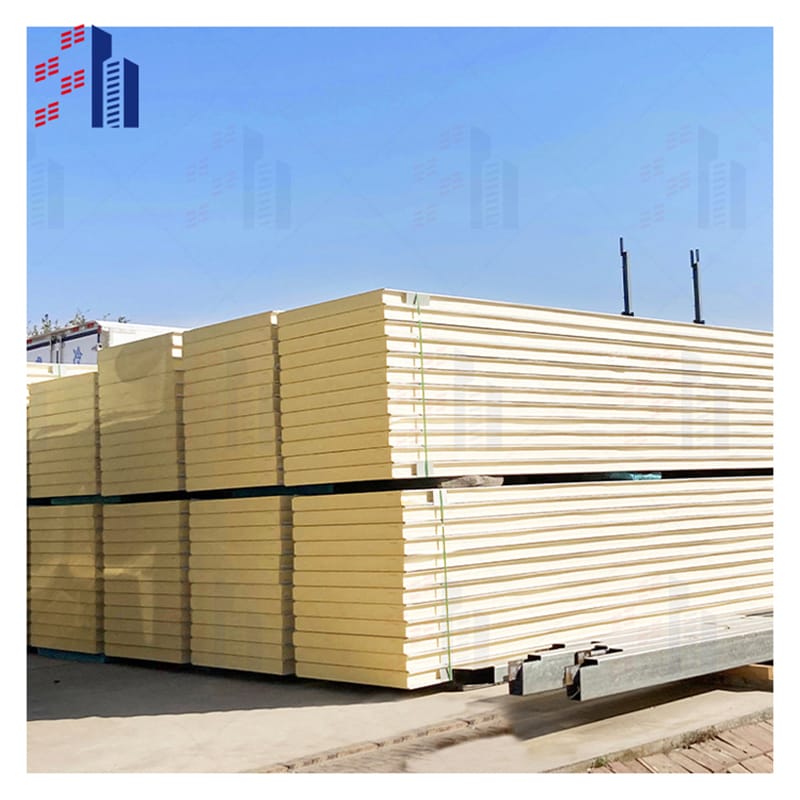

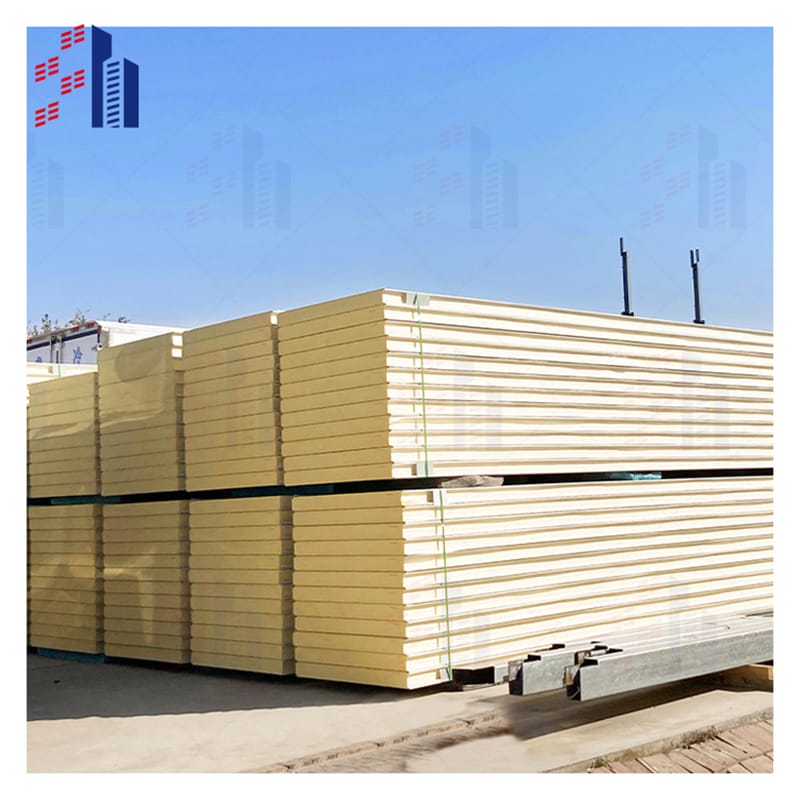

Product Overview of Polyurethane Foam Sandwich Panels

Polyurethane foam sandwich panels are a top choice for construction and insulation needs across industries. These panels combine high performance with lightweight design, making them ideal for projects that demand strength without added bulk.

At their core, these panels feature a rigid polyurethane (PU) foam core known for its excellent thermal insulation properties. This core is securely bonded between two durable outer facings, which are typically made from galvanized steel, aluminum, stainless steel, or coated steel. This sandwich structure not only enhances the mechanical strength but also provides a smooth, protective surface suited for different environments.

The main advantage of polyurethane foam sandwich panels lies in their outstanding insulation capabilities paired with superior strength and light weight. This means you get easy-to-install panels that reduce overall building weight, improve energy efficiency, and maintain durability in a variety of climate conditions. Whether you’re insulating cold storage facilities, commercial buildings, or industrial warehouses, these panels deliver consistent performance while helping reduce energy costs.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Product Features and Benefits of Polyurethane Foam Sandwich Panels

High Thermal Insulation and Low Thermal Conductivity

Polyurethane foam sandwich panels deliver excellent thermal insulation, thanks to their PU foam core with very low thermal conductivity values (around 0.022 W/mK). This means they effectively reduce heat transfer, helping maintain consistent indoor temperatures and significantly cutting down energy costs in heating and cooling.

Superior Strength to Weight Ratio

Despite being lightweight, these PU foam sandwich panels provide exceptional strength. The combination of a rigid polyurethane core with sturdy outer facings like galvanized steel or aluminum offers high compressive and flexural strength, making the panels durable and able to withstand demanding structural loads.

Fire Retardant and Safety Certifications

Safety is a top priority. Many polyurethane foam sandwich panels come with fire retardant properties and meet key standards such as UL and ASTM fire ratings. These certifications ensure they perform reliably under fire exposure, making them suitable for commercial and industrial applications requiring strict safety compliance.

Moisture Resistance and Durability

Polyurethane foam core is naturally resistant to moisture and mold, which prevents panel degradation over time. The outer facings are also designed to withstand harsh environmental conditions, providing long-term durability and maintaining panel integrity in humid or wet settings.

Easy and Fast Installation Process

Our PU sandwich panels are designed for quick and straightforward installation. Lightweight panels with tongue-and-groove or shiplap joints speed up assembly and reduce labor time on site. This efficiency lowers project costs and minimizes downtime during construction.

Eco Friendly and Energy Efficient

Polyurethane foam is a highly energy-efficient insulation material helping reduce building energy consumption. Additionally, many panels are produced with environmentally responsible methods and contain no harmful CFCs or HCFCs, aligning with green building standards.

Long Service Life and Low Maintenance

Thanks to their robust construction and resistance to environmental factors, these sandwich panels offer a long service life with minimal maintenance needs. This durability translates to lower lifecycle costs and reliable performance over the years, making them a smart investment for U.S. customers looking for value and sustainability.

By focusing on these features, polyurethane foam sandwich panels stand out as a premium choice for insulation and structural needs across many industries in the United States.

Technical Specifications of Polyurethane Foam Sandwich Panels

Our polyurethane foam sandwich panels are designed to meet diverse construction needs across the U.S., blending superior insulation with structural strength. Here’s a clear breakdown of their key technical features:

Core Material and Density Options

- Core: High-quality polyurethane (PU) foam forms the core, known for its excellent thermal insulation.

- Density: Available densities range from 30 kg/m³ up to 45 kg/m³, allowing for options tailored to insulation and load requirements.

- Thickness: Core thickness varies from 30mm to 150mm, offering flexibility depending on the insulation needs of your project.

Facing Materials

- Galvanized Steel: Durable and cost-effective, ideal for general industrial and commercial use.

- Aluminum: Lightweight and corrosion-resistant, perfect for harsher environments or where weight reduction is critical.

- Stainless Steel: Provides superior corrosion resistance, often chosen for food processing or pharmaceutical facilities.

- Coated Steel: Steel panels coated with special finishes improve durability and aesthetic appeal, suitable for outdoor or harsh weather conditions.

Panel Thickness and Sizes

- Total Thickness: The complete sandwich panel thickness ranges from 30mm to 150mm, combining core and facing layers.

- Standard Width: Usually around 1,000mm to 1,200mm wide to fit common structural framing in the U.S. market.

- Length: Customizable in most cases to meet your project’s specific dimension needs.

Thermal Performance

- Thermal Conductivity: Our PU foam core provides an outstanding low thermal conductivity rate, typically around 0.022 W/mK, delivering exceptional energy efficiency and thermal insulation.

Mechanical Properties

- Compressive Strength: PU foam core panels support heavy loads, with compressive strength generally in the range of 100 to 200 kPa, providing structural reliability.

- Flexural Strength: The combination of facing materials and foam core offers robust flexural strength, ideal for wall and roof applications where resistance to bending is important.

Fire Ratings and Certifications

- Panels comply with key safety standards including UL 1715, ASTM E84, and other relevant fire retardant certifications, making them safe for use in commercial buildings and regulated facilities.

- Fire retardant sandwich panels options are available to meet strict code requirements.

Customization and Standard Sizes

- We offer both standard size options ready for immediate supply and custom dimensions tailored to project specifications, ensuring you get exactly what your build demands.

This combination of materials and properties makes our PU foam sandwich panels a smart choice for anyone in the U.S. needing lightweight, strong, and energy-efficient insulated panels fit for a wide range of industries.

Applications of Polyurethane Foam Sandwich Panels

Polyurethane foam sandwich panels are a versatile choice for many construction and insulation needs across industries in the United States. Their combination of lightweight structure, high thermal insulation, and durability makes them ideal for various settings where performance and energy efficiency matter.

Industrial Cold Storage and Refrigerated Rooms

These panels are widely used in cold storage facilities and refrigerated rooms due to their excellent thermal insulation properties. The PU foam core limits heat transfer, helping maintain consistent low temperatures, which is critical for food preservation and pharmaceutical storage. Their moisture resistance also prevents condensation and mold growth, extending the life of the structure.

Commercial and Residential Insulation

Polyurethane foam core panels provide superior energy efficiency in commercial buildings and homes. They help reduce heating and cooling costs by maintaining stable indoor temperatures. These panels are suitable for walls, ceilings, and roofing, delivering easy installation with minimal maintenance over the years.

Clean Rooms and Pharmaceutical Facilities

The need for stringent hygienic conditions and controlled environments in clean rooms and pharmaceutical plants suits the non-porous, fire retardant, and easy-to-clean surfaces of PU foam sandwich panels. Their structure supports airtight construction, minimizing contamination risks and supporting strict regulatory compliance.

Warehouses and Logistics Centers

In storage and logistics facilities, these panels offer quick assembly and durable wall and roof protection. Their strength-to-weight ratio allows for large spans and wide coverage without heavy structural support, enhancing both safety and efficiency in warehouse setups.

Roof and Wall Cladding for Industrial Buildings

Polyurethane foam sandwich panels are favored for industrial roofing and wall cladding because they provide strong weather resistance and good sound insulation. Plus, their fire safety ratings meet strict industrial codes, ensuring protection against unforeseen hazards.

Food Processing Plants and HVAC Systems

The panels’ thermal and moisture resistance play a critical role in food processing environments where temperature control is mandatory. They are also used in HVAC system enclosures for their insulating capacity, which improves system efficiency and reduces energy costs.

In , polyurethane foam sandwich panels make an excellent insulating and structural choice across cold storage, commercial and residential builds, clean facilities, and industrial applications, thanks to their unmatched balance of strength, thermal efficiency, and longevity.

Installation and Handling of Polyurethane Foam Sandwich Panels

Recommended Installation Procedures for PU Foam Sandwich Panels

Proper installation of polyurethane foam sandwich panels ensures maximum performance and durability. Start by preparing a clean, level surface to support the panels. Align the panels carefully before fastening to maintain straight lines and avoid gaps. Use compatible sealants to secure joints, enhancing thermal insulation and moisture resistance.

- Install panels with the foam core vertical to reduce stress on joints.

- Overlap joints where possible and seal with high-quality tape or foam to ensure airtightness.

- Follow manufacturer guidelines for fastener spacing to avoid panel deformation.

Fixing and Joining Methods for PU Sandwich Panels

Fixing and joining PU sandwich panels correctly is key for structural integrity and insulation.

- Utilize self-drilling screws with rubber washers to prevent moisture infiltration.

- Employ metal or plastic joining strips depending on the panel facing material.

- Use urethane or silicone-based sealants in all seams to maintain a continuous insulation barrier.

- For roof installations, consider specialized ridge and edge trims designed to handle expansion and contraction.

Handling and Storage Guidelines

Handling and storing polyurethane foam core panels appropriately preserve their quality and make installation smoother.

- Handle panels with care to prevent dents or damage to the facings.

- Store panels flat on level ground in a dry, covered area away from direct sunlight.

- Avoid exposure to heavy winds or moisture to prevent warping or core water absorption.

- Use protective gloves and equipment when moving panels to avoid scratches.

Maintenance Tips for Long-Term Performance

Routine maintenance extends the life of polyurethane foam sandwich panels and keeps them in top shape.

- Inspect panels periodically for signs of damage, especially after storms or heavy winds.

- Clean facings with mild detergent and water, avoiding abrasive cleaners.

- Check sealants and joints annually, resealing if cracks or gaps appear.

- Address any corrosion on metal facings promptly to prevent spread.

Following these detailed installation and handling practices ensures you get the best out of your polyurethane foam sandwich panels in terms of strength, insulation, and durability.

For more information on related panels and installation options, check out our thermal insulation sandwich panel and foam core sandwich panels pages.

Comparison of Polyurethane Foam Sandwich Panels with Alternatives

When choosing insulated sandwich panels for your project, understanding how polyurethane foam sandwich panels stack up against other options like PIR and EPS panels is crucial. Here’s a straightforward look at their key differences and advantages.

Polyurethane Foam Sandwich Panels vs PIR Panels

Thermal Performance

Both polyurethane (PU) and polyisocyanurate (PIR) foam cores offer excellent insulation. PU panels typically have a thermal conductivity around 0.022 W/mK, which is slightly better or on par with PIR’s insulation values. This means PU panels deliver superior energy efficiency, helping lower heating and cooling costs.

Fire Resistance

PIR foam boasts enhanced fire resistance due to its chemical structure, often achieving higher fire ratings. However, modern fire retardant polyurethane foam sandwich panels come with improved additives and meet rigorous safety standards (UL, ASTM), making them sufficiently safe for many industrial and commercial applications.

Cost and Availability

PU panels are generally more cost-effective than PIR. They provide a great balance of price and performance, making them attractive for large-scale or budget-conscious projects without severely compromising on fire safety or insulation quality.

Advantages Over EPS Foam Panels

Strength and Durability

Compared to EPS (expanded polystyrene) foam panels, polyurethane foam panels have a higher compressive strength and better resistance to moisture and chemicals. This makes PU sandwich panels more durable and longer-lasting in demanding environments.

Thermal Insulation

PU foam typically outperforms EPS foam in thermal insulation, as it has a lower thermal conductivity value. This translates to better energy savings and thinner panels to achieve the same R-value.

Fire Performance

EPS is more flammable and less fire-resistant than polyurethane foam. PU sandwich panels often come with fire retardant grades, significantly improving building safety.

Cost Effectiveness and Performance

| Feature | Polyurethane Foam Panels | PIR Panels | EPS Panels |

|---|

| Thermal Conductivity | ~0.022 W/mK | ~0.021-0.023 W/mK | ~0.030-0.040 W/mK |

| Fire Resistance | Good (with retardants) | Superior | Poor |

| Compressive Strength | High | High | Moderate |

| Moisture Resistance | Excellent | Good | Lower |

| Cost | Moderate (Best value) | Higher | Low |

| Durability | Long-lasting | Long-lasting | Moderate |

In short: Polyurethane foam sandwich panels strike a solid balance between cost, performance, and safety, making them the preferred choice for many US construction, cold storage, and industrial projects. They offer better insulation and durability than EPS panels and a more budget-friendly solution compared to PIR while meeting high standards for fire safety and mechanical strength.

Certifications and Quality Assurance for Polyurethane Foam Sandwich Panels

When choosing polyurethane foam sandwich panels, knowing they meet strict industry standards is crucial for your peace of mind and project success.

Industry Standards Met

Our PU foam sandwich panels comply with key international certifications, including:

- ISO standards ensuring consistent manufacturing quality

- ASTM certifications covering material strength, fire resistance, and insulation properties

- CE marking for safety, health, and environmental protection compliance within the U.S. and globally

These certifications confirm the panels deliver high thermal efficiency, fire retardancy, and durability you can count on.

Quality Control Process at Shanghe

At our polyurethane sandwich panel factory, quality is a top priority. We apply a rigorous quality control process that includes:

- Incoming raw material inspection to verify density and chemical composition of PU foam

- Continuous monitoring during production ensuring consistent foam core density and panel flatness

- Testing of outer facings like galvanized steel or aluminum for coating adhesion and corrosion resistance

- Final batch testing for mechanical strength, fire safety, and thermal conductivity results

This thorough process guarantees every panel leaving Shanghe matches the highest standards in the industry.

Warranty and After-Sales Support

We back our polyurethane foam core panels with a comprehensive warranty that covers:

- Manufacturing defects

- Panel performance related to insulation values and structural integrity

- Resistance to moisture and environmental wear

Our dedicated after-sales team is ready to support you with installation guidance, troubleshooting, and replacement panels if needed. This strong support network ensures your investment in our insulated sandwich panels is protected over the long term.

With certified quality and reliable support, our PU sandwich panels for construction offer trusted performance designed to meet the demands of the U.S. market — durable, safe, and energy efficient.

Ordering Information and Customization for Polyurethane Foam Sandwich Panels

When it comes to ordering polyurethane foam sandwich panels, we offer a range of standard sizes and thicknesses to fit your project needs. Whether you’re working on insulation for industrial cold storage or residential walls, you’ll find options tailored for performance and ease.

Standard Sizes and Thickness Options

- Panel Thickness: Typically ranges from 30mm to 150mm, allowing you to select the right insulation level.

- Standard Dimensions: Panels commonly come in widths of 1,000mm or 1,200mm and lengths up to 12,000mm, but can be adjusted depending on your requirements.

- PU Foam Density: Options vary based on strength and insulation needs, usually between 35 to 45 kg/m³.

Custom Panel Design Capabilities

We understand that every project is unique. That’s why we provide customized polyurethane foam core panels with choices in:

- Facing Materials: Galvanized steel, aluminum, stainless steel, or coated steel facings can be tailored for your environment.

- Panel Dimensions: Length, width, and thickness can be customized to fit specific architectural or functional demands.

- Special Features: Fire retardant coatings, extra moisture resistance, or enhanced structural support to meet specialized applications.

Lead Time and Delivery Details

- Production Lead Time: Typically ranges between 2 to 4 weeks, depending on the size and customization level.

- Shipping: We offer reliable delivery across the U.S., with careful packaging to protect panels during transit.

- Bulk Orders: Discounts and priority scheduling are available for large volume purchases or repeat orders.

Contact for Quotations or Samples

For precise pricing, availability, and technical support, reach out to our dedicated sales team. We provide:

- Free Samples: To help you verify panel quality and performance before committing.

- Detailed Quotes: Based on your application needs and dimensions.

- Consultation: Guidance from experts on panel selection, installation, and maintenance.

Get in touch today to discuss your project needs and receive a tailored proposal for your polyurethane foam sandwich panel requirements.

Frequently Asked Questions about Polyurethane Foam Sandwich Panels

What makes polyurethane foam sandwich panels a good choice for insulation

Polyurethane foam core offers excellent thermal insulation due to its very low thermal conductivity (around 0.022 W/mK). This means better energy efficiency and lower heating or cooling costs for buildings using PU foam sandwich panels.

How durable are these sandwich panels

Polyurethane foam sandwich panels are highly durable. The foam core resists moisture and degradation, while the outer facings (galvanized steel, aluminum, or coated steel) protect against physical damage and weather. With proper installation, these panels can last for decades with minimal maintenance.

Are polyurethane foam sandwich panels fire resistant

Most panels come with fire retardant properties meeting UL and ASTM standards. While the core is combustible, the panels are usually treated to slow flame spread and meet safety codes for many commercial and industrial applications.

What are typical thickness and size options

PU foam sandwich panels are available in thicknesses from 30mm up to 150mm or more, depending on insulation needs. Standard sizes are offered, but custom dimensions can be made to fit any project requirement.

Can these panels be used for cold storage

Absolutely. Polyurethane foam sandwich panels are a top choice for industrial cold storage and refrigerated rooms because they provide strong insulation and moisture resistance critical for maintaining low temperatures.

How easy is the installation process

These panels are designed for quick assembly using standard fixing and joining methods. Their lightweight nature makes handling easier and reduces installation time compared to heavier alternatives.

How do polyurethane foam sandwich panels compare to PIR or EPS panels

PU foam panels typically offer better insulation with slightly higher compressive strength than EPS panels. Compared to PIR, they are competitively priced while still providing strong insulation and durability, making them a popular option in the US market.

Are polyurethane foam sandwich panels eco friendly

Polyurethane foam panels can be environmentally friendly when manufactured responsibly. They help reduce energy consumption due to high insulation performance and have a long service life, which cuts down on waste.

How should these panels be stored before installation

Store panels in a dry and shaded area to protect the foam core and facing materials from direct sunlight and moisture. Avoid stacking heavy objects on top to prevent deformation.

If you have more questions about polyurethane foam sandwich panels, feel free to reach out for detailed specifications and installation guidance tailored to your project.