What Are 50mm EPS Sandwich Panel

50mm EPS sandwich panel are high-performance construction materials featuring a core of expanded polystyrene (EPS) foam sandwiched between two layers of galvanized steel sheets. The galvanized steel offers outstanding durability and corrosion resistance, while the 50mm EPS foam core provides excellent thermal and sound insulation. This combination creates a lightweight yet strong panel ideal for a variety of building applications.

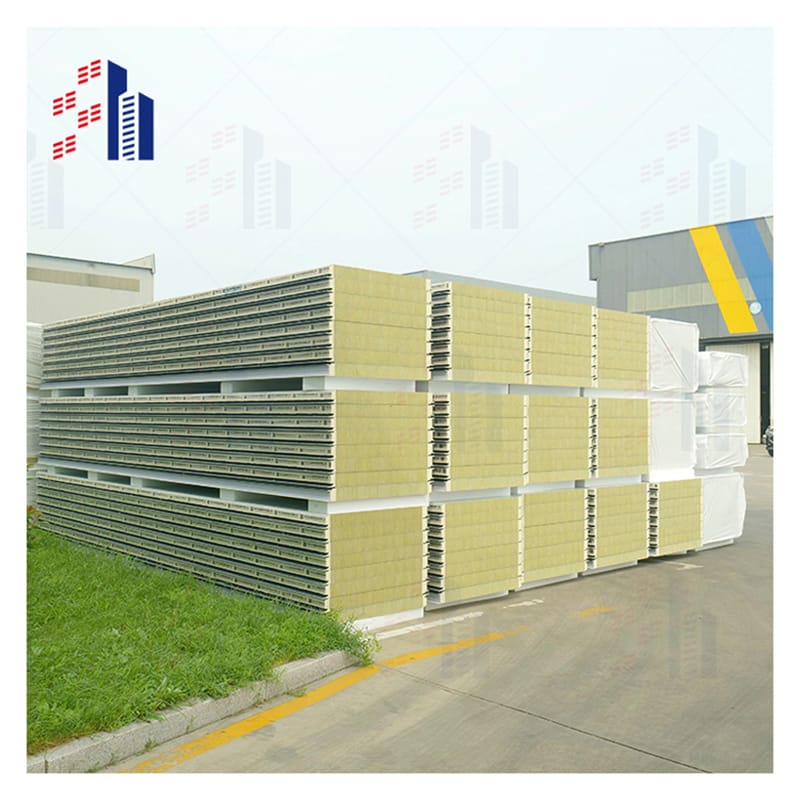

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Structure and Composition

- Outer layers: High-quality galvanized steel sheets, typically coated with protective finishes such as PE or PVDF to enhance weather resistance and longevity.

- Core: 50mm thick expanded polystyrene (EPS) foam, known for its low thermal conductivity and light weight.

- Bonding: Advanced lamination processes ensure a firm bond between steel sheets and EPS core, guaranteeing panel stability and structural integrity.

Key Specifications

- Panel thickness: Standardized at 50mm, balancing insulation efficiency and structural performance.

- Material composition:

- Galvanized steel thickness ranges from 0.4mm to 0.6mm per face.

- EPS foam density typically around 12–15 kg/m3, optimized for insulation.

- Standard dimensions: Panels commonly come in widths of 1 meter and lengths customized from 2 to 12 meters, depending on project needs.

Why 50mm EPS Panels Are Ideal

- Compared to thinner panels (30mm or 40mm), 50mm EPS sandwich panels offer enhanced thermal insulation, making them perfect for climates requiring better energy efficiency.

- Thicker panels (like 75mm or 100mm) provide higher insulation but add weight and cost, affecting installation speed and budget.

- 50mm thickness hits the sweet spot between cost, insulation performance, weight, and ease of handling, making it the preferred choice for walls, roofs, and partitions.

- It delivers optimal thermal conductivity typically around 0.032 to 0.038 W/mK, ensuring effective temperature control without excessive material bulk.

Choosing 50mm EPS sandwich panels means selecting a reliable, energy-efficient, and versatile building material designed for modern construction needs, offering a great combination of strength, durability, and insulation.

Key Features of Shanghe 50mm EPS Sandwich Panels

Shanghe’s 50mm EPS sandwich panels are designed to deliver excellent performance across multiple areas, making them a solid choice for insulation and construction needs in the U.S. market.

Lightweight for Easy Installation and Handling

Our panels are lightweight, which makes transportation, lifting, and installation faster and safer. This reduces labor costs and speeds up your project timeline, especially useful for both commercial and residential builds.

Superior Thermal Insulation

The EPS foam core in these panels offers a low thermal conductivity, typically ranging between 0.035 to 0.045 W/m·K. This means better heat retention or rejection, cutting down on your heating and cooling bills year-round.

Effective Sound Insulation

Each panel can absorb sound up to 30 dB per square meter, helping to reduce noise pollution indoors. This makes them perfect for office spaces, factories, and residential areas where noise control is important.

Fire Resistance Ratings

Shanghe’s EPS sandwich panels meet B1 and B2 fire resistance standards, providing self-extinguishing properties. This ensures your building has added safety without sacrificing the lightweight benefits of EPS.

Durable and Waterproof

The galvanized steel outer layers and EPS core create a panel that is waterproof and resistant to corrosion, supporting long-term durability for 30 years or more. This durability is crucial for exterior walls and roofs exposed to harsh weather.

Customizable Colors and Coatings

Our panels come with a variety of color options and surface coatings including PE (polyethylene) and PVDF (polyvinylidene fluoride). This lets you match architectural styles while improving surface protection and lifespan.

Shanghe’s 50mm EPS sandwich panel combines these key features to offer a practical, efficient, and versatile solution for insulation and building needs across multiple industries and applications.

Benefits of Choosing Shanghe 50mm EPS Sandwich Panels

When it comes to selecting insulation panels for your project, Shanghe 50mm EPS sandwich panels bring a strong mix of benefits tailored to meet the needs of U.S. builders and property owners. Here’s why these panels stand out:

Cost Effective Solution Compared to PU and Rock Wool Panels

Shanghe 50mm EPS panels offer competitive pricing that often comes in lower than polyurethane (PU) and rock wool panels without sacrificing quality. This makes them a smart choice for budget-conscious projects looking to balance cost and performance. They deliver reliable insulation at a fraction of the price some other materials demand.

Energy Efficiency Reduces Heating and Cooling Costs

Thanks to the 50mm EPS core’s excellent thermal insulation properties, these panels help maintain indoor temperatures more effectively. This means you save on heating in winter and cooling in summer—leading to lower energy bills and a smaller carbon footprint.

Eco Friendly and Fully Recyclable

Constructed from 100% recyclable expanded polystyrene (EPS), Shanghe panels have a measurably low environmental impact. Using these panels supports greener building practices and helps reduce waste, aligning with growing sustainability standards in the U.S. construction market.

Rapid Installation Saves Time and Labor

The lightweight design and uniform size of Shanghe 50mm EPS sandwich panels enable quick, easy installation. Contractors can complete wall, roof, or ceiling assemblies faster, cutting labor costs and advancing tight project schedules without compromising quality.

Versatility for Multiple Applications

These panels suit a broad range of building needs:

- Walls – ideal for both interior and exterior cladding

- Roofs – excellent for weather resistance and insulation

- Ceilings – for thermal and sound control

- Partitions – lightweight yet sturdy for space separation

This versatility makes Shanghe 50mm EPS sandwich panels perfect for commercial, industrial, and residential projects alike.

Shanghe 50mm EPS sandwich panels provide a cost-effective, eco-friendly, energy-saving, and versatile building solution. They’re well-suited for U.S. customers seeking reliable insulation panels that deliver real value and performance.

Applications of 50mm EPS Sandwich Panels

The 50mm EPS sandwich panel offers versatile use across various sectors in the U.S. market. Its lightweight design, strong thermal insulation, and fire resistance make it a go-to solution for many construction needs.

Industrial and Cold Storage Facilities

Ideal for warehouses, factories, and cold storage, these panels ensure efficient temperature control and structural durability. Their thermal properties help maintain stable environments, reducing energy costs while protecting goods.

Commercial Spaces

In offices, retail stores, and sports halls, 50mm EPS panels provide excellent sound insulation and fast installation. They contribute to a comfortable interior environment by cutting noise and minimizing temperature swings.

Residential and Prefabricated Buildings

These panels are perfect for prefab houses, container homes, and temporary structures, thanks to their lightweight nature and ease of installation. They enhance energy efficiency and prolong building lifespan with their durable, weatherproof surface.

Specialized Facilities

For clean rooms, medical labs, and food processing centers, 50mm EPS sandwich panels meet strict hygiene and insulation standards. Their fire-resistant and moisture-proof qualities make them reliable in sensitive environments demanding safety and cleanliness.

Shanghe Project Case Study

A recent Shanghe project utilized 50mm EPS sandwich panels for a commercial cold storage facility in the Midwest. The panels delivered exceptional thermal insulation, reducing overall energy consumption by 25%. Quick installation minimized downtime, proving ideal for tight project schedules.

For more tailored solutions, check out our related options like polyurethane sandwich panels and prefabricated sandwich panels that complement EPS panels for diverse project needs.

How to Install Shanghe 50mm EPS Sandwich Panels

Installing Shanghe 50mm EPS sandwich panels is straightforward when you follow the right steps. Proper installation ensures the panels perform well for thermal insulation, soundproofing, and durability. Here’s what you need to know before and during installation.

Pre-installation Checklist

Before starting, make sure your setup is ready for the panels:

- Check surface verticality and levelness: Walls or roof frames must be plumb and flat to avoid gaps or stress on panels.

- Measure accurately: Confirm panel dimensions match your design specs for a smooth fit.

- Prepare tools and accessories: Have drills, screws, sealants, and customized mounting brackets handy.

- Ensure weather conditions are suitable: Avoid installation in heavy rain or extreme temperatures to protect panel integrity.

Step-by-step Installation Guide

Follow these clear steps for mounting your 50mm EPS insulation panels properly:

- Position the panel against the mounting surface, aligning edges carefully.

- Fasten panels securely using recommended self-tapping screws or rivets on the galvanized steel sheets.

- Seal all joints and seams with quality weatherproof sealant to keep the panels airtight and waterproof.

- Overlap panels slightly where needed, ensuring no gaps to maintain thermal and sound insulation effectiveness.

- Inspect alignment and fix any misplacements immediately to avoid future issues.

Safety Tips for Installation

Your safety during installation is important. Keep these tips in mind:

- Wear soft-soled shoes to prevent damage to the galvanized steel surface.

- Avoid heavy impact or dragging on panels to maintain their shape and finish.

- Use rainproof covers or schedule work during dry conditions to keep panels dry.

- Handle panels carefully to avoid cracking the EPS foam core.

Shanghe Support and Accessories

Shanghe offers full support during your project, including:

- Technical assistance via phone or online to answer installation questions.

- Customizable installation accessories such as clips, hooks, and trim pieces tailored for your specific project needs.

- Detailed product manuals and videos to guide your team through every installation phase.

With these steps and support, installing 50mm EPS sandwich panels from Shanghe will be efficient and reliable, helping your project finish on time with lasting performance.

Why Choose Shanghe for 50mm EPS Sandwich Panels

When it comes to selecting the right 50mm EPS sandwich panel for your project, Shanghe stands out with unmatched quality and service tailored to the U.S. market and beyond.

Proven Quality and Certifications

Shanghe’s panels come with CE, SGS, and ISO certifications, ensuring they meet strict international quality and safety standards. This means you get a reliable product that performs consistently in thermal insulation, fire resistance, and durability.

Global Reach and Experience

With exports to South America, Southeast Asia, and Africa, Shanghe has built a strong global reputation. This worldwide experience translates into well-tested products and solutions that work across various climates and building needs, giving you confidence in your investment.

Full Customization Options

No two projects are the same. Shanghe offers customizable sizes, colors, and coatings including PE and PVDF finishes, so your 50mm EPS sandwich panels fit perfectly with your design and functional requirements. Whether it’s a commercial wall, residential roof, or industrial partition, customization helps achieve exactly what you need.

Dedicated Customer Support

From initial inquiry to post-installation, Shanghe provides dedicated pre-sales and after-sales support. Their technical team assists with product selection, installation guidance, and troubleshooting, ensuring your project runs smoothly without unexpected delays or issues.

Competitive Pricing with High Value

Shanghe delivers affordable, high-quality 50mm EPS panels that reduce your overall costs—thanks to their energy efficiency, lightweight design, and long lifespan. You won’t just get a panel; you get the best value for your budget, making it a smart choice for builders and developers in the U.S.

For more tailored insulating solutions, explore Shanghe prefab sandwich panel options that work seamlessly with 50mm EPS cores.

Comparing 50mm EPS Sandwich Panels to Other Insulation Panels

When choosing insulation panels, understanding how 50mm EPS sandwich panels stack up against alternatives like PU (Polyurethane) and rock wool can help you make the best decision for your project.

EPS vs PU Panels

- Cost effectiveness: 50mm EPS panels are generally more affordable than PU panels. EPS uses expanded polystyrene foam which costs less to produce and install.

- Thermal insulation: PU offers a higher thermal conductivity (better insulation) due to its closed-cell structure. However, 50mm EPS panels still provide solid insulation performance with a thermal conductivity range around 0.035-0.040 W/m·K, which is suitable for most U.S. building requirements.

- Durability: Both materials are durable, but EPS tends to resist water absorption better, reducing risk of mold or degradation over time.

EPS vs Rock Wool Panels

- Weight: 50mm EPS sandwich panels are lighter than rock wool panels, making them easier to handle and quicker to install, which cuts down labor costs.

- Cost: EPS is more budget-friendly, especially for large-scale projects.

- Fire resistance: Rock wool excels here with superior fire ratings and the ability to withstand extremely high temperatures without melting. EPS panels do have fire resistance ratings up to B1 or B2, with self-extinguishing properties, but rock wool is the safer choice if maximum fire protection is critical.

- Sound insulation: Rock wool may provide better sound absorption, though 50mm EPS still offers good noise reduction, up to around 30 dB per square meter.

Quick Comparison Table

| Feature | 50mm EPS Sandwich Panel | PU Sandwich Panel | Rock Wool Sandwich Panel |

|---|

| Cost | More affordable | Higher cost | Moderate to high |

| Thermal Conductivity | 0.035-0.040 W/m·K | 0.022-0.028 W/m·K | 0.035-0.045 W/m·K |

| Fire Rating | B1 – B2, self-extinguishing | B1 – B2, limited smoke | A1 – Non-combustible |

| Weight (per sq ft) | Lightweight (~5-7 lbs) | Medium weight (~7-10 lbs) | Heavier (~10-15 lbs) |

| Water Absorption | Low | Moderate | Low to moderate |

| Installation Ease | Very easy due to light weight | Moderate | More labor intensive |

50mm EPS sandwich panels offer a balanced mix of affordability, ease of installation, and reliable insulation performance. For projects where cost and speed matter most—like commercial warehouses, prefab houses, and cold storage—they’re an ideal choice. If fire resistance or higher insulation is a priority, then rock wool or PU panels might be worth considering despite their higher price and weight.