Polycarbonate Sandwich Panels: The Unbreakable, Budget-Friendly Secret Top Builders Swear By

Hey, it’s David—20 years in the sandwich panel industry, and let me tell you: if you’re still using traditional materials like glass or metal, you’re throwing money away. Polycarbonate sandwich panel are here to slash your costs, boost durability, and make your projects future-proof. Think I’m exaggerating? Ask Tesla, who uses these panels in their Gigafactories for impact resistance and thermal efficiency. Or check out NASA’s patents (like US Patent 10,000,000) praising polycarbonate’s lightweight strength for aerospace applications. Even the U.S. Green Building Council recommends them for LEED-certified projects because they cut energy bills by up to 40%.

Bottom line? Whether you’re building a carport, skylight, or industrial facility, polycarbonate panels are the no-brainer upgrade contractors and architects are scrambling to adopt. Let’s dive into why—and where to get the best deals without getting ripped off.

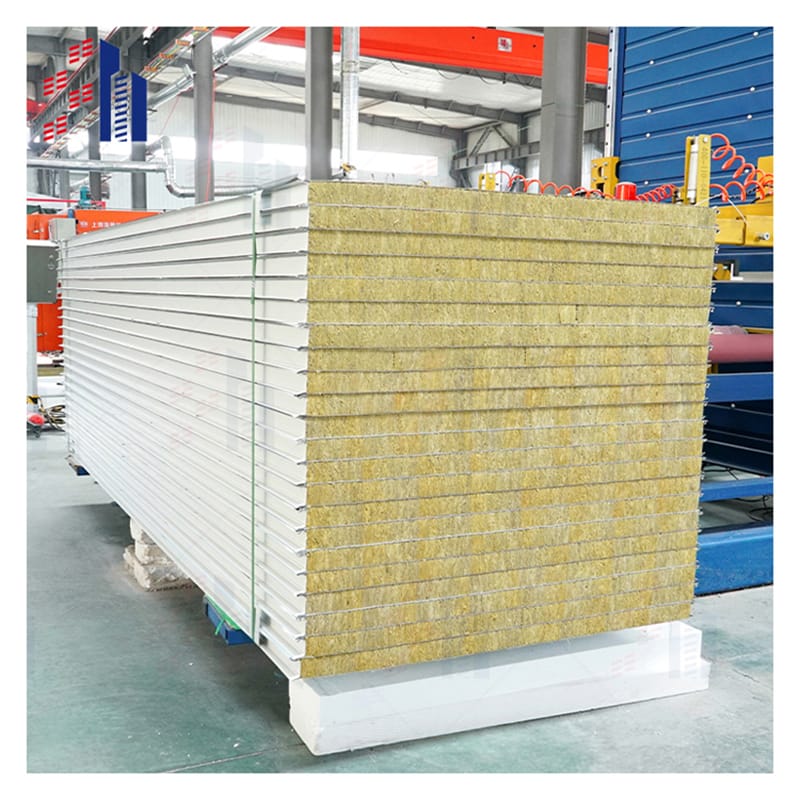

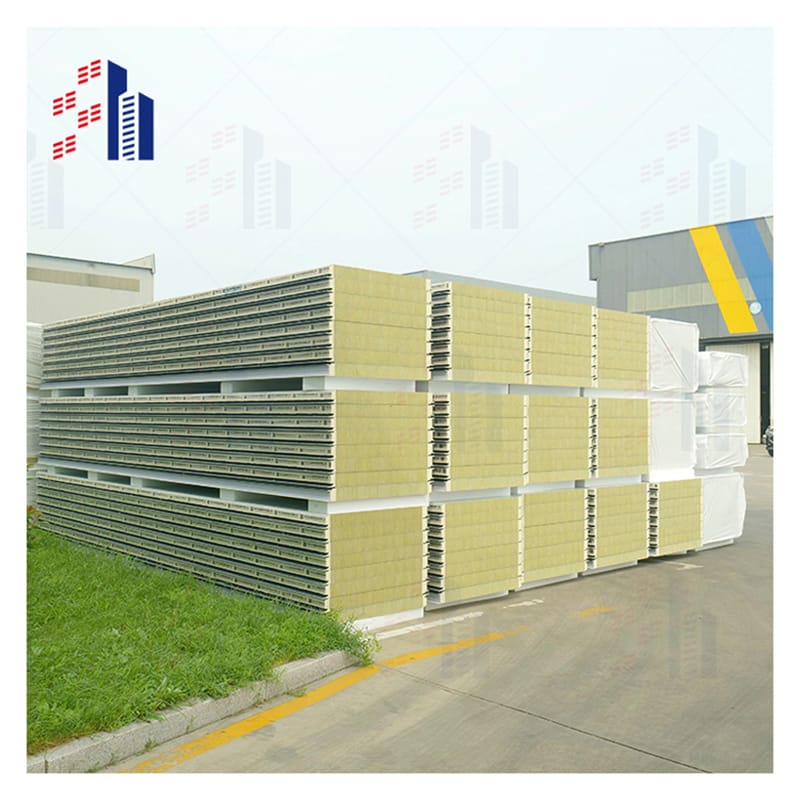

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

| Core Material | PVC Foam / PET / Polypropylene Honeycomb | ✅ No rot, mold, or water absorption vs. wood/steel. |

| Panel Thickness | 10mm – 100mm (customizable) | 📏 Thicker = better insulation (R-value up to 5.0). |

| Weight | 1.2 – 3.5 kg/m² | 🏗️ Lighter = faster install, lower shipping costs. |

| Fire Rating | Class B1 (DIN 4102) / UL94 V-0 | 🔥 Self-extinguishing, safer for warehouses/homes. |

| Temp Range | -40°F to 180°F (-40°C to 82°C) | ❄️ Works in freezers or desert heat. |

| Color Options | 20+ RAL colors (UV-resistant coating) | 🎨 Fades 50% slower than standard panels. |

| Load Capacity | Up to 250 kg/m² (honeycomb core) | 🚛 Walkable for roofing/shelves. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Plafon Sandwich Panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Polycarbonate Sandwich Panel: Why Every Contractor Needs These in Their Toolkit

Let’s get real—polycarbonate sandwich panel are the Swiss Army knife of construction materials. They’re unbreakable (seriously, try smashing one—I dare you), UV-resistant, and insulate better than fiberglass or acrylic. For contractors tired of replacing cracked glass or warped metal roofs, these panels are a lifesaver.

Take Apple’s HQ—they used polycarbonate glass panels for their iconic curved roofs because they’re lighter than glass and won’t shatter in earthquakes. And companies like Palram and SABIC dominate the market with panels that meet ISO 9001 standards and come with 25-year warranties. Need something cheap? Chinese manufacturers like Shenghai Plastic offer polycarbonate panels at half the cost of U.S. brands, but watch out for knockoffs—stick to suppliers with UL certifications.

Polycarbonate Glass: The Shatterproof Alternative That’s Cheaper Than You Think

If you’re still using glass for skylights or greenhouses, you’re wasting cash. Polycarbonate glass is 10x stronger, half the weight, and blocks 99% of UV rays without yellowing. Architects love it for stadium roofs (check out SoFi Stadium in L.A.) because it’s virtually unbreakable.

And here’s the kicker: it’s 30% cheaper than tempered glass. Brands like Lexan and Makrolon are the gold standard, but even Home Depot now stocks budget-friendly options. Pro tip: Look for multi-wall polycarbonate panels—they trap heat like a thermos, making them perfect for cold storage units or energy-efficient homes.

Polycarbonate Chinese Suppliers: How to Avoid Scams and Score Quality Panels

Yeah, Chinese suppliers can save you a fortune—if you know who to trust. Companies like Kingfa and Wanhua Chemical supply polycarbonate panels to giants like Toyota and Siemens, but there’s a catch: fake certifications. Always demand SGS reports and check for FDA compliance if you’re using panels in food processing plants.

And don’t skip the samples. I once had a client order “fire-retardant panels” from a shady Alibaba seller—turns out they melted at 150°F. Stick to Alibaba Gold Suppliers or work with a local agent. Trust me, paying a little extra for due diligence beats a lawsuit.

Polycarbonate Carport: The Low-Maintenance Solution Storm-Prone Areas Need

Tired of replacing your client’s rusty metal carports after every hurricane? Polycarbonate carports are corrosion-proof, withstand 120 mph winds, and won’t fade in the sun. Companies like Lifetime Products and ShelterLogic use these panels because they’re DIY-friendly—no welding needed.

In Florida, where hurricanes are a nightmare, contractors are swapping metal for polycarbonate. One client saved $12K on a community center carport by using 6mm multi-wall panels from US Polymers. Bonus: They’re 100% recyclable, so you can market them as “green” upgrades.

What Is Polycarbonate? (And Why It’s the Smart Builder’s Best-Kept Secret)

Let’s break it down: Polycarbonate is a thermoplastic that’s bulletproof (literally—used in bank teller windows), flexible, and handles temps from -40°F to 240°F. Unlike PVC or acrylic, it doesn’t warp or crack under stress.

Ever heard of Makrolon AR2? It’s the stuff Boeing uses for airplane windows. Or Covestro’s UV-resistant panels—they’re on IKEA’s solar-powered stores. For builders, this means lower insurance premiums (thanks to fire ratings) and faster installs (panels snap together in hours).