Product Overview of Polyurethane Sandwich Panel Production Line

The polyurethane sandwich panel production line is a specialized manufacturing system designed to produce high-quality insulated panels efficiently and reliably. These panels consist of a polyurethane foam core sandwiched between metal facings, offering exceptional thermal insulation, structural strength, and durability. Widely used in the construction, refrigeration, and cold storage industries, these panels deliver energy-saving solutions that meet the growing demand for environmentally conscious building materials.

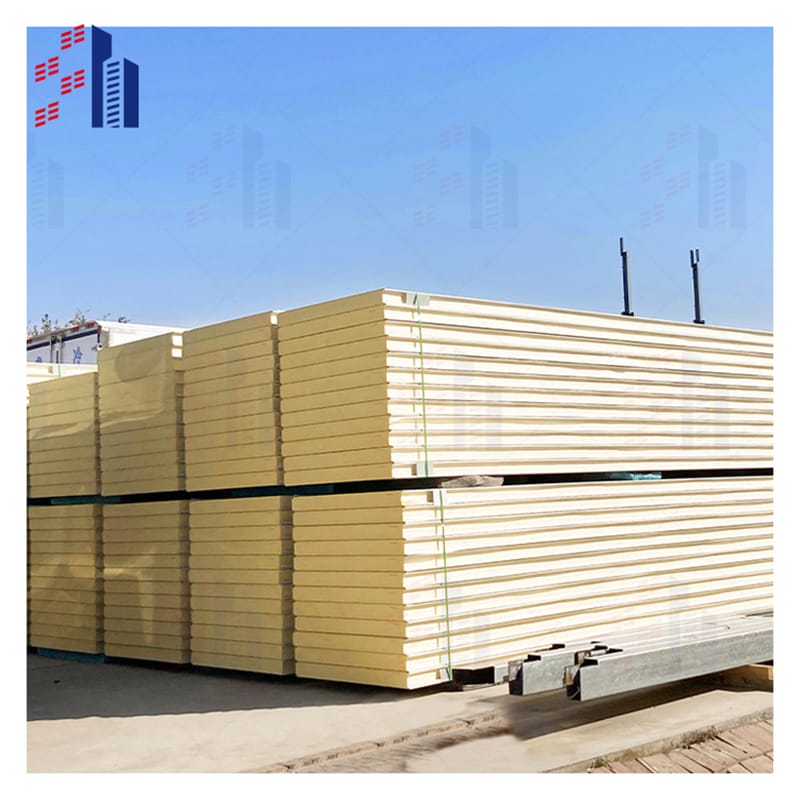

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Polyurethane sandwich panels are crucial in today’s insulation and construction markets. They provide superior thermal performance, enhanced fire resistance, and noise reduction, making them ideal for walls, roofs, clean rooms, and industrial applications. Their lightweight nature also means easier handling and faster installation, which translates into cost savings on site.

Shanghe stands out as a trusted manufacturer and supplier in the polyurethane sandwich panel production industry. With years of technical expertise and commitment to quality, Shanghe offers a complete line of production equipment that integrates advanced polyurethane foam technology with precision roller and cutting systems. Recognized globally, Shanghe’s production lines deliver high efficiency, flexibility, and environmentally friendly operations, supporting manufacturers to meet diverse market requirements with precision and reliability.

Choose Shanghe for your PU sandwich panel production machinery needs and benefit from a proven track record of reliability, innovation, and customer satisfaction.

Key Features and Benefits of Polyurethane Sandwich Panel Production Line

Our polyurethane sandwich panel production line delivers high efficiency with fully automated production capabilities. Designed to meet diverse project demands, it offers adjustable panel thickness and width settings, allowing you to produce panels that fit various specifications with ease.

Advanced Insulation Technology

The line incorporates advanced polyurethane foaming technology, ensuring panels have superior insulation performance—key for energy-saving buildings and cold storage facilities. This technology guarantees consistent foam density and durability across all panels.

Precision Manufacturing for Quality Panels

Equipped with precision roller and cutting systems, the production line ensures a clean, accurate finish every time. This results in uniform panel surfaces and precise cuts, minimizing material waste and improving overall product quality.

Energy Efficient and Environmentally Friendly

Our system is engineered with energy-saving components and operates with minimal environmental impact, helping your facility lower power costs and reduce its carbon footprint.

Easy Operation and Control

The production line features a user-friendly PLC control system combined with an intuitive human machine interface (HMI). Operators can easily monitor and adjust production parameters in real-time, reducing downtime and speeding up troubleshooting.

Modular Design for Flexibility and Maintenance

The modular structure of the machinery allows for easy upgrades and maintenance. This means you can expand your line or replace parts without major disruptions, ensuring your production stays competitive and efficient.

of Benefits

- Fully automated, high throughput production

- Customizable panel dimensions for versatile applications

- Superior polyurethane foam insulation quality

- Precision rollers and cutters for clean, high-quality panels

- Energy-saving and eco-friendly operation

- Intuitive PLC and HMI controls for smooth operation

- Modular design that simplifies upgrades and maintenance

This production line gives your business the flexibility, efficiency, and quality control needed to excel in the competitive PU sandwich panel manufacturing market.

Technical Specifications of Polyurethane Sandwich Panel Production Line

Understanding the technical specs is key when investing in a polyurethane sandwich panel production line. Here’s a clear breakdown of the core parameters and features you need to know.

Production Capacity and Panel Dimensions

- Max Output: Up to 30 panels per hour, depending on panel size and line configuration.

- Min Output: Around 10 panels per hour for custom or thicker panels.

- Panel Width Range: Adjustable from 600 mm to 1250 mm (23.6″ to 49.2″).

- Panel Thickness: Can be set between 30 mm to 150 mm (1.2″ to 5.9″) to meet different insulation requirements.

- Panel Length: Customized with cutting system, usually from 2 meters up to 12 meters (6.5 ft to 39.4 ft).

Foam Density and Curing

- Polyurethane Foam Density: Adjustable, typically between 40 to 45 kg/m³, ensuring excellent thermal insulation and structural integrity.

- Curing Time: Optimized with advanced foaming technology, typically 3 to 5 minutes depending on foam thickness and ambient conditions.

Power and Energy Consumption

- Power Requirements: Standard supply is 380V, 50Hz, 3-phase, compatible with most US industrial settings (custom voltage options available).

- Energy Consumption: Designed for efficiency, the line consumes approximately 60 kW, balancing performance and operational cost savings.

Material Compatibility

- Metal Types Supported: Compatible with cold-rolled steel, galvanized steel, aluminum sheets, and color-coated steel coils frequently used in the US market.

- Core Materials: Works seamlessly with premium polyurethane raw materials sourced for consistent quality and fire rating compliance.

Machine Dimensions and Weight

- Overall Length: Typically 25 meters (82 feet) for a complete line, but customizable based on factory space.

- Width: Around 3 meters (10 feet), allowing flexible installation.

- Weight: Ranges between 12 to 15 tons, depending on configuration and optional modules.

Automation Level and Control Systems

- Automation: Fully automated with integrated feeding, foaming, cutting, and stacking stages to maximize productivity and reduce manual labor.

- Control System: Features an easy-to-use PLC control system combined with an intuitive Human Machine Interface (HMI). This setup allows real-time monitoring, quick adjustments, and supports data logging to enhance quality and traceability.

This polyurethane sandwich panel production line blends high output rates with versatile panel specs and advanced automation, perfectly suited for US-based manufacturers aiming to meet construction and insulation standards efficiently.

Production Process Workflow of Polyurethane Sandwich Panel Production Line

Our polyurethane sandwich panel production line is designed to deliver consistent, high-quality panels efficiently. Here’s a clear step-by-step look at how raw materials transform into finished insulated panels ready for use:

Raw Material Feeding and Preparation

- The process begins with loading metal coil sheets (typically steel or aluminum) onto the decoiler.

- These sheets move into the straightener and feeder systems to ensure flat, smooth surfaces for panel formation.

- The production line supports multiple metal types and thicknesses, allowing customization based on project needs.

Panel Forming and Lamination

- The upper and lower metal sheets are formed into the desired profile through precision rollers.

- A polyurethane foam injection system then applies the liquid polyurethane core evenly between the metal layers.

- This process uses advanced PU foam sandwich panel manufacturing techniques for better adhesion and panel strength.

Polyurethane Foam Injection and Curing

- The injected polyurethane foam expands and cures inside the sandwich panel, creating a solid insulation core.

- Curing time is controlled precisely to maximize insulation performance while keeping the production speed efficient.

- The system ensures uniform foam density and excellent bonding to the metal layers.

Panel Cutting and Stacking

- After curing, the continuous sandwich panel reaches the cutting station.

- High-precision cutting equipment slices panels to the customer’s required length, minimizing waste and ensuring clean edges.

- Finished panels are then stacked automatically, ready for packing or further processing.

Quality Control Integration

- Throughout the entire process, quality checkpoints monitor critical parameters such as metal sheet alignment, foam density, panel thickness, and surface finish.

- Automated sensors and manual inspection stages help maintain consistent product standards.

- This tight quality control guarantees the insulated panel production line meets industry and customer expectations every time.

Our production workflow combines fully automated systems with flexible controls, delivering both efficiency and reliability in PU sandwich panel production. This makes it an ideal solution for manufacturing high-quality, energy-efficient insulated panels for the U.S. market.

Applications of Polyurethane Sandwich Panels Production Line

Our polyurethane sandwich panel production line delivers panels that serve a wide range of industries requiring efficient insulation and structural strength. Here are the main applications where these panels truly stand out:

Building and Construction

Polyurethane sandwich panels are widely used for walls and roofs in commercial and residential buildings. Their superior insulation properties help maintain indoor temperature, improving energy efficiency and reducing heating and cooling costs. The panels provide excellent fire resistance, weatherproofing, and durability, making them a preferred choice for modern construction projects.

Cold Storage and Refrigeration

The PU sandwich panel production equipment produces panels ideal for cold storage warehouses and refrigeration facilities. These panels deliver outstanding thermal insulation that keeps temperatures stable, ensuring energy savings and maintaining product safety. The panels can be customized for different thicknesses and sizes to meet various cooling requirements in the food industry and pharmaceuticals.

Clean Rooms and Industrial Facilities

In industries like electronics, pharmaceuticals, and biotechnology, maintaining controlled environments is critical. Panels made from this production line meet stringent hygiene and insulation standards required for clean rooms and other controlled industrial environments. Their smooth surface finish and tight sealing capabilities prevent dust and contaminant infiltration.

Energy Efficient Housing

As energy codes and green building trends rise in the United States, polyurethane sandwich panels are key to energy-efficient housing solutions. They help builders meet insulation standards while speeding up construction with prefabricated panel systems. The panels improve thermal resistance to reduce energy consumption, lower utility bills, and offer enhanced comfort year-round.

panels from our production line excel across applications where effective insulation, structural strength, and quick installation are essential. From freezing cold warehouses to modern green buildings, these panels combine high-quality foam insulation and durable metal surfaces to meet diverse industry needs smoothly and reliably.

Customization Options for Polyurethane Sandwich Panel Production Line

Our polyurethane sandwich panel production line offers flexible customization to meet diverse manufacturing needs and market demands across the U.S. Here’s how we tailor the line and panels for your operation:

Adjustable Panel Size and Thickness

- Custom panel widths and thicknesses to fit specific project requirements

- Supports panel thickness from as thin as 30mm up to 200mm or more

- Variable panel width settings up to 1200mm or wider depending on production model

- Allows manufacturing of various PU foam sandwich panels used in construction, cold storage, and clean rooms

Surface Finishing and Steel Coil Options

- Compatible with multiple steel coil thicknesses ranging from 0.3mm to 1.2mm, adjustable based on panel strength needs

- Options for different surface coatings such as galvanized, color steel, or pre-painted steel for enhanced corrosion resistance and aesthetics

- Supports various coil materials including pre-painted galvanized steel, aluminum, and stainless steel to suit industry specifications

Optional Accessories and Automation Upgrades

- Add-ons like automatic feeding systems, enhanced foam injection units, and high-precision cutting modules

- Upgrade to advanced PLC control systems and HMI interfaces for easier operation and monitoring

- Supports integration of remote diagnostics and data logging for proactive maintenance and quality control

By offering these options, Shanghe’s production line empowers U.S. manufacturers to produce high-quality panels tailored precisely to their market needs—whether for energy-efficient housing, refrigerated warehouses, or industrial buildings. Customization means you get the flexibility without compromise on performance or efficiency.

After Sales Service and Support for Polyurethane Sandwich Panel Production Line

Our commitment doesn’t end when your polyurethane sandwich panel production line is up and running. We provide comprehensive after sales service and support designed to keep your operations smooth and efficient.

Installation and Commissioning Assistance

We offer full installation support and expert commissioning services to ensure your production line starts up quickly and correctly. Our experienced technicians guide you through setup on-site, optimizing your PU sandwich panel production equipment for peak performance from day one.

Technical Training and Operation Manuals

To help your team operate the line confidently, we provide detailed, easy-to-follow operation manuals along with hands-on technical training. This equips your staff with the knowledge to maintain quality output and troubleshoot common issues, minimizing downtime.

Maintenance Contracts and Spare Parts Supply

Regular maintenance is crucial for long-term success. We offer customizable maintenance contracts tailored to your production needs, along with a reliable supply of genuine spare parts. This ensures your insulated panel production line stays in top condition, reducing unexpected repairs and costly interruptions.

24/7 Customer Service and Remote Diagnostics

Our dedicated customer service team is available 24/7 for quick support. With advanced remote diagnostics, we can identify and solve many problems without delays or the need for onsite visits, helping you maximize uptime and meet production targets consistently.

By choosing our polyurethane sandwich panel production line, you gain more than just machinery—you get a full support system designed to grow with your business.

Why Choose Shanghe Polyurethane Sandwich Panel Production Line

When it comes to selecting a polyurethane sandwich panel production line, Shanghe stands out for several solid reasons. Here’s why we are the preferred PU sandwich panel production equipment supplier for manufacturers across the United States and beyond:

Proven Industry Experience and Expertise

With over a decade of hands-on experience, Shanghe knows the ins and outs of polyurethane foam sandwich panel manufacturing. Our team of engineers and technicians brings deep technical know-how, ensuring every production line delivers high efficiency and consistent quality. This expertise translates into machinery that works reliably day after day, minimizing downtime and boosting your output.

Trusted by Global Clients

Shanghe has a strong track record with clients worldwide. We’ve supplied insulated panel production lines to various industries, including construction, cold storage, and industrial manufacturing. Our machines have helped businesses meet high standards while reducing operational costs. This global trust reinforces our reputation as a dependable PU panel production line supplier that delivers on promises.

Commitment to Quality and Innovation

Quality and continuous improvement are at the core of Shanghe’s manufacturing philosophy. We use the latest technologies in polyurethane core panel lines to enhance foam density control, precision cutting, and energy efficiency. Our production lines are not just built for today’s needs but are designed with modular upgrades in mind, keeping you ahead in the competitive market.

Competitive Pricing and Flexible Payment Options

We understand purchasing a sandwich panel machine is a big investment. That’s why Shanghe offers competitive pricing without compromising on quality. Plus, we provide flexible payment terms to help businesses of all sizes access top-tier prefabricated panel production machinery. Our goal is to make your decision easy and budget-friendly.

of Why Shanghe

- Years of industry experience and solid technical expertise

- Proven success with global clients and varied applications

- Strong focus on quality assurance and ongoing innovation

- Affordable pricing combined with flexible payment plans

Choosing Shanghe means investing in a polyurethane sandwich panel production line that’s built to perform, backed by a team that supports you every step of the way.

Customer Testimonials and Case Studies on Polyurethane Sandwich Panel Production Line

At Shanghe, customer satisfaction stands at the core of our polyurethane sandwich panel production line success. Clients across the United States and worldwide have shared their positive experiences, highlighting the reliability, efficiency, and quality our PU sandwich panel manufacturing lines deliver.

Global Customer Feedback

- Consistent high performance: Many customers appreciate the stable operation and high output capacity, which helps them fulfill large orders without delays.

- Ease of use: The user-friendly PLC control system and intuitive HMI make running the line simpler and reduce training time for operators.

- Energy efficiency: Feedback often points out the energy-saving features that lower operational costs without compromising quality.

- Customization success: Businesses needing varying panel sizes and thicknesses find our modular design and adjustable settings incredibly valuable.

- After-sales support: Customers praise our technical support and remote diagnostics services, ensuring smooth production with minimal downtime.

Case Studies of Successful Deployments

- Cold Storage Facility Manufacturer in Texas improved their production efficiency by 30% after switching to our polyurethane sandwich panel machine. They highlighted superior insulation quality from the advanced PU foaming technology.

- A prefabricated building supplier in California reported a 25% reduction in material waste and enhanced product finish due to our precision roller and cutting systems.

- A refrigeration panel manufacturer in Florida scaled up production with the fully automated insulated panel production line, meeting increasing demand without additional labor costs.

- An industrial cleanroom equipment producer praised the consistent foam density and panel durability, which helped them maintain strict quality standards in sensitive environments.

Why These Outcomes Matter

These stories showcase how our PU sandwich panel production equipment directly supports:

- Increased production capacity

- Enhanced product quality

- Lower operating costs

- Flexibility in product specifications

- Long-term reliability and service support

Choosing Shanghe means partnering with a supplier committed to your success in the competitive polyurethane core panel line market.

For proven results and trusted performance, our machine stands ready to boost your manufacturing capabilities.

Contact Us for Polyurethane Sandwich Panel Production Line Solutions

Ready to boost your production with a high-quality polyurethane sandwich panel production line? Reach out today for personalized quotations and consultations tailored to your specific needs.

- Get a Fast Quote – Fill out our inquiry form online to receive detailed pricing and equipment options quickly.

- Speak to an Expert – Our knowledgeable team is available to discuss your project requirements and recommend the best PU sandwich panel production equipment for your setup.

- Schedule a Factory Visit – We invite you to tour our manufacturing facility to see the production lines in action and understand our quality standards firsthand.

- Request a Demo – Experience the full capabilities of our PU foam sandwich panel manufacturing line through a live demonstration tailored to your production goals.

Whether you’re looking for a new supplier or upgrading existing machinery, Shanghe offers reliable, customizable, and energy-efficient solutions for the U.S. market. Contact us now and take the first step toward transforming your insulated panel production process.