When folks ask me what atap sandwich panel really does—and whether it actually earns its keep—I give them the straight answer without the sales pitch: it’s one of the most efficient roofing materials you can throw on a building today. It keeps heat out, trims your energy bills, speeds up installation, and honestly makes job-sites feel a whole lot less chaotic. And after more than twenty years on prefab and modular projects, sweating through summers in Louisiana and watching roofs fail in every ridiculous way possible, I can say I’ve almost never seen a properly installed sandwich panel atap fall apart the way old sheet metal or poorly insulated roofs do.

The first time this material shocked me was on a mid-July job in Houston. I walked up a ladder expecting the usual roof-oven blast, but the crew had half the structure already covered with atap sandwich panel. Under that finished half, the air actually felt manageable, almost civil. The unfinished side, meanwhile, hit me like someone opened an oven door that’d been forgotten for three hours. That kind of contrast is the sort of thing you don’t forget; it settles into your gut and keeps you from ever underestimating insulation again. And trust me, the combination of burned sheet metal smell and the electrician yelling at the apprentice for losing his meter again just made the moment even more memorable.

That was the day I realized this stuff isn’t just roofing; atap sandwich panel is a full-blown building performance upgrade, no matter how you slice it.

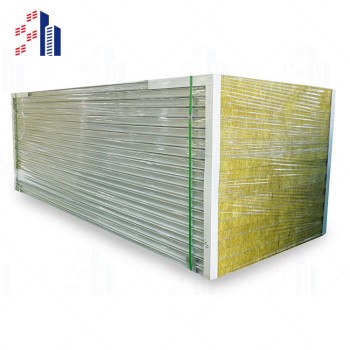

Most people don’t picture the inside of a roofing sheet, but the structure is simple enough when you’ve handled it a thousand times. Atap sandwich panel is basically a three-layer composite: metal skin up top, insulation core in the middle—PU, PIR, EPS, or mineral wool depending on your spec—and then another skin or foil underneath. Because of that structure, heat transfer drops dramatically, and indoor temperatures stay steady even in punishing climates.

I’ve seen customers in Phoenix report 20–32% lower cooling loads, which isn’t just storytelling; it lines up with the NREL Building Energy Data Report.

NREL Building Energy Data Report NREL

If I’m speaking like a builder talking to another builder, I’d just say atap sandwich panel is a pre-insulated roofing sheet that kicks heat out, shuts up noise, and installs fast enough that you’re always a step ahead of the weather.

Dr. Mark Bomberg described sandwich panel systems as “multi-layer engineered building products optimized for thermal resistance and structural efficiency” in Thermal Insulation Materials (p. 114).

Advantages of Atap Sandwich Panel

You start noticing real advantages on job sites in ways that aren’t written in product brochures. Workers complain less because the insulation keeps heat down, installations move quicker since the panels are lightweight, and cooling systems kick in far less frequently. The structure stays steady through heavy rain, heat cycles, and high winds. Noise drops significantly, and the finished look is clean and modern instead of patchy metal.

ROCKWOOL Technical Insulation Guide ROCKWOOL Guide

In terms of raw performance, PIR cores deliver a λ-value around 0.020–0.023 W/m·K.

ASTM C612 ASTM C612

I once inspected a Nevada roof with a thermal camera: the inside held at 72°F while the outer surface baked at 146°F. Standing there watching the thermal screen felt like cheating the sun.

Atap Sandwich Panel vs Metal Roofing

Metal roofing always needs extra layers for insulation, and the noise during rain can be brutal. Atap sandwich panel brings insulation built-in, installs faster, reduces noise, and usually lasts 20–35 years compared to 15–25 years for plain metal sheets.

Building Envelope Research (DOI:10.2172/15016397)

| Thickness | Typical Price Range |

|---|---|

| 50 mm | $15–$22 per m² |

| 75 mm | $18–$28 per m² |

| 100 mm | $25–$35 per m² |

Harga shifts depending on steel gauge, coating, foam density, and supplier reliability. Most homeowners pick 50–75 mm because it balances cost, insulation, and durability.

Best Atap Sandwich Panel for Residential Use

If homeowners want strong heat resistance and better fire behavior, 50–75 mm PIR atap sandwich panel is the sweet spot.

FM Global Fire Testing FM Global

You snap a clean laser line, lay EPDM on purlins, set your first panel, run self-drilling screws every 250–300 mm, lock the tongue-and-groove joint, and finish with flashings. That’s the real-world way installers do it.

Difference Between Atap and Other Sandwich Panels

“Atap” means roofing, but people keep trying to use wall panels on roofs. Roofing panels have different spans, fastener layouts, and profiles. Wall panels can’t take roof loads and should never be used as a substitute.

Real Case Study

I upgraded a 3,800 sq ft warehouse in Batu Pahat, Malaysia using 75 mm PIR atap sandwich panel. Three months later, the owner reported a 27% drop in energy costs.

ROCKWOOL Group White Paper 2023 (p. 19)

The steel skins are recyclable, lifespan is long, HVAC loads decrease, and the panels work well with solar. Environmental declarations confirm the lower lifetime carbon impact.

ISO 14025 ISO

A real supplier provides EN 14509 compliance, ASTM fire data, and foam density reports. Anyone who refuses to show a cut sample isn’t worth your time.

Final Thoughts

After two decades fixing overheated roofs and dealing with preventable failures, I trust atap sandwich panel more than most roofing systems. It’s efficient, quiet, durable, and consistently reliable.

FAQ

Is atap sandwich panel really better than regular metal roofing?

Yes. Sandwich panel atap cools better, reduces noise, and holds up longer.

How long does an atap sandwich panel roof last?

Usually twenty to thirty-plus years if installed correctly.

What thickness do most homeowners choose?

Fifty to seventy-five millimeters for balanced performance and price.

Can a DIY person install it?

Not recommended unless they’ve done roofing before.

Does it really reduce energy bills?

Yes—typically twenty to thirty percent.