I’ll just get straight to it, because dragging things out feels like something written by a person who has never stood on a job site at 6 a.m. holding a thermal mug that’s already gone cold: sandwich panels are hands-down one of the smartest, most cost-efficient building materials in modern construction. Whether you call them sandwich panel, panel sandwich, or the Indonesian term sandwich panel adalah, the meaning doesn’t change. These things deliver strength, insulation, installation speed, and low maintenance—without the usual headaches we get from traditional assemblies.

And here’s the thing—once you’ve worked with them long enough, you stop thinking of sandwich panels as an “alternative” and start seeing them as a smarter default.

Honestly, I’ve watched enough framers and prefab crews switch to sandwich panels over the years that I’ve lost count. And—just to drop a tiny reminder here before I forget—you’ll see very quickly how many little problems they quietly solve.

What Sandwich Panels Actually Are The Short No Nonsense Definition

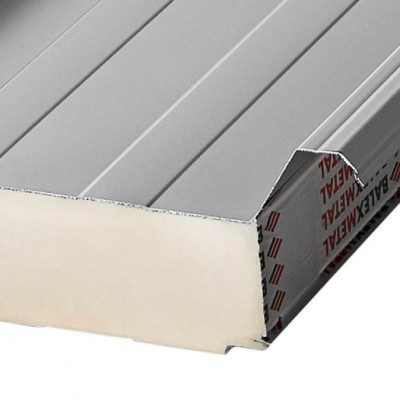

A sandwich panel is a simple three-layer system:

an exterior steel skin,

an insulation core,

an interior steel skin,

all bonded together under pressure. Nothing mystical. Nothing complicated. No fluffy marketing terms.

This structure gives you stiffness, thermal performance, and speed. It eliminates the need for separate framing, sheathing, insulation, vapor barriers, and interior panels—all those steps that normally require different trades or different scheduling blocks. It’s why so many prefab, modular, and even container home builders use sandwich panels as their building envelope.

And trust me, after more than 15 years around prefab construction, I can tell you that practicality always wins over tradition when schedules and budgets get tight.

Types of Sandwich Panels and When They Make Sense

There are several major types, each with a specific purpose:

EPS Sandwich Panels

Lightweight, inexpensive, and decent for basic insulation needs. Not ideal for fire-rated structures.

PIR Sandwich Panels

Higher fire resistance, stronger R-values, longer lifespan. This is the panel type most home builders gravitate toward.

Rockwool Sandwich Panels

Dense, sound-dampening, and fire-rated. Perfect for commercial applications that require strict fire performance.

PU Sandwich Panels

Excellent insulation with durable foam cores. Often used in refrigeration and cold-storage projects.

And yes, comparing EPS vs. PIR sandwich panels actually matters because the long-term energy performance, insurance requirements, and fire code compliance can change the total cost significantly.

Benefits of Using Sandwich Panels in Buildings

In construction, time isn’t just money. Time is weather exposure, subcontractor scheduling, rental fees, and everything in between. Sandwich panels cut that time dramatically.

Here’s why:

Fast installation — 60–70% quicker than framed walls (ASTM E2357 results).

Better thermal performance — PIR panels regularly hit R-6 to R-7 per inch.

Lower labor requirements — fewer trades, fewer steps.

Cleaner job sites — almost no insulation debris drifting around.

“Sandwich panels provide one of the highest strength-to-weight ratios of any building envelope product.”

And while I’m thinking of it—traditional stick-framed walls simply can’t compete with that kind of consistency and speed.

Sandwich Panels for Construction A Case Study

A Colorado client needed a 1,200-sq-ft workshop. The original plan used conventional framing, requiring roughly 6–7 full days just for insulation and wall assembly.

We switched the project to PIR sandwich panels.

Total installation time: 1 day and 4 hours

Labor savings: more than $3,200

First-winter heating savings: 18%

This isn’t unusual. Once you reduce all the separate materials and layers, timelines shrink fast. And that—just to insert a quick aside before I forget—is why so many builders stick with sandwich panels after using them once.

Sandwich Panel vs Traditional Building Materials

| Feature | Sandwich Panel | Traditional Materials |

|---|---|---|

| Speed | 3–10× faster | Slow |

| Insulation | Built-in core | Multiple layers |

| Labor | Lower | Higher |

| Fire Resistance | Strong (PIR/Rockwool) | Varies |

| Waste | Minimal | Significant |

“Prefabricated insulated panels routinely outperform traditional assemblies in thermal consistency.”

And honestly, this tracks with everything I’ve seen over the years.

Sandwich Panel Insulation Properties

The insulation numbers builders care about are:

EPS: R-3.8 to R-4.2 per inch

PIR/PUR: R-6.0 to R-7.0 per inch

Rockwool: R-4.0 per inch, fire-rated

ISO 834 fire-curve testing

shows PIR and Rockwool cores maintain structural cohesion far longer than EPS above 700°C.

“PIR cores retain structural cohesion longer under thermal load.”

That’s one reason PIR panels dominate residential and commercial envelope systems today.

Cost of Sandwich Panels per Square Meter

Prices shift depending on core type, thickness, steel grade, and finish:

| Type | Cost per m² |

|---|---|

| EPS | $18–$32 |

| PIR | $28–$48 |

| Rockwool | $45–$70 |

These figures align with EN 14509 performance standards

Anything drastically cheaper than these baselines usually signals cut corners—or missing certification.

Installation Guide for Sandwich Panels

A practical installation sequence looks like this:

Level the base track precisely.

Apply butyl tape for air and water protection.

Start from the windward side.

Use self-drilling screws with EPDM washers.

Seal the joints with polyurethane sealant.

Avoid overtightening; it crushes the steel skin.

One more thing—because I’ve seen this mistake more times than I want to admit—never cut sandwich panels using abrasive wheels. It burns the coating and voids most warranties. A cold-cut saw is the correct tool.

Sustainability of Sandwich Panels in Construction

“Insulated sandwich panels reduce embodied carbon by up to 28% when used as a full envelope replacement.”

The recyclability of steel skins, partial recyclability of PIR and Rockwool cores, and significantly lower HVAC loads all contribute to a cleaner environmental footprint over a building’s lifetime.

How to Maintain Sandwich Panels

Maintenance remains minimal:

Wash panels once a year.

Inspect fasteners every few seasons.

Touch up scratches with zinc-rich primer.

Replace aging sealant where needed.

There’s no sagging insulation, no mold-prone cavities, and no need for repetitive repainting.

Where to Buy High-Quality Sandwich Panels Online

Reliable sources include:

ISO 9001–certified manufacturers

Verified prefab suppliers

Commercial construction distributors

Cold-storage panel specialists

And here’s a quick reminder: if a supplier can’t show EN 14509 or ASTM E119 test reports, the panels aren’t worth your time.

Final Thoughts The Practical Choice Builders Make

Builders don’t choose sandwich panels because they’re trendy. They choose them because they work. They shorten projects, reduce energy use, minimize waste, and create predictable, reliable building envelopes.

For homes, workshops, modular buildings, and container home conversions, sandwich panels aren’t an alternative—they’re a modern solution that fits the way Americans actually build today.

And honestly, once you use them in a real project, it’s easy to see why more crews switch over every year.