What Are Fiber Cement Sandwich Panel

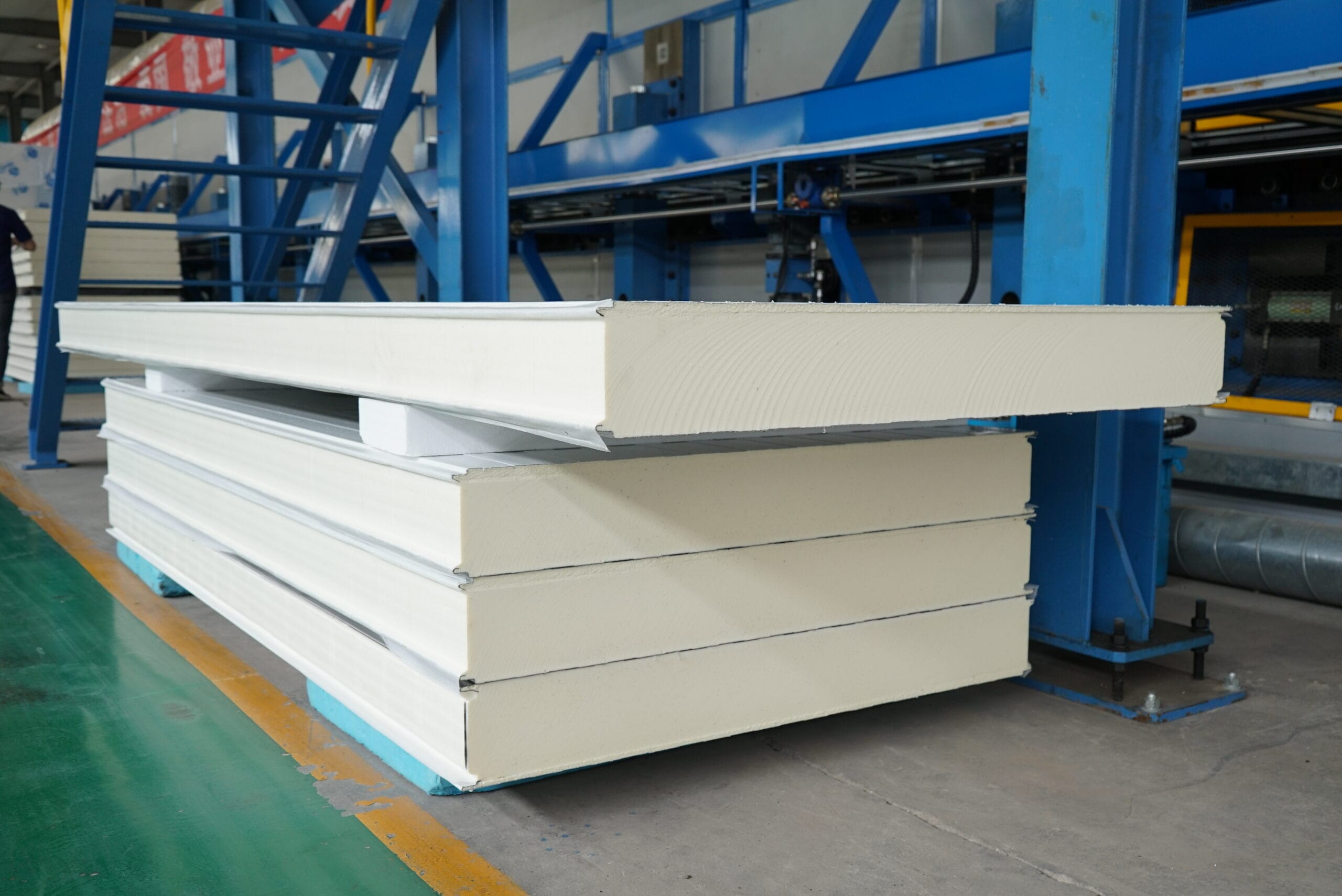

Fiber cement sandwich panel are advanced building materials made by layering fiber cement boards on both sides of a core material. This core is usually lightweight and provides insulation, while the fiber cement layers offer strength and durability. The manufacturing process involves bonding these layers under pressure and heat to create a rigid, composite panel.

The key components include:

- Fiber cement outer layers: Made from cement, cellulose fibers, and additives, these layers provide fire resistance, weather protection, and structural support.

- Core material: Often made from foam or mineral wool, the core improves thermal and sound insulation while keeping the panel lightweight.

- Adhesives: Strong bonding agents hold the layers together for long-lasting performance.

Compared to traditional materials like wood, vinyl, or concrete, fiber cement sandwich panels offer several advantages. They are more durable, resistant to pests, fire, and moisture, and require less maintenance. Unlike heavy concrete panels, they are lightweight, making installation easier and reducing structural load. Their thermal insulation properties also outperform many traditional siding materials, contributing to energy-efficient buildings.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification (Metric) | U.S. Standard | Why It Matters |

|---|

| Core Material | PIR (Polyisocyanurate) | ASTM E84 Class A | Stops fires + cuts cooling costs by 40% |

| Fire Rating | A1 (Non-combustible) | UL 94 V-0 | Meets NYC high-rise codes – no toxic smoke |

| Thickness | 50mm, 75mm, 100mm | – | 100mm = -40°F freezer compliance (ASHRAE) |

| Thermal Conductivity (λ) | 0.022 W/m·K | R-6.5 per inch | Beats fiberglass (R-3.7) – cheaper long-term |

| Panel Strength | 150 kPa compressive | ASTM C165 | Walkable roof loads (25 psf) – no dents |

| Custom Sizes | Up to 40ft x 4ft | – | Fewer seams = faster install + better insulation |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | steel foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Benefits of Shanghe Fiber Cement Sandwich Panels

Shanghe fiber cement sandwich panels offer strong durability, standing up to fire, water, pests, and harsh weather without breaking down. This makes them a reliable choice for long-lasting exterior and interior use.

They’re also eco-friendly, made from natural materials with low VOC emissions, and fully recyclable. This helps you build greener, healthier spaces while reducing environmental impact.

Thanks to their lightweight design, these panels are easy to install and put less load on your building structure. That means faster construction and lower labor costs.

On top of that, Shanghe panels provide excellent thermal and sound insulation. They help keep your energy bills down by maintaining indoor temperatures and reduce noise for a quieter, more comfortable environment.

Finally, their aesthetic versatility lets you customize finishes to match any style or project need. Whether you want a modern look or something more traditional, these panels adapt easily.

For all these benefits and more, contact Shanghe today to learn how fiber cement sandwich panels can improve your next project.

Applications of Fiber Cement Sandwich Panels

Fiber cement sandwich panels are versatile and fit a wide range of building needs across the U.S. Here’s where they shine:

- Exterior Wall Cladding: Perfect for both commercial buildings and residential homes, these panels offer durable, fire-resistant, and weatherproof siding that stands up to harsh conditions while maintaining a clean, modern look.

- Interior Partition Walls: Their lightweight design makes them ideal for creating flexible interior walls. They help save space and provide good sound insulation, making offices, schools, and homes more comfortable and functional.

- Roofing and Ceiling Solutions: These panels provide excellent thermal insulation, helping reduce energy costs. They’re also resistant to moisture and pests, making them a smart choice for roofing and ceiling applications. Check out Shanghe’s sandwich panels for roof for tailored roofing options.

- Prefabricated Shelters and Modular Construction: Because they’re lightweight and easy to install, fiber cement sandwich panels are widely used in prefabricated buildings and modular homes. They speed up construction while ensuring durability and energy efficiency.

- Real World Project Examples: Many U.S. builders trust fiber cement sandwich panels for schools, healthcare facilities, retail spaces, and residential developments. Their combination of strength, insulation, and design flexibility makes them a go-to choice for modern construction projects.

For more on how these panels fit into prefab construction, see our prefabricated sandwich panel options.

Why Shanghe Stands Out in Fiber Cement Sandwich Panels

At Shanghe, we focus on delivering top-quality fiber cement sandwich panels that meet the needs of today’s builders and designers. Our commitment to quality, innovation, and sustainability sets us apart in the industry. We use advanced manufacturing techniques and eco-friendly materials to ensure every panel performs well and lasts long.

We back our products with certifications and rigorous testing to meet U.S. and international building codes. This means you get reliable, fire-resistant, and weatherproof panels that comply with industry standards.

Customization is another key strength. Whether you need specific sizes, thicknesses, or core materials, Shanghe offers flexible options to fit your project perfectly. This versatility helps you achieve the right balance of strength, insulation, and weight.

Our customer support doesn’t stop at purchase. We provide expert guidance during selection, installation advice, and responsive after-sales service to ensure your project runs smoothly.

Ready to upgrade your build with durable, eco-friendly fiber cement sandwich panels? Contact Shanghe today to request a quote and see how we can help with your next project.

Installation Guide for Fiber Cement Sandwich Panels

Installing fiber cement sandwich panels is straightforward if you follow the right steps. Here’s a simple guide to get you started:

Step by Step Installation Process

- Surface Preparation: Make sure the wall or surface is clean, dry, and level. Remove any debris or old materials.

- Cutting Panels: Use a diamond-tipped saw to cut panels to the right size. This helps prevent cracking or chipping.

- Applying Adhesive: Use a high-quality construction adhesive designed for fiber cement panels to secure them in place.

- Fixing Panels: Fasten panels with corrosion-resistant nails or screws to withstand weather and time.

- Finishing Touches: Seal joints with weatherproof caulk and paint or finish as needed to match your design.

Tools Required

- Diamond-tipped saw for clean cuts

- Corrosion-resistant nails or screws

- Measuring tape and level

- Caulking gun for sealant

- Safety gear like masks and goggles

Safety Tips

- Fiber cement dust can irritate lungs and skin. Always wear a dust mask and goggles.

- Work in a well-ventilated area to reduce inhaling dust.

- Use gloves to protect your hands from sharp edges.

Professional vs DIY Installation

- DIY: Suitable if you have experience with power tools and construction basics.

- Professional: Recommended for larger projects or complex designs. Certified installers ensure panels are installed correctly for maximum durability and warranty compliance.

Maintenance Tips

- Clean panels regularly with mild soap and water to remove dirt and grime.

- Inspect for cracks or damage annually and repair promptly to prevent water infiltration.

- Repaint or reseal finishes every few years to maintain appearance and protection.

Following these steps will help ensure your fiber cement sandwich panels last long and perform well under various conditions. If you’re unsure, contacting a professional installer is always a smart move.

Comparing Fiber Cement Sandwich Panels to Other Materials

When choosing building materials, it helps to see how fiber cement sandwich panels stack up against common options like wood, vinyl, and concrete.

Fiber Cement vs Wood

- Durability: Fiber cement panels resist warping, cracking, and rotting much better than wood.

- Pest Resistance: Unlike wood, fiber cement won’t attract termites or other pests.

- Maintenance: Wood needs regular painting and sealing. Fiber cement requires far less upkeep, saving time and money.

Fiber Cement vs Vinyl

- Eco-Friendliness: Fiber cement uses natural materials and has low VOC emissions, making it a greener choice than vinyl, which is plastic-based.

- Aesthetic Appeal: Fiber cement offers a more natural, premium look with customizable finishes. Vinyl often looks cheaper and can fade over time.

Fiber Cement vs Concrete

- Weight: Fiber cement panels are much lighter than traditional concrete, easing handling and installation.

- Cost and Installation: Concrete is heavier and usually more expensive to install. Fiber cement panels reduce labor time and costs due to their lightweight design.

Quick Comparison Table

| Feature | Fiber Cement Sandwich Panels | Wood | Vinyl | Concrete |

|---|

| Durability | High | Moderate | Moderate | Very High |

| Pest Resistance | Excellent | Poor | Good | Excellent |

| Maintenance | Low | High | Low | Moderate |

| Eco-Friendliness | High | Moderate | Low | Moderate |

| Weight | Lightweight | Lightweight | Lightweight | Heavy |

| Installation Ease | Easy | Moderate | Easy | Difficult |

| Cost | Moderate | Moderate | Low | High |

| Insulation Value | Good | Moderate | Low | Low |

Fiber cement sandwich panels offer a balanced mix of durability, eco-friendliness, and ease of use, making them a smart choice for many U.S. building projects.

Market Trends and Future of Fiber Cement Sandwich Panels

The demand for fiber cement sandwich panel is growing fast, especially as more builders focus on sustainable construction. In the U.S. and globally, there’s a big push toward eco-friendly building materials that offer durability and energy efficiency. The Asia Pacific region is leading this growth, with a strong compound annual growth rate (CAGR) driven by urban development and stricter building codes.

On the technology side, fiber cement panels are evolving. Innovations include using recycled content and advanced core materials that improve insulation and strength without adding weight. These upgrades make fiber cement sandwich panel even more attractive for modern construction projects focused on green building.

Shanghe is at the forefront of these trends. We invest in research and development to bring cutting-edge solutions that meet the changing needs of builders and architects. Our panels combine sustainability with performance, helping push the industry forward.

Looking ahead, the market for fiber cement sandwich panel is expected to expand steadily through 2033. Increased demand for prefabricated building panels and energy-efficient facades will keep driving growth, making fiber cement sandwich panels a smart choice for future-ready construction.