What Are Composite Foam Sandwich Panels eps with

Composite foam sandwich panels eps(Expanded Polystyrene) with are advanced building materials designed to offer exceptional thermal insulation, durability, and lightweight. These panels consist of an EPS foam core sandwiched between two rigid outer skins, typically made from galvanized steel, aluminum, or other sturdy materials. This layered structure creates a high-performance insulated wall panel ideal for various construction needs.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Foamed Pcw |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Structure and Definition of EPS Foam Core Panels

At the heart of these composite foam panels is the EPS foam core, known for its rigid cellular structure that traps air effectively. This foam core provides:

- Lightweight construction: EPS is remarkably light, reducing structural load and easing installation.

- High thermal insulation: With low thermal conductivity, EPS minimizes heat transfer, supporting energy-efficient building designs.

- Moisture resistance: EPS offers good resistance to moisture, preventing mold and structural damage.

The outer skins firmly bond to the EPS core, enhancing panel strength and durability while protecting the foam from physical damage and environmental exposure.

Properties of EPS Foam

EPS foam is favored for its combination of important properties:

- Lightweight yet strong: EPS weighs significantly less than traditional insulation materials, decreasing transportation and labor costs.

- Superior thermal insulation: Its closed-cell structure offers R-values typically ranging between R-3.6 to R-4.0 per inch, making it ideal for heat retention and cold storage applications.

- Environmental resistance: EPS maintains performance in humid environments and is resistant to biodegradation.

- Cost-effective: Compared to other foam cores, EPS balances performance with low cost — a key factor for large-scale projects.

Comparison with Polyurethane and Rockwool Core Materials

While EPS shares some benefits with other core options, understanding its strengths relative to polyurethane (PUR/PIR) and rockwool is vital:

| Feature | EPS | Polyurethane (PUR/PIR) | Rockwool |

|---|

| Thermal Insulation | Good (R-3.6 – 4.0/in) | Higher (R-6+ per inch) | Moderate (R-3.0 – 3.3/in) |

| Weight | Very lightweight | Slightly heavier | Heaviest |

| Cost | Most cost-effective | Higher cost | Moderate |

| Fire Resistance | Moderate, can be enhanced | Good, varies by formulation | Excellent, inherently fire-resistant |

| Water Resistance | Good | Good | Absorbs moisture if untreated |

| Environmental Impact | Recyclable, eco-friendly | Less eco-friendly | Natural mineral-based |

EPS panels strike a balance, especially where lightweight, cost efficiency, and insulation are priorities. They are less expensive than polyurethane and provide better moisture resistance than rockwool.

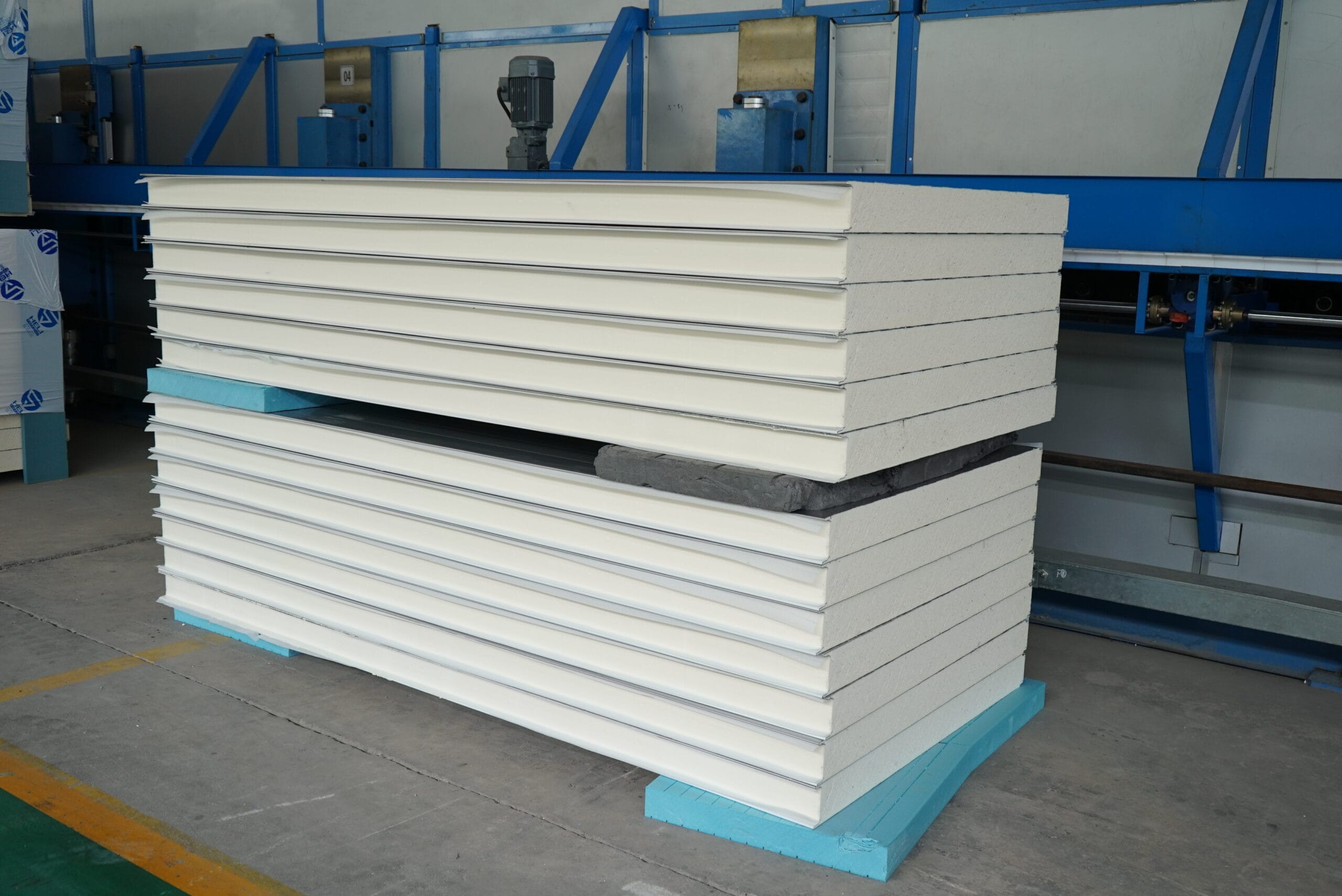

Shanghe’s Manufacturing Process for Durability and Quality

At Shanghe, our composite foam sandwich panels with EPS undergo an advanced, tightly controlled manufacturing process that ensures consistent strength, durability, and thermal performance. Key elements include:

- Automated lamination lines bonding EPS cores to skins with high-strength adhesives, minimizing delamination risk.

- Precision cutting and profiling for customizable panel sizes without compromising integrity.

- Quality control tests for compression strength, thermal conductivity, and fire resistance, meeting strict international standards.

- Use of premium raw materials sourced to guarantee long-lasting panel life even in demanding environments.

This meticulous approach makes Shanghe EPS sandwich panels an ideal choice for projects requiring reliable insulation, lightweight construction panels, and cost-effective performance.

For more on EPS core panels and options, check out our Polystyrene Sandwich Panel and Foam Core Sandwich Panels collections.

Key Benefits of Shanghe EPS Sandwich Panels

Shanghe EPS sandwich panels offer a range of advantages that make them a top choice for construction and insulation projects across the United States. Here’s a closer look at why these composite foam panels stand out:

Outstanding Thermal Insulation and Energy Efficiency

The core of Shanghe EPS sandwich panels is made from expanded polystyrene (EPS), known for its excellent thermal insulation. This means buildings stay warmer in winter and cooler in summer, significantly reducing heating and cooling costs. The panels help maintain a stable interior climate, improving energy efficiency which translates to lower utility bills over the long run.

Lightweight Design Advantages

One of the biggest benefits of these lightweight construction panels is easy handling and faster installation. EPS panels are much lighter compared to traditional materials such as concrete or brick, reducing labor costs and speeding up project timelines. Additionally, their light weight places less stress on the building structure, allowing more flexible design options.

Cost-Effectiveness Compared to Traditional Materials

Shanghe EPS sandwich panels combine performance and affordability. Their production and installation costs are typically lower than conventional insulation and wall materials like polyurethane or rockwool panels. This makes them an economical solution—especially for large-scale industrial and commercial builds—without compromising on quality or durability.

Fire Resistance and Safety Features

Safety is a priority in US construction codes, and Shanghe EPS panels meet strict fire resistance standards. The panels can be treated with fire-retardant coatings, enhancing their ability to resist ignition and slow fire spread. This feature provides peace of mind for applications where fire safety is critical, such as in cold storage facilities and public buildings.

Sound Insulation Benefits

Besides thermal properties, these sandwich panels also provide good sound insulation. The EPS foam core acts as an effective barrier against noise, making them suitable for environments requiring quieter interiors like offices, shopping centers, and residential units.

Eco-Friendly and Recyclable Materials

Shanghe EPS sandwich panels are made from eco-friendly and recyclable expanded polystyrene. This fits well with growing US demands for sustainable building materials that reduce environmental impact. The panels can be recycled at the end of their lifecycle, aligning with green building standards and helping lower your project’s carbon footprint.

By choosing Shanghe composite foam sandwich panels with EPS, you’re investing in materials that deliver energy savings, ease of use, safety, sound control, and sustainability—all essential for today’s modern construction needs.

Applications of EPS Composite Foam Sandwich Panels

EPS composite foam sandwich panels are versatile and widely used across different sectors in the U.S. Their lightweight construction, excellent thermal insulation, and durability make them a popular choice for many building projects.

Industrial Uses

EPS sandwich panels shine in industrial settings like warehouses and cold storage facilities. Their superior insulation properties help maintain consistent temperatures, reducing energy costs and protecting stored goods. These panels also offer quick installation, which minimizes downtime during facility upgrades or expansions.

Commercial Applications

In commercial construction, EPS composite foam panels are commonly used in shopping centers, offices, and retail spaces. Their energy efficiency contributes to lower utility bills, while their clean, sleek appearance fits modern commercial designs. They support sustainable building practices, which is a growing priority in commercial real estate.

Residential Uses

For residential projects, EPS sandwich panels are great for prefab homes and modular buildings. They provide excellent thermal insulation and easy installation, speeding up construction times. Their lightweight nature also reduces structural load, helping keep overall building costs down.

Specialized Uses

EPS panels are trusted in specialized buildings like sports halls, cold rooms, and refrigeration units. The panels’ fire resistance and sound insulation add safety and comfort to these sensitive environments. They protect against moisture and temperature fluctuations, crucial for refrigerated storage and athletic facilities.

Case Study Local Implementation

In a recent project in the Midwest, a warehouse utilized Shanghe EPS composite foam sandwich panels for its new cold storage addition. The panels delivered energy savings of up to 30%, with easy installation reducing construction time by two weeks. This project highlights how EPS panels are a reliable, cost-effective solution tailored to U.S. industrial needs.

EPS sandwich panels combine performance with flexibility, making them a top pick for a wide range of applications across industrial, commercial, residential, and specialized buildings.

Technical Specifications of Shanghe EPS Sandwich Panels

Shanghe’s composite foam sandwich panels EPS are engineered to meet diverse construction needs across commercial, industrial, and residential applications in the U.S. market. Here’s a detailed look at the key specs that make our EPS sandwich panels a reliable choice:

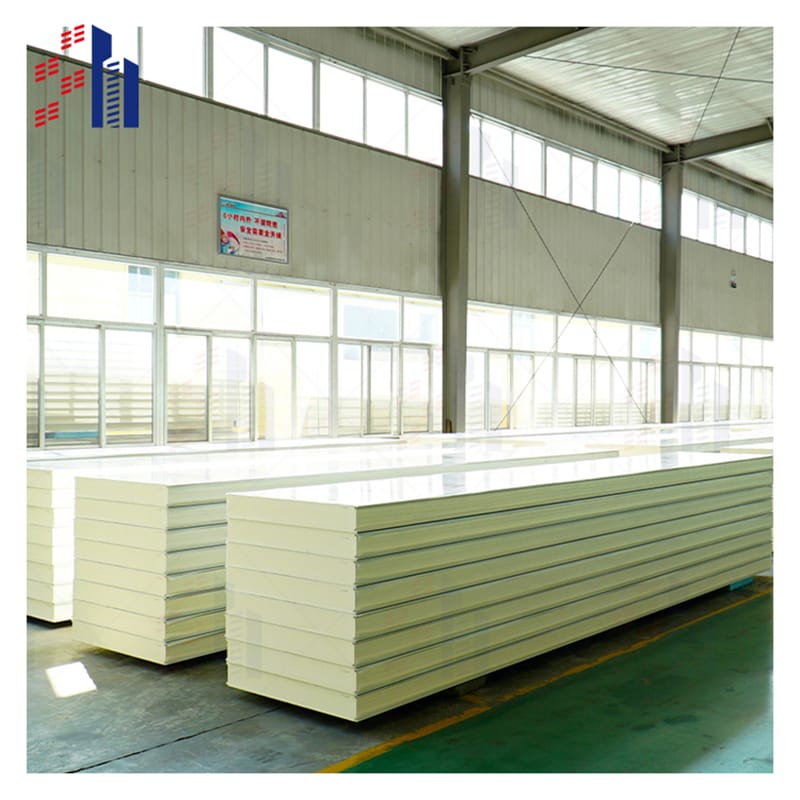

Panel Dimensions and Customizable Sizes

- Standard Thickness: Ranges from 50mm to 200mm, customizable depending on insulation and structural requirements

- Width: Typically 1,000mm or 1,200mm, with options to tailor widths for specific project needs

- Length: Custom cut to project specifications, often up to 12 meters, accommodating both small and large-scale builds

- Edge Profiles: Tongue and groove, shiplap, or butt joint options for easy installation and weather-tight sealing

Core Density for Optimal Insulation

- EPS Foam Core Density: From 12 to 30 kg/m³, controlled for consistent thermal insulation performance

- Higher density cores provide better thermal resistance and durability while maintaining a lightweight profile

- Density selection depends on specific energy efficiency goals and structural demands

Available Skin Materials

- Galvanized Steel: Hot-dip galvanized with standard coatings to prevent corrosion, ideal for industrial and exterior wall panels

- Aluminum: Lightweight yet durable, perfect for cleanroom environments or where corrosion resistance is critical

- Other Options: Pre-painted steel, stainless steel available upon request to suit aesthetic and functional preferences

Customization Options

- Colors: Wide range of standard and custom colors available through advanced coating technologies for UV resistance and weather durability

- Coatings: Options include polyester, PVDF, and HDP coatings designed for scratch resistance and long lifespan

- Surface Finishes: Textured or smooth finishes to match architectural design requirements

- Integration of fire-retardant additives and enhanced barrier layers for specific regulatory compliance

Compliance with International Standards

- Shanghe EPS sandwich panels comply with key U.S. and international building codes:

- ASTM E84 for fire performance

- ASTM C518 for thermal conductivity

- UL 1715 and NFPA standards for fire resistance

- ISO 9001 certified manufacturing process ensures consistent quality and performance

- Our panels meet rigorous energy efficiency regulations making them suitable for green building certifications

For a complete look at our core EPS sandwich panels and accessories, check out our EPS sandwich panel product page.

These exacting specifications allow our panels to deliver excellent structural integrity, energy savings, and long-term durability tailored for the U.S. construction market.

Why Choose Shanghe for Your EPS Sandwich Panel Needs

When it comes to composite foam sandwich panels EPS, Shanghe stands out as a trusted name in the U.S. market. Here’s why we should be your top choice for quality and service.

Trusted Brand and Quality Assurance

At Shanghe, quality is non-negotiable. Our EPS foam sandwich panels go through strict manufacturing controls to ensure durability, thermal efficiency, and fire resistance. We use premium expanded polystyrene cores combined with steel or aluminum skins, delivering consistent performance that meets U.S. construction standards. Each panel is tested against industry benchmarks to guarantee it stands up to the demands of commercial, industrial, and residential projects.

Comprehensive Customer Support From Start to Finish

We know choosing the right insulated wall panels can be overwhelming. That’s why Shanghe offers personalized consultation to help you select the perfect panel thickness, density, and finish for your project. Beyond that, our team assists with logistics and installation tips to ensure your panels are handled and set up correctly—maximizing their lifespan and efficiency. We’re here every step of the way, from your first inquiry to final installation.

Commitment to Sustainability and Eco-friendly Production

Shanghe is dedicated to producing eco-friendly composite foam sandwich panels. Our EPS cores are made from recyclable materials, and our manufacturing processes minimize waste and energy consumption. Choosing our panels means you’re investing in sustainable building materials that reduce environmental impact without compromising performance.

Get Your Free Quote and Samples Today

Ready to see why Shanghe’s EPS sandwich panels are the right fit for your project? Contact us now for a free quote or to request samples. Experience firsthand the balance of lightweight design, thermal efficiency, and reliable fire safety only Shanghe delivers.

Choosing Shanghe means you’re backed by a reliable EPS sandwich panel supplier committed to quality, support, and sustainability—perfect for any U.S. building project needing durable, cost-effective insulation solutions.

How to Choose the Right EPS Sandwich Panels for Your Project

Selecting the right composite foam sandwich panels EPS for your project means paying close attention to several important factors. Choosing the appropriate panel ensures your building gets the best thermal insulation, durability, and safety suited to your specific needs.

Key Factors to Consider

- Thickness: Panel thickness directly impacts insulation performance. Thicker EPS cores offer better thermal resistance, ideal for cold storage or energy-efficient buildings. Common thickness ranges from 1.5 inches to over 4 inches depending on the project needs.

- Core Density: EPS foam density affects rigidity, insulation, and load-bearing capacity. Standard densities range from 10 to 20 kg/m³. Higher density panels provide stronger structural support for industrial or commercial use.

- Fire Rating: Fire safety is crucial, especially in residential and commercial buildings. Choose fire-resistant sandwich panels with proper certifications that meet local US fire codes. Shanghe offers panels with enhanced fire retardant treatments to improve safety without sacrificing insulation.

- Skin Material: Outer skins like galvanized steel or aluminum offer different benefits from weather resistance to aesthetics. Consider your environment and building use; for example, aluminum skins are great for corrosion resistance in coastal areas.

- Customization: Look for panels with customizable sizes, colors, and coatings to match your project requirements, especially for prefab building applications or specialized industrial setups.

Installation Tips to Preserve Panel Integrity

Proper installation is key to maintaining the performance of EPS sandwich panels:

- Avoid Panel Damage: Handle panels carefully during transport and installation. Avoid impacts or bends that could compromise the EPS core.

- Sealing Joints: Use high-quality sealing materials on panel joints to eliminate thermal bridging and moisture infiltration.

- Proper Fastening: Use recommended fasteners and spacings to ensure panels are securely attached without crushing the foam core.

- Follow Manufacturer Instructions: Always follow the panel supplier’s installation guidelines. This ensures compliance with warranties and standards.

Expert Consultation Services by Shanghe

Choosing the right EPS sandwich panels can be complex, especially when balancing thermal efficiency, fire safety, and budget. Shanghe offers expert consultation to help you:

- Assess your building’s insulation requirements

- Select the right panel thickness, density, and fire ratings

- Customize skins, colors, and sizes for your project

- Guide you through installation best practices

Get in touch with Shanghe’s technical team for personalized advice tailored to your specific project needs. Their experience in EPS composite foam panels ensures your investment delivers the performance and longevity your building demands.

Frequently Asked Questions About Composite Foam Sandwich Panels EPS

Lifespan and Durability of EPS Sandwich Panels

EPS sandwich panels from Shanghe are built to last. With proper installation and maintenance, these panels typically have a lifespan of 25 to 30 years. Their durable EPS foam core maintains structural integrity against moisture and compression over time, while the outer skins—usually galvanized steel or aluminum—offer strong resistance to corrosion and physical damage. This makes them ideal for long-term use in both industrial and residential projects across the U.S.

Fire Safety Features of EPS Panels

One common concern is fire safety. Shanghe’s composite foam sandwich panels EPS are engineered with fire-retardant additives and meet strict fire resistance standards. Although EPS is combustible, these panels comply with U.S. fire codes when paired with proper facing materials and fire-resistant coatings. For projects requiring higher fire ratings, we can offer panels with special fireproof skins or alternative core materials like mineral rockwool, ensuring safety without sacrificing thermal performance.

Comparison with Polyurethane and Rockwool Panels

When choosing insulation panels, understanding differences is key:

- EPS Panels are lightweight, affordable, and provide excellent thermal insulation, making them a favorite for budget-conscious U.S. applications.

- Polyurethane Panels offer slightly better insulation but at a higher price point and often heavier weight.

- Rockwool Panels excel in fire resistance and soundproofing but tend to be heavier and more expensive.

Shanghe’s EPS sandwich panels strike a great balance for most U.S. construction needs where cost-efficiency, insulation, and ease of handling are priorities.

Customization Options for Panel Sizes

We know every project is unique. Shanghe offers custom sizing on all EPS composite foam sandwich panels to fit your exact requirements:

- Panel thickness ranges typically from 40mm to 200mm

- Widths usually between 950mm and 1150mm

- Lengths customizable up to 12 meters or more

- Various skin options including galvanized steel, aluminum, and color-coated finishes

These options allow you to optimize thermal insulation and panel performance without extra waste or on-site modifications.

Where to Buy Shanghe EPS Sandwich Panels

For U.S. customers, Shanghe EPS sandwich panels are available directly through our authorized distributors and factory sales channels. We provide straightforward ordering, reliable shipping, and local customer support to ensure timely delivery for your projects. Reach out today for a free quote or sample, and we’ll help you pick the right EPS composite foam sandwich panels tailored to your climate, budget, and building type.