What Are sandwich panels suppliers

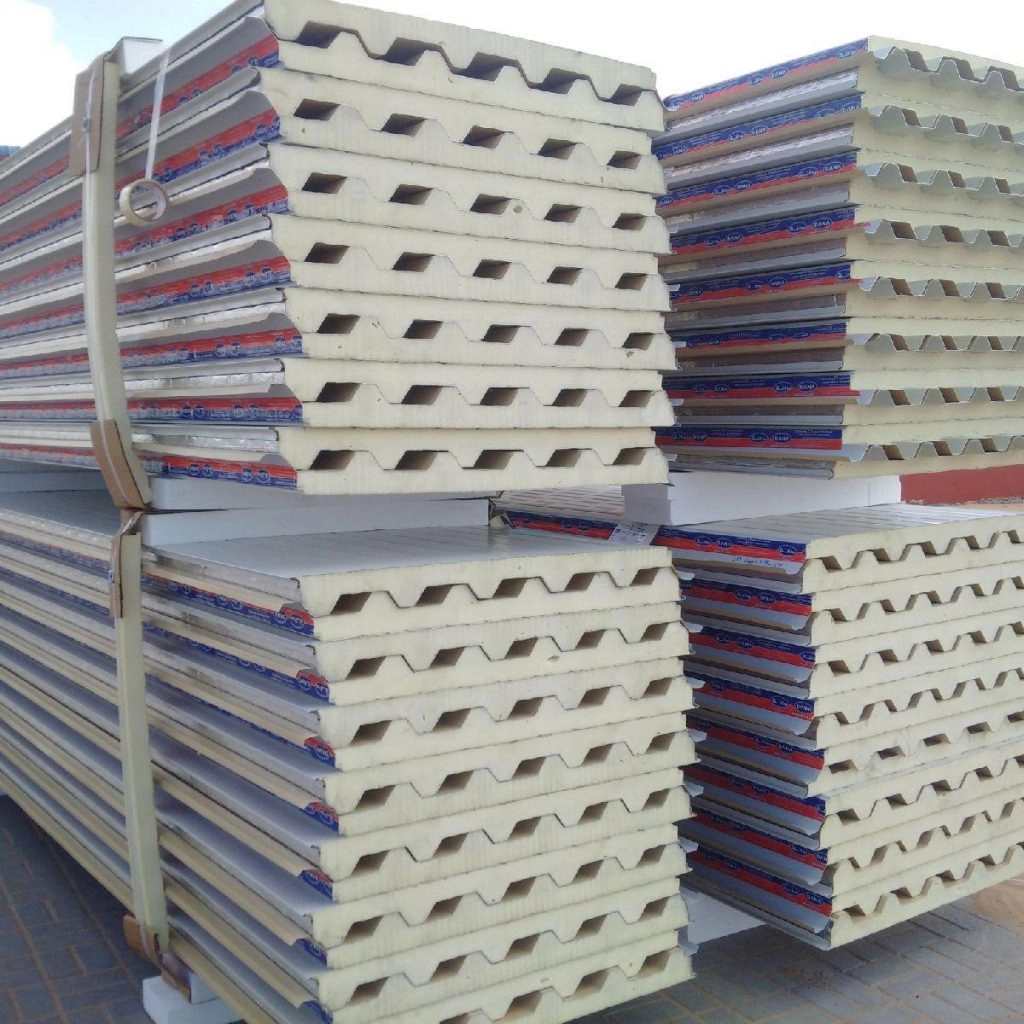

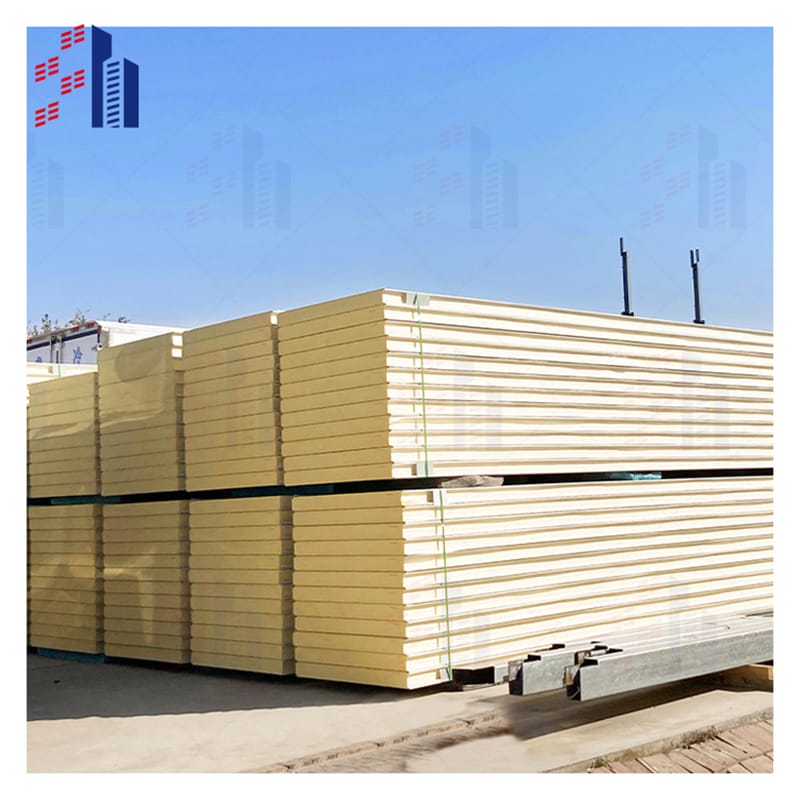

sandwich panels suppliers are advanced construction materials made up of two thin, strong outer metal facings bonded to a lightweight insulating core. This layered structure combines thermal insulation, structural integrity, and lightweight properties, making sandwich panels an ideal choice for modern construction needs. Typically, these panels use metal facings like galvanized steel or aluminum paired with various core materials such as polyurethane (PUR), polyisocyanurate (PIR), rock wool, or expanded polystyrene (EPS).

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines,china | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Benefits of Sandwich Panels

- Thermal Insulation: The core materials provide excellent temperature control, helping maintain stable indoor environments and reducing energy costs.

- Structural Integrity: Strong metal facings contribute to overall durability, allowing sandwich panels to support heavy loads and withstand harsh weather conditions.

- Lightweight Design: Compared to traditional building materials, sandwich panels are lighter, simplifying handling and speeding up installation without compromising strength.

Common Applications for Sandwich Panels

Sandwich panels are widely used across various industries due to their versatility and performance:

- Industrial Buildings: Perfect for factories and warehouses needing robust walls and roofs with insulation.

- Cold Storage Facilities: Maintain low temperatures efficiently in refrigerated warehouses and food storage units.

- Commercial Premises: Offices, shopping centers, and other commercial properties benefit from easy installation and energy savings.

Overall, sandwich panels from trusted sandwich panels suppliers like Shanghe provide reliable, cost-effective solutions tailored to the needs of the US construction market.

Why Choose Shanghe as Your Sandwich Panels Supplier

When it comes to reliable sandwich panels suppliers in the U.S. market, Shanghe stands out with years of solid industry experience in delivering high-quality insulated wall panels. Our strong track record in manufacturing and exporting makes us a trusted partner for contractors and builders looking for consistent quality and service.

Proven Industry Experience and Company Profile

Shanghe operates a state-of-the-art factory equipped to produce a wide range of sandwich panels, including polyurethane, PIR, rock wool, and EPS sandwich panels. Our team has deep expertise in serving both commercial and industrial sectors, understanding local needs from cold storage to modular construction. This experience translates into panels suited for the varying climates and building codes across the United States.

Certified Quality You Can Trust

All our sandwich panels meet stringent quality standards backed by international certifications like ISO 9001, SGS inspection, and CE marking. These ensure the panels deliver excellent performance in thermal insulation, fire resistance, and durability. As a customer, this means peace of mind knowing that you’re sourcing from a reliable fire-resistant sandwich panels provider and structural panels supplier.

Dedicated Customer Service and Timely Delivery

At Shanghe, we value your project timelines. Our team is committed to offering responsive support throughout the ordering process, providing technical advice as needed. We guarantee on-time deliveries whether you’re ordering for single or bulk projects. Our logistics network handles both local and international shipments efficiently, helping you keep your build on schedule.

Customized Sandwich Panels to Fit Your Needs

Every project is unique, so we provide customization options across panel thickness, core materials, and dimensions. Whether you need thicker panels for improved insulation or specific core materials like PIR for enhanced fire resistance, we tailor solutions to your exact specifications. This flexibility makes Shanghe the go-to choice for architects and builders requiring insulated roofing panels or specialized solutions.

Key Customization Features:

- Panel thickness ranging from 30mm to 200mm

- Core options including PUR, PIR, rock wool, and EPS

- Surface materials featuring galvanized steel, aluminum, and color-coated finishes

- Adjustable panel widths and lengths to match construction demands

By choosing Shanghe, you work with a structural sandwich panels supplier dedicated to quality, adaptability, and unmatched service aimed at supporting your project goals.

Types of Sandwich Panels Offered by Shanghe Your Trusted Sandwich Panels Supplier

At Shanghe, we offer a wide range of sandwich panels designed to meet diverse construction needs across the United States. Each panel type is engineered for specific performance benefits including thermal insulation, structural strength, fire resistance, and sound absorption.

Polyurethane PUR Sandwich Panels

Our Polyurethane (PUR) sandwich panels are known for their excellent thermal insulation and lightweight properties. The PUR core provides a low thermal conductivity value (typically around 0.022 W/m·K), making these panels ideal for energy-efficient buildings. They offer high structural integrity combining galvanized steel or aluminum facings, suitable for commercial and industrial applications.

Polyisocyanurate PIR Sandwich Panels

PIR sandwich panels feature a polyisocyanurate core, offering even better fire resistance and thermal performance compared to standard PUR panels. With improved insulation efficiency and a thermal conductivity value as low as 0.019 W/m·K, PIR panels are perfect for projects requiring enhanced energy savings and fire safety compliance. These panels are widely used in cold storage and clean rooms.

Rock Wool Sandwich Panels

Rock wool sandwich panels are favored for their outstanding fire resistance and sound absorption qualities. The core is made from mineral wool, which resists high temperatures and provides superior acoustic dampening. Rock wool panels are highly suited for environments where fire safety is critical, such as factories and public buildings.

EPS Expanded Polystyrene Sandwich Panels

Our EPS (Expanded Polystyrene) sandwich panels offer cost-effective thermal insulation solutions with decent fire-retardant properties. EPS cores deliver good performance for lightweight wall and roofing panels used in residential construction and modular buildings. These panels balance affordability with effective energy savings.

Fire-resistant and Acoustic Sandwich Panels

Shanghe also supplies specialty fire-resistant and acoustic sandwich panels tailored for projects demanding high performance in either fire safety or noise control. These panels combine advanced core materials and multi-layer facings to meet strict regulatory standards in hospitals, schools, and specialized industrial facilities.

By choosing the right panel type for your project, you benefit from optimized insulation, structural strength, and compliance with U.S. building codes. Whether you need a polyurethane sandwich panels supplier, a rock wool supplier known for sound absorption, or fire-resistant sandwich panels provider, Shanghe offers customized solutions tailored to your exact specifications.

Technical Specifications of Sandwich Panels

Understanding the technical specs of our sandwich panels is key to choosing the right product for your project. Here’s a detailed look at the core materials, panel sizes, surface finishes, and performance ratings that define our offerings.

Core Materials and Densities

Our panels use a variety of core materials tailored for different insulation and structural needs:

- Polyurethane (PUR): Density ranges from 38 to 42 kg/m³, offering excellent thermal insulation with low thermal conductivity.

- Polyisocyanurate (PIR): Denser than PUR, typically 40 to 45 kg/m³, with enhanced fire resistance and thermal performance.

- Rock Wool: Density between 80 and 140 kg/m³, known for superior fire resistance and sound absorption.

- Expanded Polystyrene (EPS): Lightweight with densities from 12 to 16 kg/m³, cost-effective insulation.

These core options allow customization based on thermal insulation requirements, fire safety standards, and budget.

Panel Thickness and Dimensions

Our sandwich panels come in versatile thicknesses and dimensions to fit various applications:

- Thickness range: 30 mm up to 200 mm, depending on the insulation needed.

- Width: Standard widths from 1000 mm to 1200 mm for easy installation.

- Length: Customizable lengths up to 13 meters to reduce joints and speed up assembly.

This flexibility ensures you get panels that align well with your building’s structural demands and design constraints.

Surface Materials and Finishes

The surface facings of our panels are designed for durability and aesthetic appeal. Options include:

- Galvanized steel: Provides corrosion resistance and strength, ideal for harsh industrial environments.

- Aluminum sheets: Lightweight and rust-proof, perfect for commercial or residential use.

- Color coated steel: Offers a wide range of colors with UV protection to maintain appearance over time.

All surface materials meet strict quality standards for weather resistance, wear, and impact durability.

Thermal Conductivity and Insulation Performance

Our sandwich panels deliver efficient thermal insulation with low thermal conductivity values:

- PUR panels typically have thermal conductivity around 0.022 to 0.025 W/m·K.

- PIR panels perform slightly better with values near 0.021 W/m·K.

- Rock Wool and EPS panels vary but maintain effective insulation for cold storage and climate control.

These values are crucial for reducing energy costs in commercial, industrial, and residential buildings.

Fire Ratings and Certifications

Safety is paramount, so our sandwich panels come with recognized fire ratings and certifications:

- European EN 13501-1 fire classification available on PIR and Rock Wool panels.

- UL94 ratings for flame retardant properties in relevant products.

- Certifications like ISO 9001, SGS, and CE ensure compliance with international quality and safety standards.

Choosing fire-resistant sandwich panels supports safer building practices in industrial and commercial projects.

Our detailed technical specs help you choose the right sandwich panels supplier who understands your needs for performance, safety, and durability. Whether you need insulated wall panels for cold storage or fire-resistant roofing panels, our options deliver trusted results.

Applications and Industry Uses of Sandwich Panels

Sandwich panels are trusted across various industries in the U.S. for their thermal insulation, structural strength, and lightweight features. Here’s where these insulated wall panels and roofing solutions really stand out:

Commercial and Industrial Buildings

Sandwich panels provide excellent insulation and durability for warehouses, factories, and office buildings. Their fire-resistant and acoustic properties help maintain safety and comfort while reducing energy costs. Structural sandwich panels support quick construction, making them ideal for large-scale projects.

Cold Storage and Refrigerated Warehouses

Our PIR and polyurethane sandwich panels are perfect for cold storage, offering reliable thermal insulation that keeps temperatures steady and energy use low. These panels also prevent condensation and support long-term temperature control, essential for food storage or pharmaceutical industries.

Clean Rooms and Hospitals

In environments where hygiene and air control are critical, like hospitals and laboratories, sandwich panels with smooth, easy-to-clean surfaces help maintain sterile conditions. Their superior insulation supports energy-efficient HVAC systems, crucial for these sensitive facilities.

Agricultural and Livestock Facilities

Rock wool and EPS sandwich panels are popularly used in barns, poultry houses, and livestock storage buildings. These panels provide sound absorption, temperature regulation, and durability against harsh environmental conditions, improving animal comfort and biosecurity.

Residential and Modular Construction

Sandwich panels are increasingly used in modern housing and modular building projects. Their lightweight nature reduces structural load while providing top-tier insulation, noise reduction, and fire safety—perfect for fast, efficient residential construction.

whether it’s industrial, commercial, or residential, our sandwich panels are engineered to meet the diverse needs of U.S. projects with reliable thermal performance, strength, and flexibility.

Ordering Process and Supply Chain for Sandwich Panels Suppliers

How to Request a Quote or Sample

Getting started with Shanghe as your trusted sandwich panels supplier is simple. You can request a quote or a sample by contacting our sales team via phone, email, or through our website inquiry form. Provide your project specifications such as panel type, thickness, core material, and dimensions, and we’ll respond promptly with a detailed offer tailored to your needs. Samples are available to help you evaluate product quality before you place a bulk order.

Minimum Order Quantity and Packaging Details

We understand that project sizes vary, so our minimum order quantity (MOQ) is set to accommodate both small and large projects. Typically, MOQ starts at 100 square feet, but we can be flexible depending on your requirements. Sandwich panels are carefully packaged with protective wrapping and secured on pallets to prevent damage during transit, ensuring your panels arrive in excellent condition.

Delivery Times and Logistics Support

We aim for timely delivery to keep your project on schedule. Typical lead times range from 10 to 25 business days, depending on the panel type and order size. Our logistics specialists coordinate closely with you to arrange efficient shipping routes, whether it’s for local delivery within the U.S. or international shipments. We partner with reliable freight carriers to ensure safe and on-time delivery.

Shipping and Handling Local and International

As a leading insulated wall panels supplier and steel sandwich panels dealer, we manage shipping for both local U.S. customers and international clients. We handle all aspects of shipping and customs paperwork for exports. Whether your project requires trucking to your site or container shipments overseas, we offer comprehensive support, including:

- Tracking and shipment updates

- Packaging tailored to transit mode

- Coordination with freight forwarders

By trusting Shanghe, you benefit from a smooth supply chain experience backed by years of expertise in manufacturing and distributing quality sandwich panels across the globe.

Customer Support and After-Sales Service for Sandwich Panels Suppliers

At Shanghe, we understand that quality sandwich panels are only part of the equation. Reliable customer support and after-sales service are just as important to ensure your project runs smoothly from start to finish. Whether you’re sourcing polyurethane sandwich panels, rock wool insulated wall panels, or fire-resistant sandwich panels, our team is here to help with every step.

Technical Consultation and Support

Our experts provide detailed technical advice tailored to your project needs. Whether you’re unsure about the best panel type for cold storage or need help with structural sandwich panels specifications, we offer clear, practical solutions. This helps you choose the right product for thermal insulation, sound absorption, or fire resistance.

Installation Guidance and Manuals

Proper installation makes the difference between average and long-lasting performance. We supply comprehensive installation manuals and step-by-step guides designed to assist contractors and builders. These resources cover panel handling, fastening techniques, and sealing best practices to maintain insulation integrity and structural strength.

Warranty and Product Maintenance Tips

We back our sandwich panels with industry-standard warranties, giving you peace of mind about durability and performance. Plus, we offer easy-to-follow maintenance advice to maximize your panels’ lifespan. From cleaning recommendations to inspecting panel joints for wear, our tips help keep your insulated roofing panels and walls in top shape.

Contact Information for Sales and Service Teams

Need quick support or customized service? Our dedicated sales and after-sales support teams are just a call or email away. We respond promptly to inquiries about bulk purchases, customization options, shipping schedules, or technical issues. Here’s how to reach us:

- Phone: [Insert Local US Number]

- Email: support@shanghepanels.com

- Online Chat: Available 9 AM to 6 PM EST

Choosing Shanghe as your sandwich panels supplier means you get more than just a product—you get a partner committed to your project’s success through expert advice, clear installation support, and consistent follow-up service.

FAQs About Sandwich Panels Suppliers

What is the Best Sandwich Panel for Cold Storage

For cold storage, polyurethane (PUR) and polyisocyanurate (PIR) sandwich panels are the top choices due to their excellent thermal insulation and low thermal conductivity. These panels help maintain consistent temperatures and reduce energy costs. Both PUR and PIR panels offer high structural integrity and moisture resistance, essential for cold storage environments.

If fire resistance is a priority alongside insulation, rock wool sandwich panels provide superior fire safety while offering decent insulation and sound absorption.

Can Panels Be Customized for Specific Projects

Yes, customization is one of our key strengths. We tailor sandwich panels based on:

- Panel thickness ranging from 20mm to 200mm to suit insulation and structural needs.

- Choice of core materials such as PUR, PIR, EPS, or rock wool.

- Dimensions and lengths per your project specifications.

- Surface finishes including galvanized steel, aluminum, or color-coated sheets.

This flexibility ensures the panels fit perfectly, whether for commercial buildings, industrial sites, or residential modular construction.

What is the Lead Time for Orders

Our typical lead time depends on the panel type and order size but generally ranges from 10 to 25 working days after order confirmation. For bulk or customized orders, we advise early planning to secure timely delivery. We prioritize efficient scheduling and reliable logistics to meet project deadlines.

Are Samples Available Before Placing Bulk Orders

Yes, we provide sample panels so you can assess quality, finish, and performance firsthand before committing to larger orders. Samples are a smart way to verify material compatibility and style for your project needs. Contact us to request samples—local and international customers are both welcome.

For more in-depth product details about different types of panels, visit our pages on polyurethane sandwich panels and rock wool sandwich panels.

By choosing Shanghe as your sandwich panels supplier, you get customized solutions backed by experience, quality assurance, and excellent customer service.

Related Products and Accessories for Sandwich Panels

To ensure your sandwich panel installations are secure, efficient, and durable, we offer a full range of related products and accessories designed to complement our core panels.

Fasteners and Sealants for Sandwich Panels

- High-quality fasteners designed for metal sandwich panels provide strong, corrosion-resistant connections for steel or aluminum facings.

- Specialized sealants ensure airtight and watertight joints, enhancing thermal performance and preventing moisture infiltration.

- Compatible with PUR, PIR, EPS, and rock wool panels for flexible application.

- Ideal for both wall and roofing panel installations to maintain structural integrity and sound absorption qualities.

Structural Components Steel Frames and Rails

- Durable steel frames and rails customized for sandwich panel support offer excellent load-bearing capacity.

- Galvanized or color-coated options available to resist rust and match panel colors.

- Suitable for modular constructions, commercial buildings, cold storage, and clean rooms.

- Designed to integrate seamlessly with insulated wall panels suppliers’ products to ensure proper fit and stable installation.

Insulation and Complementary Building Materials

- Additional insulation materials available to boost energy efficiency in conjunction with sandwich panels.

- Vapor barriers, moisture membranes, and soundproofing layers to suit specific project needs.

- Accessories like flashing, trims, and junction profiles improve aesthetics and prevent thermal bridging.

- All materials meet U.S. industry standards to comply with safety and building codes, supporting your project’s longevity and performance.

By choosing accessories and complementary products from Shanghe, you ensure that your insulated roofing panels supplier offers a one-stop solution with reliable, compatible components that make your construction process simpler and your building stronger.

Contact us today for details on fasteners, structural components, or any other accessories you need to complete your sandwich panel project efficiently.

Request a Quote from Shanghe Your Trusted Sandwich Panels Supplier

Ready to find the perfect sandwich panels supplier for your project? Request a quote today from Shanghe to get competitive pricing tailored to your specific needs. Whether you’re looking for polyurethane sandwich panels, rock wool panels, or custom sizes, our team is here to provide fast, accurate quotes.

Contact Us for Technical Support and Samples

Have questions about which panel fits your application best? Need samples to evaluate quality and specs? Reach out to our knowledgeable support team for free technical consultation and sample requests. We’re committed to helping you make informed decisions with expert advice and support every step of the way.

Stay Updated with Latest Products and Offers

Subscribe to our newsletter to receive updates on new sandwich panel products, special offers, and industry insights. Stay ahead with Shanghe—your reliable partner for insulated wall panels, fire-resistant panels, and customized sandwich panels designed to meet the demands of the U.S. market.

Contact Shanghe today and experience quality, service, and value from a leading sandwich panels supplier.

Explore our full range of products here: