Introduction to Shanghe panel sandwich polyurethane for sale

Looking for reliable insulated sandwich panels for sale? Shanghe panel sandwich polyurethane for sale are designed to meet demanding construction needs across the U.S. market. These panels feature a polyurethane (PU) foam core sandwiched between durable outer metal sheets, making them a trusted solution for energy-efficient building envelopes.

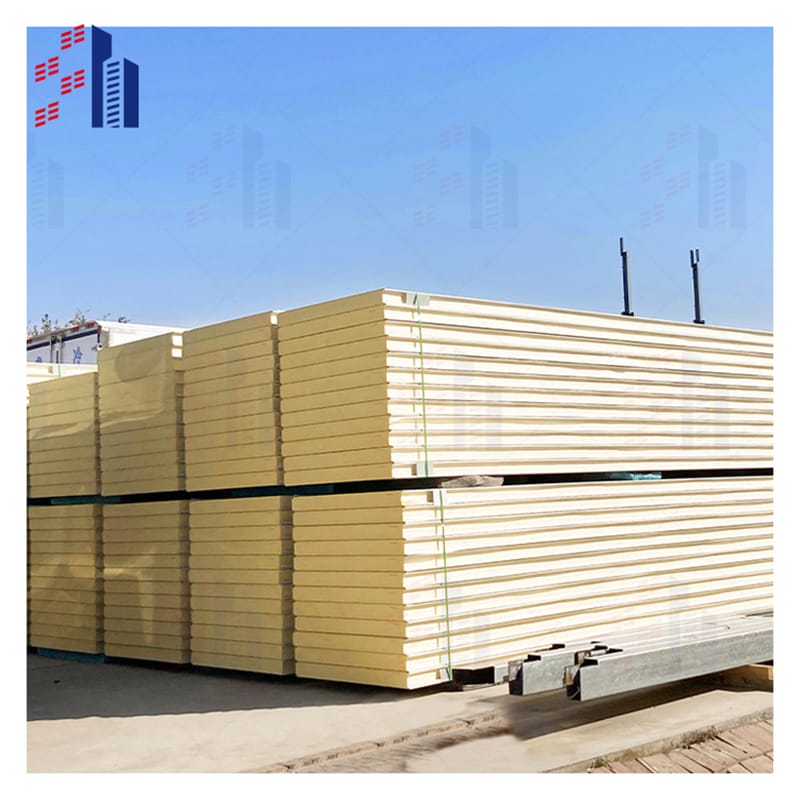

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

What Makes Shanghe Sandwich Panels Stand Out

Our panels combine high-performance insulation with structural strength. The core features rigid polyurethane foam, known for its excellent thermal insulation, while the outer layers typically consist of coated steel or aluminum, ensuring long-lasting protection from weather and wear. This combination delivers:

- Superior insulation and energy savings

- Lightweight yet strong panel construction

- Resistance to moisture, corrosion, and pests

Why Polyurethane Cores Matter

Polyurethane foam cores make all the difference. Here’s why they are preferred over other options:

- Excellent thermal insulation with low thermal conductivity, reducing heating and cooling costs

- Durability: PU foam maintains shape and performance over time without sagging or compressing

- Energy efficiency: Keeps interiors comfortable while lowering energy consumption

- Moisture resistance: Prevents damage from water infiltration, critical in humid or harsh climates

- Lightweight design that eases installation and reduces structural load

By selecting panel sandwich polyurethane for sale, you invest in a product that delivers both performance and longevity tailored for modern residential, commercial, and industrial buildings.

With Shanghe polyurethane sandwich panels, you get the right balance of strength, insulation, and cost-effectiveness designed for today’s construction demands.

Product Specifications of Panel Sandwich Polyurethane for Sale

Panel Dimensions and Thickness Options

Our polyurethane sandwich panels come in customizable sizes to fit various project needs:

- Length: Up to 12 feet (custom lengths available upon request)

- Width: Standard 36 inches (3 feet) per panel

- Thickness: Ranges from 1.5 inches to 4 inches, depending on insulation requirements

This flexibility allows use across roofing, wall cladding, and cold storage applications.

Core Material Properties

The core of each panel is high-density polyurethane (PU) foam, known for its outstanding thermal insulation. Key specs include:

- Density: 40 to 45 kg/m³ for optimal strength and insulation balance

- Thermal Conductivity: As low as 0.022 W/m·K, ensuring excellent heat retention

This delivers superior energy efficiency compared to other foam cores like EPS or PIR.

Outer Layer Materials and Finishes

The sandwich panels are encased in durable metal sheets with several options:

- Steel: Galvanized or pre-painted steel for corrosion resistance

- Aluminum: Lightweight, corrosion-proof alternative for specific environments

- Coatings: Polyurethane or PVDF finishes available in multiple colors for aesthetics and protection

- Surface texture: Smooth or embossed finishes depending on project design requirements

This combination enhances panel longevity and fits various architectural styles.

Weight per Panel

Polyurethane foam panels are lightweight, easing transportation and installation:

- Weight: Approximately 10 to 15 pounds per square foot, varying with thickness and outer material

This makes them ideal for structures needing strong yet light building materials.

Fire Resistance and Insulation Values

Our polyurethane sandwich panels meet robust safety standards:

- Fire Rating: Classified as Class B or better depending on panel configuration and coatings

- R-Value: Ranges from 7 to 18 per inch thickness, offering industry-leading insulation

- U-Value: As low as 0.18 Btu/hr·ft²·°F, minimizing energy loss

These ratings ensure compliance with US building codes and support energy-saving goals.

By combining customizable sizing, superior insulation core, durable metal layers, and certified fire resistance, Shanghe’s panel sandwich polyurethane for sale stands out as a high-performance solution tailored to US construction demands.

Product Benefits of Polyurethane Sandwich Panels for Sale

When you choose panel sandwich polyurethane for sale, you’re getting a product built to deliver real advantages for your project. Here’s what makes Shanghe polyurethane foam sandwich panels stand out:

Superior Thermal Insulation and Energy Efficiency

Our polyurethane core sandwich panels offer exceptional thermal insulation, helping maintain consistent indoor temperatures. This means lower heating and cooling costs—ideal for both homes and commercial spaces. The low thermal conductivity of the PU foam core boosts energy efficiency, making these insulated sandwich panels a smart choice for climate control.

Lightweight Yet Strong and Durable

Shanghe’s PU insulated wall panels balance being lightweight with impressive strength. This means easier handling during installation without compromising structural integrity. The sandwich construction ensures panels resist bending and impact, making them durable for long-term use in roofing or wall cladding.

Resistance to Moisture Corrosion and Pests

The polyurethane foam core inside the polyurethane sandwich panel for sale is closed-cell, meaning it won’t absorb water or support mold growth. This makes our panels highly resistant to moisture and corrosion. Additionally, the materials used deter pests such as termites, extending panel life especially in humid or rural environments.

Versatility Across Multiple Applications

Whether you need polyurethane roofing panels for residential buildings, insulated walls for cold storage units, or clean room panels for labs, our sandwich panels are highly adaptable. They work well in:

- Roofing and wall cladding

- Refrigerated warehouses and cold storage facilities

- Clean rooms and laboratories

- Industrial buildings and agricultural structures

Environmentally Friendly and Energy Saving Solution

Our panels promote sustainability by reducing building energy consumption. The thermal insulation panels with PU core lower carbon footprints tied to heating and cooling. Plus, they use eco-conscious materials with minimal environmental impact during production and disposal.

Choosing Shanghe’s prefabricated sandwich panels with polyurethane doesn’t just improve building performance—it also saves money over the lifetime of your facility, making them a reliable and affordable choice for U.S. customers.

Applications of Polyurethane Sandwich Panels for Sale

Our polyurethane sandwich panels offer versatile solutions across a wide range of industries. Thanks to their outstanding insulation and durability, these panels are ideal for:

Residential and Commercial Buildings

Perfect for energy-efficient homes and commercial spaces, these panels provide strong thermal insulation, helping reduce heating and cooling costs. They are lightweight and easy to install, making them a popular choice for modern construction and renovation projects.

Industrial Warehouses and Factories

In industrial settings, PU sandwich panels stand up to heavy use, maintaining structural integrity while offering excellent temperature control. They resist moisture, corrosion, and pests, ensuring long-lasting performance in warehouses and manufacturing plants.

Cold Storage Facilities and Refrigerated Units

Our panels are widely used in cold storage and refrigerated buildings because of their superior insulation properties. The polyurethane core offers an effective thermal barrier, critical for maintaining consistent low temperatures and energy efficiency. For more specialized insulation solutions, explore our cold room panels insulation solutions.

Agricultural Buildings

Agricultural structures benefit from the panels’ resistance to moisture and pests, vital for barns, storage sheds, and processing areas. Their lightweight design makes transportation and installation easy, even in remote locations.

Clean Rooms and Laboratories

In environments that require strict contamination control, such as clean rooms and labs, polyurethane foam sandwich panels provide airtight, easy-to-clean surfaces with excellent thermal insulation. Their non-toxic materials comply with health and safety standards important in these sectors.

Key Advantages for These Applications

- Energy saving: Exceptional insulation cuts utility bills.

- Durability: Resistant to weather, moisture, and pests.

- Lightweight: Easier installation reduces labor costs.

- Versatile finishes: Options like steel, aluminum, or special coatings fit your project needs.

For a closer look at other panel types, visit our prefab sandwich panel page to compare options and find the best fit for your project.

Ordering and Availability of Panel Sandwich Polyurethane for Sale

When you’re looking to buy panel sandwich polyurethane for sale, having clear ordering options and reliable availability is key. Here’s what you need to know about purchasing polyurethane foam sandwich panels from Shanghe.

Purchase Options and Minimum Order Quantities

- Flexible purchase options available to suit different project sizes—from small renovations to large-scale commercial builds.

- Minimum order quantities typically start at 50 square feet, but larger orders benefit from better pricing and priority production.

- We offer a variety of customization possibilities, including:

- Panel thickness ranging from 40mm to 150mm

- Different outer layer metals like steel or aluminum with various finishes

- Custom colors to match your design or branding needs

- Special core densities for unique insulation requirements

Stock Availability and Delivery Lead Times

- We maintain a steady inventory of standard-size PU sandwich panels for quick dispatch.

- For standard panels, delivery typically takes 1 to 2 weeks within the United States.

- Customized panels or bulk orders may require 3 to 6 weeks, depending on the specifications and current demand.

- Partner warehouses and local distributors help ensure faster access depending on your region.

Pricing Tiers Based on Volume Thickness and Finish Options

- Pricing varies based on panel thickness, with thicker panels carrying higher costs due to increased core material.

- Bulk orders unlock tiered discounts, making large volume purchases more cost-effective.

- Choice of outer metal—including galvanized steel, aluminum, or coated finishes—also influences pricing. Premium coatings with enhanced durability or color options cost slightly more but add value in longevity.

- Contact us for a detailed quote tailored to your project size, panel specifications, and delivery requirements.

Ordering polyurethane sandwich panels from Shanghe is straightforward and flexible. We cater to various project scales with options to customize dimensions, finishes, and insulation properties. Our solid stock and reliable delivery ensure you get your insulated sandwich panels promptly—ideal for roofing, wall cladding, and cold storage solutions. Reach out anytime for pricing or to discuss your specific needs.

Installation and Maintenance of Panel Sandwich Polyurethane for Sale

Basic Installation Guidelines for Polyurethane Sandwich Panels

Installing polyurethane foam sandwich panels from Shanghe is straightforward when following these guidelines:

- Compatible Framing: Use steel or aluminum frames designed to support sandwich panels. Ensure the frame is level and properly aligned to avoid panel stress.

- Fixing Methods: Secure panels with self-drilling screws or concealed fasteners recommended by Shanghe to maintain panel integrity and weather tightness.

- Sealing: Apply weatherproof sealants at panel joints and edges to prevent moisture infiltration and air leaks.

- Handling: Handle panels carefully to avoid damage to the polyurethane core or outer metal layers. Use lifting equipment if panels are large or heavy.

For more details on fixing methods and framing compatibility, see our metal sandwich panel guide.

Maintenance Tips to Prolong Panel Life and Performance

To keep your PU polyurethane sandwich panels in prime condition and maximize their thermal insulation and durability:

- Regular Cleaning: Use mild detergent and water to clean the surface. Avoid abrasive cleaners or harsh chemicals that can damage coatings.

- Inspect Seals: Check panel seals and joints quarterly to ensure no gaps or wear have developed.

- Repair Minor Damage: Small dents or scratches should be repaired promptly using recommended touch-up coatings to prevent corrosion.

- Avoid Impact: Protect panels from heavy impact or sharp objects that could compromise the polyurethane core or metal faces.

Warranty and Service Information by Shanghe

Shanghe stands behind its polyurethane sandwich panels with comprehensive warranty and service commitments:

- Warranty Coverage: Typically includes protection against core delamination, metal coating failures, and insulation performance for up to 10 years depending on panel type and application.

- Customer Support: Dedicated technical support teams assist with installation, maintenance, and troubleshooting to ensure panels perform as expected.

- After-Sales Service: Options for replacement panels, repair services, and custom advice tailored to your project needs.

For exact warranty terms tied to your panel purchase, contact Shanghe sales or visit the support section on our site.

Following these installation and maintenance best practices ensures your Shanghe panel sandwich polyurethane for sale remains energy-efficient, durable, and a cost-effective building solution for years to come.

Why Choose Shanghe Polyurethane Sandwich Panels for Sale

When you’re looking for panel sandwich polyurethane for sale, Shanghe stands out as a top choice in the U.S. market. Here’s why:

Proven Quality Assurance and Certifications

At Shanghe, quality is non-negotiable. Our polyurethane foam sandwich panels undergo strict quality control and meet recognized industry standards, including fire resistance and thermal insulation certifications. This ensures each panel delivers consistent performance for your projects, whether roofing, walls, or cold storage.

Expertise and Experience You Can Trust

With years of experience manufacturing PU insulated wall panels, Shanghe has mastered the art of blending superior materials with advanced production techniques. Our panels are designed to provide excellent energy efficiency, durability, and lightweight strength tailor-made for American construction needs.

Reliable Customer Support and After-Sales Service

Buying from Shanghe means more than just quality panels. We provide responsive customer service from ordering to installation support and beyond. Whether you need help choosing the right polyurethane core sandwich panels or advice on maintenance to extend panel life, our team is ready to assist.

Real Results from Satisfied Customers

Many businesses and builders nationwide rely on Shanghe’s prefabricated sandwich panels with polyurethane. Our case studies show projects benefiting from improved climate control, lower energy costs, and fast installation times, making us a trusted partner in insulated building solutions.

Choose Shanghe for your next project and experience the difference in quality, service, and performance with our premium polyurethane foam sandwich panels for sale.

Frequently Asked Questions About Panel Sandwich Polyurethane for Sale

How Durable Are Polyurethane Foam Sandwich Panels

Our polyurethane sandwich panels are designed for long-lasting performance. The PU core provides excellent resistance against moisture, pests, and corrosion, ensuring panels maintain strength over time. These panels hold up well under various weather conditions, making them ideal for both interior and exterior uses.

How Effective Are Polyurethane Core Sandwich Panels for Insulation

These panels offer superior thermal insulation thanks to the low thermal conductivity of polyurethane foam. This helps keep buildings energy-efficient by reducing heating and cooling costs. The insulation values (R-value and U-value) meet or exceed industry standards, offering reliable climate control.

What Are the Shipping and Return Policies for Polyurethane Sandwich Panels

- Shipping: We ship across the U.S. with estimated delivery times based on location and order size. Panels are carefully packaged to avoid damage during transit.

- Returns: Returns are accepted on defective or damaged panels within a limited period. Custom orders or made-to-spec panels may have specific return restrictions, so please check before purchase.

Can I Customize Polyurethane Sandwich Panels

Yes, our PU insulated wall panels and roofing panels come with customizable options including:

- Panel thickness

- Core density

- Outer sheet metal type and color finish

- Dimensions tailored to your project needs

We work with clients to ensure panels meet specific performance or aesthetic requirements.

Are Polyurethane Composite Panels Suitable for Cold Storage

Absolutely. The prefabricated sandwich panels with polyurethane cores are widely used in refrigerated units and cold storage facilities because of their excellent insulation and moisture resistance, which helps maintain stable internal temperatures.

How Can I Be Sure of Fire Safety Ratings

Our panels comply with standard fire resistance ratings applicable to commercial and industrial buildings. The outer layers and core materials are tested to reduce flame spread and provide safe performance under fire conditions.

If you have more questions about ordering, installation, or specifications for polyurethane foam sandwich panels for sale, our support team is ready to help. Contact us anytime for tailored advice or a project consultation.

Contact and Support for Panel Sandwich Polyurethane for Sale

If you’re interested in panel sandwich polyurethane for sale, getting in touch with us is straightforward. We provide professional support to help you find the right polyurethane foam sandwich panels or PU insulated wall panels to fit your project needs.

How to Reach Us

- Sales Inquiries: For pricing, product specifications, or custom orders, contact our sales team directly via email or phone. We’re here to guide you through choosing the correct polyester core sandwich panels and answer any technical questions.

- Request a Quote or Sample: Interested in reviewing product samples or getting a detailed quote? Submit a request through our website or contact your local distributor. We offer samples of polyurethane roofing panels and prefabricated sandwich panels with polyurethane to help you make an informed decision.

- Local Distributors and Warehouses: To ensure fast delivery across the U.S., we maintain partnerships with trusted warehouses and distributors nationwide. This means shorter lead times for insulated sandwich panels for sale and easier logistics no matter where your project is located.

Why Contact Us

- Expert Advice: We understand the U.S. market demands and can recommend the best PU sandwich panel price options based on your requirements.

- Customization Support: Need specific thickness, color, or metal coating finishes? Our team helps you customize your order to match project conditions.

- After-Sales Service: Beyond purchase, we provide ongoing support to keep your polyurethane foam sandwich panels performing well, including warranty assistance.

Make it simple to get top-quality polyurethane sandwich panel for sale with direct access to reliable contacts and support throughout your buying process. Reach out today to discuss your needs and experience our professional service firsthand.

What Are Polyurethane Sandwich Panels

Polyurethane sandwich panels are prefabricated construction materials made by bonding two metal sheets with a rigid polyurethane foam core in between. This core acts as an excellent thermal insulation layer, providing strength, durability, and energy efficiency to buildings. The outer layers are usually steel or aluminum, coated to protect against corrosion and weather damage.

Composition and Structure

- Core: High-density polyurethane foam (PU) – known for its superior insulation properties, low thermal conductivity, and lightweight nature.

- Outer Layers: Typically galvanized steel or aluminum sheets with protective coatings and color finishes tailored for aesthetic and durability.

- Bonding: The foam core is securely laminated between metal sheets, creating a strong, rigid panel structure.

Comparison With Other Sandwich Panel Types

| Feature | Polyurethane (PU) | Polyisocyanurate (PIR) | Expanded Polystyrene (EPS) |

|---|

| Insulation Efficiency | Excellent thermal resistance (low thermal conductivity) | Slightly better heat resistance than PU | Moderate insulation, higher conductivity than PU and PIR |

| Fire Resistance | Good, often meets fire codes with additives | Generally higher fire resistance than PU | Poor fire resistance without treatment |

| Density | Medium density, lightweight | Similar to PU but slightly denser | Lower density, lightweight |

| Moisture Resistance | High moisture resistance | Good but less than PU | Less resistant, susceptible to water absorption |

| Cost | Mid-range cost | Higher cost due to enhanced properties | Lower cost, budget-friendly |

| Use Cases | Roofing, walls, cold storage, clean rooms | Fire-sensitive areas, commercial projects | Budget projects, moderate insulation needs |

Why Choose Polyurethane Foam Sandwich Panels

- Superior insulation and energy efficiency reduce heating and cooling costs.

- Lightweight yet strong, making installation easier and reducing structural load.

- Highly resistant to moisture, pests, and corrosion, extending panel lifespan.

- Suitable for a wide range of applications from commercial buildings to cold storage units.

For detailed product options, check Shanghe’s insulated sandwich panels here.

polyurethane sandwich panels strike the right balance of performance, durability, and cost, making them the ideal choice over other core materials like PIR and EPS for many building projects across the United States.

Key Features of Shanghe Polyurethane Sandwich Panels

Superior Thermal Performance and Energy Savings

Shanghe polyurethane sandwich panels are designed with a high-quality polyurethane core that offers excellent insulation. This core has a low thermal conductivity, which means it effectively minimizes heat transfer. For U.S. customers, this translates to lower energy bills by maintaining consistent indoor temperatures, whether for residential, commercial, or industrial spaces. The panels help reduce reliance on heating and cooling systems, making them an energy-efficient choice for climate control.

Lightweight yet Strong and Durable

One major advantage of Shanghe’s panels is their lightweight construction. Despite being light, the sandwich panel’s polyurethane foam core combined with tough outer metal sheets (steel or aluminum) provides impressive structural strength and durability. This makes installation quicker and easier while offering reliable long-term performance. These panels resist warping and maintain integrity under stress, ideal for various climates and building types across the U.S.

Fire Resistance and Safety Compliance

Safety is a top priority with building materials, especially in the U.S. Shanghe’s PU polyurethane sandwich panels for sale meet stringent fire resistance standards. The panels typically feature fire-retardant cores and metal facings that improve flame resistance and slow fire spread, providing crucial extra time in emergencies. This makes them suitable for commercial buildings, warehouses, and public facilities where fire safety compliance is required by building codes.

Additional Highlights

- Moisture and Pest Resistance: The dense PU core stops moisture absorption and blocks pests, reducing maintenance and extending panel life.

- Versatile Finishes: Available in various colors and coated metals to match aesthetic and functional needs.

- High R-Value and Low U-Value: Ensures better insulation compared to traditional sandwich panels with EPS or polyiso cores.

Choosing Shanghe polyurethane foam sandwich panels means investing in panels that combine energy savings, strength, and safety, fitting perfectly with the demands of modern U.S. construction projects.

Technical Specifications and Sizes Available for Panel Sandwich Polyurethane for Sale

When you’re looking for panel sandwich polyurethane for sale, knowing the exact specifications helps you pick the right fit for your project. Here’s a detailed breakdown of what Shanghe offers in terms of size, core density, and surface options.

Standard Thickness and Customization Options

- Thickness range: 40mm to 200mm

We provide a wide variety of thicknesses depending on your insulation needs. Standard sizes like 50mm, 75mm, 100mm, and 150mm are popular for roofing and walls, but custom thickness can be made on request. - Custom sizing: Lengths up to 12 meters available

Need a longer panel? We can cut panels to meet custom lengths, reducing on-site waste and installation time.

Core Density and Insulation Ratings

- Polyurethane foam core density: Typically ranges from 38 to 45 kg/m³

Our PU sandwich panels feature high-density polyurethane foam for superior strength and insulation. - Thermal conductivity: Around 0.022 W/m·K

This low thermal conductivity means excellent energy efficiency and thermal insulation, helping cut down HVAC costs. - Insulation values:

- R-value: Up to R-7.1 per inch thickness

- U-value: As low as 0.14 W/m²·K depending on panel thickness

These values make polyurethane core sandwich panels ideal for climates requiring tight temperature control.

Outer Metal Sheet Details Coatings Color Options

- Outer layers:

- Galvanized steel (G550)

- Aluminum sheets

- Option for stainless steel on request

- Surface coatings:

- Polyester (PE) coatings – standard, affordable, and reliable

- Polyvinylidene fluoride (PVDF) – superior weather resistance and color retention

- Silicon-modified polyester (SMP) for extra durability

- Finishes available: Smooth, stucco embossed, or granular texture to fit both aesthetic and functional needs

- Color options: Wide RAL color spectrum available for customization to match building design and branding

Weight Per Panel

- Depends on thickness and metal type but usually ranges from 10 to 15 lbs per square foot, making it lightweight for easier handling and installation without compromising strength.

By selecting the right thickness, core density, and surface finish, polyurethane sandwich panels from Shanghe provide reliable performance, durability, and energy savings tailored to your project needs. Reach out to us for personalized recommendations or specific requirements.

Benefits of Using Polyurethane Panels in Construction

When it comes to panel sandwich polyurethane for sale, these panels offer clear advantages that make them a smart choice for contractors and builders across the United States.