Precast Insulated Sandwich Panels: Why They’re David’s Recommendation After 10 Years in Cladding

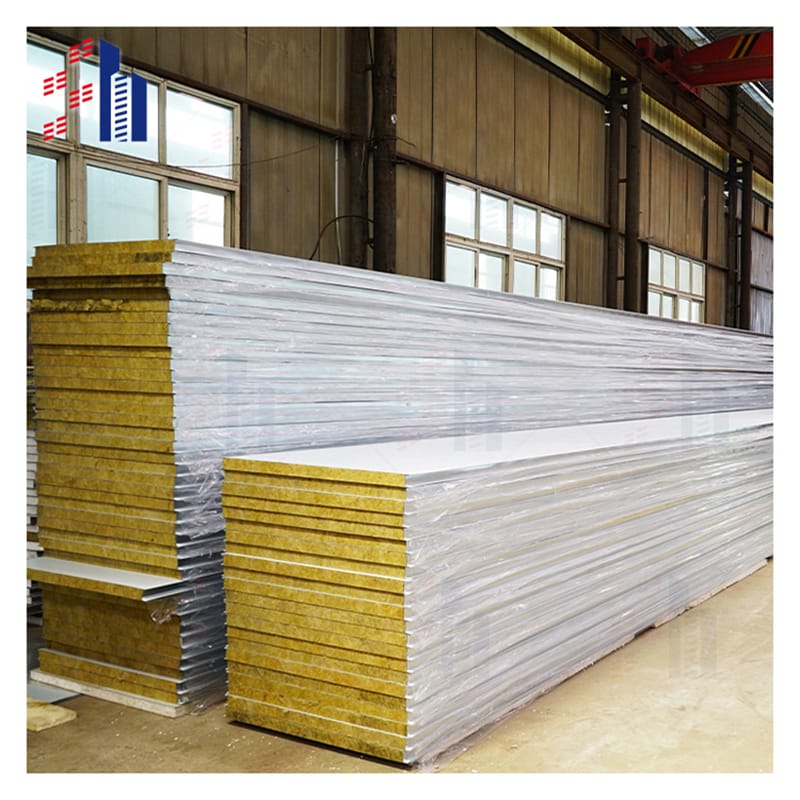

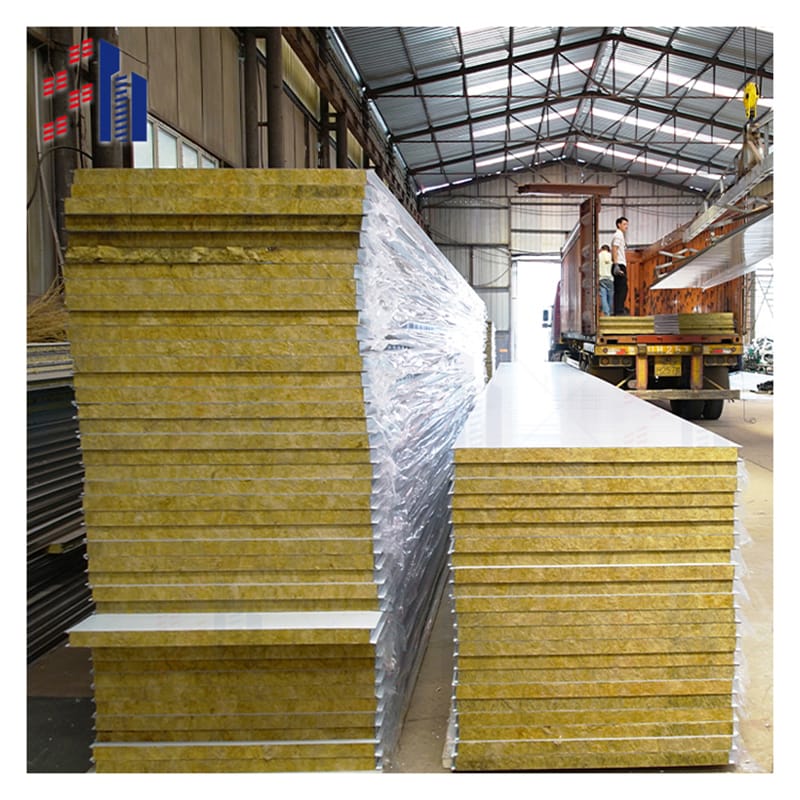

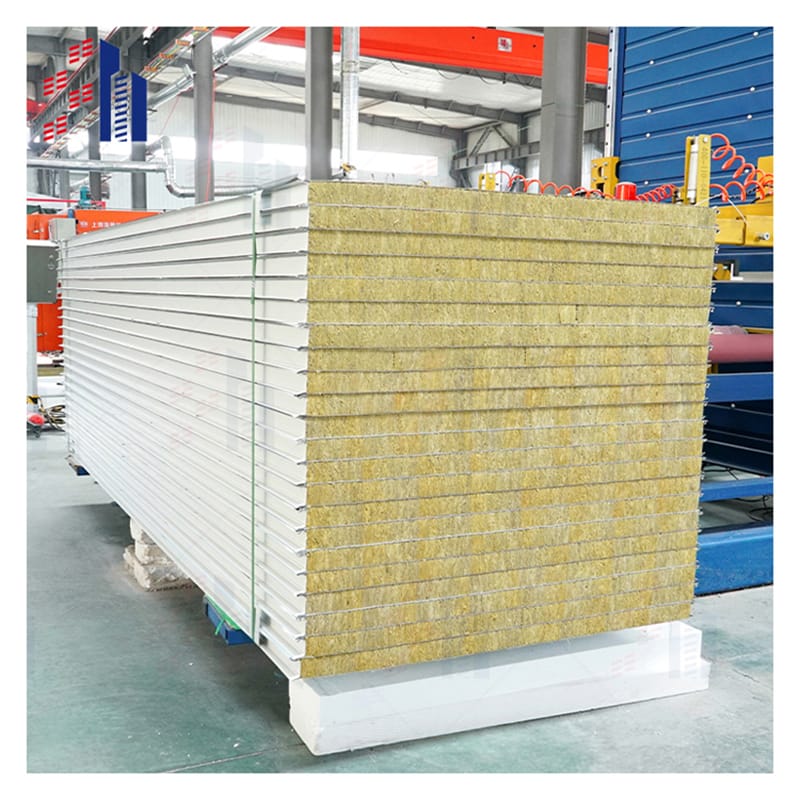

Let’s get real—construction timelines are tight, budgets are tighter, and nobody wants to deal with energy leaks or moldy walls. That’s exactly why David, with 10 years of sweat equity in the cladding game, swears by precast insulated sandwich panels. These panels aren’t just “another option”; they’re a triple threat: speed, durability, and thermal efficiency baked into one system. Think of them like a concrete Oreo—two weather-resistant concrete layers with a foam insulation core that laughs at humidity, fire, and sky-high HVAC bills.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | precast insulated sandwich panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

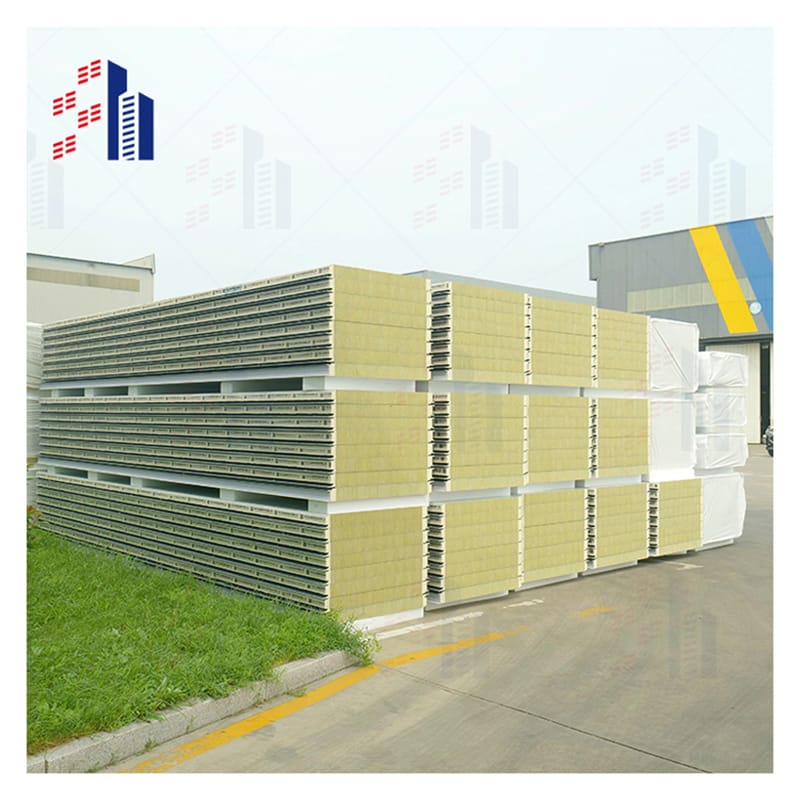

Precast Concrete Insulated Sandwich Wall Panels: How to Slash Labor Costs Without Sacrificing Quality

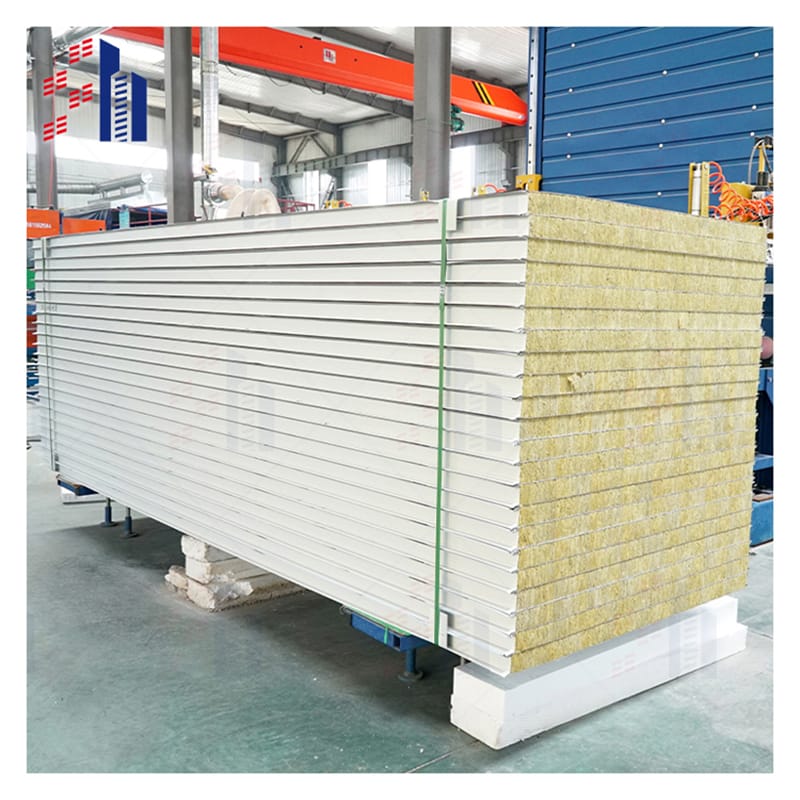

Here’s the thing: traditional masonry eats up weeks of labor, and let’s not even talk about winter delays. David’s seen too many projects bleed cash over slow installations. Precast concrete insulated sandwich wall panels flip the script. They’re cast in controlled factories (no weather drama), shipped ready-to-install, and crane-lifted into place faster than you can say “overtime pay.” Bonus? The insulation is factory-sealed—no gaps, no thermal bridges, no callbacks. LEED-certified projects love these panels because they hit energy targets without the premium price tag.

Precast Concrete Insulated Sandwich Panels vs. Stick-Built: Which Saves More Money Long-Term?

Spoiler: It’s not even close. David’s clients used to panic over upfront costs until they saw the math. Precast concrete insulated sandwich panels might cost 15% more initially, but they cut heating/cooling bills by 30%+ and last decades longer than wood or steel. One hospital project in Hong Kong saved $200K annually on HVAC alone—thanks to the airtight foam core. Plus, mold-resistant concrete means zero maintenance headaches. As David says, “Cheap now costs more later.”

Why Hong Kong Skyscrapers Can’t Build Without It

Hong Kong’s skyline isn’t just pretty—it’s a logistics miracle. With space tighter than a subway at rush hour, precast concrete is the MVP. David’s team supplied panels for a 50-story tower in Kowloon that shaved 4 months off the schedule. Why? No onsite curing, no weather delays, and panels arrive numbered like IKEA kits. For high-rises, it’s not optional—it’s survival.

Precast Facade Fails: 3 Mistakes Architects Make (and How to Dodge Them)

Even geniuses mess up. David’s seen “innovative” facade designs crack under Hong Kong’s typhoon winds. The fix? Precast facades designed for local codes. One architect ignored expansion joints—$50K in repairs later, they learned. Key rules: 1) Work with factories early (no last-minute changes), 2) Use corrosion-resistant rebar (salty air kills cheap steel), 3) Test mockups. MIT’s 2022 study proved precast cuts facade defects by 60% vs. traditional methods.

Precast Concrete Panel Myths—Busted by a 20-Year Cladding Vet

“Precast looks ugly.” Tell that to the sleek curves of the Hong Kong Arts Centre. “It’s too heavy.” Wrong—foam cores make panels 40% lighter than solid concrete. David’s biggest pet peeve? “It’s not customizable.” Modern factories like China’s SCPG use 3D-printed molds for wild shapes (yes, even dinosaur-themed schools). The truth: today’s precast concrete panels are Lego meets Picasso—fast, flexible, and fireproof.

Insulated Precast Sandwich Wall Panels: The Secret to Quieter Homes in Noisy Cities

Hong Kong’s streets hit 100 decibels—that’s chainsaw-level noise. David’s residential clients used to beg for solutions. Enter insulated precast sandwich wall panels. The foam core isn’t just for temperature; it’s a sound sponge. Tests show they block 50% more noise than double-brick walls. A luxury condo in Mid-Levels used them, and residents now sleep through midnight traffic. Pro tip: Pair with laminated glass for a “silent fortress” effect.