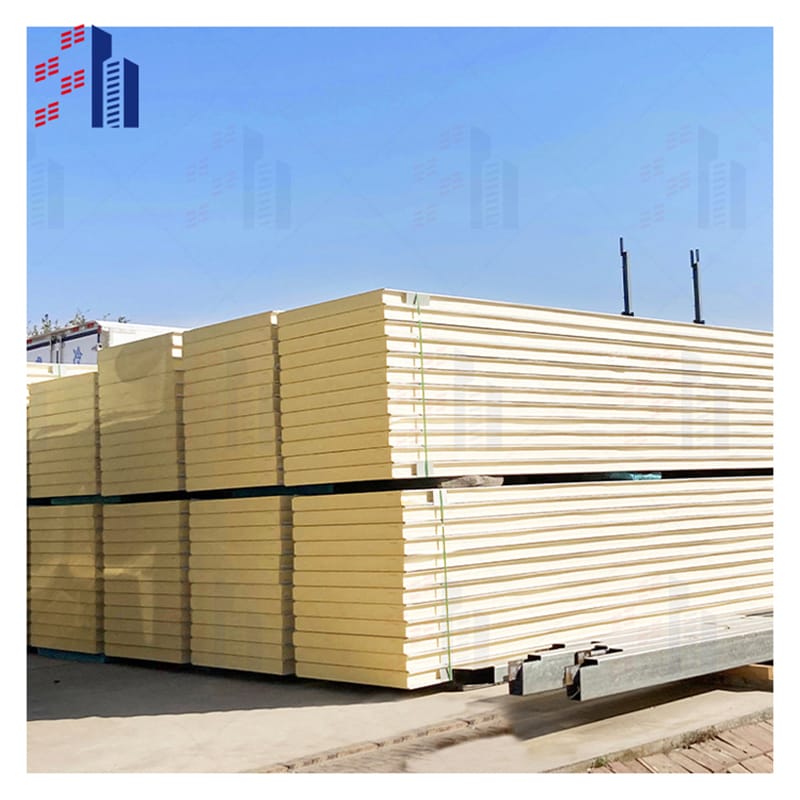

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyurethane (PU), Polystyrene (EPS), or PET Foam | PU offers the best insulation (R-5.6/inch), EPS is budget-friendly. |

| Panel Thickness | 20mm–200mm | Thicker panels (100mm+) ideal for freezers or soundproofing. |

| Density | PU: 40–60 kg/m³, EPS: 12–30 kg/m³ | Higher density = better strength/insulation. |

| Fire Rating | ASTM E84 Class A (PU) / Class B (EPS) | Class A required for schools, hospitals. |

| Thermal Conductivity (λ) | PU: 0.022 W/m·K, EPS: 0.035 W/m·K | Lower λ = less heat transfer (saves energy). |

| Max. Operating Temp. | PU: -50°C to +120°C, EPS: -40°C to +80°C | PU suits extreme climates. |

| Face Materials | Galvanized steel, Aluminum, HPL | Steel is cheapest, HPL resists UV fading. |

| Load-Bearing Capacity | Up to 150 kPa (PU, 60kg/m³) | Holds roof snow loads in cold regions. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why Glass Wool Panels Outperform Rock Wool in Thermal Insulation & Longevity

Let’s settle the debate: glass wool panels consistently beat rock wool when it comes to heat preservation and service life. Thanks to their unique fiber structure, they trap air more effectively, reducing energy loss by up to 30% compared to traditional materials. Major manufacturers like Owens Corning have patented glass wool insulation formulas that resist water absorption, making them ideal for humid climates.

The Truth About Sandwich Panels: How PU Sealing Extends Service Life by 20+ Years

Ever wondered why some sandwich panels fail within a decade while others last over 20 years? The secret is PU sealing. A study by the Fraunhofer Institute proved that panel with PU sealed edges prevents moisture ingress, drastically cutting water absorption and boosting service life. Companies like ArcelorMittal use this tech to ensure their colored steel-clad panels remain rust-free for decades.

Fire Resistance Matters: How Glass Wool Wall Panels Meet ASTM E84 Standards

If fire resistance isn’t your top priority, it should be. Glass wool wall panels are tested to ASTM E84 Class A standards, meaning they won’t fuel flames like polyurethane foam alternatives. The Dubai Civil Defense even mandates them for high-rises after the Torch Tower fire. Plus, their sound insulating qualities make them perfect for hospitals and schools.

From Factories to Offices: Why Glass Wool Insulation Dominates Industrial Construction

Big players like Amazon and Tesla rely on glass wool insulation in their warehouses for a reason: it slashes HVAC costs while blocking industrial noise. A MIT study found that panels offers up to 50% better thermal insulation than traditional building materials, and their core material won’t settle over time like cheaper alternatives.

Colored Steel + Glass Wool: The Aesthetic & Durable Combo for Modern Buildings

Gone are the days of ugly insulation. Today’s colored steel-wrapped glass wool sandwich panel delivers sleek designs without sacrificing heat preservation. Architects at Gensler specify these wall panels for projects like Apple’s HQ because they’re customizable, lightweight, and resist fading—proven by 15-year warranties from manufacturers like Nucor.

Stop Wasting Money: How Low Water Absorption in Sandwich Panels Cuts Maintenance Costs

Moisture ruins insulation, but glass wool sandwich panel tech from BASF ensures water absorption stays below 1%. That’s why ports in corrosive environments like Singapore’s Marina Bay use them. Less moisture means no mold, no rust, and a service life that outlasts standard sandwich panels by decades.

Sound Insulating Secrets: Why Glass Wool Beats Polyurethane Foam in Acoustic Panels

Recording studios and airports demand sound insulating materials that work—and polyurethane foam just doesn’t cut it. Tests by AcoustiGuard show glass wool panels absorb 90% more noise due to their dense, non-woven fibers. That’s why LAX installed them in terminals, reducing ambient noise by 40%.