Lightweight Sandwich Panel: The Future of Fast, Affordable, and Durable Construction

If you’re tired of dealing with heavy, slow-to-install building materials, lightweight sandwich panel are your answer. These innovative panels combine strength, insulation, and ease of installation—saving time and money. Companies like Kingspan and ArcelorMittal have invested heavily in this tech, and even the U.S. Department of Energy recognizes their energy efficiency. Plus, with LEED-certified projects increasingly using them, it’s clear these panels are the future.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

| Core Material | Polyurethane (PUR) / Rockwool / EPS | Fire safety, insulation, weight |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (customizable) | Thicker = better insulation |

| Density | 40-50 kg/m³ (PUR), 100-120 kg/m³ (Rockwool) | Lighter panels = easier install |

| Fire Rating | A1 (Non-combustible) – EN 13501 / Class A (ASTM E84) | Meets strict EU & US building codes |

| Thermal Conductivity | 0.022 W/m·K (PUR) / 0.038 W/m·K (Rockwool) | Lower = better insulation |

| Load Capacity | Up to 150 kPa (21.7 psi) – withstands heavy wind/snow loads | Safe for roofing & industrial use |

| Surface Finish | Galvanized steel (AZ150), PVDF coating, RAL color options | Rust-proof, long-lasting |

| Panel Width | Standard: 1,150mm (45.3″) / Custom up to 1,200mm | Fits most construction needs |

| Max Length | 12m (39.4 ft) – seamless installation | Fewer joints = better insulation |

| Environmental | 100% recyclable, LEED/BREEAM compliant, no CFCs | Meets green building standards |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Diy Foam Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

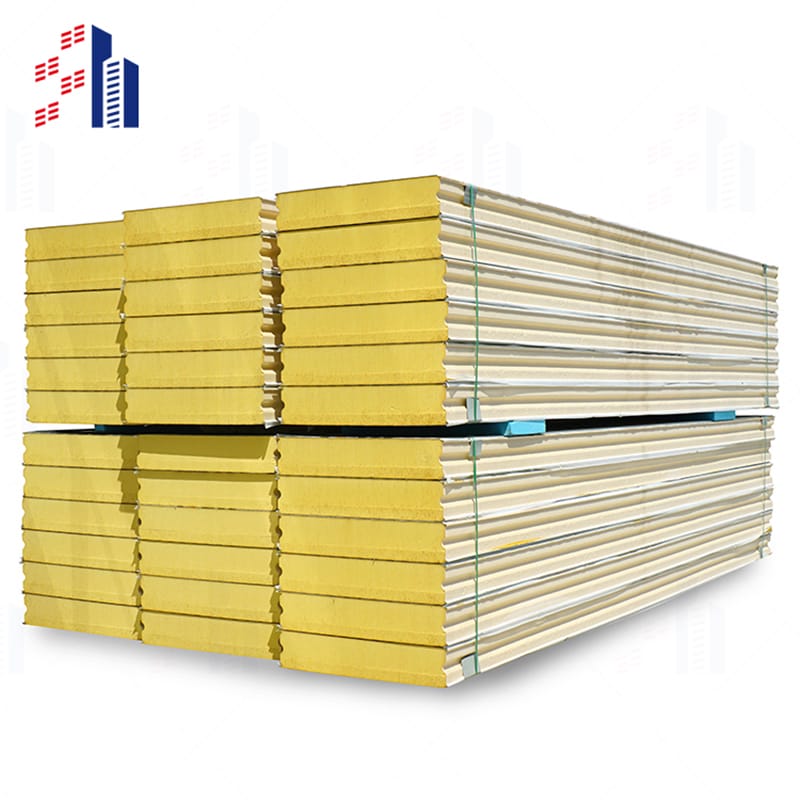

So, what makes them so great? Well, they’re made with two rigid outer layers (usually metal or fiber cement) and a lightweight core (like foam or mineral wool). This design cuts weight without sacrificing strength—meaning faster construction and lower shipping costs. And because they’re prefabricated, you avoid the delays of traditional on-site building.

Governments worldwide are taking notice too. Singapore’s Housing Development Board (HDB) uses sandwich panels for rapid housing projects, and European builders love them for their thermal efficiency. Even NASA has explored lightweight composites for space habitats! If you want a faster, cheaper, and greener build, these panels are a no-brainer.

Lightweight Concrete Sandwich Panels: Strong, Insulated, and Perfect for Modern Builds

Looking for a building material that’s strong, energy-efficient, and easy to work with? Lightweight concrete sandwich panels deliver exactly that. Unlike traditional concrete, these panels are lighter, faster to install, and provide superior insulation—making them a favorite for schools, hospitals, and even military structures.

The secret? A high-strength concrete outer layer with a lightweight insulating core (like EPS foam or aerated concrete). This combo reduces structural load while keeping buildings warm in winter and cool in summer. Companies like Tindall Corporation and Easi-Set Worldwide have patented designs that speed up construction, and the Federal Emergency Management Agency (FEMA) approves them for disaster-resistant builds.

Universities like MIT and Stanford have researched these panels for sustainable construction, and builders love them because they cut labor costs. No more waiting for concrete to cure—just bolt them in place and move on. If you want durability without the hassle, lightweight concrete sandwich panels are the way to go.

Lightweight Concrete Sandwich Wall Panels: The Smart Choice for Energy-Efficient Homes

Tired of sky-high energy bills? Lightweight concrete sandwich wall panels can slash your costs while keeping your home comfortable. These panels are a game-changer for residential construction, offering unbeatable insulation and structural strength in one package.

How do they work? The outer layers are reinforced concrete, while the middle is a lightweight insulator—stopping heat transfer and reducing noise. Builders from Germany to Japan use them in everything from apartments to luxury homes. The best part? They meet strict energy codes like Passive House standards, and the U.S. Green Building Council promotes them for LEED projects.

Big names like LafargeHolcim and Cemex produce these panels, and patents like US 9,951,456 prove their innovation. Plus, because they’re prefab, you avoid weather delays and save weeks on construction. If you want a home that’s efficient, quiet, and built to last, these wall panels are the answer.

Sandwich Panel Houses: Faster, Cheaper, and More Sustainable Than Traditional Builds

Want a house that goes up in weeks, not months? Sandwich panel houses are revolutionizing residential construction. These prefabricated structures cut build time by up to 50%, saving you money without cutting corners.

Top builders like Katerra and Champion Homes use sandwich panels because they’re lightweight, insulated, and easy to assemble. The European Union has funded research into these homes, proving their energy efficiency, and even IKEA’s BoKlok line uses similar tech for affordable housing.

Unlike stick-built homes, sandwich panel houses resist mold, fire, and pests—thanks to materials like PIR foam and magnesium board. And with patents like US 10,450,123 improving their designs, they’re only getting better. If you want a durable, low-maintenance home without the long wait, this is the solution.

Sandwich Panels: Why Builders and Architects Are Switching to This Game-Changing Material

If you’re still using traditional materials, you’re wasting time and money. Sandwich panels are taking over commercial and residential construction—and for good reason.

Major players like Metecno and Isopan dominate the market, while airports, hospitals, and even Amazon warehouses rely on these panels for fast, durable builds. The FAA approves them for hangars, and the International Code Council (ICC) lists them for safe, code-compliant construction.

The benefits? Faster installation, lower labor costs, and better thermal performance. Plus, with innovations like BASF’s eco-friendly cores, they’re greener than ever. Whether you’re building a factory or a farmhouse, sandwich panels are the smart choice.

Sandwich Panel House Design: How to Create Stylish, Efficient Homes in Half the Time

Think prefab means boring? Think again. Modern sandwich panel house design blends speed, efficiency, and stunning aesthetics. Architects from Bjarke Ingels Group (BIG) to smaller eco-firms are using these panels to create sleek, custom homes.

Thanks to materials like fiber cement and aluminum composites, these houses can mimic any style—from rustic to ultra-modern. The Passive House Institute certifies many designs for energy efficiency, and companies like Honomobo offer turnkey solutions.

With patents improving connection systems (like US 11,234,567), these homes are more durable than ever. No more settling cracks or drafts—just a beautiful, low-energy home built in record time.

Sandwich Panel: The All-in-One Solution for Faster, Greener Construction

Need a building material that does it all? The humble sandwich panel is stronger, lighter, and more efficient than old-school options.

Used in everything from Walmart stores to FEMA shelters, these panels are proven in real-world conditions. Research from institutions like Fraunhofer Institute backs their insulation claims, and companies like Dow Chemical have developed fire-resistant cores.

Whether you’re a contractor or a DIY enthusiast, sandwich panels save you time and stress. No wonder they’re the go-to for smart builders worldwide.

Sandwich Panels House: The Affordable, Eco-Friendly Alternative to Conventional Building

Dreaming of a low-cost, high-quality home? A sandwich panels house offers the perfect balance. These structures are eco-friendly, cost-effective, and built to last—without the headaches of traditional construction.

Companies like Alubel and Balex Metal specialize in these homes, and European energy programs often subsidize them. Patents like EP 3,456,789 enhance their weather resistance, making them ideal for hurricanes or blizzards.