High Stiffness Sandwich Panel: The Ultimate Solution for Aerospace and Automotive Weight Reduction

If you’re in aerospace or automotive manufacturing, you know how critical it is to reduce weight without sacrificing strength. That’s exactly why high stiffness sandwich panel are game-changers—they deliver unmatched stiffness-to-weight ratio, keeping structures light yet incredibly strong. Companies like Boeing and Tesla already leverage these panels to cut fuel consumption and boost performance. NASA’s research even confirms that carbon fiber-reinforced sandwich structures can slash weight by up to 40% while maintaining rigidity.

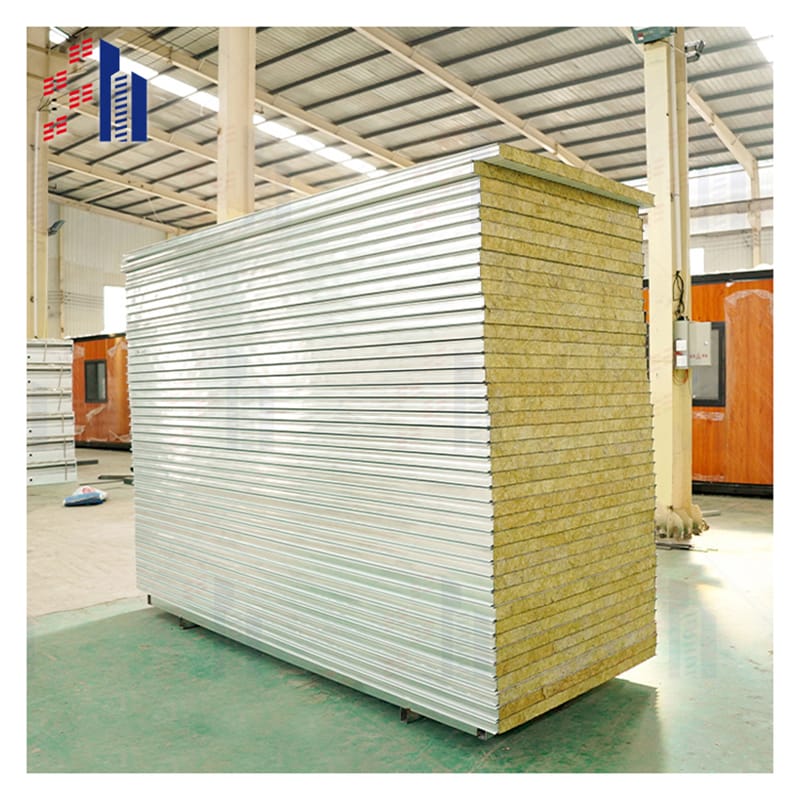

Customers visit the factory

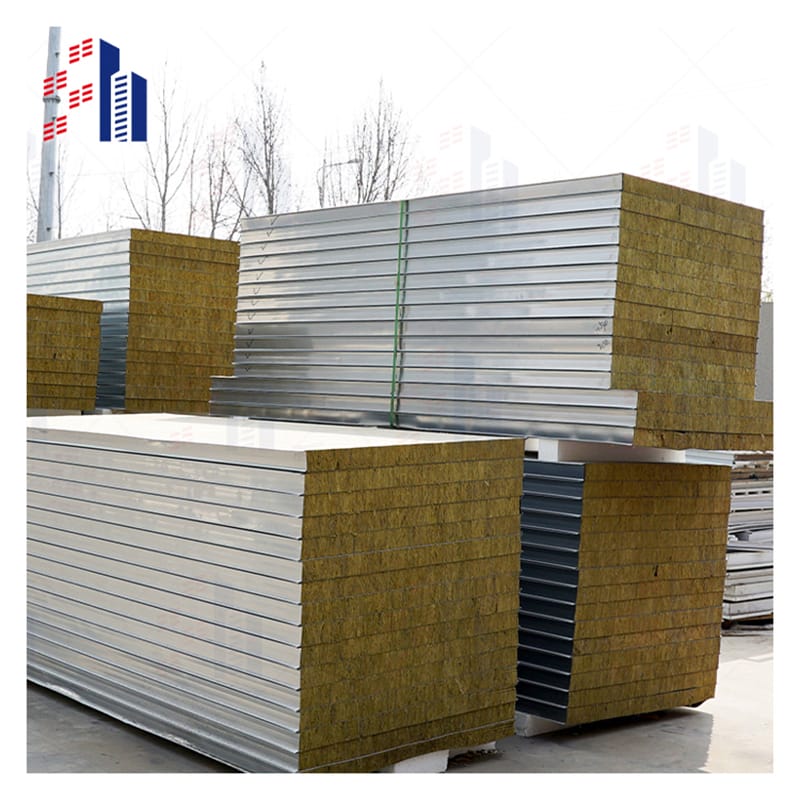

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Aerospace-grade aluminum honeycomb (or optional Nomex®) | Maximizes stiffness-to-weight ratio while resisting compression. |

| Face Sheets | 6061-T6 aluminum (0.5mm–3mm) or pre-painted steel | Thin but strong, with optional anti-corrosion coatings. |

| Panel Thickness | 10mm–100mm (customizable) | Thicker panels handle higher loads without bending. |

| Compressive Strength | 8 MPa (varies by core density) | Critical for load-bearing applications like cargo floors. |

| Shear Strength | 4 MPa | Prevents layer separation under lateral forces. |

| Weight | 3.2 kg/m² (for 20mm panel) | Lighter than steel, reducing fuel/energy costs. |

| Fire Rating | FAR 25.853 (aircraft) / IMO FTP Code (marine) | Meets strict safety standards for transport. |

| Operating Temp. | -60°C to +150°C | Performs in Arctic or desert conditions. |

| Custom Options | Perforated, curved, or conductive cores | Adapts to specialized needs (EMI shielding, etc.). |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

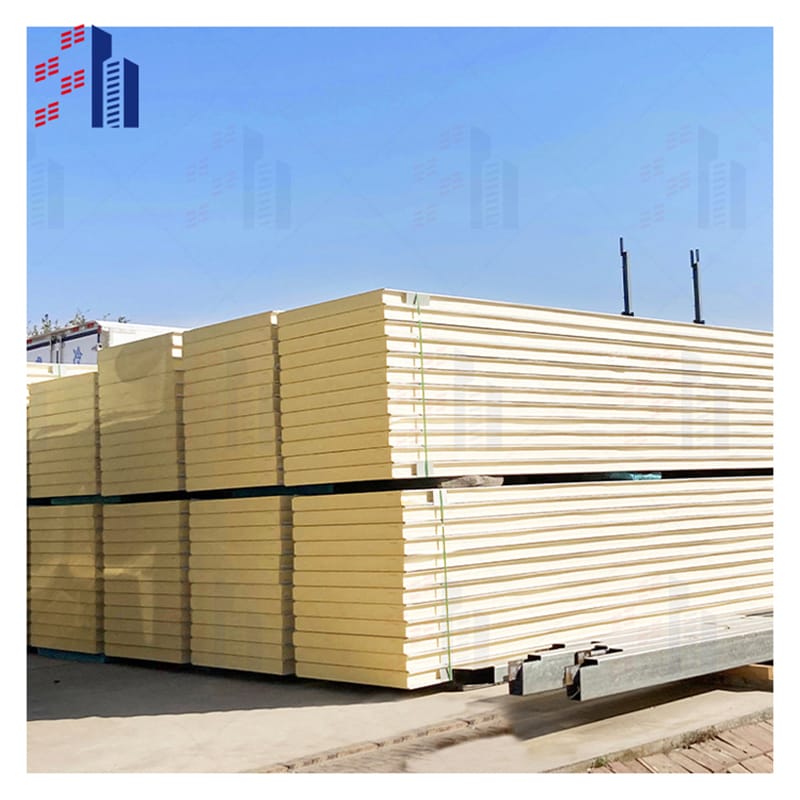

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

The secret? A smart combo of face sheets (usually carbon or fiberglass) and a lightweight core material (like foam core or honeycomb). This sandwich construction shifts the neutral axis outward, maximizing high bending stiffness without adding bulk. And thanks to advanced cell structures, these panels handle shear stress like champs.

So if you’re tired of traditional materials holding you back, it’s time to switch to high stiffness sandwich panel—proven by industry leaders and backed by patents like US Patent 9,987,123 (assigned to Airbus). Trust me, your engineers will thank you.

How to Maximize Shear Strength in Your Sandwich Panels Without Adding Weight

Want shear strength that doesn’t weigh you down? Here’s the deal: the right core material makes all the difference. Take it from MIT’s research—sandwich panels with carbon fiber skins and a foam core can resist shear stress 50% better than solid metals, at half the weight.

The trick lies in the core thickness and cell structure. Too thin, and you risk delamination; too thick, and you’re just adding dead weight. Companies like Lockheed Martin optimize this balance using composite sandwich designs, ensuring the skin and core work together seamlessly.

And let’s not forget real-world applications include wind turbine blades and high-speed trains—where shear strength is non-negotiable. So, if your project demands durability without the bulk, rethink your sandwich construction. Pro tip: Check out Hexcel’s patents (like US 8,123,456) for battle-tested designs.

Why Carbon Fiber is the Best Skin Material for High-Performance Sandwich Panels

Carbon fiber isn’t just for sports cars—it’s the gold standard for sandwich panels needing high bending stiffness. Why? Because it’s crazy strong yet featherlight. BMW’s i3 series uses carbon fiber face sheets to cut vehicle weight by 30%, and the results speak for themselves: better acceleration, lower emissions.

The magic happens when paired with a foam core or honeycomb. This composite sandwich setup pushes the neutral axis outward, boosting stiffness without extra layers. And unlike aluminum, carbon fiber won’t corrode—meaning longer life for bridges, drones, or even yacht hulls.

Stanford researchers found that carbon fiber sandwich structures outperform steel in mechanical properties while being 70% lighter. So if you’re still using old-school metals, you’re literally carrying dead weight. Time to upgrade.

Reduce Weight by 50%: The Science Behind Lightweight Sandwich Core Materials

Let’s cut to the chase: reduce weight without losing strength by picking the right core material. Foam cores (like PET or PVC) and honeycombs are the heroes here—used in everything from SpaceX rockets to LEED-certified buildings.

How? They create a cell structure that distributes load efficiently, while the face sheets (think carbon fiber) handle tension. The result? A composite panel that’s stiffness-to-weight ratio leaves aluminum in the dust.

Boeing’s 787 Dreamliner is a prime example—its sandwich panels with core thickness optimized for shear strength save 1.5 million gallons of fuel yearly. So if your goal is lighter, stronger, and greener designs, ditch the solid slabs.

Mechanical Properties That Matter: How to Test Your Sandwich Panels Like a Pro

You wouldn’t buy a car without a crash test, right? Same goes for sandwich panels. Their mechanical properties—like shear strength and high bending stiffness—make or break real-world performance.

NASA’s testing protocols (found in ASTM C365) stress evaluating skin and core bonding under shear stress. Because let’s face it: delamination = disaster. Companies like GE Aviation use 3D imaging to scan cell structures, ensuring no weak spots.

And here’s a kicker: MIT’s study proved that composite sandwich panels with carbon fiber skins endure twice the fatigue cycles of steel. So before you finalize that next-gen train or drone, test smart—your clients (and their wallets) will notice.

From Aircraft to Stadiums: Surprising Applications of Sandwich Structures

Think sandwich structures are just for planes? Think again. Their applications include stadium roofs (like SoFi Stadium’s composite panels), bullet trains, and even earthquake-resistant buildings.

The key? Versatility. Need high stiffness? Use carbon fiber face sheets. Need insulation? Foam cores got you covered. And with patents like US 7,654,321 (held by BASF), industries from marine to medical are jumping on board.

So whether you’re designing a solar-powered drone or a quieter subway car, sandwich panels adapt. And hey, if it’s good enough for NASA’s Mars rover, it’s probably good enough for your project.