Product Processing Video

Why David Swears by Them After 20 Years in the Industry

Why David Swears by Them After 20 Years in the Industry

Let me tell you, if you’re looking for a lightweight, durable, and cost-effective building solution, plywood foam sandwich panels are the way to go. After two decades in the sandwich panel industry, I—David—can confidently say these panels are a game-changer. They combine the strength of plywood with the insulating power of foam, making them perfect for walls, roofs, and even flooring.

What’s the biggest pain point I hear? People worry about traditional materials being too heavy, expensive, or lacking insulation. Well, plywood foam sandwich panels solve all that. They’re up to 50% lighter than solid wood, cutting down on labor and transport costs. Plus, the foam core provides excellent thermal and acoustic insulation—something LEED-certified builders love for sustainable projects.

And here’s the kicker: they’re easy to install. No need for heavy machinery or specialized tools. Just cut, fit, and secure. Whether you’re a contractor or a DIY enthusiast, these panels save time and hassle. Trust me, after 20 years, I’ve seen how they outperform traditional materials every single time.

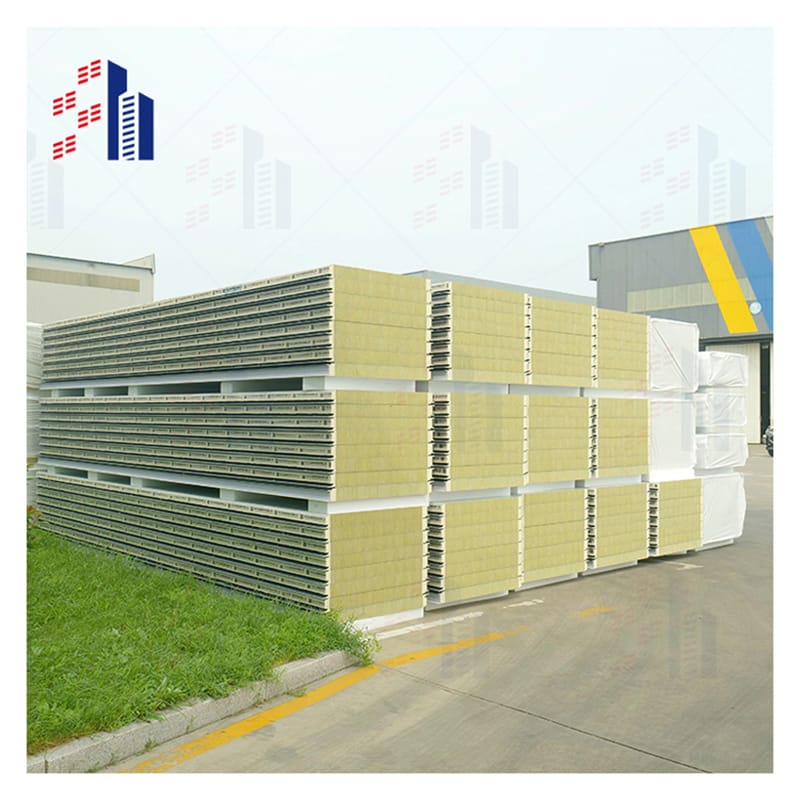

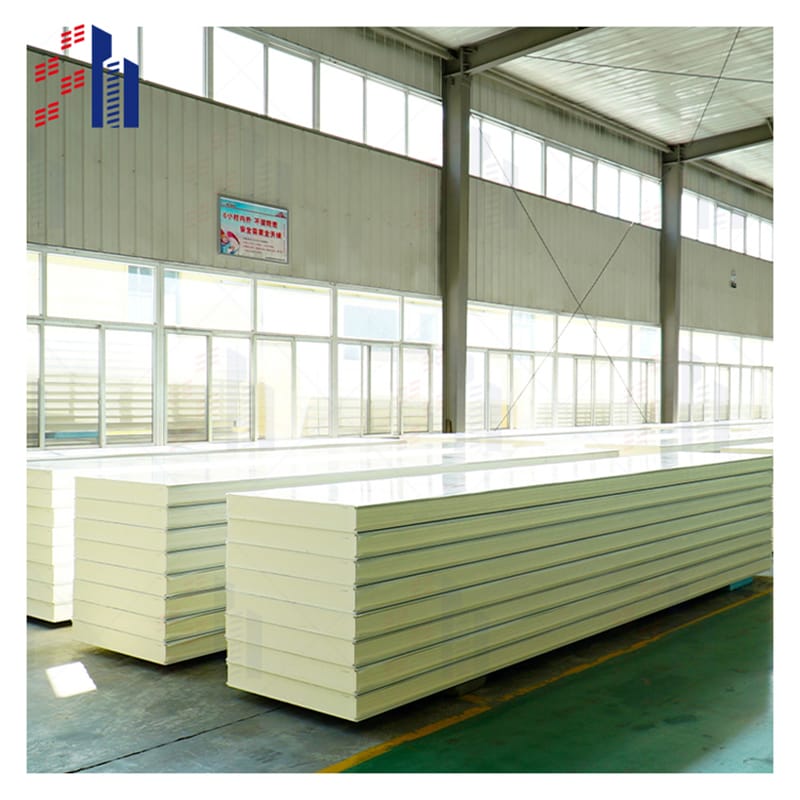

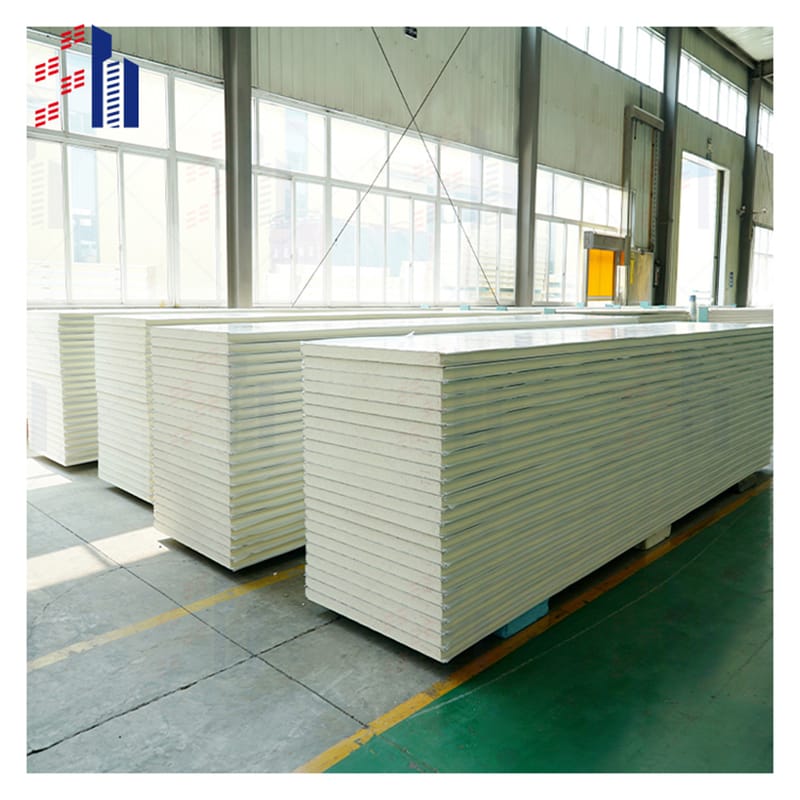

Customers visit the factory

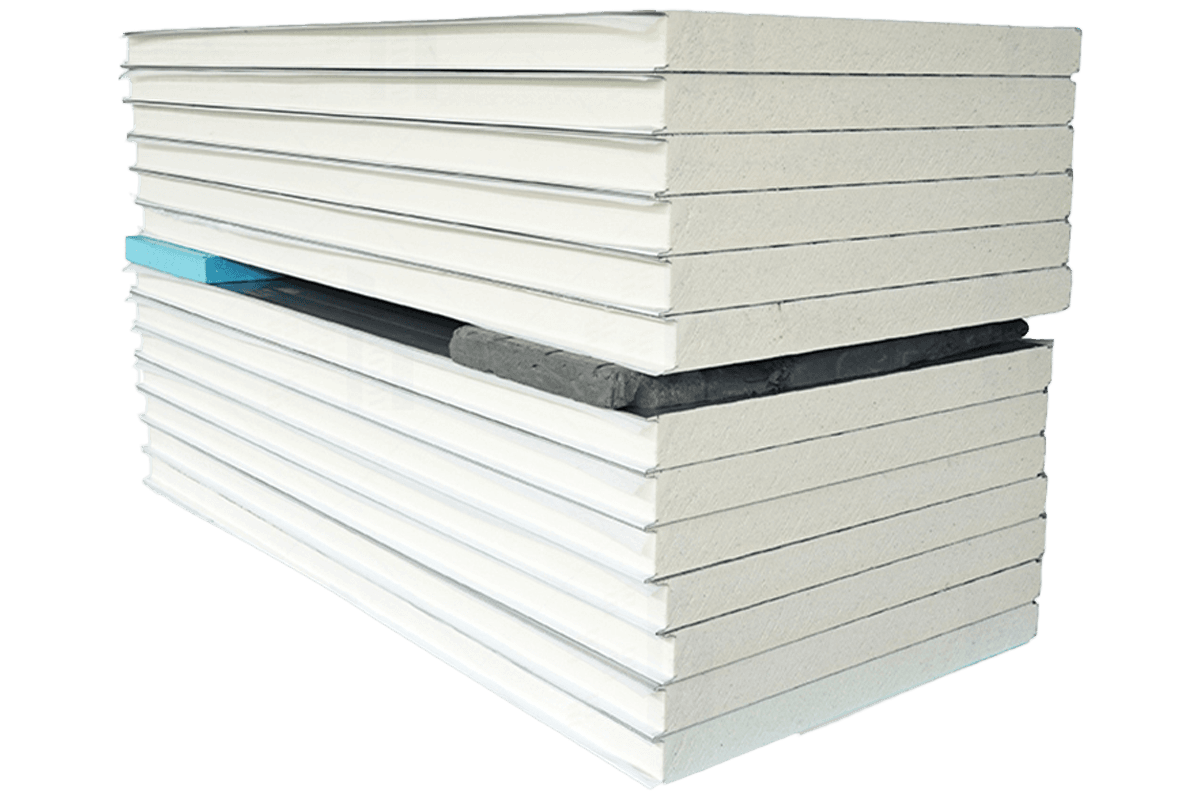

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | XPS Foam (ASTM C578) or EPS Foam (ASTM D6817) | XPS = higher moisture resistance; EPS = lower cost. |

| Plywood Faces | 3/8″ to 3/4″ Birch/Spruce (FSC Certified) | Thicker plywood = better screw-holding strength. |

| R-Value | R-5 (1″) to R-12 (3″) | Higher R-value = better insulation for cold climates. |

| Panel Thickness | 1″ to 4″ (custom increments) | Thinner for walls, thicker for roofs/floors. |

| Weight | 1.8–3.2 lbs/sq ft | Lighter than solid wood = faster install. |

| Fire Rating | Class A (ASTM E84) – Optional FR coating | Meets US/Canada building codes for walls. |

| Max Load Capacity | Up to 250 PSF (static) | Safe for flooring/RV use. Test reports available. |

| Customization | Pre-cut sizes, tongue & groove edges | Saves 20%+ labor vs. on-site cutting. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | plywood foam sandwich panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

plywood foam sandwich panels: David’s Top 5 Reasons They Beat Solid Wood Every Time

Alright, let’s settle this debate once and for all—plywood boards are simply better than solid wood for most projects. Why? First off, they’re more stable. Solid wood warps and cracks with humidity changes, but plywood’s cross-layered construction keeps it rock-solid.

Second, cost. Plywood is way more affordable without sacrificing quality. Third, versatility. You can use it for everything from subfloors to custom furniture. Fourth, ease of use. It’s lighter, easier to cut, and holds screws better. And fifth? Sustainability. Many plywood brands are FSC-certified, meaning they come from responsibly managed forests.

I’ve had clients swear they’d never go back to solid wood after switching. One even told me, “David, I saved 30% on my build and got twice the durability.” Need more proof? Look at modern construction—plywood is everywhere because it just works.

Plywood Feature Wall Secrets: How David Makes Them Look High-End on a Budget

Want a stunning plywood feature wall without breaking the bank? Here’s the secret: it’s all about finish and spacing. After 20 years in the industry, I’ve perfected the art of turning basic plywood into a luxury statement piece.

First, sand it smooth—no one wants rough edges. Then, choose a stain or paint that matches your vibe. Dark walnut stains give a rich, modern look, while whitewashed plywood keeps things airy and Scandinavian. Next, play with patterns. Herringbone, vertical planks, or even geometric cutouts can make it look custom-designed.

The best part? Cost savings. A high-end feature wall with solid wood can cost thousands, but plywood does the same job for a fraction. One of my clients, a boutique hotel owner, said, “Guests think it’s reclaimed oak—until I tell them it’s plywood!”

Pro tip: Seal it properly. A good polyurethane coat ensures it lasts for years without wear. Trust me, with the right touches, no one will guess it’s plywood.

Plywood 101: David’s No-Nonsense Guide to Picking the Right Type for Your Project

Plywood isn’t just plywood—there are different grades, cores, and finishes, and picking the wrong one can ruin your project. After 20 years, I’ve seen too many folks grab whatever’s cheapest and regret it later. Let’s fix that.

For structural projects (like flooring or roofing), go for CDX plywood. It’s tough, moisture-resistant, and built to last. For interior finishes (cabinets, furniture), birch or maple plywood gives a smooth, paintable surface. Need something water-resistant? Marine-grade plywood is your best bet, even though it’s pricier.

And here’s a big mistake I see: using particleboard instead of plywood for heavy loads. Particleboard sags over time—plywood doesn’t. As one contractor told me, David, I learned the hard way that cheap materials cost me double in repairs.