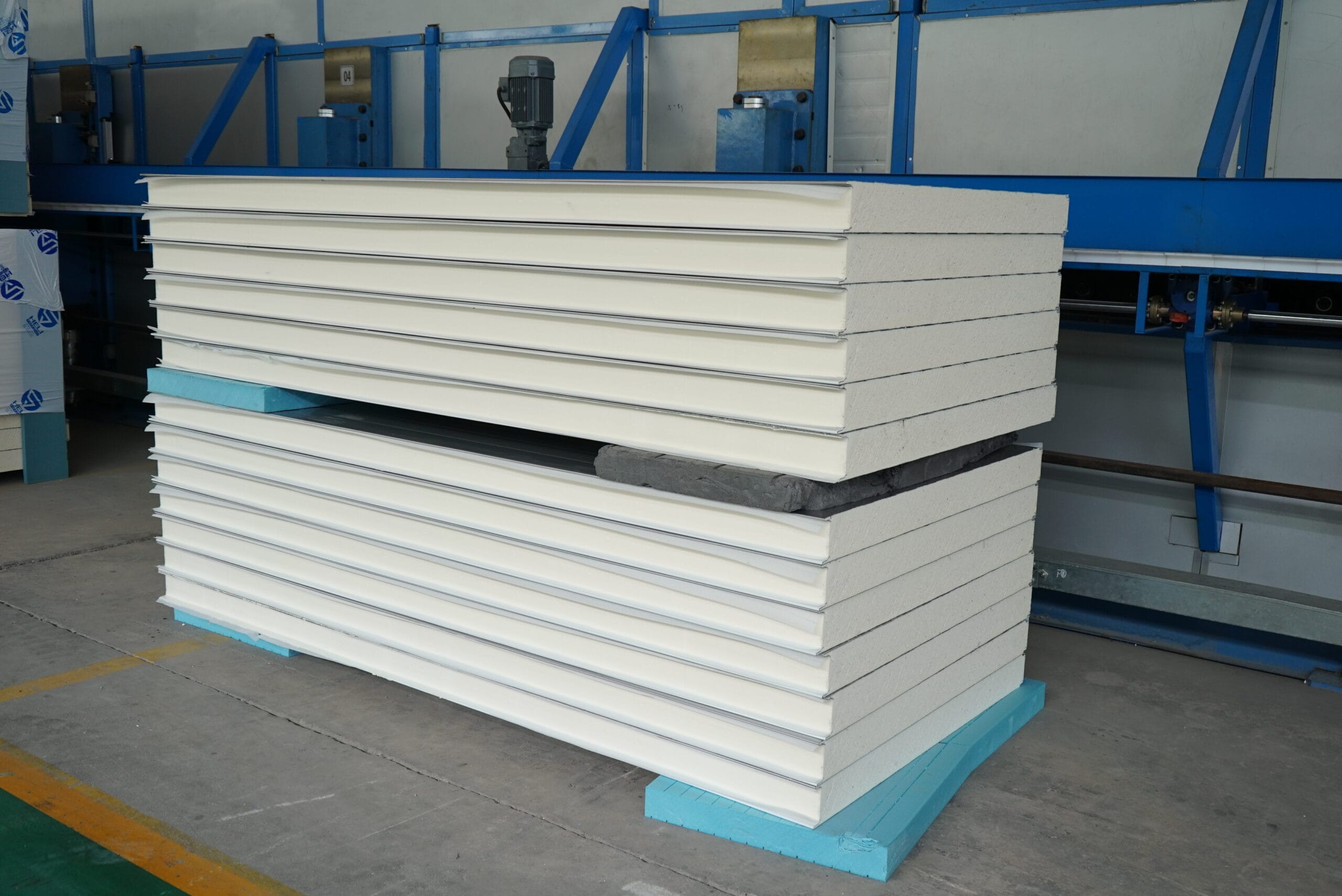

What Are fiberglass plywood sandwich panels

fiberglass plywood sandwich panels are composite building materials made of fiber cement boards on the outer layers with a lightweight core in between. This design combines the strength and durability of fiber cement with the insulation and weight benefits of the core material.

The fiber cement layers are made from a mix of cement and cellulose fibers, which provide excellent resistance to fire, moisture, and impact. The core is usually made from materials like expanded polystyrene (EPS) or mineral wool, adding thermal insulation and structural support.

Compared to traditional construction materials like brick or plain cement boards, fiber cement sandwich panels are lighter, easier to install, and offer better energy efficiency. They also require less maintenance and provide superior protection against weather and wear, making them a smart choice for modern construction projects.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 50mm eps sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Features of Shanghe Fiber Cement Sandwich Panels

Shanghe fiber cement sandwich panels stand out for their durability. They’re fire-resistant, moisture-proof, and tough enough to handle impact, making them reliable for various building needs. When it comes to energy efficiency, these panels offer high thermal insulation and a low U-value. That means better temperature control and lower energy bills for your property.

The panels are also designed to be lightweight, which makes them easy to transport and install. This helps reduce labor time and overall project costs. On the environmental side, Shanghe panels are eco-friendly—they’re asbestos-free and made from sustainable materials, so you can build green without compromise.

Lastly, these panels are customizable. They come in different thicknesses, sizes, and finishes, letting you pick the right look and performance for your project, whether it’s residential, commercial, or industrial.

Applications of Shanghe Fiber Cement Sandwich Panels

Shanghe fiber cement sandwich panels are versatile and fit a wide range of projects across residential, commercial, industrial, and prefabricated structures.

- Residential Construction: Perfect for exterior and interior walls, partitions, and roofing in homes. These panels offer durability and energy efficiency that help keep houses comfortable year-round.

- Commercial Buildings: Ideal for offices, hotels, retail spaces, and warehouses. Their fire-resistant and moisture-proof qualities make them a reliable choice for busy commercial environments.

- Industrial Use: Widely used in factories, cold storage facilities, and clean rooms where strong, insulated, and hygienic walls are critical. Check out their cold storage sandwich panel options built specifically for these needs.

- Prefabricated Structures: Great for schools, hospitals, and modular buildings thanks to their lightweight design and easy installation. These panels speed up construction without sacrificing quality or safety.

A recent sustainable commercial project utilized Shanghe fiber cement panels for its exterior walls, reducing energy costs while meeting stringent green building standards—proof of their real-world performance and eco-friendliness.

For more on panels used in prefab buildings, see our prefab sandwich panel options.

Benefits of Choosing Shanghe Panels

Choosing Shanghe fiber cement sandwich panels comes with clear advantages for any building project in the U.S. Here’s why they stand out:

Cost Savings

- Cuts down on construction time thanks to lightweight materials and quick installation.

- Reduces labor costs because the panels are easy to handle and fit together smoothly.

Sustainability

- Made from eco-friendly, asbestos-free materials that support green building certifications like LEED.

- Helps lower your project’s environmental footprint without sacrificing quality.

Ease of Installation

- Features a modular design with tongue and groove edges for fast, secure assembly.

- Minimizes the need for specialized tools or extra labor, speeding up your build.

Versatility

- Works well in a variety of U.S. climates, from humid coasts to dry inland areas.

- Fits different architectural styles, making it ideal for residential, commercial, or industrial spaces.

Long-Term Value

- Requires low maintenance, saving money over the panel’s lifespan.

- Built strong to resist fire, moisture, and impacts, ensuring your investment lasts for years.

Why Shanghe Stands Out

Shanghe sets itself apart with years of manufacturing expertise and a strong commitment to quality. Their fiber cement sandwich panels are made using advanced production methods that ensure consistent strength, durability, and performance for every project.

They meet and exceed international building standards, holding key certifications that guarantee safety, fire resistance, and environmental compliance. This gives you peace of mind knowing the panels are built to last and approved for use across the U.S.

On top of quality products, Shanghe offers excellent customer support. Their team provides technical guidance throughout your project, helping you choose the right panel type, thickness, and core material for your needs. They also offer customization options—different sizes, finishes, and insulation levels—to match any design.

Delivery with Shanghe is reliable and prompt, so your project stays on schedule. Many customers have shared positive reviews, praising the panels’ performance and the company’s helpful service. Their reputation makes Shanghe a trusted choice when you need fiber cement panels that deliver long-term value.

How to Choose the Right Fiber Cement Sandwich Panel

Picking the right fiber cement sandwich panel depends on a few simple but important factors:

- Project Type: Are you working on a residential home, commercial building, or industrial site? Different projects have different needs for strength, insulation, and fire resistance.

- Climate: For hotter areas, look for panels with better thermal insulation. In places with heavy rain or snow, moisture-proof and durable panels are key.

- Budget: Balance cost with performance. Shanghe offers options that fit various budgets without sacrificing quality.

- Aesthetic Preferences: Fiber cement panels come in different finishes and thicknesses. Choose one that matches your design vision.

Shanghe’s product range includes standard panels, insulated panels, and fire-rated panels to suit these different needs.

Tips for Selecting Panel Thickness and Core Material

- Thicker panels typically offer better insulation and durability but are heavier.

- Lightweight core materials like EPS improve energy efficiency and ease of installation.

- Fire-rated cores are essential for commercial and industrial buildings needing extra safety.

- Always consider the balance between weight, insulation, and fire resistance based on your specific project.

Choosing the right fiber cement sandwich panel with Shanghe means you get a solution tailored to your project’s demands, climate conditions, and budget.

Installation Guide for Shanghe fiberglass plywood sandwich panels

Installing Shanghe fiber cement sandwich panels is straightforward when you follow the right steps. Here’s a simple overview to get you started:

Step by Step Installation

- Preparation: Make sure your surface is clean, level, and dry. Measure and plan the layout before cutting.

- Cutting: Use a circular saw with a diamond-tipped or carbide blade for clean cuts. Always wear a dust mask and safety goggles.

- Adhesive Application: Apply high-quality construction adhesive recommended by Shanghe evenly on the panel’s back.

- Panel Placement: Fit the panels with the tongue and groove system for a tight join. Press firmly to ensure good contact.

- Fastening: Secure the panels with corrosion-resistant screws, following spacing guidelines.

- Finishing: Seal joints with appropriate weatherproof sealant to prevent moisture penetration.

Tools Required

- Circular saw with the right blade

- Drill and screwdriver

- Measuring tape and level

- Safety gear (gloves, goggles, dust mask)

- Caulking gun for sealants

Safety Precautions

- Always wear protective equipment when cutting panels.

- Work in a well-ventilated area to avoid dust buildup.

- Handle panels carefully to avoid damage or injury.

For detailed steps, including video tutorials and product-specific tips, check out Shanghe’s official installation manual here. This guide ensures your panels are installed right for long-lasting durability and performance.