Aluminum sandwich panels are advanced composite materials made by bonding two durable aluminum sheets around a lightweight core. These panels combine strength, lightness, and insulation, making them a preferred choice for a wide range of applications such as construction facades, transportation interiors, and industrial equipment. As a leading aluminum sandwich panel manufacturer, we focus on delivering panels that meet strict performance and durability standards.

General Applications

Our insulated aluminum panels serve diverse industries, including:

- Building and construction for exterior cladding, interior walls, and roofing systems

- Transportation including bus, train, and truck body panels where weight reduction and rigidity are key

- Industrial sectors for equipment casings, clean rooms, and modular structures

Their versatility comes from the balance of lightweight design and robust structural integrity, coupled with excellent thermal, fire, and sound insulation properties.

Why Choose Our Aluminum Sandwich Panels

We set ourselves apart by offering:

- High-quality manufacturing using premium aluminum and advanced core materials such as polyethylene (PE), fire-resistant mineral cores, and aluminum honeycomb

- Customizable options for thickness, panel size, surface finishes, and coatings tailored to your project needs

- Consistent performance with panels that meet stringent fire resistance and structural standards

- Competitive pricing combined with reliable supply and fast lead times

- Sustainability through environmentally friendly materials and production processes

Our aluminum sandwich panel suppliers prioritize innovation and quality control to ensure your projects benefit from panels that are strong, lightweight, and built to last. Whether you need a fire-resistant sandwich panel or a decorative aluminum facade panel, we provide solutions engineered for performance and durability.

Materials and Construction of Aluminum Sandwich Panels

Our aluminum sandwich panels are crafted with high-quality materials to ensure durability, strength, and versatility. Understanding the core and skin materials, along with the available panel sizes and thicknesses, will help you choose the right product for your application.

Core Material Types

The core material is central to the panel’s insulation, fire resistance, and structural properties. We offer several core options, including:

- Polyurethane (PU) Foam: Lightweight, excellent thermal insulation, and good fire-retardant qualities. Ideal for energy-efficient buildings.

- Polyisocyanurate (PIR) Foam: Similar to PU but with enhanced fire resistance and higher insulation value.

- Rockwool Core: Fire-resistant and sound-insulating, perfect for projects requiring strict fire safety standards. See more details on our rockwool sandwich panels.

- EPS Foam (Expanded Polystyrene): Cost-effective, good thermal insulation, suited for less demanding fire safety requirements.

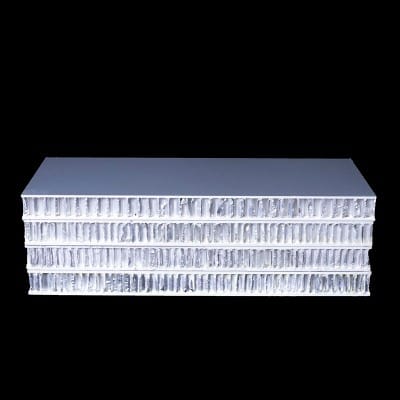

- Aluminum Honeycomb Core: Offers excellent strength-to-weight ratio, used in structural aluminum panels where load-bearing capacity matters.

Aluminum Skin Specifications

The outer and inner layers are made from high-grade aluminum sheets, providing corrosion resistance and a sleek finish. Key features include:

- Thickness: Typically ranges from 0.4 mm to 1.0 mm, depending on panel use.

- Grade: Usually 3003 or 3105 series aluminum alloys, known for their excellent strength and weather resistance.

- Surface Treatment: Options like PVDF or polyester coating improve durability and color retention in outdoor environments.

- Finish Options: Smooth, embossed, or textured finishes meeting different aesthetic requirements.

Panel Thickness and Size Options

Our aluminum core panel producer offers flexible thickness and size options to fit your project specs:

- Thickness Range: From 20 mm up to 200 mm, depending on insulation and structural needs.

- Standard Sizes: Panels are available in widths of 1000 mm and 1200 mm, with lengths adjustable up to 12 meters or more, to minimize joints and speeding up installation.

- Custom Sizes: We provide custom aluminum sandwich panels tailored to your exact dimensions.

Choosing the right combination of core material, skin specification, and panel size is crucial for achieving optimal performance in thermal insulation, fire resistance, and structural integrity. For detailed options on foam-based sandwich panels, visit our PU foam sandwich panels page.

Technical Specifications of Aluminum Sandwich Panels

Our aluminum sandwich panels are engineered to meet the high standards required in construction, transportation, and industrial applications. Here’s a breakdown of the key technical specs that make our panels reliable and efficient.

Weight per Square Meter

- Lightweight design ranges typically from 6 to 12 kg/m², depending on core material and panel thickness.

- Lightweight panels ease handling and reduce structural load, ideal for both new builds and renovations.

Thermal Insulation Values

- Panels offer excellent thermal resistance with R-values ranging from 1.5 to 4.0 depending on the core selected (e.g., polyurethane, mineral wool).

- Helps maintain indoor comfort and reduce energy costs, perfect for insulated aluminum panels used in climate-sensitive projects.

Fire Resistance Ratings

- Fire-resistant sandwich panel options meet or exceed Class A fire ratings.

- Core materials such as mineral wool provide enhanced fire protection, suitable for commercial buildings and transportation needs.

- Panels comply with relevant ASTM E84 and local fire safety standards.

Sound Insulation

- Our panels are designed with cores that reduce noise transmission providing sound insulation ratings from STC 25 to 45 dB.

- Ideal for industrial sites, schools, medical facilities, and other places where noise control matters.

Structural Performance and Standards Compliance

- Compliant with international standards including ASTM, EN 14509, and local building codes.

- High structural strength due to quality aluminum skins and reinforced core materials withstand impact and environmental stresses.

- Tested for wind load resistance, compression, and bending performance, ensuring durability in demanding installations.

| Specification | Range / Rating |

|---|

| Weight (kg/m²) | 6 – 12 |

| Thermal R-Value | 1.5 – 4.0 |

| Fire Resistance | Class A (ASTM E84 compliant) |

| Sound Insulation (STC) | 25 – 45 dB |

| Standards Compliance | ASTM, EN 14509, Local Codes |

These specs highlight why our custom aluminum sandwich panels are a go-to choice for projects requiring lightweight, insulated, fire-resistant, and structurally sound panels.

Customization Options for Aluminum Sandwich Panels

As a leading aluminum sandwich panel manufacturer, we understand that every project has unique needs. That’s why we offer a wide range of custom aluminum sandwich panels tailored to your specifications.

Custom Sizes and Thicknesses

- Panel thickness: Choose from 10mm up to 50mm or more, depending on your insulation and structural requirements.

- Dimensions: We can produce panels in standard or oversized formats to fit precise installation needs, ensuring minimal waste and easy handling.

- Core type: Various core materials (PVC, polyethylene, fire-resistant mineral core) customizable by thickness for different performance levels.

Surface Finishes and Colors

- Finishes: Options include smooth, embossed, or brushed aluminum skins that enhance appearance and improve durability.

- Colors: Wide color palette available through PVDF or polyester coatings, including custom colors to match your branding or architectural design.

- Texture: Choose from matte, glossy, or satin finishes for the perfect look and feel.

Optional Coatings and Treatments

- Anti-corrosion coatings: Extend panel life in harsh environments, ideal for coastal or industrial areas.

- Fire-retardant treatments: For enhanced safety, especially in commercial or public buildings.

- UV resistant coatings: Protect colors from fading under intense sunlight, perfect for outdoor façade applications.

- Anti-graffiti and easy-clean coatings: Keep panels looking new and minimize maintenance efforts.

| Feature | Options Available | Benefit |

|---|

| Thickness | 10mm – 50mm+ | Tailored insulation & strength |

| Size | Standard and custom | Fits exact project measurements |

| Surface Finish | Smooth, embossed, brushed | Aesthetic and functional choice |

| Color | Custom colors with PVDF/polyester | Match design and branding |

| Coatings | Anti-corrosion, fire-retardant, UV resistant, anti-graffiti | Increased durability and safety |

By choosing our customizable aluminum composite panel manufacturing services, you get a product built around your needs, optimized for local U.S. building codes, climate demands, and aesthetic trends.

Manufacturing Capabilities of Aluminum Sandwich Panel Manufacturer

High Production Capacity

As a top aluminum sandwich panel manufacturer, we maintain a robust production line capable of handling large-scale orders efficiently. Our facilities are equipped to produce thousands of square meters of lightweight aluminum panels monthly, ensuring we meet the demands of commercial and industrial projects across the United States.

Advanced Quality Control Systems

Quality is at the heart of our manufacturing process. We implement rigorous quality control systems at every stage—from raw material inspection to final product testing. These include:

- Detailed checks on aluminum core panel producer materials

- Thickness and flatness measurements

- Adhesion and bonding tests to ensure panel durability

- Fire and thermal resistance verification

- Compliance checks with structural standards

This thorough approach guarantees that each panel meets or exceeds industry standards, giving our customers confidence in their purchase.

Efficient Lead Times and Reliable Delivery

We understand the importance of timely delivery in construction and transportation projects. Our streamlined operations enable us to offer competitive lead times, typically ranging from 2 to 4 weeks depending on order size and customization needs. We also collaborate with reliable shipping partners to ensure secure and on-time delivery anywhere in the US.

By focusing on these manufacturing capabilities, we position ourselves as a dependable sandwich panel supplier who delivers quality, precision, and prompt service consistently.

Certifications and Standards for Aluminum Sandwich Panel Manufacturer

ISO Certifications

As a trusted aluminum sandwich panel manufacturer, we prioritize quality and consistency. Our production process is fully compliant with ISO 9001 quality management standards. This ensures that every panel meets strict quality controls from raw materials to final inspection. We also align with ISO 14001 for environmental management, emphasizing our commitment to sustainable manufacturing practices.

Fire and Safety Certifications

Safety is a top concern in the U.S. building and transportation markets. Our fire-resistant sandwich panels comply with key fire safety standards such as ASTM E84 (UL 723) for surface burning characteristics. We also meet NFPA 285 requirements for multi-story building façade systems, making our insulated aluminum panels a reliable choice for fire-sensitive applications. These certifications verify that our panels provide excellent fire protection without compromising on performance.

Environmental Compliance

Environmental responsibility is part of our manufacturing philosophy. Our aluminum sandwich panels are produced using eco-friendly methods, ensuring they meet RoHS (Restriction of Hazardous Substances) and REACH regulations. Additionally, the aluminum used is often recycled, contributing to resource conservation and reducing environmental impact. This aligns with growing demand from U.S. customers for sustainable construction materials that support green building certifications like LEED.

Applications of Aluminum Sandwich Panels

Construction

Our aluminum sandwich panels are widely used in construction for their strength, lightweight nature, and excellent insulation. They’re perfect for facade cladding, interior partitions, roofing, and ceilings. Builders prefer these panels because they are easy to install, reduce overall building weight, and offer superior thermal efficiency. Whether it’s commercial buildings or residential projects, insulated aluminum panels help meet energy codes while enhancing the building’s appearance.

Transportation

In transportation, these panels stand out due to their lightweight aluminum panel design and durability. They’re commonly applied in truck bodies, trailers, railway cars, buses, and even marine vessels. The strong aluminum skin combined with core materials like honeycomb or foam provides excellent noise reduction, impact resistance, and fire safety—critical factors for vehicle manufacturers looking for high-performance and fuel-efficient solutions.

Industrial

Our panels are a go-to for various industrial applications where structural aluminum panels are essential. They serve as protective walls, cleanroom panels, cold storage, and equipment enclosures thanks to their fire resistance and thermal insulation. The panels’ resistance to corrosion and ease of cleaning make them ideal for manufacturing plants, warehouses, and food processing facilities. Their customizable features allow you to tailor panels to meet strict industrial requirements.

In all these sectors, our aluminum sandwich panels combine reliability, performance, and flexibility, making us a trusted supplier in the U.S. market for both standard and custom applications.

Why Choose Shanghe Aluminum Sandwich Panel Manufacturer

Proven Experience and Industry Expertise

With years in the business, Shanghe stands out as a trusted aluminum sandwich panel manufacturer in the U.S. market. We combine deep industry know-how with cutting-edge production technology to deliver high-quality, lightweight aluminum panels that meet diverse project needs. Our team understands the nuances of aluminum composite panel manufacturing, ensuring every product offers durability, fire resistance, and superior insulation.

Positive Client Testimonials

Our reputation is built on consistent customer satisfaction. Clients across construction, transportation, and industrial sectors highlight our reliability, product performance, and timely deliveries. Here’s what some say:

- “Shanghe’s panels boosted our building’s energy efficiency and look fantastic.”

- “They customized panels to our exact size and finish requirements, no hassle.”

- “Excellent communication and dependable after-sales support.”

Strong After-Sales Support and Guarantees

We don’t just supply panels; we back them with comprehensive after-sales service. This includes:

- Technical support during installation

- Warranty coverage on materials and manufacturing defects

- Quick response to any product concerns throughout the project lifecycle

Choosing Shanghe means you get trusted expertise, quality product assurance, and responsive customer care—key factors when selecting a reliable aluminum sandwich panel supplier.

Ordering Aluminum Sandwich Panels Contact Information

When you’re ready to order custom aluminum sandwich panels or have questions about our aluminum composite panel manufacturing, we make it easy to get in touch and start your project.

Request a Quote

To get a detailed quote tailored to your project’s needs:

- Visit our online Request a Quote form on the product page

- Provide essential details like panel size, thickness, core material, and required quantity

- Include any specific customization or finish preferences

- Our team will respond promptly with pricing, lead times, and further recommendations

This process ensures you receive an accurate offer for your insulated aluminum panels or fire-resistant sandwich panels.

Contact Channels

For direct assistance, you can reach our sales and support team via:

- Phone: Quick answers to product specs, availability, and orders

- Email: Send inquiries or detailed requests at your convenience

- Live Chat: Immediate support for quick questions or guidance during business hours

We prioritize timely communication and aim to support your project from quote to delivery.