What Are 20mm Sandwich Panel

20mm sandwich panel are a type of lightweight composite panel featuring a core material sandwiched between two rigid outer layers. This structure offers a smart balance of strength, insulation, and durability, making it a popular choice in sandwich panel construction for various industries.

The 20mm thickness is especially significant because it provides an ideal combo of thermal insulation and structural rigidity without adding excess weight. It’s thick enough to deliver solid insulation performance, yet slim enough to keep projects cost-effective and easy to handle.

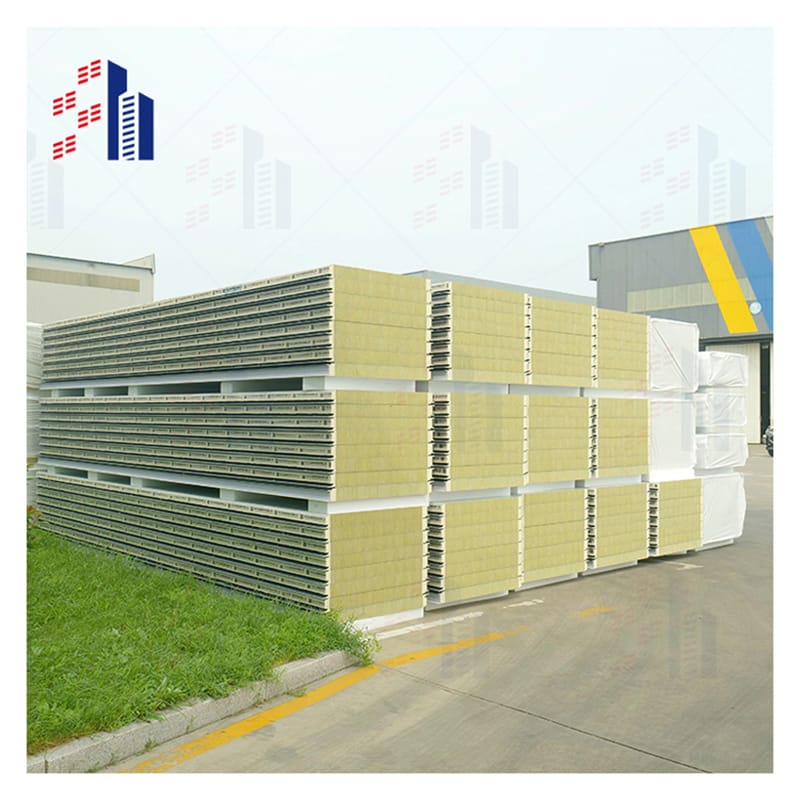

Customers visit the factory

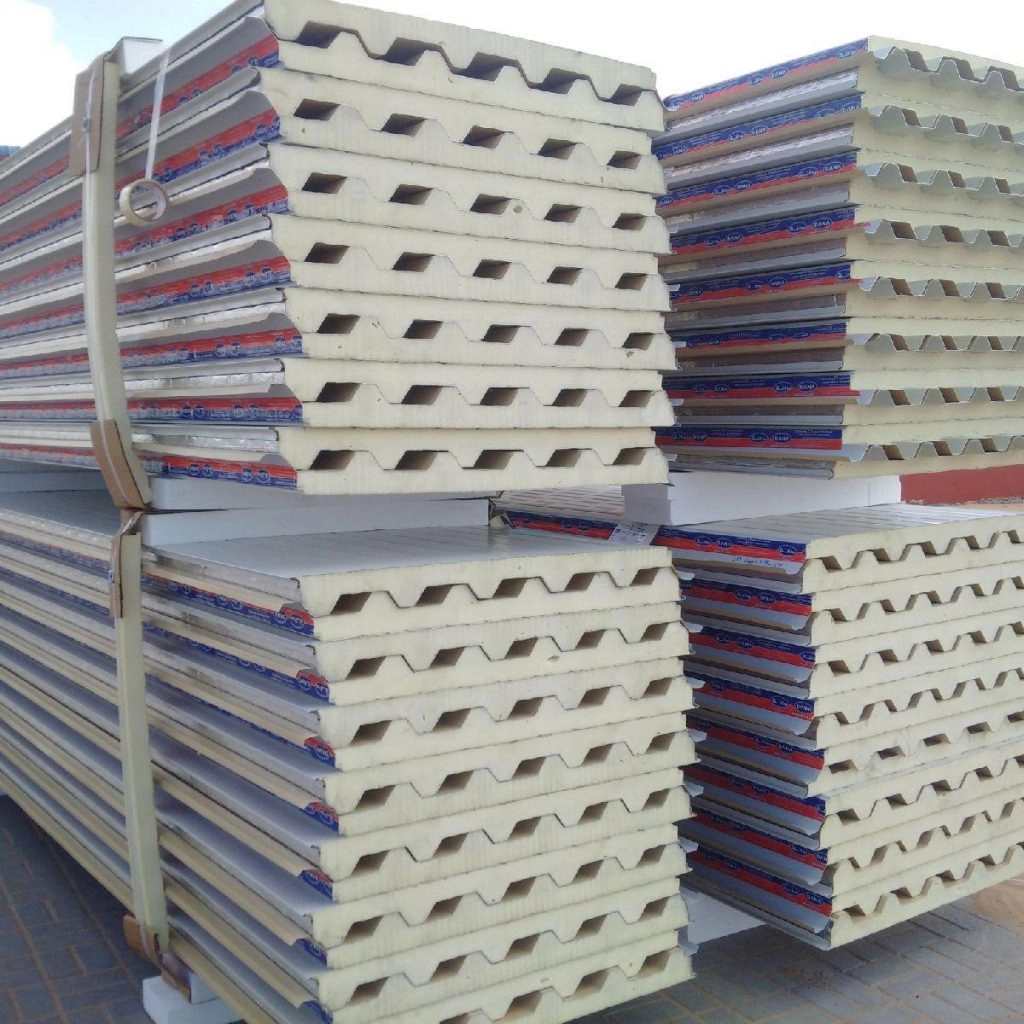

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Overview of Shanghe 20mm Sandwich Panel Specifications

Shanghe’s 20mm sandwich panels boast impressive engineering optimized for the US market’s needs. Key specs include:

- Core Material Options: High-quality PET foam or PIR foam for excellent thermal insulation and fire resistance.

- Panel Size: Standard widths from 1000mm to 1200mm, customizable lengths to fit roofing, wall cladding, partitions, and more.

- Surface Finishes: Galvanized steel, aluminum, or color-coated steel options that enable tailored aesthetics and enhanced durability.

- Weight: Lightweight design ranging between 7 to 9 kg/m² depending on core type and surface, making it easy to handle and install.

- Thermal Performance: R-values ranging from 2.5 to 3.5, promoting energy savings in residential, commercial, and industrial buildings.

- Moisture Resistance: Excellent waterproof and vapor barrier properties protect against mold and corrosion in harsh environments.

With a focus on lightweight yet strong structural rigidity, the Shanghe 20mm sandwich panel fits seamlessly into modular building materials, industrial sandwich panels, and eco-friendly sandwich panels categories. Its specifications make it versatile enough for roofing, wall, partitioning, and specialized uses like RV floor sandwich panels and prefab construction.

Choosing a 20mm panel from Shanghe means getting a high-strength composite panel that ticks the boxes for performance, sustainability, and convenience across a range of construction and transportation applications.

Key Features of Shanghe 20mm Sandwich Panels

Shanghe 20mm sandwich panels stand out for their lightweight design combined with strong structural rigidity. This balance makes them easy to handle and install while providing excellent support and stability for various construction needs.

Superior Thermal Acoustic and Moisture Insulation

These panels offer top-notch insulation properties, helping keep interiors comfortable by minimizing heat transfer and reducing noise pollution. The 20mm thickness serves as an effective barrier against moisture, preventing condensation and protecting building structures over time.

Eco-Friendly Design and Sustainable Manufacturing

Made with environmentally conscious processes, Shanghe 20mm panels use eco-friendly materials and sustainable production techniques. This approach reflects growing demand in the U.S. market for green building solutions that reduce carbon footprint without compromising performance.

Customizable Surface and Size Options

Whether you need specific colors, textures, or panel sizes, Shanghe provides flexible customization to fit your project’s exact requirements. This adaptability supports applications ranging from modular building materials to lightweight composite panels in industrial settings.

High Durability for Harsh Environments

Designed for long-lasting performance, these sandwich panels resist corrosion, UV damage, and other environmental stresses common in American climates. This durability ensures you get a reliable product suitable for exterior wall cladding, roofing, and specialized uses like cold rooms or RV floors.

Explore more options like our polyurethane sandwich panel and roof panel sandwich for enhanced insulation and protection tailored to your project needs.

Applications of 20mm Sandwich Panels

20mm sandwich panels are extremely versatile and fit a wide range of uses across industries, thanks to their lightweight design, strong insulation, and durability. Below are key applications where the Shanghe 20mm panels truly shine.

Construction Uses

- Roofing: The panels provide excellent thermal insulation, keeping buildings cooler in summer and warmer in winter, which helps reduce energy costs.

- Wall Cladding: Their rigid structure and weather resistance make them perfect for exterior walls, boosting building strength and aesthetic appeal.

- Partitions: Lightweight and easy to install, these panels serve well for interior partitions, offering good sound insulation and privacy.

Transportation Applications

- RV Floors: The light weight and high strength of 20mm panels improve vehicle fuel efficiency while maintaining durability under heavy loads.

- Cargo Truck Bodies: Superior moisture resistance protects cargo, while the panels’ rigidity ensures the structural integrity of truck bodies even on rough roads.

Specialized Uses

- Cold Rooms: The panels’ thermal insulation blocks heat transfer, essential for maintaining low temperatures inside refrigeration units.

- Modular and Prefabricated Buildings: Their quick-to-install nature and consistent quality make them ideal for fast assembly, cutting down construction time and labor costs.

Real World Projects and Case Studies

Shanghe 20mm sandwich panels have been successfully used in various projects across the United States, including commercial warehouses, mobile homes, and refrigerated transport units. These cases demonstrate how the panels perform in both demanding industrial environments and everyday construction needs, proving their reliability and versatility.

of Benefits in Applications:

- Lightweight but strong for easy handling and long-term structural support.

- Thermal and acoustic insulation suited for energy-efficient buildings and quiet interiors.

- Moisture resistance critical for transportation and cold storage.

- Fast installation supports modular construction and reduces downtime.

Choosing Shanghe 20mm sandwich panels means selecting a product built to meet diverse needs — from standard construction to specialized industrial use — all backed by proven performance.

Benefits of Choosing Shanghe 20mm Sandwich Panels

Shanghe 20mm sandwich panels offer clear advantages for both commercial and residential projects, especially when you consider cost, installation, energy efficiency, and environmental impact.

Cost Effectiveness and Material Savings

These 20mm sandwich panels reduce overall project costs by minimizing the amount of material needed without sacrificing strength or insulation. Their lightweight nature means less support structure and easier handling, which cuts down labor and transportation expenses.

- Lower material costs compared to thicker, heavier panels

- Reduced installation time means fewer labor hours and expenses

- Minimal waste during installation thanks to precise panel sizing

Quick and Modular Installation

Designed for ease of use, Shanghe sandwich panels come with modular features that speed up assembly. Their lightweight composite panels fit together seamlessly, making them perfect for tight schedules and fast-track construction.

- Snap-fit and tongue-and-groove edges simplify installation

- Ideal for roofing, walls, and partitions in modular buildings

- Minimal on-site adjustments required, saving time and effort

Energy Savings from Enhanced Insulation

With superior thermal insulation panels at 20mm thickness, these panels perform well in maintaining indoor temperatures. This means less reliance on heating and cooling systems, leading to significant energy savings over time.

- Excellent thermal resistance cuts energy bills

- Helps keep indoor spaces cooler in summer, warmer in winter

- Contributes to reducing carbon footprint and utility costs

Environmentally Friendly and Sustainable

Shanghe sandwich panels are made with eco-friendly sandwich panels principles in mind, using sustainable materials and production methods that comply with green building standards. This impacts not just your project costs but also your environmental responsibility goals.

- Manufactured using recyclable materials

- Low VOC emissions enhance indoor air quality

- Supports LEED certification and other sustainability programs

Comparisons With Other Thicknesses

While thicker panels (e.g., 30mm or 40mm) provide additional insulation and rigidity, 20mm panels hit the sweet spot for many projects by balancing performance and cost. They offer:

| Feature | 20mm Panel | Thicker Panels (30-40mm) | Thinner Panels (10-15mm) |

|---|

| Thermal Insulation | Good to excellent | Superior | Moderate |

| Weight | Lightweight | Heavier | Ultra-light |

| Cost | Cost-effective | Higher cost | Lower cost, less durable |

| Installation time | Faster, modular | More complex, longer | Quick, less sturdy |

| Best Use | Walls, roofing, partitions | Cold storage, heavy-duty walls | Temporary or light-duty projects |

For US builders and contractors, Shanghe 20mm panels offer an optimal blend of strength, insulation, and cost that supports faster construction timelines and energy-efficient buildings. If you want durable, eco-conscious, and budget-friendly panels, these are a smart choice.

Why Choose Shanghe for 20mm Sandwich Panels

When it comes to 20mm sandwich panels, Shanghe stands out because of its focus on innovation, quality, and customer service—all tailored for the U.S. market’s high standards.

Advanced Thermal Fusion Technology and Eco-Friendly Production

Shanghe uses innovative thermal fusion technology to bond core materials and surface layers seamlessly. This ensures superior structural integrity and improved insulation performance compared to traditional adhesives. The process not only boosts the panel’s durability but also supports eco-friendly sandwich panels by reducing harmful emissions and waste during manufacturing.

Strict Quality Assurance and Industry Compliance

Every panel undergoes rigorous quality testing and industry compliance checks to meet U.S. construction codes and international standards. From fire resistance to load-bearing capacity and thermal insulation, Shanghe panels deliver consistent, verifiable performance. This commitment helps ensure that your project meets safety and durability expectations without compromise.

Extensive Local Availability and Distribution Network

Shanghe’s local distribution centers and partnerships mean you get faster access to panels, cutting down lead times significantly. Having suppliers close by supports quicker project timelines and easier logistics, especially important for tightly scheduled construction or modular building projects.

Expert Customer Support and Customization Options

Choosing Shanghe means tapping into a knowledgeable support network ready to help you select the right 20mm PET foam panel or other core types matching your specific needs. Whether it’s adjusting surface finishes, panel size, or insulation properties, Shanghe offers customizable options designed to fit your project perfectly.

of Advantages

- Thermal fusion bonding for stronger, more reliable panels

- Environmentally responsible manufacturing process

- Panels tested to meet or exceed U.S. and international standards

- Fast and local availability across the United States

- Personalized support and tailored product options

To explore more about our thermal insulation solutions, check out our Thermal Insulation Sandwich Panel and for panels geared toward structural uses, see our High Stiffness Sandwich Panel.

Choosing Shanghe means investing in panels that combine performance, sustainability, and convenience—key factors for any U.S.-based project using lightweight composite panels.

How to Select the Right 20mm Sandwich Panel for Your Project

Choosing the right 20mm sandwich panel can make a big difference in your build’s performance, cost, and durability. When selecting panels, focus on these key factors to ensure you get exactly what your project needs:

Core Material

- EPS (Expanded Polystyrene): Lightweight and budget-friendly, great for general insulation.

- PET Foam: Offers better fire resistance and moisture control, ideal for harsh or humid environments.

- Rockwool: Excellent fire protection and sound insulation, but heavier and pricier.

Surface Finish

- Consider your exposure environment:

- Galvanized steel or aluminum facings provide corrosion resistance and are easy to clean, great for outdoor or industrial sites.

- Stainless steel panels are best when high durability and hygiene are required, such as in food or medical-grade facilities.

Environmental Conditions

- Panels for extreme weather need superior thermal and moisture barriers.

- For moist or coastal areas, prioritize panels with enhanced corrosion-resistant surfaces.

Load-Bearing Requirements

- Ensure the panel provides the right structural rigidity for your application — especially if used for roofing or floor systems like in RVs or cargo trucks.

- Shanghe’s 20mm sandwich panels offer a high strength-to-weight ratio, balancing durability and lightness.

Insulation Performance

- Choose panels with the thermal insulation properties that fit your energy-saving goals. Thicker panels naturally insulate better, but the core material type makes a big impact.

Budget Considerations

- Compare the upfront cost vs. long-term energy savings. Sometimes investing a bit more upfront on better insulation pays off over the life of your building.

- Look for panels that offer quick, modular installation to save on labor costs.

Shanghe 20mm Sandwich Panels Comparison

| Feature | Shanghe EPS Panels | Shanghe PET Foam Panels | Competitor Panels |

|---|

| Thermal Insulation | Good | Superior | Varies, often lower |

| Fire Resistance | Moderate | Higher | Often lower |

| Weight | Lightweight | Slightly heavier | Can be heavier |

| Surface Options | Steel, Aluminum | Steel, Stainless Steel | Limited |

| Durability | High | Very High | Varies |

| Eco-Friendly | Recyclable | More sustainable | Varies |

| Cost | Moderate | Higher | Often cheaper but less reliable |

Buyer Tips to Pick the Best Panel

- Define your project’s priorities: Is insulation, fire safety, weight, or budget driving your decision?

- Match core material and surface for your setting—moisture, heat, or exposure matter.

- Check warranty and certifications: Shanghe panels comply with industry standards, ensuring quality you can trust.

- Consult with suppliers: Work with local experts to get panels tailored to your exact specs and delivery timelines.

For more details on specific Shanghe sandwich panel products, check out our offerings like the Prefabricated Sandwich Panels and EPS Sandwich Panels, designed to meet a variety of construction and industrial needs.