Key Features of Shanghe Fiberglass Foam Sandwich Panels

When it comes to choosing a reliable fiberglass foam sandwich panels, Shanghe offers a product designed to meet high standards across multiple demanding applications. Here are the standout features that make our panels a top choice for industries like construction, marine, and transportation.

Customers visit the factory

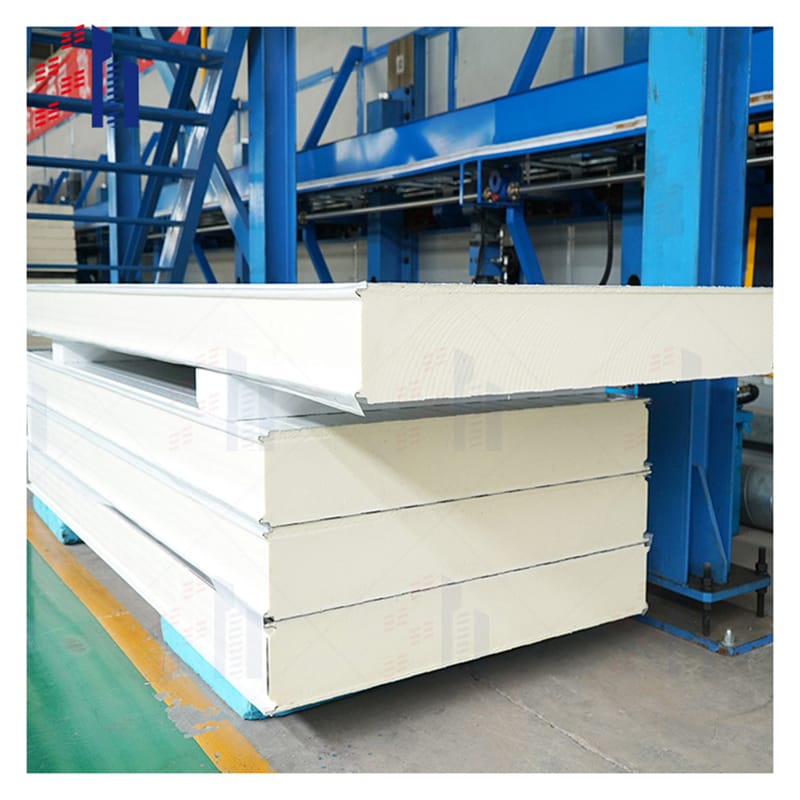

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Lightweight Design for Easy Handling and Efficiency

Our fiberglass sandwich panel uses a specialized foam core combined with strong FRP (Fiber Reinforced Plastic) outer layers. This results in a lightweight composite panel that reduces overall structural weight without compromising strength. The lightness helps:

- Cut down transportation and installation costs

- Improve fuel efficiency in vehicles and boats

- Offer easier handling on the job site

Shanghe panels typically weigh significantly less than traditional materials, providing a key advantage for heavy-duty applications.

High Strength and Durability for Long-Term Performance

Built with a robust GRP sandwich panel structure, Shanghe fiberglass foam panels provide exceptional mechanical strength. The polyurethane (PU) or XPS foam core reinforces stiffness and impact resistance, making it suitable for tough environments. Benefits include:

- Excellent load-bearing capacity

- Resistance to dents, cracks, and deformation

- Extended service life even under continuous stress

These panels are ideal for both static and dynamic applications where durability is critical.

Thermal and Sound Insulation for Comfort and Efficiency

The foam core acts as an efficient thermal insulation panel, helping maintain stable interior temperatures. This minimizes heating and cooling costs in buildings, vehicles, and marine vessels. Additionally, the panel’s sandwich structure reduces noise, making it great for:

- Residential and commercial construction

- Recreational vehicles (RV composite panels)

- Transportation trucks and vans

The combination of fiberglass and foam provides an excellent sound dampening effect.

Waterproof and Corrosion Resistance for Harsh Conditions

Shanghe’s marine fiberglass panel technology ensures excellent waterproofing and resistance to corrosion, ideal for outdoor and marine environments. The outer fiberglass layers protect against:

- Water infiltration and moisture damage

- Chemical exposure and saltwater corrosion

- Fungal and mildew growth

This makes the panels reliable for boats, docks, and coastal construction where durability against weathering is key.

Customization Options to Match Your Requirements

We understand that every project has unique needs. Shanghe offers customization in terms of:

- Foam core type (PU foam sandwich panel or XPS foam core panel)

- Panel thickness and size

- Surface finish and color

- Fire retardant treatments

Whether you need a construction sandwich panel or a specialized RV composite panel, we tailor the product to fit your exact specifications.

Shanghe fiberglass foam sandwich panels perfectly balance lightweight design, strength, insulation, and durability with customizable options. This makes them the smart choice for anyone wanting reliable performance and efficient solutions in a wide range of industries.

Applications of Shanghe Fiberglass Foam Sandwich Panels

Shanghe fiberglass foam sandwich panels are versatile and suited for a variety of industries thanks to their lightweight composite design, durability, and insulation properties. Here’s a breakdown of where these panels truly shine:

Construction Industry

In construction, fiberglass foam sandwich panels are prized for being strong yet lightweight, making them perfect for walls, ceilings, and roofing. Their thermal insulation and waterproof features help improve energy efficiency while resisting moisture damage, which is crucial for both residential and commercial buildings. These panels reduce installation time and labor costs, offering a smart alternative to traditional building materials.

Recreational Vehicles and Trailers

For RVs and trailers, weight matters a lot. The RV composite panel design of Shanghe’s products makes them ideal for keeping vehicles light without sacrificing strength. The panels also provide excellent sound and thermal insulation, making trips more comfortable by controlling cabin temperature and reducing outside noise. Plus, their corrosion-resistant properties fend off deterioration caused by changing weather and road conditions.

Marine and Boating

Marine environments demand materials that can handle constant moisture and salt exposure. Shanghe’s marine fiberglass panel solutions fit the bill perfectly. They are waterproof, corrosion-resistant, and offer durable performance even in harsh conditions. Whether it’s boat interiors, decks, or bulkheads, these panels provide lightweight strength that improves fuel efficiency and longevity.

Transportation Trucks and Vans

In commercial transportation, keeping vehicles as light as possible while maintaining robustness is key for fuel efficiency and payload capacity. Shanghe’s fiberglass foam sandwich panels offer both. They act as thermal insulation panels while protecting cargo spaces from moisture and physical damage. Their easy customization options also allow for fitting different vehicle sizes and specific user requirements.

Other Uses

Beyond these major sectors, these panels are also well-suited for modular structures, cold storage facilities, and specialty industrial applications. Their adaptability as PU foam sandwich panels or with XPS foam core means they can match a range of insulation and strength requirements across different projects.

In : Shanghe fiberglass foam sandwich panels combine lightweight design, excellent insulation, and weather resistance, making them an excellent choice for construction, transportation, marine, and more. They help U.S. businesses save on weight, energy, and maintenance costs — making each application more efficient and durable.

Why Shanghe Fiberglass Foam Sandwich Panels Stand Out

When it comes to fiberglass foam sandwich panels, Shanghe offers standout advantages that make their products a reliable choice for many industries across the U.S. Here’s why Shanghe is a top pick:

Advanced Manufacturing Process for Superior Quality

Shanghe uses state-of-the-art manufacturing techniques to produce fiberglass sandwich panels with consistent quality and performance. Their advanced process ensures:

- Uniform bonding between the fiberglass outer layers and the foam core (often PU foam or XPS foam core panels).

- Precise control over panel thickness and density for optimized strength and insulation.

- Reduced weight without sacrificing structural integrity—a must in markets like marine fiberglass panels and RV composite panels.

This attention to manufacturing detail results in lightweight composite panels that perform well under stress and last longer.

Quality Assurance to Meet Industry Standards

Shanghe’s commitment to quality means every fiberglass foam sandwich panel undergoes rigorous testing for:

- Strength and durability metrics to match or exceed industry benchmarks.

- Thermal insulation and waterproofing capabilities for real-world use.

- Resistance to corrosion and impact, essential for marine and transportation use.

They back their products with consistent quality checks, so buyers in construction, transportation trucks, and other sectors get reliable thermal insulation panels and FRP foam core panels.

Competitive Pricing and Global Supply Network

Offering competitive pricing without compromising quality is a highlight of Shanghe’s market approach. They have:

- Cost-effective solutions for both large-scale construction sandwich panels projects and smaller applications like DIY panels.

- A global supply chain that allows for timely delivery across the United States and other international markets.

This balance of affordability and availability helps keep projects on budget and on schedule.

Customer Support You Can Count On

Shanghe values the customer experience. Their knowledgeable support team helps:

- Guide you in choosing the right panel for your specifics.

- Answer questions related to fiberglass foam sandwich panel strength figures, customization, or installation.

- Provide post-sale assistance to ensure your project runs smoothly.

This commitment gives peace of mind when investing in GRP sandwich panel products.

For more details on their range, check out their composite foam sandwich panels EPS or explore their polyurethane sandwich panels for superior insulation and durability.

How to Choose the Right Fiberglass Foam Sandwich Panel

Selecting the right fiberglass foam sandwich panel for your project means matching the panel’s qualities with your specific needs. Whether you’re considering a fiberglass sandwich panel, FRP foam core panel, or PU foam sandwich panel, these steps will help you make the best call.

Consider Your Application

Start by clearly identifying where and how you’ll use the panel. Different uses demand different features. For example:

- Construction Industry: Prioritize panels with strong structural integrity and excellent thermal insulation capabilities, like a thermal insulation panel or XPS foam core panel.

- Marine and Boating: Look for marine fiberglass panels that offer excellent corrosion resistance and waterproof features.

- Recreational Vehicles and Trailers: Choose lightweight yet durable panels such as an RV composite panel to keep overall vehicle weight down without compromising strength.

- Transportation Trucks and Vans: Panels must combine impact resistance with thermal protection for cargo.

Knowing your end-use helps you zero in on the right core material, thickness, and skin type.

Evaluate Specifications

Look beyond just the thickness. Important specs include:

- Strength Figures: Check the panel’s compressive strength and impact resistance to ensure durability.

- Weight: A lightweight composite panel can reduce overall project weight and lower transport costs.

- Thermal Performance: Review R-values or insulation ratings if temperature control is a priority.

- Waterproof and Corrosion Resistance: Essential for outdoor, marine, or humid environment applications.

- Fire Resistance: If you need compliance with fire codes, confirm the panel meets those standards.

Request detailed data sheets or test reports to compare these specs accurately.

Partner with a Trusted Supplier

Choosing a reputable supplier like Shanghe guarantees you get panels made with advanced manufacturing and quality assurance standards. Here’s what to look for in a supplier:

- Proven track record for consistent product quality.

- Ability to customize solutions to your specific needs.

- Transparent pricing with no hidden fees.

- Reliable global shipping and local customer support.

- Clear communication and technical assistance.

The right partner helps you avoid costly mistakes and keeps your project running smoothly.

By focusing on your application, carefully reviewing panel specs, and working with a trusted supplier, you’ll find the perfect fiberglass foam sandwich panel that offers lasting value and dependable performance.