When people ask whether sandwich panels are waterproof, the accurate answer is that modern sandwich panels can achieve waterproof performance, provided that the correct type is selected, the installation follows proper sealing practices, and the system is designed according to building-science principles. This conclusion comes from technical evaluations across multiple regions such as Texas, Florida, Singapore, Malaysia, and the Philippines, where high humidity and heavy rainfall consistently test the moisture resistance of building materials. Because of these varying environments, the performance of sandwich panels under water exposure can be assessed in a more objective and predictable way.

Additionally, when different project teams evaluate these systems, they often note that the concept of “waterproof” is frequently misunderstood. Therefore, the essential point is that waterproof performance is determined by the panel’s physical composition, joint engineering, protective coatings, and correct assembly rather than anecdotal installation experiences. Across multiple facilities and climate zones, the consistent outcome is that sandwich panels are capable of resisting water intrusion when engineering and installation guidelines are followed.

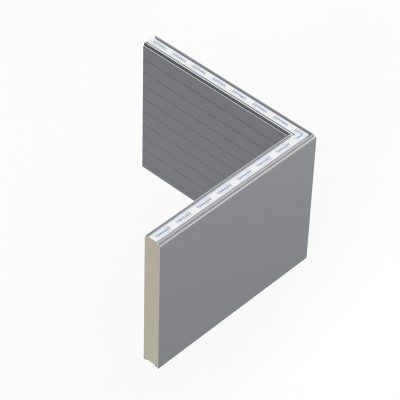

Can Sandwich Panels Resist Water

Yes, sandwich panels can resist water, although the level of resistance varies depending on material composition and the overall system design.

This is supported by Dr. J.M. Davies in Lightweight Sandwich Construction (Woodhead Publishing, 2001, pp. 88–94), where it is explained that closed-cell core materials like PIR and PU offer lower water absorption rates compared to EPS, which may absorb moisture through exposed edges. Consequently, selecting a core material with controlled water absorption characteristics significantly increases resistance.

Furthermore, this assessment aligns with comparative data gathered from different climate zones, showing that PIR panels retain dimensional and thermal stability even when exposed to prolonged atmospheric moisture. Because water resistance is a function of both the core and the exterior skins, selecting high-quality metal facings and coatings also contributes to reduced water penetration.

What Are The Waterproof Properties Of Sandwich Panels

Waterproof performance comes primarily from several engineered characteristics:

Closed-cell foam cores such as PU and PIR, which have water absorption rates below 2% according to Prof. Vasudev Marathe, Polymer Testing (2019, DOI:10.1016/j.polymertesting.2019.06.020).

Metal skins that form a continuous protective barrier.

Factory-applied coatings designed for corrosion and moisture resistance.

Interlocking joint profiles that minimize water ingress.

Sealants, gaskets, and butyl tapes used at installation joints.

Additionally, Prof. Andrea Bernasconi, in Composites Part B: Engineering (2010, DOI:10.1016/j.compositesb.2010.05.001), demonstrates that PU and PIR outperform EPS and phenolic cores in long-term water absorption testing. Therefore, appropriate material choice remains essential.

How To Make Sandwich Panels Waterproof

Effective waterproofing requires the following steps:

Applying double-layer butyl tape in joints.

Using high-grade exterior weatherproof mastics on longitudinal seams.

Installing end caps and closed edges to prevent exposure.

Flashing all penetrations made during construction.

Adding drip-edge flashing at roof edges to redirect water.

As Dr. Mark Bomberg notes in Moisture Control in Buildings (Journal of Building Physics, 2018, DOI:10.1177/1744259118766501), installation errors at panel edges are the primary cause of moisture intrusion. Therefore, strict adherence to installation guidelines is essential for achieving intended performance.

Sandwich Panels Vs Other Building Materials For Waterproof Applications

| Material | Waterproof Performance | Risk Level | Notes |

|---|---|---|---|

| Sandwich Panels | High | Low | Effective when factory joints are sealed correctly |

| Fiber-Cement | Medium | Medium | Moisture absorption at cut edges |

| Wood Sheathing | Low | High | Requires multiple waterproofing layers |

| Concrete Panels | Medium | Medium | Susceptible to cracking |

Because of these characteristics, sandwich panels often outperform traditional layered systems, especially in high-humidity or heavy-rainfall regions.

Best Practices For Using Sandwich Panels In Humid Environments

Humid regions such as Florida, Singapore, and Manila require:

Selecting PIR or high-density PU cores.

Using hidden-joint systems with engineered laps.

Adding secondary vapor barriers where interior humidity is high.

Keeping panel edges elevated from standing water.

Scheduling installation during lower humidity periods when possible.

These recommendations correspond to findings from Prof. L. Gibson, Cellular Materials in Nature and Medicine (MIT Press, 2010, p. 156), which notes that closed-cell materials preserve performance under high vapor pressure.

Are There Any Special Considerations When Installing Sandwich Panels In Areas With High Rainfall

Yes. Projects in regions with frequent heavy rainfall should incorporate:

Extended roof overhangs.

Two-stage sealing at roof laps.

Roof slopes of at least 3%.

Capillary-break trim at vertical interfaces.

These adjustments reduce the likelihood of water penetration and enhance long-term performance.

Waterproof Sandwich Panel Manufacturers

Reliable manufacturers normally comply with the following standards:

EN 14509

ASTM E96

FM 4471

ISO 9227

Referenced standards:

EN 14509: Link

ASTM E96: Link

ISO 9227: Link

FM Approvals: Link

Advantages And Disadvantages Of Using Waterproof Sandwich Panels

Advantages

Faster overall installation

High water resistance

Reduced structural load

Improved thermal insulation

Low maintenance requirements

Disadvantages

EPS edges are vulnerable if not sealed

Joint alignment must be precise

Installation quality strongly affects results

Do All Types Of Sandwich Panels Have The Same Level Of Water Resistance

No. The ranking based on performance is:

PIR

High-density PU

Rockwool (waterproof skins only; core not waterproof)

EPS

This hierarchy aligns with Bernasconi’s 2010 absorption study.

Comparing Costs Waterproof Sandwich Panels Versus Traditional Waterproofing Methods

Waterproof sandwich panels frequently replace assemblies such as:

Concrete with membrane layers

Stud walls with OSB + WRB + siding

Metal walls requiring separate insulation and vapor barriers

When labor, adhesives, curing, and additional layers are considered, sandwich panels often deliver 20–35% overall cost savings, depending on regional labor rates and installation proficiency.

Applications Of Waterproof Sandwich Panels In Construction

Waterproof sandwich panels are commonly used for:

Cold storage facilities

Modular building units

Temporary structures in typhoon regions

Warehousing

Food-processing spaces

Remote construction camps

These applications rely on the panels’ ability to maintain moisture control under varied climatic conditions.

How Does The Weather Affect The Performance Of Waterproof Sandwich Panels

Environmental variables influence performance:

Heat increases metal expansion

Low temperatures may stiffen sealants

Rain affects installation but not inherent performance

Salt-air regions require corrosion-resistant coatings

Weather impacts installation more than the panel’s intrinsic waterproof capacity.

Is It Possible To Repair Damaged Waterproof Sandwich Panels

Yes. Repair methods include:

Sealing surface punctures

Replacing compromised joints

Installing supplementary flashing

Replacing individual panels when necessary

These procedures typically require limited time and labor.

Certifications And Standards For Waterproof Sandwich Panels

The following certifications indicate reliable waterproof performance:

EN 14509

ASTM E96

ISO 9227

FM 4471 / FM 4880

Compliance demonstrates the panel’s ability to meet structural, moisture, and corrosion-resistance requirements.

Maintenance Tips For Keeping Sandwich Panels Waterproof

Recommended maintenance practices include:

Re-sealing joints every 8–10 years

Inspecting fasteners annually

Maintaining clear drainage paths

Checking flashing after storms

Removing vegetation near panel surfaces

Periodic maintenance ensures sustained waterproof performance across decades of service life.