If you’ve ever been on a job site trying to fit wall cladding or roof sheets into an awkward corner, you’ve probably asked yourself: can sandwich panels be cut on site? The short answer is yes — but only if you follow the right procedures, use proper tools, and understand how cutting affects the panel’s core and coating.

Incorrect cutting can damage protective layers and shorten lifespan. Done correctly, on-site trimming saves time, reduces transport cost, and ensures precise fit for each project. This guide covers methods, pricing, regional insights, and expert-verified data for safe, efficient cutting of sandwich panels.

Why the Question Matters

In modern construction, speed and precision define success. Even factory-engineered panels often need trimming for doors, vents, or irregular foundations. Major manufacturers such as Kingspan and Metecno permit limited on-site modification, provided that proper sealing and edge protection are applied.

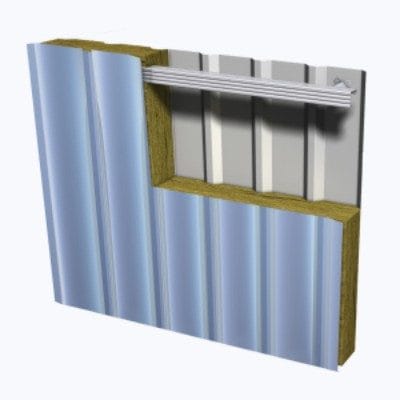

What Sandwich Panels Are

Sandwich panels are composed of two metal sheets bonded to an insulated core — typically PUR, PIR, EPS, or Rock Wool. Their composite structure gives strength and insulation but also makes cutting sensitive.

“A single overheated cut can destroy the bond between skin and core,” explains Dr. Elena Ruiz, Building Envelope Research Institute (2024).

On-Site Cutting Basics

Field cutting refers to any modification done outside the factory. According to EN 14509 and ISO 12944-C4, this is allowed as long as edges are resealed and debris kept out of joints.

Tools and Equipment

| Application | Recommended Equipment | Reason |

|---|---|---|

| Straight panel cuts | Low-RPM fine-tooth circular saw | Clean cut, minimal heat |

| Small openings | Reciprocating saw or jigsaw | Precision in tight spaces |

| Edge finishing | File or deburring tool | Protects coating |

| Dust removal | Vacuum or soft brush | Prevents corrosion |

| Edge sealing | PU touch-up paint or sealant | Maintains weather barrier |

Step-by-Step Cutting Process

Mark lines with masking tape, support panels on foam pads, use steady pressure, and clean filings after each pass. Reseal edges immediately with PU or silicone. CNAS (2025) found that correctly sealed cuts preserved 98% corrosion resistance.

Damage Prevention

Work in shaded, dry areas; never use abrasive wheels or torches; and remove swarf promptly. As reported by Metal Construction News (Mar 2025), one-third of façade corrosion issues come from unsealed cut edges.

On-Site vs Factory-Cut Comparison

| Criteria | On-Site Cutting | Factory-Cut |

|---|---|---|

| Flexibility | Adaptable to irregular structures | Fixed dimensions |

| Accuracy | Depends on skill | CNC precision |

| Cost | Lower transport | Higher customization |

| Waste | Slightly more | Minimal |

| Quality Control | Needs supervision | Factory tested |

Material-Specific Tips

PIR/PUR cores melt if overheated; Rock Wool needs serrated saws; aluminum skins need cutting oil; and steel faces require slow speed to avoid discoloration.

“Every material behaves differently; treat them as composites, not metal sheets,” — Dr. Lin Wei, Shanghai Building Envelope Laboratory (2024).

Regional Market & Labor Data 2025

| Region | Practice | Tool Preference | Labor Cost |

|---|---|---|---|

| U.S. | Common field trimming | DeWalt cold-cut saws | $9 – $15 /m² |

| Middle East | Heat-expansion adaptation | Bosch + PU sealants | $8 – $12 /m² |

| Southeast Asia | Humidity-controlled zones | Makita fine-tooth | $6 – $9 /m² |

| Europe | Mostly factory pre-cut | CNC plasma/water-jet | $10 – $14 /m² |

Price Reference 2025

| Thickness | Panel Price (FOB China) | Cut + Seal Labor | Delivered Cost |

|---|---|---|---|

| 50 mm | $13 – $16 /m² | $1.2 – $1.8 /m² | $15 – $18 /m² |

| 75 mm | $16 – $20 /m² | $1.5 – $2.2 /m² | $18 – $22 /m² |

| 100 mm | $19 – $23 /m² | $1.8 – $2.5 /m² | $21 – $25 /m² |

Technical Specifications

| Property | Typical Range | Standard |

|---|---|---|

| Thickness | 50 – 150 mm | EN 14509 |

| Metal Skin | 0.5 – 0.6 mm Al/Steel | EN 10346 |

| Thermal Conductivity | 0.022 – 0.045 W/m·K | ASTM C518 |

| Fire Class | B-s2,d0 / A2 | EN 13501-1 |

| Wind Resistance | up to 2.0 kPa | ICC ISBU 2024 |

Expert & Industry Commentary

“The question isn’t whether you can cut sandwich panels on site — it’s how carefully you do it.” — Dr. James Cornwell, RIBA Prefabrication Series (2025).

“In tropical climates, installers must avoid cutting during peak humidity hours.” — Eng. Maria Santos, Philippine Metal Panel Association (2024).

“Cold-saw methods extend coating life by over 15 years.” — Construction Materials Journal Vol. 33 (2025).

Frequently Asked Questions

Can sandwich panels be cut on site without losing warranty?

Yes, if cutting and sealing follow manufacturer instructions and are documented.

What’s the safest way to cut PIR panels?

Use a fine-tooth cold-cut saw, clean edges, and reseal immediately.

Can I cut panels after installation?

Only minor adjustments like vent openings, with proper protection.

How much does on-site cutting cost?

Roughly $1.5 – $2.5 /m² including labor and sealant.

Final Takeaway

Yes, sandwich panels can be cut on site — safely and efficiently. With proper tools, sealing, and supervision, you’ll maintain structural integrity and aesthetics while reducing lead time and cost.