Sandwich Board Panels: Why 20-Year Veteran David Says Most Buyers Regret Their Choice

Let me tell you something—after 20 years in the sandwich board panels industry, I’ve seen too many buyers get burned. Why? Because they don’t know what separates a high-quality panel from a cheap imitation. The wrong choice means leaks, poor insulation, and even structural issues down the line.

Here’s the deal: Not all sandwich board panels are created equal. The core materials—whether PU, PIR, mineral wool, or EPS—determine insulation, fire resistance, and durability. And let’s not even get started on bad installation. I’ve had clients call me in a panic because their “budget-friendly” panels started warping in less than a year.

Look, if you want panels that last, focus on tested materials (like LEED-certified options) and trusted suppliers. Because when it comes to sandwich board panels, cutting corners now costs you way more later.

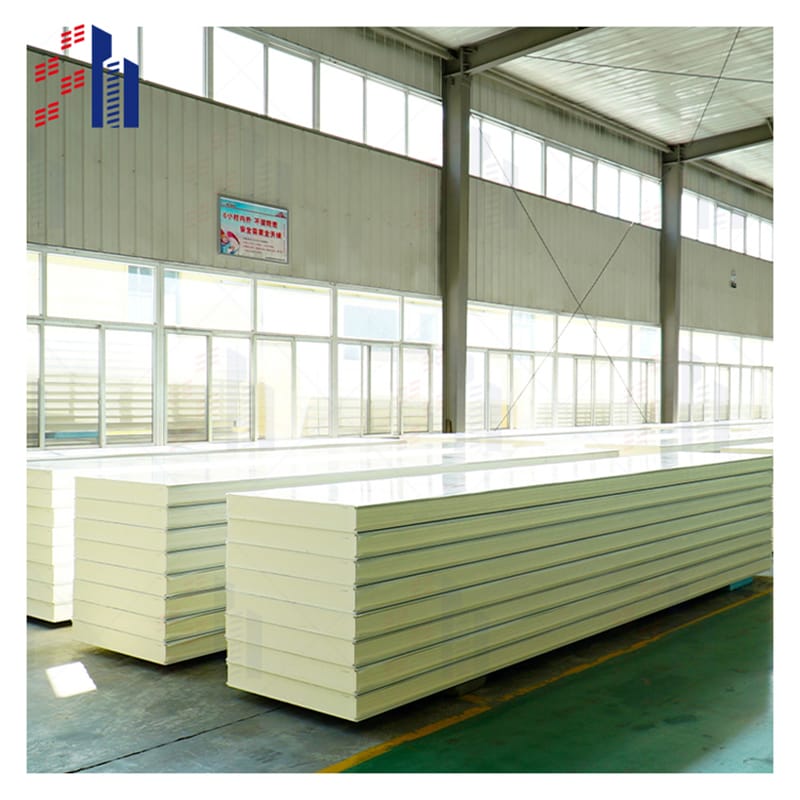

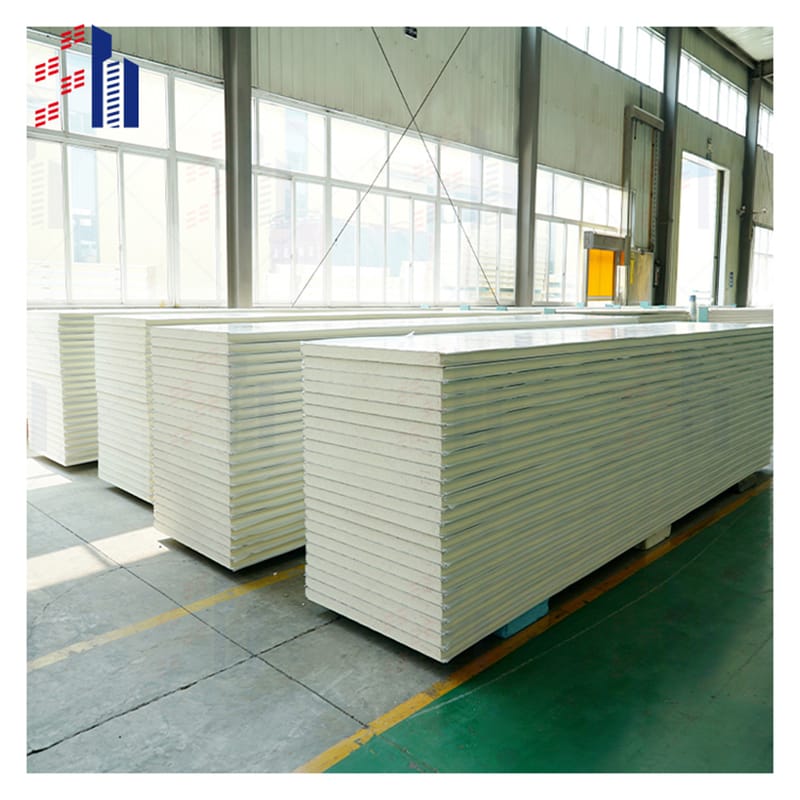

Product Processing Video

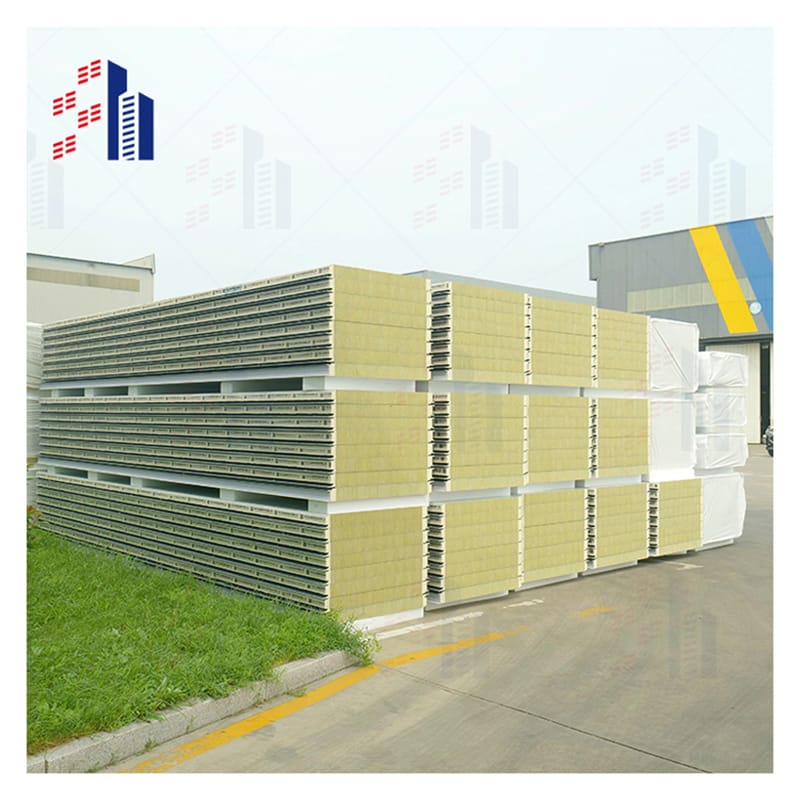

Customers visit the factory

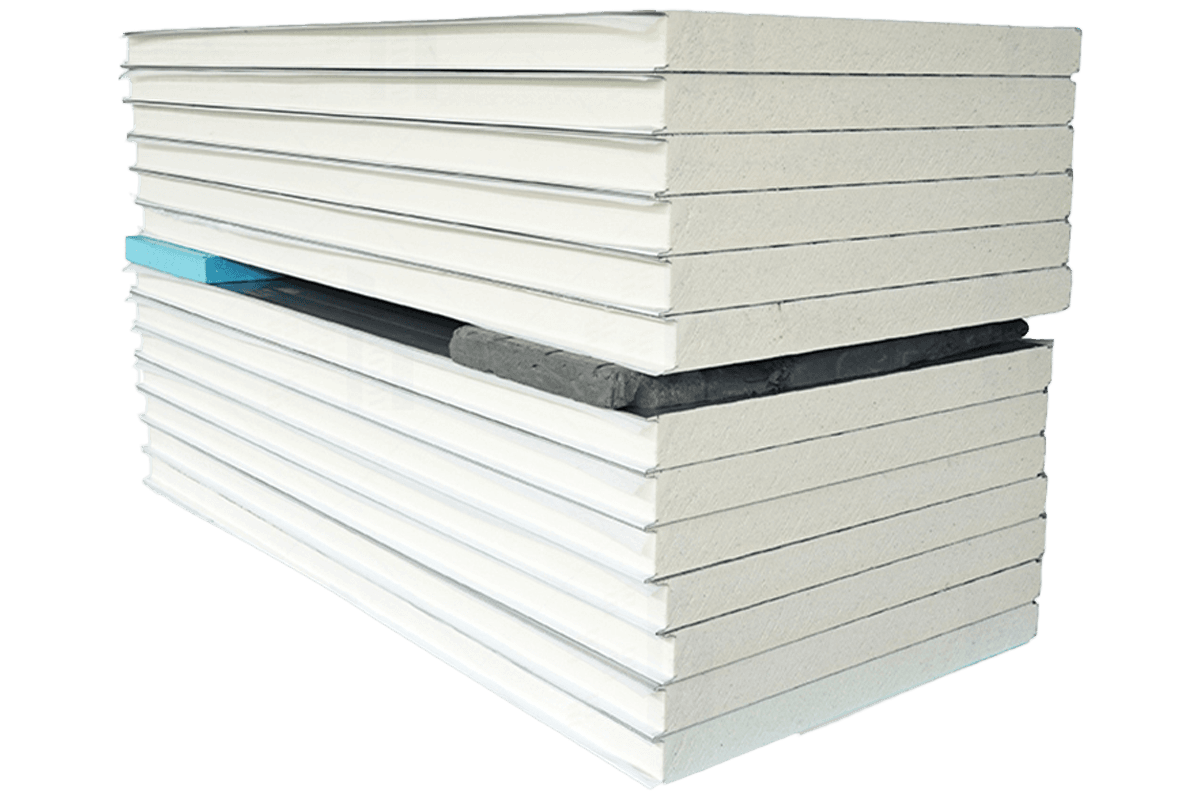

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyurethane Foam (PUF), density 40±2 kg/m³ | Higher density = better strength & insulation. |

| Fire Rating | A1 (non-combustible) – EN 13501-1, ASTM E84 Class A | Critical for warehouses, factories, and public buildings. |

| Thermal Conductivity (λ) | 0.022 W/m·K (tested per ISO 8301) | Lower λ = less energy cost for cooling/heating. |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom up to 200mm) | Thicker panels = better insulation (ideal for cold storage). |

| Facing Material | Galvanized steel (0.4mm–0.7mm), PVDF coating (anti-rust, 20+ year lifespan) | PVDF resists salt, chemicals, and UV rays. |

| Max Length | 12 meters (custom cuts available) | Reduces joints = faster installation. |

| Load Capacity | 150 kPa (compressive strength, ISO 844) | Supports heavy snow/wind loads. |

| Installation | Tongue-and-groove, hidden clips (no visible screws) | Clean finish, no thermal bridges. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich board panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Sandwich Board Wall Panels: The Mistake Contractors Make (And How to Avoid It)

Alright, let’s talk sandwich board wall panels—specifically, the biggest mistake I see contractors make. They assume all panels install the same way. Wrong. Depending on whether you’re working with aluminum, steel, or fiberglass-faced panels, the sealing and fastening methods change. And guess what? Screw this up, and you get moisture buildup, mold, or worse—energy leaks.

David here, and in my two decades installing sandwich board wall panels, I’ve learned this: Precision matters. For example, steel-faced panels need thermal breaks to prevent condensation. Skip that step? Enjoy rust stains in a few months.

Pro tip: Always check the manufacturer’s guidelines (bonus points if they’re ISO-certified). Because a proper install isn’t just about speed—it’s about avoiding callbacks.

Sandwich board panels: Why “R-Value” Alone Won’t Save You

If you’re picking sandwich-board insulation just based on R-value, you’re missing half the story. Yeah, R-value matters for heat resistance, but what about fire safety? Or moisture resistance? I’ve seen buildings with “high R-value” panels turn into sponges after one rainy season.

Here’s what matters more: composite performance. For instance, PIR cores have great R-values and fire resistance (up to Class 0 in some tests). But EPS? Cheap, but melts like butter in a fire.

My advice? Demand third-party test reports. Because real-world performance beats a shiny spec sheet every time.

Sandwich Panel Durability: 3 Signs You’re Buying Junk (According to David)

Listen, not all sandwich panels are built tough. Some delaminate after a few years, others fade or dent if you sneeze on them. How do you spot the bad ones? Here’s what I check after 20 years in the game:

Coating quality: Cheap PE coatings peel. Go for PVDF or SMP.

Core adhesion: Tap the panel—hollow spots mean poor bonding.

Warranty: If it’s under 10 years, walk away.

Trust me, spending 10% more now saves you 50% in repairs later.

Metal Sandwich Panel Myths—Busted by an Industry Insider

“Metal sandwich panels are noisy.” “They rust easily.” Nope—not if you buy the right ones. As someone who’s sourced panels for stadiums and factories, I can tell you: most complaints come from bad buys.

For example, galvanized steel with a fluorocarbon coating won’t rust. And noise? Add a mineral wool core, and it’s quieter than drywall.

The takeaway? Don’t believe the myths. Believe the specs.