Types of Sandwich Panels Available

As an experienced fabricante de panel sandwich (sandwich panel manufacturer), we offer multiple configurations to meet different project requirements:

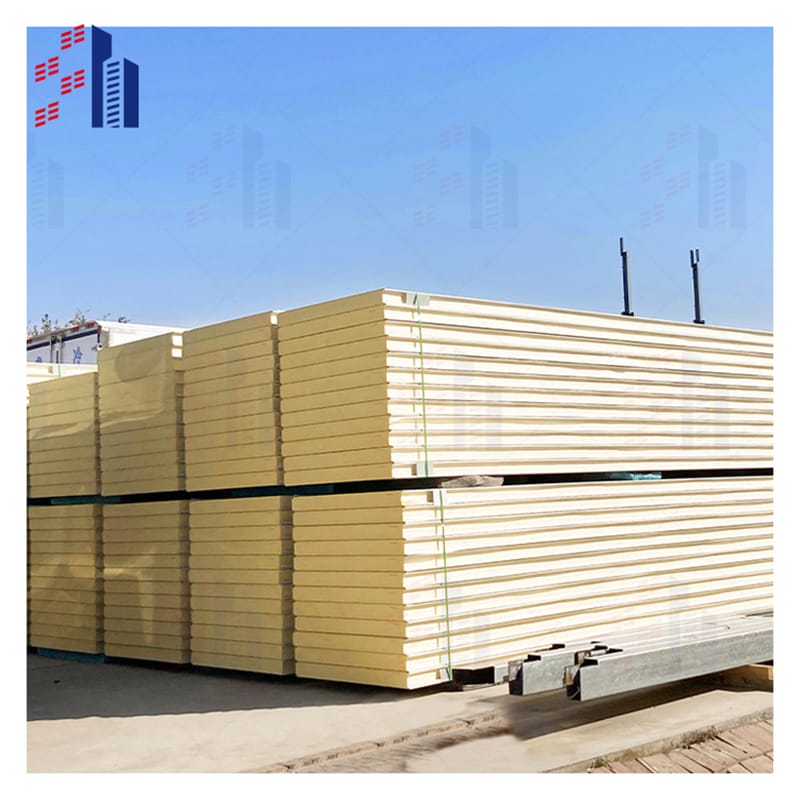

- PU (Polyurethane) Sandwich Panels – Excellent thermal insulation, lightweight, suited for refrigeration and cold storage.

- PIR (Polyisocyanurate) Core Panels – Improved fire resistance and insulation stability for industrial and commercial buildings.

- EPS (Expanded Polystyrene) Sandwich Panels – Cost-effective insulation for large surface areas.

- Rockwool Sandwich Panels – Superior fire resistance and acoustic performance for high-safety applications.

Key Advantages of Sandwich Panels

Our insulated sandwich panels offer a set of benefits that make them a preferred choice for architects, contractors, and facility owners:

- Excellent Thermal Insulation – Keeps interiors at optimal temperatures while reducing energy costs.

- Fire Resistance – Options available that meet strict fire safety classifications.

- High Strength with Low Weight – Lightweight structure simplifies handling and installation without compromising strength.

- Versatility – Suitable for walls, roofs, ceilings, partitions, and specialized enclosures.

- Durable Surfaces – Coated steel resists corrosion, moisture, and UV damage.

These features make sandwich panels an efficient and reliable solution for industrial warehouses, commercial premises, cold rooms, and residential projects.

Key Technical Specifications of Sandwich Panels

Our sandwich panels are engineered with precision to meet U.S. building standards for durability, insulation, and fire safety. Below are the core specifications that matter when choosing the right solution for your project.

Core Materials Options

We offer different insulating cores to suit various applications and performance needs:

- PU (Polyurethane) – High thermal insulation, lightweight, cost-effective.

- PIR (Polyisocyanurate) – Better fire performance than PU, same great insulation.

- EPS (Expanded Polystyrene) – Economical, moisture resistant, and reliable.

- Rockwool – Superior fire resistance, sound insulation, and thermal stability.

Outer Surface Materials and Coatings

The outer sheets of our panels are designed for long-term use and weather resistance:

- Materials: Galvanized steel, aluminum, or stainless steel.

- Finishes: Polyester coating, PVDF coating for harsh climates, or plastisol for impact resistance.

- Durability: Coatings protect against UV damage, corrosion, and color fading.

Thickness Options Based on Application

We provide multiple thickness ranges to adapt to structural needs and insulation targets:

| Panel Core Type | Common Thicknesses | Typical Uses |

|---|

| PU / PIR | 40–150 mm | Warehouses, cold storage, industrial walls |

| EPS | 40–120 mm | Agricultural buildings, temporary structures |

| Rockwool | 50–200 mm | Fire-rated walls, sound-insulated areas |

Thermal Conductivity and Energy Benefits

- PU/PIR panels: λ ≈ 0.022–0.028 W/m·K for top insulation performance.

- EPS panels: λ ≈ 0.035–0.040 W/m·K.

- Rockwool panels: λ ≈ 0.039–0.045 W/m·K, with added fire protection.

- Lower λ values mean better energy efficiency and reduced heating/cooling costs.

Fire Classification Standards

Our panels comply with international and U.S. fire safety standards:

- PIR: Class B-s2,d0 / NFPA compliant for low flame spread.

- Rockwool: Class A1 – Completely non-combustible.

- Certified per ASTM E84 and EN 13501-1 where required.

Custom Sizes and Configurations

- Standard widths: 1000–1150 mm coverage (varies by profile).

- Lengths: Up to 15 m in a single piece for faster installation.

- Profile choices: Smooth, micro-ribbed, or deep-ribbed for added strength.

- Custom colors available to match branding or design.

Manufacturing Excellence and Quality Assurance

State of the Art Sandwich Panel Manufacturing Facilities

As a fabricante panel sandwich with years of experience, we operate modern, high-capacity production lines designed for accuracy and efficiency. Our facilities are equipped with automated roll forming, continuous lamination systems, precision cutting, and advanced bonding technology to ensure every panel meets exact specifications.

From receiving raw materials to the final product, every stage is controlled with strict quality checks. This allows us to produce consistent, defect-free panels whether we’re making PU sandwich panels, PIR core panels, Rockwool panels, or EPS insulated panels.

Certifications and Compliance

Our products are backed by internationally recognized ISO 9001 quality management certification and CE marking for compliance with European safety standards. These certifications guarantee that our panels match global construction quality benchmarks for strength, safety, and reliability — essential for use in industrial, commercial, and residential projects.

Rigorous Testing for Durability and Performance

Each batch of panels undergoes comprehensive mechanical, thermal, and fire resistance testing to make sure they perform in real-world conditions. This includes:

- Compressive strength tests for structural stability

- Thermal conductivity testing for insulation performance

- Fire classification tests in line with ASTM, EN, and NFPA standards

- Weather resistance checks against UV, moisture, and corrosion

By applying these strict protocols, we can supply panels for cold storage facilities, fire-rated buildings, and high-load industrial structures with complete confidence in their performance.

Commitment to Sustainability

We follow environmentally responsible manufacturing practices to reduce waste and energy use. Our production lines are optimized for minimal material loss, and we use eco-friendly polyurethane foams that comply with low-GWP (Global Warming Potential) refrigerant standards.

Where possible, we integrate recyclable metals and sustainable coatings, making our panels not only high-performing but also better for the planet. Our sustainability strategy aligns with green building standards, supporting LEED and other energy-efficient certification goals.

Product Range and Customization for Sandwich Panels

As an experienced fabricante panel sandwich and supplier to the U.S. market, we offer a wide selection of insulated sandwich panels designed to meet the needs of different industries. Our panels are engineered for durability, energy efficiency, and ease of installation, and can be tailored in size, color, finish, and performance specs.

Variety of Sandwich Panels

We manufacture and supply multiple panel types to fit various applications:

- PU Sandwich Panels – Lightweight with excellent insulation, ideal for cold storage, commercial buildings, and residential projects.

- PIR Core Panels – Better fire performance with great thermal insulation, suited for industrial and public buildings.

- EPS Sandwich Panels – Cost-effective option for general wall and roofing solutions.

- Rockwool Sandwich Panels – High fire resistance and sound insulation for factories, warehouses, and specialized facilities.

- Metal Sandwich Panels – Strong and weather-resistant for long-lasting exterior use.

Custom Colors and Thicknesses

We know U.S. projects require flexibility in design and performance. That’s why our fabricación de paneles sandwich includes:

- Color options: Standard RAL colors or custom-matched shades.

- Panel thicknesses: Ranging from 30 mm to 200 mm, depending on thermal and structural requirements.

- Core densities: Customized for weight and insulation balance.

Special Surface Coatings

To meet demanding environments, we offer enhanced coatings and surface finishes:

- Waterproof coatings to protect in high-moisture or coastal areas.

- UV-resistant finishes for long-term outdoor exposure without fading.

- Antibacterial coatings for food processing, healthcare, or cleanroom applications.

- Scratch-resistant layers to reduce damage during transport and installation.

Technical Customization Options

| Specification | Standard Range | Custom Options Available |

|---|

| Length | Up to 40 ft | Project-specific cutting |

| Width | 3 to 4 ft | Non-standard widths |

| Core Material | PU, PIR, EPS, Rockwool | Mixed core solutions |

| Coating Thickness | 25–120 microns | Specialty coatings |

| Thermal Conductivity | 0.018–0.045 W/m·K | Optimized insulation |

With this range and customization flexibility, our fabricantes de panel sandwich ensure you get panels that match your exact performance, design, and compliance needs for U.S. building codes.

Installation Maintenance and Support for Sandwich Panels

Professional Installation Guidance

As a fabricante panel sandwich and trusted sandwich panel manufacturer, we make installation as straightforward as possible while ensuring top performance.

We provide:

- Clear installation manuals for each panel type (PU, PIR, EPS, Rockwool).

- Step-by-step diagrams for roof, wall, and ceiling layouts.

- On-site technical support upon request to guide your crew during assembly.

- Advice on fastener selection, sealing methods, and joint alignment for maximum insulation and weatherproofing.

Key Installation Tips:

- Always prepare a clean, level structural frame before panel placement.

- Use the right panel orientation to prevent water infiltration.

- Seal all joints with high-quality sealing tape or approved sealants.

- Avoid dragging panels on rough surfaces to protect the metal coating.

Maintenance Recommendations

With the right care, insulated sandwich panels can last for decades. Simple upkeep helps preserve both the look and the performance:

- Annual inspection of joints, fasteners, and seals.

- Wash panels periodically with mild soap and water; avoid abrasive cleaners.

- Re-coat any scratched areas immediately to prevent corrosion.

- Ensure gutters and drainage remain clear to avoid water pooling.

- In cold storage applications, monitor interior humidity to prevent condensation damage.

Warranty Terms

We stand behind every panel that leaves our fábrica de panel sandwich with:

- Standard warranty of 10–15 years for structural integrity.

- Extended warranties available for specific coatings or fire-resistant options.

- Warranty covers manufacturing defects, delamination, and thermal insulation performance within the specified period.

- Conditions: Panels must be installed and maintained according to our guidelines.

Customer Service Commitments

Our service doesn’t stop at delivery. Customers in the United States enjoy:

- Quick-response technical help via phone, email, or online chat.

- Access to experienced field engineers for troubleshooting.

- Replacement panel supply with priority production for urgent projects.

- Assistance with code compliance documentation and product data sheets.

Applications of Sandwich Panels Across Industries

Our sandwich panels are built for versatility, making them a reliable choice for a wide range of industries in the United States. Whether you need thermal insulation, fire protection, or durable wall and roof systems, our solutions adapt to your specific environment and performance needs.

Industrial Warehouses and Factories

- Durable and impact-resistant to handle heavy equipment and constant activity

- Superior thermal insulation to reduce heating and cooling costs

- Quick installation cuts down construction time and labor costs

- Available in both wall and roof configurations for complete building envelopes

Cold Storage and Refrigerated Rooms

- PU and PIR core panels designed for low thermal conductivity

- Maintains consistent temperature control for perishable goods

- Meets food safety and hygiene requirements

- Custom thickness options for different refrigeration levels

Commercial Buildings and Offices

- Modern, clean exterior finishes to enhance building appearance

- Fire-resistant panels for increased safety in public spaces

- Can be customized with color and coating to match branding

- Suitable for both interior partition walls and external facades

Agricultural Buildings and Food Processing Facilities

- Resistant to moisture, pests, and chemical exposure

- Easy-to-clean surfaces meet FDA and USDA standards

- Withstand temperature swings in barns, processing areas, or greenhouses

- Antibacterial coating options available for hygiene-sensitive facilities

Residential Construction

- Lightweight for faster builds and lower labor costs

- Keeps homes comfortable year-round with high insulation performance

- Works well for modular houses, garages, and home extensions

- Low-maintenance exterior for long-term value

By combining energy efficiency, fire resistance, structural strength, and design flexibility, our fabricante panel sandwich solutions adapt to almost any project type — from high-tech manufacturing facilities to family homes.

Why Choose This Sandwich Panel Manufacturer

Proven Manufacturing Expertise

With years of experience in fabricación de panel sandwich, we have grown into a trusted sandwich panel manufacturer serving clients across the United States and abroad. Our production process is backed by ISO 9001 and CE certifications, ensuring each insulated sandwich panel meets strict global quality standards.

Global Reach with Local Support

We supply to a wide range of markets — from industrial sandwich panels for warehouses to fire resistant Rockwool sandwich panels for high safety applications. Our logistics network allows for nationwide delivery and export to multiple countries, without adding long lead times.

Competitive Pricing and Quality Control

We balance affordable pricing with premium materials, giving customers lasting value. Every batch goes through thermal insulation testing, fire performance assessment, and durability checks before shipping.

Benefits of Working with Us:

- Direct factory pricing — No unnecessary middleman costs

- Certified quality — ISO 9001, CE, and compliance with FM and ASTM standards

- Flexible customization — Color, thickness, core material, and coating options

- Durability guaranteed — Tested for extreme environments

Track Record in Multiple Industries

Over the years, we have completed successful projects in cold storage facilities, food processing plants, office complexes, manufacturing hubs, and agricultural structures. Many of our clients return for repeat orders due to consistent performance and energy savings.

| Feature | Details |

|---|

| Core Materials | PU, PIR, EPS, Rockwool |

| Fire Classification | Meets ASTM E84 and EN 13501 standards |

| Standard Thickness Range | 30mm – 200mm |

| Coatings Available | Polyester, PVDF, anti-bacterial, and UV-resistant |

| Quality Certifications | ISO 9001, CE, FM, ASTM compliant |

| Delivery Options | Local and nationwide freight, export-ready packaging |

Comprehensive After Sales Support

Our job doesn’t end at delivery. We provide:

- Technical advice on optimal panel selection for your project

- On-site installation guidance if needed

- Maintenance tips to extend service life

- Warranty coverage on structural and coating performance

For U.S. buyers, we focus on fast response times, dependable shipments, and support that keeps your project on schedule — whether you’re a contractor, distributor, or end-user looking for prefabricated sandwich panels.

Ordering Process and Getting a Quote for Sandwich Panels

How to Contact Us for Quotes and Inquiries

If you’re ready to price out your project or need more details, getting in touch is simple:

- Phone Support – Speak directly to a sales representative for fast answers.

- Email – Send your project specs, and we’ll reply with a tailored sandwich panel quote.

- Online Quote Form – Fill out our quick form with core type, panel thickness, dimensions, and color.

We respond to most inquiries in 24 business hours for standard orders. For custom fabrication or high-volume runs, our team will guide you through the additional details needed.

Shipping and Delivery Zones

As a sandwich panel manufacturer and supplier, we deliver across the United States, including:

- Continental US (all 48 states)

- Alaska and Hawaii (special freight arrangements)

- Selected export destinations by request

Lead times typically range from:

5–7 business days for stock PU or PIR panels

10–15 business days for custom Rockwool, special coatings, or non-standard sizes

We partner with reliable freight carriers to ensure each panel arrives secure, undamaged, and ready for installation.

What to Include When Requesting a Quote

To get an accurate price, include:

Core material (PU, PIR, EPS, Rockwool)

Panel thickness and length

Profile type (roof, wall, cold room)

Surface material and coating (galvanized steel, pre-painted, special finish)

Quantity required

Delivery location ZIP code

FAQs for Buyers of Sandwich Panels

Q: Do you offer small order quantities?

We supply both bulk orders and smaller quantities for special projects.

Q: Are installation accessories included?

Fasteners, flashings, and sealants are available upon request.

Q: Do you ship to job sites directly?

Yes, we arrange direct-to-site deliveries nationwide.

Q: Are your insulated sandwich panels covered by warranty?

All panels come with a manufacturer warranty for structural integrity and coating performance (exact terms depend on product type).