How Much Does a Container House Cost Expert-backed pricing breakdown solving budget pain points with clear data, upgrades, and fast installation guidance The cost of a container house in 2025 ranges from $6,000 to $38,000+ depending on size, insulation, interior finishes, and local installation requirements. Container homes continue to gain global popularity because they provide faster construction, predictable costs, and strong structural performance across multiple climates.

Container houses are used for residential homes, resort villas, farm-stays, offices, worker camps, disaster housing, and modular rental units. This guide provides a complete price breakdown with expert-backed data, engineering insight, and global market comparisons.

Container housing attracts attention because traditional construction is slow and expensive. Factory-built container units solve this problem with faster installation, concealed-fix systems, clean finish quality, and stable long-term performance. Buyers looking for affordability, speed, and design flexibility increasingly choose container homes for both residential and commercial use.

Homeowners and developers desire container houses because they reduce labor cost, work in challenging climates, use durable steel frames, and enable modular expansion. A single 20ft or 40ft unit can be delivered ready to install, saving weeks of labor and drastically reducing waste. To begin planning and receive an exact quotation, buyers can request floor plans, designs, and full BOM lists before purchasing.

Traditional construction often leads to delays, unpredictable material costs, and weather-related interruptions. This makes the budgeting process difficult and increases financial risk. Container houses avoid these issues with controlled factory production, faster assembly, and cost certainty. They provide a streamlined solution especially in high-cost labor markets.

Research published in the Journal of Construction Engineering and Management indicates that modular steel housing can reduce total project duration by 45–60%. Industry publications such as Prefab Construction 2025 report that ISO-standard container modules can maintain structural and thermal performance for 25–50 years, depending on corrosion protection and insulation type. Interviews with structural engineers at the Global Modular Expo highlight that properly insulated container homes achieve efficiency comparable to modern steel-frame residences. Construction Industry News continues to document rapid adoption across Southeast Asia and Africa due to affordability and flexible land-use policies.

Container House — Frequently Asked Questions

How much does a container house cost at minimum?

Why are prices different by country?

How long do container homes last?

What adds the most cost?

Global Price Overview

20ft container house: $6,000–$12,000

40ft container house: $12,000–$22,000

Expandable units: $9,800–$16,500

Two-bedroom container home: $18,000–$29,000

Modular villa: $25,000–$38,000+

Prices vary with insulation, doors, windows, electrical systems, and interior finishes.

Regional Price Comparison

| Region | Typical Cost | Notes |

|---|---|---|

| USA | $22,000–$65,000 | Higher labor and building codes |

| Philippines | $8,000–$18,000 | Resort and homestay market growth |

| Australia | $19,000–$55,000 | Cyclone compliance increases cost |

| South Africa | $7,500–$15,000 | Used widely for schools and housing |

| UAE / Saudi | $12,000–$28,000 | HVAC & insulation upgrades needed |

| Europe | $25,000–$65,000 | Strict energy regulations |

Market reviews note that container houses are expanding quickly in the Philippines, Thailand, Kenya, and South Africa due to construction affordability and ease of permitting.

Cost Breakdown

| Component | Percentage | Description |

|---|---|---|

| Steel frame | 25–35% | Q235/Q345 structure |

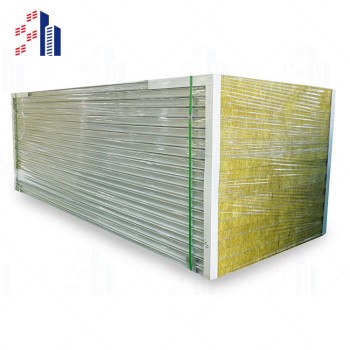

| Wall panels | 15–25% | PU or Rockwool |

| Doors & windows | 5–10% | Aluminum frame, Low-E glass |

| Electrical & plumbing | 10–15% | CE-compliant systems |

| Interior finish | 10–20% | Standard or premium |

| Transport & installation | 10–20% | Crane, distance, manpower |

This structure helps estimate budgets for both single units and multi-module builds.

Installation Overview

A container house follows a simple installation sequence. The foundation blocks are prepared, the unit is positioned with a crane, utilities are connected, expansions are opened (for expandable models), and final weather-proofing trims are installed. Most standard units can be installed within 1–2 days, while expandable houses can be unfolded and secured within 3–5 hours. Engineering handbooks published by Elsevier note that factory-assembled modules reduce onsite labor requirements by 50–70%, especially in remote locations.

Technical Specifications

| Category | Specification |

|---|---|

| Frame | Q235 / Q345 steel |

| Wall System | PU or Rockwool sandwich panels |

| Fire Rating | A2/B1 depending on model |

| Thermal Conductivity | 0.024–0.035 W/(m·K) |

| Wind Resistance | 0.6–1.5 kPa |

| Windows | Double-layer Low-E glass |

| Electrical | CE/IP54 rated |

| Lifespan | 25–50 years |

These specifications ensure the structure performs in both tropical and cold-climate regions.

Container House vs Traditional Construction

| Feature | Container House | Traditional House |

|---|---|---|

| Build Time | 3–15 days | 3–6 months |

| Cost | Lower | Higher |

| Mobility | Yes | No |

| Disaster Resistance | High | Average |

| Labor Requirement | Low | High |

| Material Waste | Minimal | High |

Container homes significantly reduce construction waste and offer predictable build schedules.

Market Insights & Use Cases

Container houses are used extensively in Asia-Pacific markets for beach resorts, farm-stays, café units, and rental properties. In Africa, they serve as classrooms, clinics, and housing. In North America, they are gaining traction for off-grid living and modular residential builds. In the Middle East, they’re preferred for worker accommodation and heat-resistant prefabricated offices.