Polyurethane Sandwich Panel Procurement Product Introduction

Polyurethane Sandwich Panel Procurement are advanced building materials composed of a rigid polyurethane foam core layered between two durable metal facings, such as galvanized steel or aluminum. This structure combines the best features of insulation and strength, resulting in panels that perform exceptionally across various construction and industrial applications.

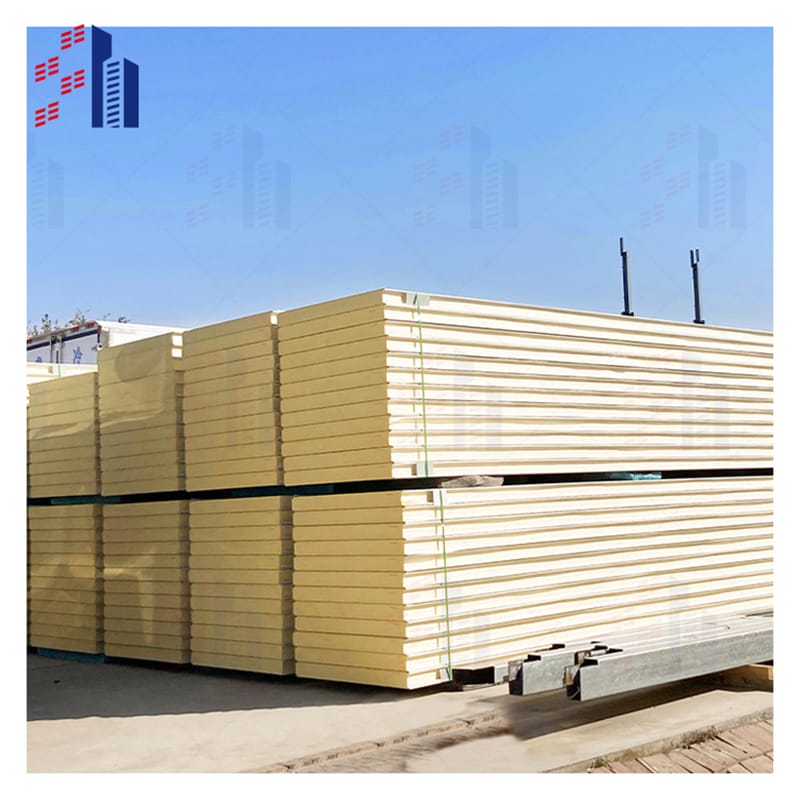

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Core Benefits of Polyurethane Sandwich Panels

Superior Thermal Insulation

Polyurethane foam offers low thermal conductivity, delivering excellent energy efficiency. These panels help maintain stable interior temperatures, reducing heating and cooling costs, making them ideal for environments requiring strict climate control.

High Structural Strength

Despite their lightweight, the composite build provides significant mechanical strength and resistance to impact, load-bearing, and harsh weather conditions. This makes them suitable for roofing, walls, and structural panels where durability is critical.

Lightweight Design

Easier to handle and quicker to install compared to traditional materials, polyurethane sandwich panels reduce labor costs and time. Their lightweight nature also lowers transportation expenses and structural load requirements.

Typical Applications of Polyurethane Sandwich Panels

Cold Storage Warehouses

Their superior insulation properties make these panels the preferred choice for temperature-controlled facilities that require minimal heat transfer and tight sealing.

Clean Rooms

Polyurethane panels support contamination control and temperature regulation in pharmaceutical, electronics, and food processing industries.

Prefabricated Buildings

Ideal for modular construction due to ease of installation, standardized sizes, and customization options.

Industrial Roofing and Walls

Provide long-lasting protection with energy efficiency benefits, suitable for factories, warehouses, and commercial complexes.

For those interested in exploring other foam-based solutions, you may also want to review our foam sandwich building panels offering at Shanghe.

Polyurethane sandwich panels represent a high-performance, cost-effective option for the US market, combining energy efficiency, structural integrity, and ease of installation to meet diverse construction and insulation needs.

Polyurethane Sandwich Panel Specifications

When choosing polyurethane sandwich panels, understanding the core specs is key to finding the right fit for your project. Here’s a detailed look at the main product specifications that matter.

Panel Core Material

- High-density polyurethane foam is used as the core. This foam offers excellent thermal insulation and structural strength while remaining lightweight.

- The PU foam core typically ranges in density to meet different insulation and strength needs depending on application.

Outer and Inner Layering Options

- The sandwich panel’s surface layers are available in galvanized steel, aluminum, or other metal facings.

- These metal facings provide durability, corrosion resistance, and impact protection.

- Custom coatings can be applied for enhanced weather resistance or aesthetic requirements.

Thickness and Size Options

- Thicknesses vary from 30mm to 200mm, allowing you to balance insulation performance with structural requirements.

- Standard panel widths and lengths are offered, but custom sizes and dimensions can be manufactured to fit specific designs.

- This flexibility makes these panels suitable for various applications like cold storage, clean rooms, and prefabricated buildings.

Thermal Performance Values

- The thermal conductivity (λ value) of the polyurethane foam core typically ranges between 0.019 to 0.024 W/m·K, delivering superior insulation.

- This translates into high R-values, which measure thermal resistance, helping reduce energy costs and maintain temperature control.

- Accurate thermal values ensure compliance with energy efficiency standards important for US construction projects.

Fire Resistance Ratings

- Fire safety is a critical factor. These panels meet multiple fire resistance ratings depending on core composition and facings.

- Common certifications include compliance with ASTM E84 (surface burning characteristics) and other relevant fire codes.

- Fire-retardant treatments and coatings are available as custom options for higher protection levels.

By focusing on these polyurethane sandwich panel specifications, you get a product that combines top-notch insulation, structural strength, and customizable options, ready to meet the demands of US-based construction, cold storage, and industrial projects.

Procurement Solutions by Shanghe for Polyurethane Sandwich Panel Procurement

When it comes to polyurethane sandwich panel procurement, Shanghe stands out with its strong manufacturing capabilities and strict quality standards. We focus on delivering panels that meet the highest expectations for thermal insulation sandwich panels and structural performance, suitable for a wide range of applications across the U.S. market.

Manufacturing Capabilities and Quality Standards

Shanghe uses advanced production lines that ensure consistent density and foam integrity in our polyurethane foam sandwich panels. Every panel undergoes rigorous testing to comply with international standards such as ISO, ASTM, and CE certifications. This means you get panels that offer reliable fire resistance, thermal insulation (with reliable R-values and λ-values), and long-lasting durability.

Supply Chain and Logistics

We offer flexible supply chain solutions tailored to your location. Whether you need local delivery within the United States or global logistics for large projects, Shanghe has the infrastructure to ensure timely shipping and secure handling. Our logistics network supports fast turnaround times, reducing lead time wherever possible.

Minimum Order Quantity and Lead Times

Understanding project demands, Shanghe provides reasonable MOQ (Minimum Order Quantity) options, making it easy for small-scale and large projects alike to procure polyurethane insulated sandwich panels. Typical lead times range from 2 to 6 weeks depending on your order size and customization requirements—enabling you to plan effectively without delays.

Customization Services

We know every project is unique, so we offer full customization services:

- Panel sizes and thicknesses customized from 30mm up to 200mm or beyond

- Variety of metal facings including galvanized steel, aluminum, and other options for walls and roofing

- Choice of colors and surface coatings to match project aesthetics and performance needs

- Advanced fire retardant treatments compliant with U.S. building codes and safety standards

Certification Compliance and Industry Standards

Shanghe’s panels meet and often exceed the key certifications you rely on, including:

- ISO 9001 for quality management system

- ASTM E84 for fire safety classification

- CE marking when applicable, ensuring compliance with regional regulations

Our commitment to these standards ensures safer, more efficient procurement for your commercial, industrial, or residential projects.

By choosing Shanghe for your PU sandwich panels procurement, you benefit from a streamlined ordering process, dependable quality information, and a supply solution designed to meet U.S. market demands.

Advantages of Procuring Polyurethane Sandwich Panels from Shanghe

Choosing Shanghe for your polyurethane sandwich panel procurement means investing in quality, reliability, and value. Here’s why we stand out in the U.S. market for insulation panels and building solutions:

Reliable Product Quality and Durability

Shanghe ensures every polyurethane insulated panel meets strict quality controls. Using high-density PU foam cores combined with durable metal facings (galvanized steel or aluminum), our panels offer long-lasting thermal insulation and structural strength. This reliability makes them ideal for cold storage, industrial roofing, and prefabricated buildings where performance matters.

Competitive Pricing and Flexible Payment Terms

We understand budget constraints in construction and industrial projects. That’s why we offer competitive prices on bulk purchases of PU foam sandwich panels and flexible payment options designed to fit various project sizes. This balance ensures you get high-quality panels without overspending.

Expert Technical Support and Post-Sale Services

Our team provides in-depth support during every stage—from initial consultation to installation guidance and after-sale assistance. We help you select the right polyurethane sandwich panel specifications, advise on thermal values (U-values and R-values), and troubleshoot any issues, ensuring smooth project delivery.

Sustainable and Eco-Friendly Manufacturing Practices

Shanghe is committed to sustainability. Our manufacturing processes minimize waste and energy use, and our panels contribute to energy-efficient buildings by reducing heating and cooling costs. Procuring from us supports your green building goals and complies with evolving U.S. environmental standards.

Proven Track Record and Case Studies

We back our products with real-world success stories. Shanghe has supplied polyurethane sandwich panels for notable projects such as industrial warehouses and clean rooms in the U.S. These case studies demonstrate our panels’ consistent performance and our ability to meet tight deadlines and custom requirements.

By choosing Shanghe for your PU sandwich panels procurement, you get a trusted manufacturer with a strong reputation for quality, value, and service tailored to the U.S. construction market.

How to Place an Order for Polyurethane Sandwich Panels with Shanghe

Buying polyurethane sandwich panels from Shanghe is simple and straightforward. Here’s a clear step-by-step guide to help you through the PU sandwich panels procurement process, ensuring you get exactly what you need, on time and hassle-free.

Step 1 Contact Shanghe Sales Team

Reach out directly to Shanghe’s knowledgeable sales representatives via phone or email. For initial polyurethane insulated panels buying inquiries, you can:

- Request detailed product information

- Ask about specifications like thickness, panel size, coating, and fire ratings

- Discuss your project’s unique requirements

Step 2 Request a Quotation

Once your requirements are clear, Shanghe will provide a customized quote based on:

- Panel dimensions and thickness

- Core material density and type

- Optional coatings and fire retardants

- Order volume and delivery location

The quote will include competitive pricing and an estimated timeline for production and delivery.

Step 3 Sample Requests

For quality assurance, you can ask for sample polyurethane foam sandwich panels before placing a full order. This helps to verify:

- Surface finish and color options

- Insulation performance and structural quality

- Compatibility with your project specifications

Step 4 Confirm Your Order and Arrange Payment

After approving the quote and samples, confirm your order with Shanghe. Payment terms are flexible, with options tailored for US customers, including letters of credit or bank transfers.

Step 5 Delivery and Logistics

Shanghe offers reliable local and global delivery options, whether you need panels shipped across the US or overseas. They handle:

- Packaging designed to protect panels during transit

- Coordination with freight forwarders or local carriers

- Tracking and updates on shipment status

Step 6 Installation Support

Shanghe provides expert guidance on proper polyurethane sandwich panel installation to ensure you:

- Maintain panel integrity and insulation properties

- Follow best practices for roofing or wall mounting

- Utilize recommended fixings and sealants

If needed, Shanghe can also connect you with professional installers or provide detailed instructional materials.

By following these steps, your procurement of polyurethane sandwich insulation panels from Shanghe will be smooth, transparent, and tailored to your project’s needs. For faster processing, keep your project details handy, and don’t hesitate to ask for clarification or assistance anytime.

FAQs on Polyurethane Sandwich Panel Procurement

What are the typical specifications for polyurethane sandwich panels?

Polyurethane sandwich panels usually come with high-density PU foam cores and metal facings such as galvanized steel or aluminum. Thickness options range from 30mm to 200mm depending on your insulation and structural needs. Thermal conductivity (λ value) typically falls between 0.020 to 0.028 W/m·K, offering excellent energy efficiency. Fire resistance varies by panel type but commonly meets B1 or Class A fire ratings for safety compliance.

How long does delivery usually take?

Lead times depend on your order size and customization needs but typically range from 2 to 6 weeks. Shanghe supports both local and global shipping, ensuring timely delivery across the United States and beyond. For urgent orders, express options may be available.

Can I customize the panels?

Yes. You can customize size, thickness, panel color, surface coatings, and fire retardancy. Shanghe offers tailored solutions to fit your project’s exact requirements, whether it’s for cold storage warehouses, clean rooms, or prefabricated buildings.

What is the minimum order quantity (MOQ)?

Shanghe usually requires a minimum order quantity depending on the product line, but MOQ starts low to accommodate both large-scale projects and smaller builds. Contact the sales team for specifics on your order type.

Are installation accessories available?

Yes, Shanghe provides complementary products including fixings, sealants, and installation tools necessary for a smooth setup. Proper installation guarantees the best performance and longevity.

What warranty and maintenance come with the panels?

Polyurethane sandwich panels from Shanghe come with a standard manufacturer’s warranty covering material defects and core integrity. Routine maintenance involves simple cleaning and inspection to maintain insulation and structural properties over time.

How do I ensure the panels meet industry standards?

All panels supplied by Shanghe adhere to strict quality controls and certifications such as ISO, ASTM, and CE standards. You will receive full compliance documentation ensuring panels meet safety, fire resistance, and thermal performance expectations.

Can I get technical support after purchase?

Absolutely. Shanghe provides expert technical support and after-sale services to assist with installation guidance, troubleshooting, and maintenance advice to maximize your polyurethane sandwich panel system’s value.

When buying polyurethane sandwich panels, understanding these key procurement points helps ensure you get the right product, delivered on time, fully compliant, and backed by support for your US-based project needs.

Related Products and Services for Polyurethane Sandwich Panel Procurement

When you’re sourcing polyurethane sandwich panels, it’s helpful to know about other related products and services that can support your project from start to finish. Here’s a quick guide to what else you might consider alongside your PU foam sandwich panel purchase.

Other Types of Sandwich Panels

PIR Panels

Polyisocyanurate (PIR) panels offer excellent thermal insulation and are popular for commercial roofing and walls. They have a slightly higher fire resistance rating compared to standard polyurethane panels, making them ideal for buildings with stricter fire codes.

Rock Wool Sandwich Panels

These panels feature a natural mineral wool core known for exceptional fire resistance and soundproofing qualities. Perfect for industrial sites and environments demanding higher fire safety standards.

Composite Panels with Different Cores

Depending on your needs, you might find SIPs (Structural Insulated Panels) with varied cores to balance insulation, strength, and cost.

Complementary Accessories for Panel Installation

To get the full performance out of your sandwich panels, using the right accessories and installation tools is essential. Here are some common items recommended for polyurethane sandwich panel installations:

Fixings and Fasteners

Stainless steel screws and clips designed to securely hold panels in place while resisting corrosion and weather exposure.

Sealants and Gaskets

High-quality polyurethane or silicone sealants to prevent air and moisture leaks, ensuring maximum insulation efficiency.

Joining Profiles and Flashings

Metal profiles for smooth, weather-tight panel connections, especially critical in roofing and wall applications.

Installation Tools

Specialized cutting tools, lifting equipment, and alignment devices that help simplify working with sandwich panels safely and efficiently.

Why These Products Matter

Using the right combination of insulated sandwich panels and accessories ensures that your building’s envelope performs at its best—delivering energy efficiency, structural integrity, and durability. Proper fixings and sealants also extend the lifespan of your installation by preventing common issues like water infiltration and thermal bridging.

If you’re planning a large-scale project or need guidance on the best panel type and accessories, consulting with your polyurethane sandwich panel supplier can save time and money down the line.

By choosing the right panels, fixings, and installation tools, you set your construction or renovation project up for long-lasting success.

Request a Quote for Polyurethane Sandwich Panel Procurement

Ready to buy polyurethane sandwich panels that meet your project needs? Contact Shanghe’s procurement team today for a tailored quote. We’re here to help you with competitive pricing, bulk order discounts, and flexible delivery options that fit your timeline.

Contact Shanghe Procurement Team

- Talk to our experts for advice on panel specifications, customization, and logistics.

- Get fast responses to your questions about PU foam sandwich panel sizing, coatings, and thermal insulation values.

- Receive guidance on certifications and compliance to ensure your purchase meets industry standards.

Download Brochure and Technical Datasheet

For detailed information including panel core types, thickness options from 30mm to 200mm, fire ratings, and downloadable product specs, get our up-to-date product brochure and technical datasheet. These resources help you make informed decisions and streamline your procurement process.

- Access full details on galvanized steel, aluminum, and other metal facings.

- Review thermal conductivity (λ values) and R-values for energy-efficient insulation.

- Explore customization options like color, coatings, and fire retardants.

Make your polyurethane sandwich panel purchase hassle-free with Shanghe’s expert support. Request a quote now or download the full technical datasheet to start your project on the right foot.

Explore our range of insulated sandwich panels to find exactly what you need, including roof sandwich panels and foam sandwich panels designed for lasting performance in cold storage, industrial roofing, and more.

What Are Polyurethane Sandwich Panels

Definition and Core Components

Polyurethane sandwich panels are composite building materials designed for insulation and structural purposes. They consist of a high-density polyurethane foam core securely bonded between two layers of metal facings—commonly galvanized steel or aluminum. This layered structure creates a lightweight yet highly durable panel. The metal surfaces provide protection and strength, while the polyurethane core delivers excellent thermal insulation.

Why Polyurethane Is Preferred in Insulation Panels

Polyurethane stands out as the core material for sandwich panels because of its superior insulation properties and structural advantages:

- High thermal resistance: Polyurethane foam has very low thermal conductivity (typically λ values around 0.019–0.023 W/m·K), making it ideal for reducing heat transfer in walls and roofs. This translates to better energy efficiency and lower heating or cooling costs.

- Lightweight strength: Despite its low density, polyurethane foam provides impressive compressive strength, supporting structural integrity without adding excessive weight.

- Durability and moisture resistance: Polyurethane foam is resistant to moisture absorption and degradation, ensuring long-term performance even in humid or variable weather conditions.

- Fire resistance options: With specialized fire retardant additives, polyurethane sandwich panels meet various building code standards (such as ASTM E84 Class A), providing enhanced safety in construction projects.

- Versatility: The foam core can be customized in thickness (commonly from 30mm to 200mm) and density to fit different insulation needs and applications like cold storage, clean rooms, and industrial facilities.

In the U.S. market, polyurethane sandwich insulation panels are preferred for applications requiring reliable thermal performance combined with structural durability. Their energy efficiency, easy installation, and adaptability make them a top choice for modern construction and renovation projects.

By combining these elements, polyurethane sandwich panels offer a balanced, high-performance solution for insulated roofing, walls, and prefabricated building systems.

Key Benefits of Polyurethane Sandwich Panels for Construction and Insulation

When it comes to polyurethane sandwich panel procurement for the U.S. market, understanding the core benefits helps you make smarter decisions for your projects. These panels combine thermal insulation, structural integrity, and ease of use—qualities that matter most in construction and insulation applications.

Superior Thermal Insulation and Energy Efficiency

Polyurethane foam is known for its low thermal conductivity, typically around 0.020–0.025 W/m·K, which means these panels deliver excellent insulation. This translates to:

- Reduced energy consumption for heating and cooling, lowering utility bills.

- Consistent temperature control, especially critical for cold storage warehouses, clean rooms, and prefab buildings.

- Meeting or exceeding U.S. energy codes and efficiency standards for commercial and industrial construction.

Strong Structural Performance and Durability

Despite being lightweight, polyurethane sandwich panels offer high compressive strength and robust structural support. This means they:

- Provide reliable resistance to wind load, impact, and weather elements.

- Maintain long-term durability without sagging or degradation.

- Are suitable for load-bearing walls, roofing systems, and industrial building envelopes.

Lightweight and Easy Installation

One of the biggest advantages for contractors and builders is the lightweight nature of polyurethane sandwich panels. This results in:

- Simplified handling and faster installation, saving labor time and costs.

- Reduced structural framing requirements, cutting down overall building weight.

- Enhanced flexibility in panel sizes and configurations to fit complex designs.

By choosing panels with a high-density polyurethane foam core and durable metal facings like galvanized steel or aluminum, you get a product that balances energy efficiency, strength, and ease of installation—all crucial for projects across the U.S. construction and insulation market.

Technical Specifications of Polyurethane Sandwich Panels You Need to Know Before Purchasing

When looking into polyurethane sandwich panel procurement, understanding the key technical specs is crucial. These details help ensure you get panels that fit your project needs, perform well, and meet safety standards.

Dimensions Thickness and Density

- Thickness options typically range from 30mm to 200mm, depending on your insulation and structural strength requirements.

- Panel density can vary but usually sits between 40 to 60 kg/m³ for the polyurethane core, providing excellent rigidity without excess weight.

- Standard panel widths are commonly around 1,000mm to 1,200mm, with customizable lengths to suit your project.

- The thickness and density directly affect thermal resistance and load-bearing capacity, so choose based on climate conditions and building codes.

Fire Resistance and Safety Ratings

- Polyurethane sandwich panels from reputable manufacturers like Shanghe come with fire resistance ratings up to Class B or better, depending on panel composition and surface coatings.

- Some panels meet ASTM E84 (Surface Burning Characteristics of Building Materials) and ISO 11925-2 fire testing standards, ensuring compliance with US safety codes.

- Fire-retardant additives and coatings can enhance safety without compromising insulation performance.

- Always confirm certifications when purchasing, especially for commercial or industrial applications where fire safety is a must.

Surface Materials and Coatings

- The typical facings are made from galvanized steel, aluminum, or other metal sheets. These layers protect the core while providing aesthetic versatility and durability.

- Metal facings come with various coatings such as polyester, PVDF, or silicon-modified polyester, offering resistance to UV, corrosion, and harsh weather.

- Custom coatings and colors can be applied to match architectural styles or branding requirements.

- Surface texture options like smooth, embossed, or stucco finishes are available for both appearance and enhanced performance.

Understanding these technical specifications will equip you to select polyurethane sandwich insulation panels that balance insulation, strength, safety, and aesthetics perfectly for your project in the US market.

For more detailed specs and options, check out our polyurethane foam sandwich panels page.

Procurement Process for Polyurethane Sandwich Panels from Shanghe

When you decide to buy polyurethane sandwich panels from Shanghe, the process is designed to be straightforward and customer-friendly, especially for U.S. clients looking for reliable insulation solutions.

Customization Options Tailored to Your Project

We know every project has unique needs. That’s why Shanghe offers flexible customization on:

- Panel thickness from 30mm up to 200mm

- Choice of outer and inner facings: galvanized steel, aluminum, or other metals

- Panel size and length to fit your building dimensions

- Color and coating options for durability and aesthetics

- Fire retardant treatments that meet strict fire resistance ratings

- Special thermal conductivity targets for optimal energy efficiency

This helps ensure the panels you get match your specific insulation and structural requirements, whether for cold storage, roofing, or prefabricated buildings.

Order Minimums and Lead Times

- Minimum Order Quantity (MOQ): Typically starts at 100 square meters but can vary depending on project scale and custom specs.

- Lead Times: Standard orders usually ship within 3 to 5 weeks. For customized or large orders, please expect 5 to 8 weeks to allow for production and quality checks.

- Shanghe aims to accommodate both bulk buying and smaller project needs with flexible order volumes.

Documentation Certifications and Compliance

Buying from Shanghe means you get fully certified polyurethane insulated panels, which strictly comply with international and U.S. standards such as:

- ISO quality management systems

- ASTM insulation and fire safety standards

- CE marking for export compliance

Additionally, full documentation including product datasheets, test reports, and compliance certificates accompany every order. This ensures easy integration with your project’s building codes and inspection requirements.