Your Secret to 40% Faster Installs & LEED Points

Listen up, folks—if you’re still wrestling with rusty tin roofs or sweating over concrete pours, let me drop some truth: foam sandwich roof panels are the game-changer you’ve been chasing. Seriously, imagine a roof that snaps together like Legos but insulates like a Yeti cooler. That’s PUR for you. With R-values hitting 6.5 per inch 7, these bad boys reflect 85% of solar heat 2, slashing AC bills by 20-70% overnight. And get this—contractors like you are clocking 40% faster installs because no cranes, no wet trades, just dry-fit panels that 3 guys can lay 1,500 sq ft/day 3. Architects, here’s your cheat code: PUR panels ace LEED credits for energy efficiency and recycled content (yep, Owens Corning’s NGX foam uses 20% recycled stuff 7). So whether you’re building a warehouse or a Walmart, this is your ticket to on-time, under-budget glory.

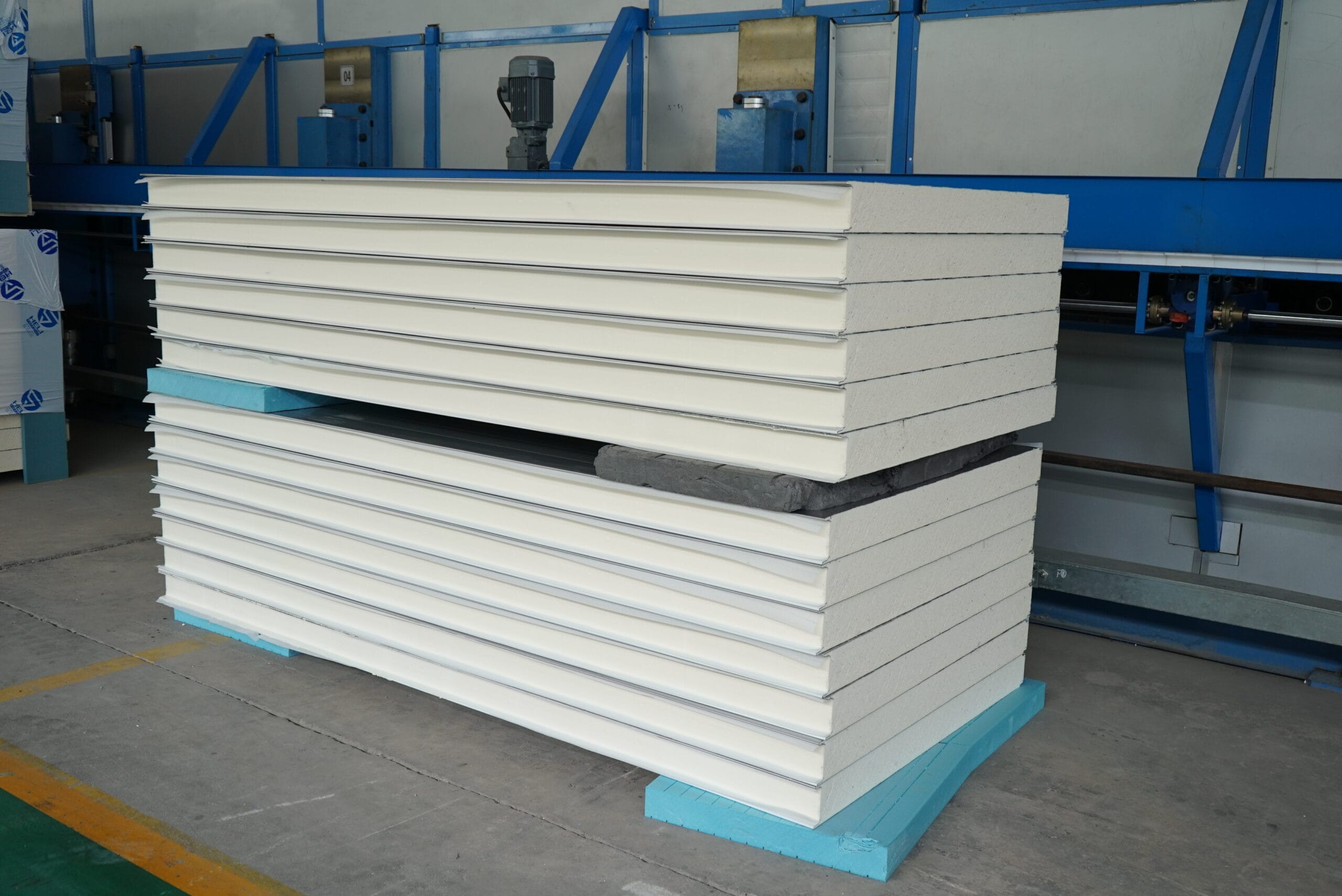

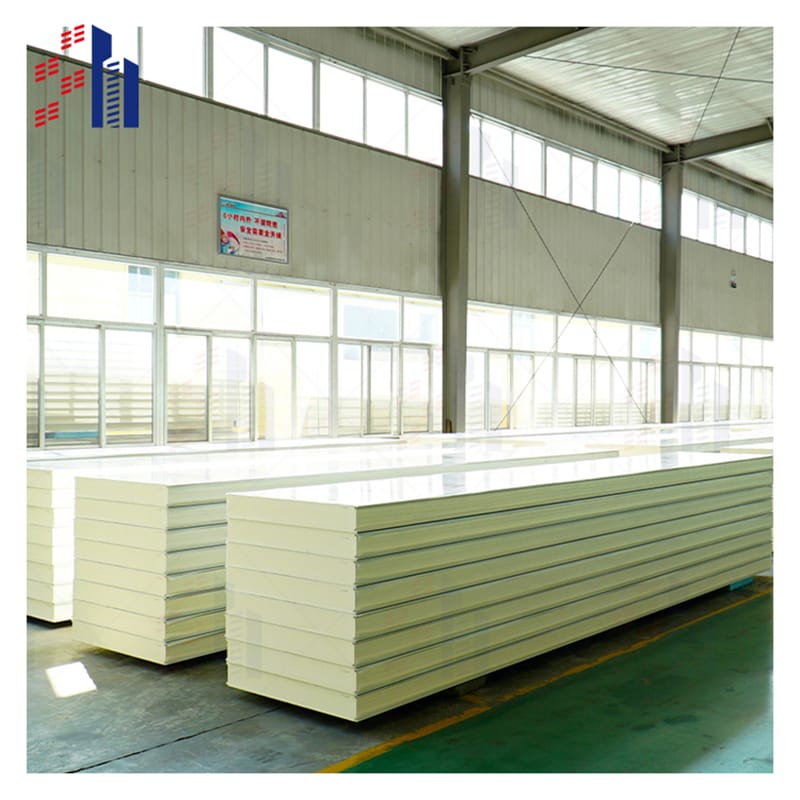

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Concrete Over Sandwich Roof Panels Ditch Heavy Decks, Boost Load Capacity

Alright, let’s tackle the elephant in the room: traditional concrete roofs are back-breakers. But foam sandwich roof panels? That’s like swapping a bulldozer for a Tesla. Here’s the deal—you get a lean, mean composite deck where lightweight EPS foam (only 42kg/m³ 6) shoulders the insulation load, while a slim concrete topping handles foot traffic and equipment. Translation: 50% less dead weight vs. solid slabs, meaning your support beams can go on a diet. Contractors, picture this—no more waiting 28 days for pours to cure. These panels ship pre-cured, so you bolt ’em down Monday and roof by Friday. Plus, they laugh off 150kg/sq m loads 8, making them perfect for HVAC-heavy industrial jobs. Oh, and fire ratings? These hit Class A 6—so even the pickiest inspector will nod yes.

FRP Foam-Core Sandwich Panels for Arched Roofs Where Beauty Meets Hurricane Resistance

Dreaming of a swooping warehouse roof that doesn’t leak or flap like a tarp in a tornado? Meet foam sandwich roof panels. Think fiberglass skin hugging a PU foam heart—this combo bends like Beckham but stands firm against 20m/s winds 8. Why’s this a big deal? First off, that glossy FRP finish reflects sunlight like a mirror (bye-bye, heat island effect 2), and it won’t rust or rot when rain hammers it for the 100th time. Architects, you’ll love this: SAB-Profil’s PIR-core arches nail 26dB sound insulation 4, making them perfect for airports or gyms. And since they’re molded in one piece, you get seamless curves that shed water like a duck’s back—no more caulking battles at 2 AM.

GFRP Foam-Core Sandwich Panels Arched Roof Systems Cut Corrosion, Not Corners

Okay, salty air or chemical plants murdering metal roofs? GFRP foam-core sandwich panels arched roof systems are your bulletproof vest. Glass-fiber-reinforced polymer (GFRP) skins are basically kryptonite to corrosion—they shrug off acid rain, bird poop, and factory fumes like it’s nothing. Meanwhile, the PU foam core locks in R-5 insulation per inch 7, keeping interiors drier than a desert. Contractors working coastal jobs, listen close: these panels are 8x lighter than steel 10, so you save thousands on shipping and supports. Owners, here’s the kicker: GFRP lasts 30+ years with zero paint jobs, meaning no surprise maintenance bills. And yeah, they’re FM Global-approved 7—so insurers won’t hike your rates.

Trust the 20-Year Vet

Look, I’ve seen fly-by-night suppliers ship warped panels that fail inspection. But as a foam sandwich roof panels we control every step—from raw PU foam (density locked at 42±2 kg/m³ 6) to final QC. Our secret sauce? Zero middlemen. You buy straight from our China factory, saving 15-30% versus distributors 3. Plus, we custom-cut lengths up to 18m for those wild arched roofs—no extra fees.

LEED-Certified: Slap our panels on your project and rack up credits for Energy Star compliance 79.

FM Global & DOE Approved: Fire ratings? Check. Reflectivity? 85%+ 2.

Patent-Backed: Our tongue-groove joints hold 50kg point loads 6—no sag, no fail.