Polyurethane Sandwich Panels Price Overview

When considering polyurethane sandwich panels price, it’s important to understand the general cost range and how these panels compare with alternative insulation options like EPS (expanded polystyrene) and rock wool.

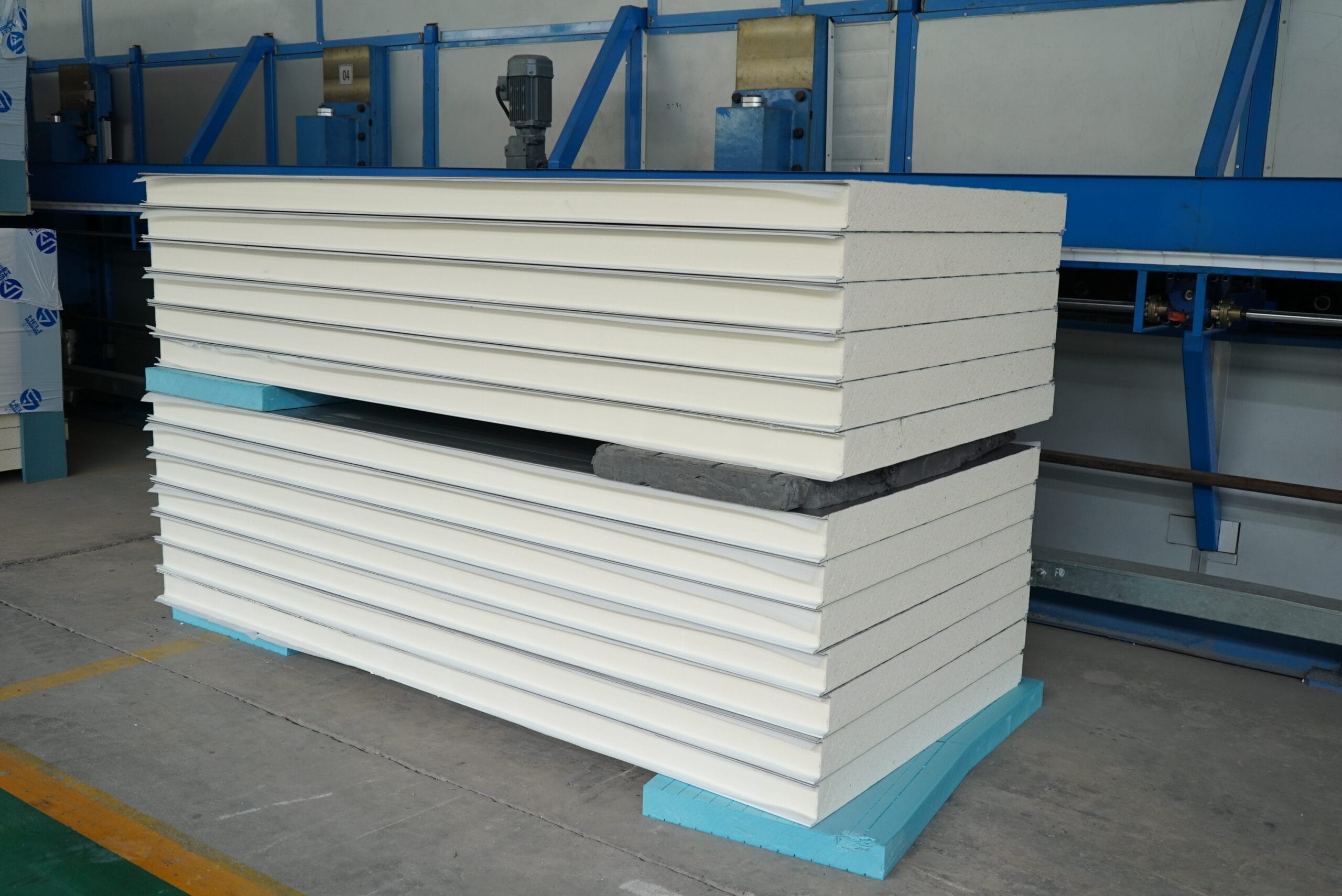

Customers visit the factory

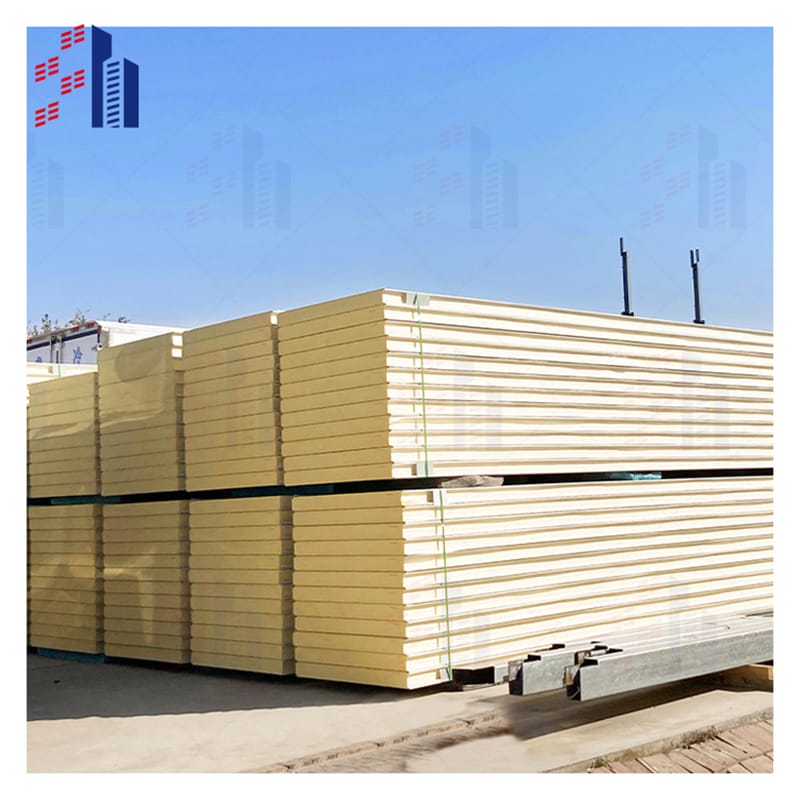

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| manufacturer | Shandong, China,philippines | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

General Price Range

- The price per square meter for polyurethane foam sandwich panels typically ranges from $25 to $45, depending on panel specifications.

- Standard panel sizes often measure around 1.0 to 1.2 meters wide and lengths up to 12 meters, with prices adjusted accordingly.

- Individual panel prices vary based on thickness and facing material choices.

Pricing Comparison with Alternative Insulation Panels

- Compared to EPS panels, polyurethane panels cost slightly more but provide higher thermal insulation efficiency (R-value) and better durability.

- In contrast to rock wool panels, polyurethane panels generally offer a more competitive price with enhanced moisture resistance and lighter weight.

- While EPS and rock wool may come cheaper upfront, PU sandwich panels deliver superior energy savings, reducing long-term costs.

Factors Influencing Polyurethane Sandwich Panel Price

Several factors impact the PU sandwich panel cost:

- Panel Thickness: Typical thicknesses include 50mm, 75mm, and 100mm, with thicker panels priced higher due to increased insulation capacity.

- Panel Size: Larger dimensions and custom lengths directly affect pricing.

- Facing Materials:

- Pre-coated galvanized steel is usually more affordable.

- Aluminum facings, especially with color coating options, command higher prices due to enhanced corrosion resistance and aesthetics.

- Customization: Special colors, perforations, or additional reinforcements will increase cost.

Bulk Order and Project-Based Discounts

- Many suppliers, including Shanghe, offer discounts for large-volume orders or ongoing projects, making polyurethane sandwich panels more affordable for bulk purchases.

- Project-specific pricing can be negotiated to optimize overall budget and delivery schedules.

By understanding these elements, buyers can make informed decisions balancing PU sandwich panel cost, performance, and project requirements.

Technical Specifications of Polyurethane Sandwich Panels Price and Quality

When considering polyurethane sandwich panels price, understanding the technical specs helps you see the value behind the cost. Here’s a clear breakdown of what you get with these panels:

Core Material Polyurethane Foam Density and R-Value

- The heart of the panel is high-density polyurethane foam, offering excellent insulation.

- Typical foam density ranges from 40 to 45 kg/m³, ensuring durability and strength.

- The R-value, which measures thermal resistance, usually falls between 6.0 to 6.5 per inch, providing superior energy efficiency compared to EPS or rock wool cores.

- This means better thermal insulation, leading to lower heating and cooling costs—invaluable for U.S. climates with extreme temperatures.

Panel Thickness Options

- We offer panels in 50mm, 75mm, and 100mm thicknesses, depending on insulation needs.

- Thicker panels mean higher prices but better thermal performance. You can pick the thickness that balances cost and insulation for your project.

Outer and Inner Facing Materials

- The panels come with durable facings made of pre-coated galvanized steel or aluminum sheets.

- These materials protect against corrosion and weather, extending the panel’s lifespan.

- Available in a variety of color options, helping you match or enhance the building aesthetics.

- The coated steel sheet thickness typically ranges from 0.4mm to 0.6mm, affecting durability and price.

Panel Size and Weight Details

- Standard panel width is about 1 meter, with lengths customizable up to 12 meters depending on your needs.

- Weight varies by panel thickness and facing material but generally ranges from 10 to 15 kg per square meter.

- These relatively lightweight panels make handling and installation easier, reducing labor costs.

Fire Resistance and Certifications

- Many polyurethane sandwich panels meet Class B or Class A fire resistance ratings, complying with U.S. building codes (ASTM E84 or UL 723 standards).

- Certifications may include FM approval, UL listings, or local fire safety certifications depending on the product variant.

- Fire resistance adds to the panels’ safety, helping protect industrial and commercial buildings.

By focusing on these specifications, you see how the polyurethane insulated panels price per square meter reflects their high performance and versatility. Customized sizes, core density, and facing materials all play a role in defining the exact cost—but you’re investing in a product proven to offer excellent insulation, durability, and compliance with safety standards.

Applications of Polyurethane Sandwich Panels

Polyurethane sandwich panels are widely used across various industries thanks to their excellent insulation and durability. Their versatility makes them a top choice for industrial buildings, warehouses, cold storage facilities, clean rooms, and commercial buildings.

Roofing and Wall Cladding Uses

These panels work well for both roofing and wall cladding, providing a strong, weather-resistant barrier that helps maintain internal temperatures regardless of outside weather. The color coated corrugated polyurethane sandwich panels add not just protection but also aesthetic appeal with customizable color options to suit any building design.

Energy Savings and Building Efficiency

One of the biggest advantages of using polyurethane insulated panels is their superior thermal performance. Thanks to the high-density polyurethane foam core, these panels deliver a high R-value, offering excellent insulation that helps keep heating and cooling costs down.

- Reduced energy consumption: The panels minimize heat transfer, keeping interiors cooler in summer and warmer in winter.

- Improved temperature control: This is crucial for temperature-sensitive environments like cold storage and clean rooms.

- Long-term cost savings: Lower energy bills and reduced HVAC system strain make polyurethane foam sandwich panels cost-effective over time.

Using polyurethane sandwich panels in your building projects means better energy efficiency, enhanced comfort, and durable protection against the elements—making them an ideal investment for U.S. commercial and industrial construction needs.

Why Choose Shanghe Polyurethane Sandwich Panels

When it comes to polyurethane sandwich panels price and quality, Shanghe stands out as a trusted supplier in the U.S. market. Here’s why choosing Shanghe makes sense for your next building project:

Quality Assurance and Warranties

Shanghe offers strict quality control at every stage of production to ensure durable, high-performance polyurethane insulated panels. Each panel is backed by warranties covering material integrity and thermal performance, giving you peace of mind on your investment.

Advanced Manufacturing Process

Our panels are made using state-of-the-art technology that guarantees consistent foam density and excellent bond strength between the polyurethane core and steel or aluminum facings. This results in panels that deliver superior insulation, fire resistance, and structural stability.

Competitive Pricing and Flexible Order Quantities

We understand the need for cost-effective solutions without compromising quality. Shanghe offers competitive PU sandwich panel prices tailored to your project size. Whether you need small batches or bulk orders, we provide flexible pricing options and discounts for large-scale purchases.

Excellent Customer Support and Timely Delivery

From initial inquiry to after-sales support, our team provides professional customer service to assist with panel selection, customization, and installation guidance. Plus, we ensure fast production turnaround and reliable shipping schedules, helping you stay on track with your construction timeline.

Choosing Shanghe means investing in high-quality polyurethane cladding panels cost-effective for roofing and wall applications without sacrificing durability or service. If you want reliable materials with expert support, Shanghe delivers on all fronts.

Ordering and Pricing Inquiry for Polyurethane Sandwich Panels Price

If you’re ready to get a detailed quote for your project, here’s how to make the process smooth and straightforward.

How to Request a Quote Based on Your Project Size and Specs

To get an accurate polyurethane sandwich panels price, we recommend providing these key details upfront:

- Project size (total square meters or number of panels needed)

- Panel thickness preferred (50mm, 75mm, 100mm)

- Facing material choice (pre-coated galvanized steel, aluminum, color options)

- Any special customization or specific requirements

This info helps us tailor the best pricing and product options for your exact needs.

Contacting Shanghe for Price Inquiry

- Visit the Shanghe website and use the quote request form available on the product page.

- Alternatively, email or call the Shanghe sales team directly using the contact info on the site.

- Make sure to mention you’re interested in polyurethane sandwich panel price so your inquiry is prioritized.

Shipping and Lead Time Details

- Typical lead times depend on order size and customization but expect around 2-4 weeks for standard orders.

- For large or bulk orders, shipping times may vary; our team will provide a detailed estimate.

- We ship panels carefully to ensure they arrive undamaged and ready for installation, with options for both regional and national shipping across the United States.

By reaching out to Shanghe with your project details, you can secure competitive pricing and get expert advice to fit your insulation and cladding needs perfectly.

Frequently Asked Questions about Polyurethane Sandwich Panels Price

How is the Price Determined

The polyurethane sandwich panels price depends on several key factors:

- Panel thickness (typically 50mm, 75mm, or 100mm) — thicker panels cost more due to more core material.

- Size and dimensions of each panel — custom sizes may affect the price slightly.

- Facing materials like pre-coated galvanized steel or aluminum influence cost, especially with different colors and finishes.

- Core foam density and R-value impact insulation performance and price.

- Order quantity — bulk purchases usually receive discounts and better pricing.

- Customization requirements like special coatings or fire resistance certifications also add to the cost.

Can I Customize Panel Size or Thickness

Yes, customization is available to meet your project needs. You can:

- Choose from standard thickness options (50mm, 75mm, 100mm).

- Request custom panel dimensions to fit unique building designs.

- Select different outer and inner facing materials with varied color options.

- Specify additional features such as enhanced fire resistance or UV protection.

What About Installation Support

Our team offers support to make your installation process smooth:

- Installation guidelines and manuals provided with your order.

- Access to experienced technical support for questions during installation.

- If needed, we can recommend trusted contractors familiar with polyurethane insulated panels.

How Do These Panels Compare in Price and Performance

Compared to other insulation options like EPS (expanded polystyrene) or rock wool panels, polyurethane sandwich panels offer:

- Higher R-value per inch, meaning better thermal insulation reduces energy costs over time.

- Stronger structural integrity due to the rigid foam core and durable steel/aluminum facings.

- While the initial PU sandwich panel cost may be slightly higher than EPS, the long-term savings in heating and cooling make it a cost-effective choice.

- Polyurethane panels are lighter and easier to install than many alternatives, saving on labor costs.

- They are also more resistant to moisture and fire compared to EPS, increasing building safety and lifespan.

Let us know your project size and specs, and we can help find the best-priced solution that fits your needs.

Customer Testimonials and Case Studies on Polyurethane Sandwich Panels Price and Performance

At Shanghe, we take pride in delivering polyurethane sandwich panels that not only meet but exceed expectations in both cost-effectiveness and performance. Our customers from various sectors across the United States have shared their experiences, highlighting real project successes using our panels. Here’s an overview:

Successful Projects Using Shanghe Polyurethane Sandwich Panels

Commercial Warehouses and Industrial Buildings

One large U.S. warehouse project saved up to 20% on energy costs thanks to the superior insulation properties of our polyurethane insulated panels. The lightweight yet durable panels simplified installation, reducing labor time and overall construction costs.

Cold Storage Facilities

Several cold storage operators reported improved temperature control and energy savings after switching to our PU roof panels and wall cladding. The panels’ R-values ensured less heat transfer, which means less power use and lower operational costs.

Clean Rooms and Commercial Spaces

Our polyurethane foam sandwich panels price offers excellent value for clean room applications. The panels provide reliable fire resistance and hygiene compliance with minimal maintenance, making them a smart investment choice.

Feedback on Cost-Effectiveness and Product Performance

Competitive Pricing Without Compromise

Customers frequently note that the PU sandwich panel cost of Shanghe products is very competitive compared to EPS or rock wool alternatives, especially when factoring in long-term energy savings and durability.

Customization and Flexibility

Buyers appreciate the ability to customize panel thickness, size, and facing materials like galvanized steel or aluminum. This flexibility helps optimize costs depending on project requirements without sacrificing quality.

Durability and Low Maintenance

Users have praised the panels for their strength and resistance to weather and corrosion, which lowers maintenance costs. This makes them a cost-effective choice for roofing and wall cladding over time.

Excellent Customer Support and Delivery

Timely shipment and responsive customer service keep projects on schedule, which customers say helps avoid costly delays.

Real Results That Speak for Themselves

- Increased energy efficiency by up to 30% compared to traditional insulation.

- Reduced installation time by up to 25% thanks to lightweight panels.

- Improved fire safety ratings and compliance in commercial builds.

- Positive ROI in under 3 years based on energy savings and reduced upkeep.

These testimonials and case studies underline why choosing Shanghe’s polyurethane sandwich panels is a smart move for cost-conscious U.S. customers prioritizing quality and performance. Our panels bring real value that goes beyond the upfront price tag.

Get Your Polyurethane Sandwich Panels Price Quote Today

Ready to buy polyurethane sandwich panels that fit your budget and project needs? Don’t wait—get a free, detailed quote from Shanghe now. Our sales team is here to offer expert consultation tailored to your specific requirements, including panel thickness, size, and facing materials.

Why contact Shanghe today:

- Accurate polyurethane sandwich panel price based on your project scale and specifications

- Personalized advice on PU panels pricing versus alternatives like EPS or rock wool

- Flexible order quantities and competitive pricing options

- Clear information on shipping, lead times, and bulk discounts

Reach out via our website or call our sales experts directly. We’ll help you find the best polyurethane insulated panels price per square meter and guide you through the ordering process with ease.

Take action now and improve your building’s efficiency with Shanghe’s trusted polyurethane foam sandwich panels.