What is a Metal Sandwich Panel

A metal sandwich panel is an advanced construction material designed for thermal insulation, structural strength, and weather resistance. It consists of two strong metal outer layers bonded to a core insulation material. These panels are widely used in insulated roofing panels, metal wall panels insulation, and prefab metal panels applications where energy efficiency and durability are essential.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Test Standard |

| Core Material | Polyurethane (PU) foam, 40±2 kg/m³ density | ISO 845 |

| Fire Rating | A1 (Non-combustible) | EN 13501-1:2018 |

| Thermal Conductivity (λ) | 0.022 W/m·K | ISO 8301 |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom 30-200mm) | – |

| Skin Material | 0.4-0.7mm Galvalume steel (AZ150 coating) | ASTM A792 |

| Compressive Strength | ≥150 kPa | ISO 844 |

| Operating Temperature | -50°C to +120°C | ASTM D2126 |

| Custom Sizes | Max. length: 12m; Width: 950/1150mm (adjustable) | – |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| solution provider | Shandong, China,philippines,china | Nature of sales | of sales |

| Brand | SH | custom made | oem odm |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | foam sandwich roof panels |

| Nature of trade | factory | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | color coated corrugated, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Components of Metal Sandwich Panels

Metal Outer Layers

The external faces of the panel are typically made from galvanized steel or aluminum, providing high strength, corrosion resistance, and a smooth finish. These metal skins can be pre-painted to enhance aesthetics and improve weather resistance. This metal cladding layer protects the core and adds to the panel’s load-bearing capacity.

Core Insulation Materials

The core is the heart of the metal sandwich panel, delivering superior insulation and fire resistance. Common core options include:

- Polyurethane (PU) for outstanding thermal insulation and lightweight properties

- Polyisocyanurate (PIR) offering enhanced fire resistance and energy efficiency

- Expanded Polystyrene (EPS) known for affordability and thermal insulation

- Mineral Wool (Rock wool) providing excellent fireproofing and sound absorption

Each core material impacts panel performance in terms of fire safety, thermal conductivity, and mechanical strength.

Introduction to Shanghe Metal Sandwich Panels

At Shanghe, we provide a premium line of metal composite panels engineered to meet strict performance criteria for various industries. Our metal sandwich panels combine high-quality outer skins with carefully selected insulation cores to deliver excellent durability, energy efficiency, and fire resistance. Whether you need insulated metal panels for cold storage warehouses, commercial buildings, or clean rooms, Shanghe’s products offer customizable solutions with reliable protection against weather, corrosion, and noise.

Discover the range of options available for thickness, metal finishes, and core materials tailored to your project needs. Shanghe’s metal sandwich panels stand out with a balanced combination of strength, lightweight design, and thermal insulation — perfect for both walls and roofs.

Learn more about our metal insulated sandwich panel offerings here and explore our full portfolio of premium sandwich panel metal cladding products.

Types of Metal Sandwich Panels

At Shanghe, we offer a range of metal sandwich panels designed to fit different insulation and structural needs. Each type features metal outer layers combined with specific core materials, delivering distinct benefits based on your project requirements.

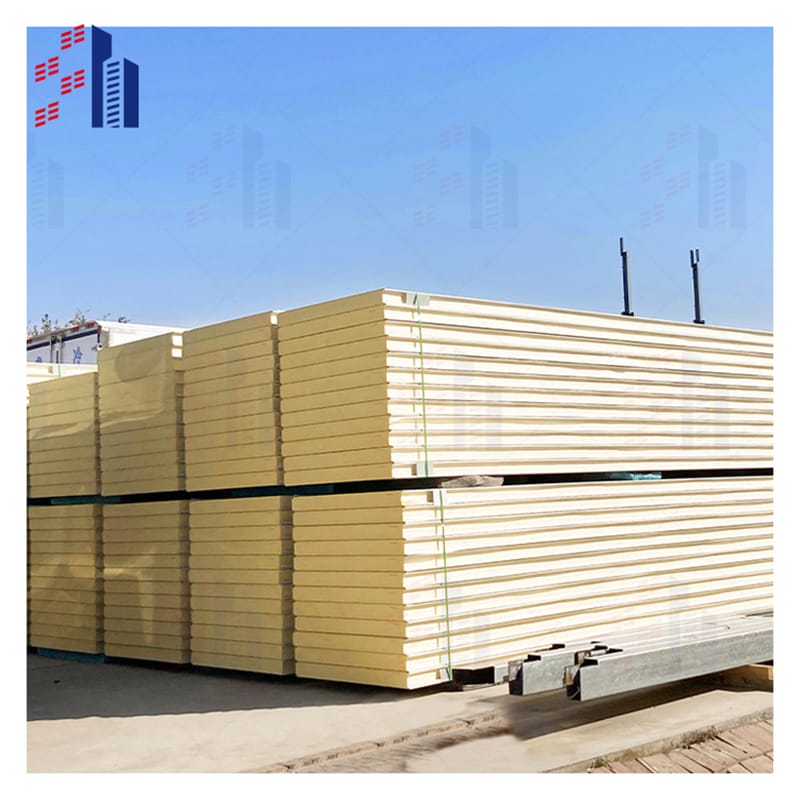

Polyurethane PU Core Panels

PU sandwich panels are widely used for their excellent thermal insulation and lightweight properties. The polyurethane core has a high R-value, providing superior energy efficiency. These panels are ideal for cold storage and refrigerated rooms where temperature control is critical. PU panels also boast good fire resistance, though they are typically rated for limited fire performance compared to mineral wool.

Key Advantages:

- Excellent thermal insulation

- Lightweight and easy to install

- Good moisture resistance

Considerations:

- Fire resistance is moderate; additional fireproof measures may be needed for high-risk areas

Polyisocyanurate PIR Core Panels

PIR sandwich panels share similarities with PU but have a more rigid molecular structure. This gives them higher fire resistance and thermal stability. PIR panels perform well in metal wall panels insulation applications where enhanced fire safety is required, such as commercial buildings and clean rooms.

Key Advantages:

- Higher fire resistance certified to ASTM E84 and EN standards

- Strong thermal performance similar to PU

- Slightly better moisture resistance

Considerations:

- Slightly higher cost than PU panels

Expanded Polystyrene EPS Core Panels

EPS core panels are a cost-effective insulated metal panel option suitable for projects where budget constraints exist without compromising thermal insulation basic needs. EPS provides a good balance between insulation and affordability, often used in industrial buildings and warehouses.

Key Advantages:

- Affordable with decent thermal insulation

- Resistant to moisture and mold

- Lightweight and easy to handle

Considerations:

- Lower fire resistance compared to PIR and mineral wool

- Slightly less durable under high mechanical stress

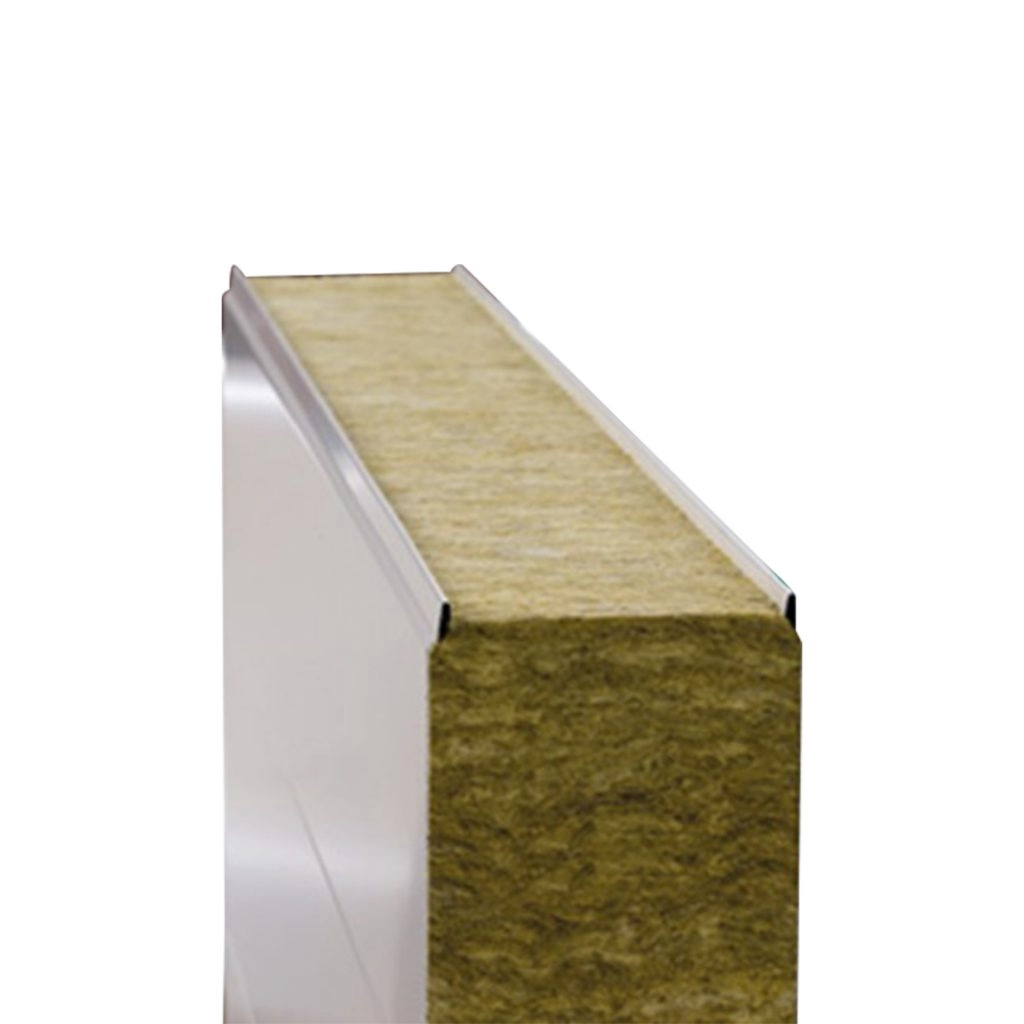

Mineral Wool Core Panels

Mineral wool sandwich panels stand out for fireproof performance and sound absorption qualities. The mineral wool core is non-combustible, making these panels perfect for applications requiring high fire safety levels such as factories, shopping malls, and exhibition centers.

Key Advantages:

- Excellent fire resistance (A1 non-combustible rating)

- Superior sound insulation and vapor barrier properties

- High durability and mechanical strength

Considerations:

- Heavier than PU and PIR panels

- Slightly higher cost and more complex installation

Comparing Core Materials Advantages and Disadvantages

| Core Material | Thermal Insulation | Fire Resistance | Weight | Cost | Best Use Cases |

|---|

| Polyurethane (PU) | High | Moderate | Light | Mid-range | Cold storage, insulated roofing |

| Polyisocyanurate (PIR) | High | High | Light-Medium | Higher | Commercial buildings, clean rooms |

| Expanded Polystyrene (EPS) | Moderate | Low | Light | Low | Warehouses, budget construction |

| Mineral Wool | Moderate | Very High (Non-combustible) | Heavy | Higher | Fireproof areas, industrial sites |

Each core material offers distinct benefits in terms of insulation, fire safety, weight, and cost. Choosing the right metal composite panels depends heavily on your specific application, budget, and local building codes in the U.S.

At Shanghe, we provide expert guidance to help you select the best sandwich panel metal cladding options to meet your project’s needs efficiently and reliably.

Key Features and Benefits of Metal Sandwich Panels

Superior Thermal Insulation and Energy Efficiency

Our metal sandwich panels provide excellent thermal insulation performance, significantly reducing heat transfer. Thanks to high-quality core insulation materials like polyurethane (PU) or polyisocyanurate (PIR), these insulated metal panels help maintain stable indoor temperatures, cutting down heating and cooling costs. This energy efficiency is a major advantage for commercial, industrial, and cold storage buildings across the U.S. market.

Fire Resistance and Safety Certifications

Fire safety is crucial. Shanghe’s metal sandwich panels are made with fire-resistant core options, including mineral wool, which is rock wool-based and naturally fireproof. Our panels meet stringent fire resistance standards such as ASTM E84 and EN 13501-1, ensuring compliance with U.S. building codes and providing peace of mind for your projects.

High Strength and Load Bearing Capacity

Designed for durability, these steel sandwich panel sheets deliver high strength and structural integrity. Both the metal outer layers and core insulation contribute to load-bearing capacity, making them ideal for roofing, wall cladding, and prefabricated metal panels in demanding industrial environments.

Lightweight and Easy Installation

Despite their strength, our metal sandwich panels are lightweight, which simplifies handling and speeds up installation. This reduces labor time and costs, especially for large-scale construction projects. The panels come with user-friendly joint systems and profiles, ensuring tight fits and minimizing on-site adjustments.

Weather and Corrosion Resistance

Shanghe’s metal composite panels feature galvanized steel or aluminum skins with durable pre-painted finishes. This protects against weathering, corrosion, and UV exposure, making them a reliable choice for diverse U.S. climates—from humid coastal regions to dry inland areas.

Sound Insulation and Vapor Barrier Properties

Beyond thermal performance, our metal wall panels insulation also offers sound absorption and vapor barrier capabilities. This helps improve indoor comfort by reducing noise pollution and controlling moisture buildup, which is vital for residential buildings, clean rooms, and pharmaceutical plants.

Shanghe metal sandwich panels combine energy efficiency, fire safety, strength, and weather resistance into one robust insulated roofing panel or wall system. These benefits make them the go-to solution for contractors and architects seeking performance and reliability in the U.S. construction market.

Technical Specifications of Metal Sandwich Panels

Panel Thickness Options

Our metal sandwich panels come in a variety of thicknesses to suit different insulation and structural needs. Standard options include:

- 50mm

- 75mm

- 100mm

- 150mm

These thicknesses provide flexibility for applications ranging from insulated roofing panels to metal wall panels insulation, ensuring optimal thermal performance and load-bearing capacity.

Metal Skin Materials and Finishes

The outer metal layers, or skins, are critical for durability and aesthetics. We offer:

- Galvanized steel: Excellent corrosion resistance, common in industrial and commercial uses.

- Aluminum: Lightweight and naturally rust-resistant, ideal for residential and exposed applications.

- Pre-painted options: Available in diverse colors to meet design needs while enhancing protection against weathering.

These finishes combine to form a robust metal composite panel suitable for the local U.S. climate and construction standards.

Panel Dimensions Standard and Customizable

Our panels typically measure:

- Width: 1000mm to 1200mm

- Length: Up to 12 meters (custom lengths available)

Custom sizing is available to fit unique project demands. This adaptability makes our prefab metal panels a go-to for cold storage warehouses, clean rooms, and commercial buildings requiring precise dimensions.

Compliance with Standards

Quality and safety are top priorities. Our insulated metal panels comply with key standards including:

- ISO (International Organization for Standardization)

- ASTM (American Society for Testing and Materials)

- EN (European Norms)

This ensures that all panels meet performance requirements for fire resistance, thermal insulation, and structural integrity in the U.S. market.

Performance Data and Test Reports

We provide detailed performance data and third-party test reports covering:

- Thermal conductivity values to confirm energy efficiency.

- Fire resistance ratings ensuring compliance with local fire safety codes.

- Load bearing capacity tests to guarantee durability under stress.

- Sound insulation effectiveness suitable for noise-sensitive environments.

These documents help architects, builders, and engineers make informed decisions, ensuring reliability and peace of mind.

By choosing Shanghe’s metal sandwich panels, you get a product engineered for quality, customization, and compliance—perfect for any U.S.-based construction project needing reliable insulated roofing panels or metal wall panels insulation.

Applications of Metal Sandwich Panels

Our metal sandwich panels are designed to serve a wide range of industries, offering reliable performance where insulation, strength, and durability matter most. Here’s where these insulated metal panels shine:

Cold Storage and Refrigerated Rooms

- Superior thermal insulation keeps the cold in and energy costs down.

- Ideal for warehouses and refrigerated facilities where temperature control is critical.

- The panels provide an effective vapor barrier to prevent moisture buildup, reducing frost and condensation risks.

Clean Rooms and Pharmaceutical Plants

- Maintains strict hygiene standards with smooth, easy-to-clean metal wall panels insulation.

- The panels’ fire-resistant versions, like mineral wool sandwich panels, comply with safety regulations in sensitive environments.

- Supports contamination control with tight panel joints and vapor barriers.

Commercial and Industrial Buildings

- Suitable for warehouses, factories, and industrial workshops requiring strong, durable metal composite panels.

- Panels provide excellent sound absorption and fireproof qualities to improve workplace safety.

- Their lightweight nature speeds up construction and reduces structural load.

Shopping Malls Exhibition Centers Garages Factories

- Offers aesthetic versatility with customizable finishes and colors to suit storefront walls and interiors.

- Panel systems withstand heavy foot traffic areas, machinery vibrations, and exterior weather conditions.

- Delivers efficient insulation, reducing heating and cooling expenses.

Residential Roofing and Wall Cladding

- Used in modern prefab metal panels for residential homes, combining thermal comfort with sleek metal sandwich panel metal cladding.

- Offers weather and corrosion resistance, extending building lifespan in various climates across the U.S.

- Panels help maintain indoor temperature stability, promoting energy efficiency in homes.

Our metal sandwich panels adapt to diverse building needs without compromising on energy efficiency, fire safety, or durability. Whether it’s for insulated roofing panels, steel sandwich panel sheets, or specialized PIR sandwich panels, Shanghe’s products meet the demands of the U.S. market effectively.

Installation and Customization of Metal Sandwich Panels

Installation Process Overview

Installing metal sandwich panels like insulated metal panels or steel sandwich panel sheets is straightforward but requires attention to detail for the best results. We recommend following these key steps:

- Prepare the structural frame, ensuring it’s level and secure.

- Handle panels carefully to avoid damage to metal cladding or core insulation.

- Use proper lifting tools depending on panel size and weight.

- Align panels carefully and secure them with recommended fasteners for a tight, weatherproof seal.

- Seal all panel joints with compatible vapor barrier tapes or sealants to maximize insulation and prevent moisture infiltration.

Following these steps ensures your panel system delivers optimal thermal insulation, sound absorption, and fireproof performance—key for commercial or residential applications across the US.

Panel Joint Systems and Profiles

We offer a variety of panel joint systems tailored for different project needs:

- Tongue and groove profiles for a snug, weather-tight fit.

- Butt-joint systems that allow faster installation while maintaining strength.

- Standing seam edges for roofing applications ensuring excellent water runoff.

Each profile type boosts durability, improves the panel’s load-bearing capacity, and strengthens resistance against weather and corrosion.

Custom Sizes and Colors Available

Because every project has unique requirements, we provide custom metal sandwich panels in:

- Various thickness options including 50mm, 75mm, 100mm, and 150mm to match insulation needs.

- Custom widths and lengths beyond standard dimensions for flexible design.

- A wide range of pre-painted coatings and finishes including galvanized steel, aluminum, and other color options to complement your building aesthetics.

This customization ensures your insulated roofing panels or metal wall panels insulation systems fit perfectly and look great.

Accessories Fasteners Seals and Flashings

Complete your installation with premium accessories designed for compatibility and durability:

- Specialized fasteners made for metal composite panels provide strong attachment without compromising insulation.

- Seals and gaskets that enhance weather resistance and sound insulation.

- Flashing components crafted to protect panel edges and joints from water and wind damage.

Using the right accessories guarantees a lasting installation that meets US building codes and climate challenges.

With precise installation and tailored customization options, Shanghe’s metal sandwich panels offer an effective and reliable solution for your insulated metal panels needs in the United States market.

Why Choose Shanghe Metal Sandwich Panels

When it comes to metal sandwich panels for your construction needs, choosing the right supplier matters. Here’s why Shanghe stands out in the U.S. market for insulated metal panels, metal composite panels, and prefab metal panels.

Industry Experience and Manufacturing Expertise

With years of specialized experience in producing metal sandwich panels, Shanghe has perfected the art of combining durable metal skins with high-quality insulation cores like PU, PIR, EPS, and mineral wool. Our advanced roll-forming machines ensure precise production, delivering consistent steel sandwich panel sheets designed to meet stringent quality standards.

Quality Control and Product Reliability

Every panel undergoes thorough inspections and testing to guarantee fireproof, sound-absorbing, and weather-resistant performance. Our commitment to quality ensures metal wall panels insulation that last, backed by certifications meeting international norms like ISO, ASTM, and EN standards.

Competitive Pricing and Local Supply Chain Advantages

We know cost matters. Shanghe offers competitive pricing on all metal sandwich panel types, including PU sandwich panels and mineral wool sandwich panels, without sacrificing quality. Plus, our local supply chain setup means faster delivery times and lower logistics costs for U.S. customers.

Customer Service and Technical Support

Our team is here to support you—whether you need help choosing the right insulated roofing panels, customizing panel sizes, or understanding fire safety certifications. We provide responsive technical support and detailed product information to help your project run smoothly.

Successful Case Studies and Client Testimonials

Thousands of satisfied clients across commercial buildings, cold storage warehouses, and clean rooms have trusted Shanghe for reliable sandwich panel metal cladding solutions. Check out our case studies showcasing projects that benefited from our durable, energy-efficient panels with excellent insulation and fire resistance.

Choose Shanghe for expert-crafted metal sandwich panels that deliver durability, safety, and energy savings—tailored for today’s U.S. market demands.

FAQs About Shanghe Metal Sandwich Panels

How Long Does Shanghe’s Metal Sandwich Panel Last

Shanghe’s metal sandwich panels are built to last. With high-quality metal outer layers like galvanized steel and aluminum combined with durable core insulation materials, these panels typically have a service life of 25 to 30 years or more under normal conditions. Proper installation and maintenance help maximize their longevity, especially in the diverse climates across the United States.

Can Panels Be Customized for Specific Climates

Absolutely. Shanghe offers customized metal sandwich panels designed to handle specific climate challenges—whether it’s high humidity, cold temperatures, or coastal salt air. By selecting the right core materials such as PU, PIR, EPS, or mineral wool, and finishes like pre-painted or corrosion-resistant coatings, we tailor panels to meet your project’s environmental needs. This ensures optimal thermal insulation, weather resistance, and performance.

What Fire Safety Standards Do Shanghe’s Panels Meet

Fire safety is a top priority. Shanghe’s metal sandwich panels comply with major fire resistance certifications relevant to the U.S. market, such as ASTM E84 and NFPA 285. Mineral wool core panels offer excellent fireproof performance, while PIR and PU cores meet stringent standards for flame retardance and smoke toxicity. Choosing the right panel type supports meeting your building’s fire safety codes and regulations.

How To Order and Delivery Lead Times

Ordering Shanghe’s metal sandwich panels is straightforward:

- Request a quote through our website or contact our sales team directly.

- Specify your panel type, thickness, dimensions, and any custom options like color or joint profiles.

- Confirm your order and arrange payment.

Typical delivery lead times range from 3 to 6 weeks, depending on order size, customization, and shipping location within the U.S. We maintain an efficient supply chain to keep timelines tight and costs competitive.

For more details on product options or to discuss your project needs, get in touch with us today. You can also explore our other insulated wall and roofing products like PU sandwich panels and EPS sandwich panels for a complete insulated metal panel solution.

Related Products Metal Roofing Sheets Insulated Wall Panels Accessories for Panel Installation

To complement our metal sandwich panels, we offer a range of related products designed to deliver a complete, high-performance building envelope solution.

Metal Roofing Sheets

Our metal roofing sheets provide excellent durability, weather resistance, and aesthetic flexibility. Available in galvanized steel and aluminum, with pre-painted finishes tailored for the U.S. climate, these roofing sheets are ideal for residential, commercial, and industrial roofing projects. They ensure strong protection against rain, snow, and wind, while being lightweight and easy to install.

- Materials: Galvanized steel, aluminum

- Finishes: Pre-painted options for UV and corrosion resistance

- Benefits: Long-lasting, rust-resistant, energy efficient

Insulated Wall Panels

Alongside our metal sandwich panels, we offer insulated wall panels that combine rigid insulation cores like polyurethane (PU), polyisocyanurate (PIR), expanded polystyrene (EPS), or mineral wool with metal facings. These panels boost thermal performance and sound insulation for walls, helping reduce energy costs in colder or hotter climates across the U.S.

- Core options: PU, PIR, EPS, mineral wool

- Faces: Steel or aluminum with custom coatings

- Advantages: Fire retardant, vapor barrier, sound absorption

Accessories for Panel Installation

We provide a full line of accessories and installation components to ensure your metal sandwich panel system performs flawlessly. Using the right fasteners, seals, flashings, and joint profiles is crucial to prevent leaks, maintain insulation integrity, and speed up installation.

- Fasteners: Corrosion-resistant screws and clips

- Sealants: Weatherproof and vapor-tight options

- Flashings: Custom profiles for corners, edges, and penetrations

- Joint Systems: Tongue-and-groove, snap-lock profiles for strong panel connection

These related products work seamlessly with insulated metal panels and metal composite panels to give you a reliable, energy-efficient, and cost-effective building solution. We back all our products with detailed specifications and support to meet U.S. building codes and standards.

Contact and Ordering Information for Metal Sandwich Panels

If you’re ready to enhance your project with metal sandwich panels, we make reaching out and ordering simple and straightforward. Whether you need insulated metal panels for commercial buildings, cold storage, or residential cladding, we’re here to help every step of the way.

Request a Quote

Getting a personalized quote is easy. Just provide your project details like:

- Panel types and core materials (PU, PIR, EPS, Mineral Wool)

- Required panel thickness and dimensions

- Quantity and delivery location

- Any customization needs such as color or panel finishes

Our team responds quickly with competitive pricing tailored to your specific needs right in the U.S. market.

Contact Sales and Support Team

Have questions about sandwich panel metal cladding, installation, or technical specs? Our expert sales and support team is available via phone, email, or live chat. We assist with:

- Choosing the right insulated roofing panels and wall systems

- Clarifying certifications and performance data

- Guiding you through customization options

- Providing post-sale technical support

Reliable, professional assistance ensures your ordering process and product use are smooth.

Download Brochures and Technical Datasheets

For detailed product information, performance reports, and compliance certifications (ISO, ASTM, EN), you can download:

- Comprehensive brochures covering all metal composite panels we supply

- Technical datasheets with full specs, including panel thickness, materials, finishes, and test results

- Installation guides and accessory catalogs for fasteners and seals

Stay informed with all the data you need to make a confident choice for insulated wall panels and roofing solutions.