What Are 75mm EPS Sandwich Panels

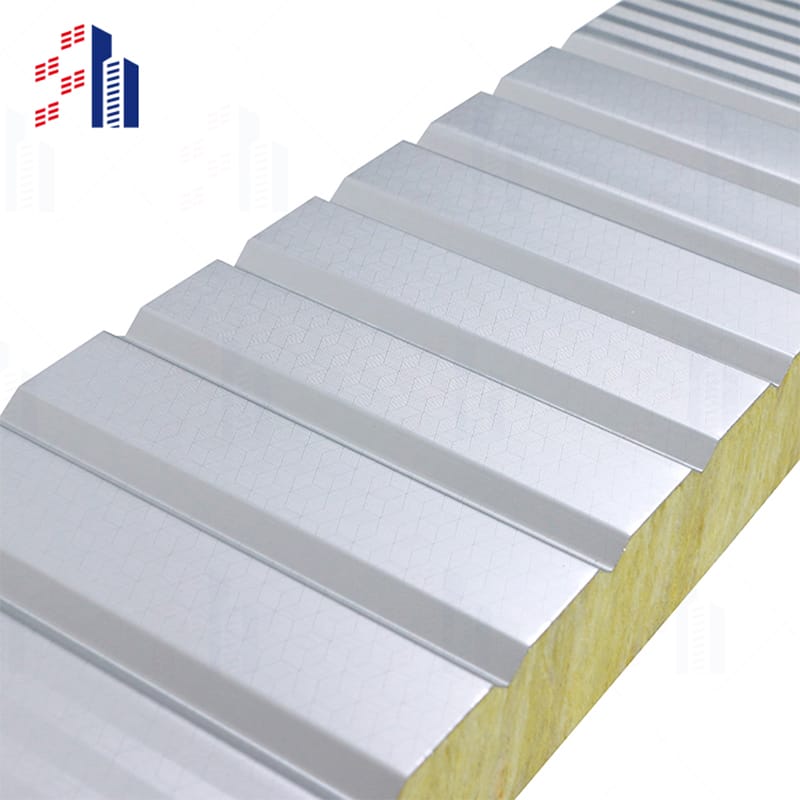

75mm EPS sandwich panel are high-performance insulated building panels featuring a three-layer structure. They consist of galvanized steel or aluminum skins on the outer layers, with a core made of expanded polystyrene (EPS) foam. This EPS core provides the panel’s main insulation properties while the metal skins offer structural strength and protection.

The 75mm thickness strikes an excellent balance between thermal insulation, mechanical strength, and cost-efficiency. It’s thick enough to deliver solid energy savings and sound insulation but still manageable for most construction applications without excessive weight or price spikes.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why 75mm Thickness Matters

- Better insulation than 50mm panels, improving energy efficiency by reducing heat loss.

- More cost-effective and lighter than 100mm options, making it easier to handle and install.

- Adaptable for a wide range of building types such as warehouses, residential walls, and cold storage.

Shanghe’s 75mm EPS Panel Features

Shanghe’s panels stand out with their lightweight design that reduces transport and labor costs without sacrificing durability. They are also customizable in size, color, and skin material to fit various aesthetic and functional needs. Plus, the panels are eco-friendly, made from recyclable materials and produced via energy-efficient processes that help lower the environmental footprint of your project.

The 75mm EPS sandwich panels from Shanghe provide a smart choice for those who want a versatile, reliable, and sustainable insulation solution that doesn’t break the budget or slow down construction.

Key Benefits of Shanghe 75mm EPS Sandwich Panels

Shanghe’s 75mm EPS sandwich panels offer a well-rounded package that fits the needs of energy-efficient building projects across the U.S. Here’s a closer look at their main advantages:

Thermal Insulation for Energy Savings

These panels feature low thermal conductivity, meaning they keep heat in during winter and out in summer. This energy-efficient insulation cuts down on HVAC costs, making your building more sustainable and budget-friendly.

Sound Insulation for Versatile Use

Whether for industrial sites or residential buildings, the EPS core provides effective noise reduction, helping create quieter, more comfortable indoor environments.

Fire Resistance with Safety Enhancements

Concerns about EPS panels and fire safety are common. Shanghe addresses this by applying fire retardant coatings and other safety upgrades, ensuring their panels meet strict fire standards without compromising insulation.

Durable and Weather Resistant

The galvanized steel or aluminum skins used resist corrosion and weather damage, making these panels ideal for long-term outdoor exposure. This durability reduces repair and replacement needs.

Cost Efficiency Over Traditional Materials

Shanghe’s panels lower both installation and maintenance costs. Their lightweight design speeds up assembly, cutting labor expenses, and the robust finished product lasts longer than many conventional building materials.

Eco Friendly and Sustainable

Made from 100% recyclable EPS materials, these panels support green building goals. Shanghe’s production process is designed to be energy efficient, further reducing the environmental footprint of your project.

Choosing Shanghe’s 75mm EPS sandwich panels means getting a reliable, efficient, and cost-effective solution tailored for the American market’s building demands.

Applications of 75mm EPS Sandwich Panels in Construction and Industry

75mm EPS sandwich panels are a versatile choice for many building projects across the United States, offering excellent thermal and sound insulation along with durability. Their lightweight yet strong structure makes them suitable for a wide variety of applications, whether commercial, residential, or specialized.

Commercial and Industrial Use

- Warehouses and Factories: The panels provide consistent temperature control and insulation, reducing energy costs in large-scale storage and manufacturing spaces.

- Cold Storage and Refrigeration: Thanks to the low thermal conductivity of the EPS core, these panels are ideal for cold rooms, maintaining required temperatures efficiently.

- Clean Rooms: In industries like pharmaceuticals and electronics, the panels help maintain sterile environments with their smooth, easy-to-clean surfaces.

Residential Applications

- Prefabricated Houses: Lightweight and easy to assemble, 75mm EPS panels are widely used in modular and prefabricated homes, offering energy efficiency and quick build times.

- Partitions and Ceilings: These panels are perfect for interior walls and ceilings, providing both thermal comfort and sound reduction in homes and apartments.

Specialized Facilities

- Medical Centers: The panels contribute to hygienic, controlled environments required in hospitals and clinics.

- Food Processing Plants: Their durable, corrosion-resistant skins meet health and safety standards for food-grade spaces.

- Shipping Container Insulation: Ideal for retrofitting shipping containers, the panels improve insulation without adding excessive weight.

Real World Examples

- A major refrigerated warehouse in Texas used Shanghe’s 75mm EPS insulated panels to cut energy consumption by 30%, thanks to their superior thermal insulation.

- A healthcare facility in California integrated these panels into their clean rooms, benefiting from the panels’ fire retardant coatings and smooth finishes that meet strict sanitation requirements.

- In Florida, a prefab housing project leveraged Shanghe’s panels to speed up construction while ensuring energy efficiency, earning LEED credits for sustainable building.

In all these cases, Shanghe’s 75mm EPS sandwich panels stood out for their balance of performance, cost-effectiveness, and ease of installation — making them a favored choice for professionals across industries.

Technical Specifications of Shanghe 75mm EPS Sandwich Panels

Shanghe’s 75mm EPS sandwich panels are designed to offer a strong balance of insulation, durability, and versatility for a range of U.S. building projects. Here’s a clear overview of the key technical specs to help you decide if these panels fit your needs.

Dimensions and Customization

- Standard width: 1,000 mm (but can be tailored)

- Length: Customizable up to 12 meters to suit different building requirements

- Perfect for prefabricated wall panels, cold room insulation, or lightweight construction materials needing specific size adjustments

EPS Core Density

- Options at 12 kg/m3 and 16 kg/m3 for optimal thermal insulation and mechanical strength

- Denser cores improve insulation and rigidity without compromising weight

Outer Skin Materials

- Galvanized steel for corrosion resistance and long service life

- Aluminum skins available for lightweight applications or aesthetic needs

- Custom coatings and color options available, allowing you to match building designs or enhance weather resistance

Thermal Conductivity

- Ranges from 0.023 to 0.040 W/m·K, ensuring excellent thermal insulation

- Low thermal conductivity means energy-efficient panels that reduce heating and cooling costs

Certifications and Compliance

- Manufactured in line with international standards: ISO, CE, plus local certifications from regions including Australia and Kenya

- Ensures reliability, safety, and suitability for a broad spectrum of industries and locations

Professional Resources

- A detailed downloadable spec sheet is available for architects, engineers, and contractors

- The spec sheet covers load values, thermal performance, and installation guidelines for precise project planning

For more details on related panel types, you might find our Foam Core Sandwich Panels or Metal Sandwich Panels pages useful.

Choosing Shanghe’s 75mm EPS sandwich panels means getting custom-sized, high-grade insulated panels with reliable performance backed by certified quality.

Why Choose Shanghe for 75mm EPS Sandwich Panels

When it comes to 75mm EPS sandwich panels, Shanghe stands out as a top choice for builders, contractors, and architects across the United States. Here’s why:

Quality Assurance You Can Trust

Shanghe uses advanced manufacturing technology combined with strict quality control processes to ensure every panel meets high standards. This means you get consistent thermal insulation performance, durability, and structural integrity in every batch. The galvanized steel skins and eco-friendly EPS core are carefully tested for strength and weather resistance, giving dependable results building after building.

Customization That Fits Your Project

No two projects are the same — that’s why Shanghe offers custom sizes, colors, and coatings for their 75mm insulated panels. Whether you’re working on a commercial warehouse, residential prefab home, or specialized cold storage, you can specify panel length, core density, or even surface finishes to match your needs. This flexible approach saves you time and reduces waste on site.

Global Reach with Local Efficiency

Shanghe supports projects nationwide with efficient logistics and experienced handling. Whether you’re in California, Texas, or New York, you can expect timely delivery and local support. By combining global expertise with attentive service, they manage smooth shipments and quick responses, helping you keep your construction timeline on track.

Competitive Pricing Straight From the Factory

Cut out the middleman with Shanghe’s factory-direct pricing on 75mm EPS sandwich panels. This means you get high quality at a better price without unnecessary markups. The cost efficiency extends beyond purchase, as these panels lower installation and maintenance expenses compared to traditional materials, offering real value to your budget.

Expert Support From Start to Finish

Shanghe doesn’t just sell panels; they provide comprehensive support to make your project easier. Their team offers expert consultation on panel selection and installation, detailed guides, and thorough after-sales service. If you need assistance with assembly, sealing joints, or maintaining your panels, they’re just a call away.

Choosing Shanghe means opting for a trusted partner delivering reliable, customizable 75mm EPS sandwich panels designed to meet the demands of energy-efficient construction in the U.S.

Installation Guide for 75mm EPS Sandwich Panels

Preparation and Tools Needed

Before you start installing 75mm EPS sandwich panels, make sure you have the following:

- Measuring tape and level for precise alignment

- Screwdriver or drill with appropriate bits

- Sealant and weatherproof tape for joint sealing

- Safety gear including gloves and goggles

Proper preparation is key to a smooth installation and long-lasting performance.

Step-by-Step Installation Overview

- Inspect panels on delivery for any damage or defects.

- Prepare the structure where the panels will be mounted, ensuring it is clean and level.

- Start from a corner or edge, placing the first panel securely with screws through the galvanized steel or aluminum skins.

- Use Shanghe’s tongue and groove joint system, designed for quick and precise panel locking without gaps. This ensures tight seams and improved insulation performance.

- Align each panel carefully before fastening. Misalignment can cause thermal bridging or water leaks.

- Seal the joints with recommended weatherproof sealants or tapes for airtightness and moisture protection.

- Continue panel installation until the entire wall or roof section is covered.

Addressing Common Installation Challenges

- Panel alignment: Use a level and measuring tape to keep panels straight and flush. The tongue and groove system helps but double-check to prevent gaps.

- Sealing joints: Don’t skip sealing. Unsealed joints reduce thermal and sound insulation efficiency and allow moisture intrusion.

- Handling panels: Panels are lightweight but handle with care to avoid dents or surface damage.

Easy Assembly with Shanghe’s Tongue and Groove System

One standout feature for Shanghe’s 75mm insulated panels is the tongue and groove joint system. This system:

- Allows panels to snap together tightly

- Reduces installation time

- Minimizes errors and gaps

- Improves overall structural integrity and energy efficiency

Getting Help and Resources

To assist installers and builders, Shanghe provides:

- Video tutorials demonstrating step-by-step installation examples

- Downloadable PDF guides with detailed instructions and tips

- Online support for any installation questions

Make sure to utilize these resources for a smooth and professional installation process.

For more on wall panel options and installation methods, check out our Prefabricated Wall Panels and explore how EPS panels compare to other materials in real projects.

Comparing 75mm EPS Sandwich Panels to Other Materials

When choosing insulated panels for your project, it’s important to understand how 75mm EPS sandwich panels stack up against other common materials like PU (polyurethane) panels and mineral wool. This helps make the best decision based on cost, performance, and specific needs.

EPS vs PU Polyurethane Panels

- Cost Efficiency: EPS panels are generally more affordable than PU panels, offering a lower upfront cost without sacrificing much on performance.

- Insulation Performance: PU panels have a slightly better thermal insulation value with lower thermal conductivity, but 75mm EPS panels still provide excellent energy savings and comfort for most typical building needs.

- Weight and Handling: EPS panels are lighter, making them easier and faster to install, which means less labor cost.

- Environmental Impact: EPS is often considered more eco-friendly due to its recyclability and lower environmental footprint in production.

EPS vs Mineral Wool Panels

- Fire Resistance: Mineral wool naturally resists fire better than EPS, which is important for projects with strict fire codes. However, Shanghe enhances EPS panels with fire retardant coatings to meet safety standards.

- Weight and Durability: Mineral wool panels are heavier, which can increase structural load and installation effort. EPS panels maintain durability with galvanized steel skins that resist corrosion and weather better in many environments.

- Sound Insulation: Mineral wool excels at sound dampening, but 75mm EPS panels still offer effective noise control suitable for most commercial and residential uses.

Why Choose Shanghe’s 75mm EPS Sandwich Panels

- Balanced Performance: Shanghe’s 75mm EPS panels hit the sweet spot—offering solid thermal insulation, useful fire safety features, and good sound insulation while remaining lightweight.

- Cost-Effective and Versatile: For most projects—from warehouses to prefabricated homes—these panels deliver great value without compromising key features.

- Easy Installation and Maintenance: Their lightweight nature and tongue and groove joint system speed up assembly and reduce long-term maintenance costs.

- Eco Friendly: Recyclable EPS core and energy-efficient manufacturing make these panels a sustainable choice.

Shanghe’s 75mm EPS sandwich panels provide a well-rounded, affordable, and reliable solution that works for a wide range of applications, balancing cost, efficiency, and safety better than many alternatives on the market today.

How to Order 75mm EPS Sandwich Panels from Shanghe

Ordering 75mm EPS sandwich panels from Shanghe is straightforward and hassle-free. Here’s how you can get started:

Simple Ordering Process

- Request a Quote: Reach out to Shanghe with your project details. Include desired panel dimensions, skin materials (galvanized steel or aluminum), core density, and any color or coating preferences.

- Customize Specifications: Shanghe offers tailored solutions to fit your exact building needs. Whether you want specific lengths up to 12m, color options, or enhanced fire resistance, just let them know.

- Confirm Delivery: Once your quote is finalized, confirm your order and schedule delivery. Shanghe coordinates every step to ensure timely arrival.

Local Availability and Fast Shipping

Shanghe serves customers across the United States with efficient logistics and warehouse support in key regions. This means you get your lightweight, energy-efficient insulated panels quickly — perfect for keeping construction projects on track.

Get Your Free Quote Today

Contact Shanghe today for a free quote on their 75mm EPS sandwich panels. Their expert team will guide you through the process to ensure you get panels that balance quality, cost, and performance for your commercial or residential project.

Make building easier with Shanghe’s reliable, customizable, and eco-friendly insulated panels delivered right to your site.