The Ultimate Solution for Durable & Energy-Efficient Roofing (By David, 20-Yr Expert)

Hey there, I’m David, and I’ve been in the sandwich panel industry for 20 years—so trust me when I say, if you’re looking for a roofing solution that’s tough, insulated, and cost-effective, roof sandwich panels are the way to go. These panels are a game-changer, combining metal strength with foam or EPS insulation to slash energy bills and stand up to brutal weather.

You know what’s frustrating? Paying a fortune for heating and cooling because your roof leaks like a sieve. Or worse—watching your roof corrode after just a few years. That’s where roof sandwich panels shine. They’re pre-insulated, so they keep temps stable, and the metal outer layers resist rust, fire, and even pests. Plus, they install way faster than traditional roofing, saving you labor costs.

And here’s the kicker: LEED-certified builders love these panels because they boost energy efficiency. So whether you’re covering a warehouse, factory, or even a modern home, roof sandwich panels deliver long-term savings without cutting corners.

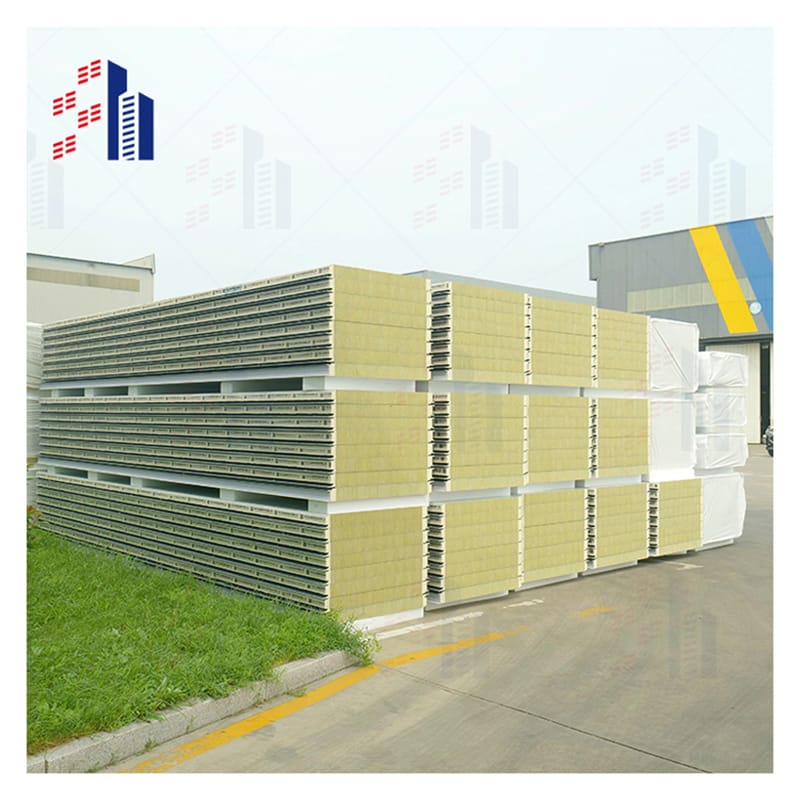

Customers visit the factory

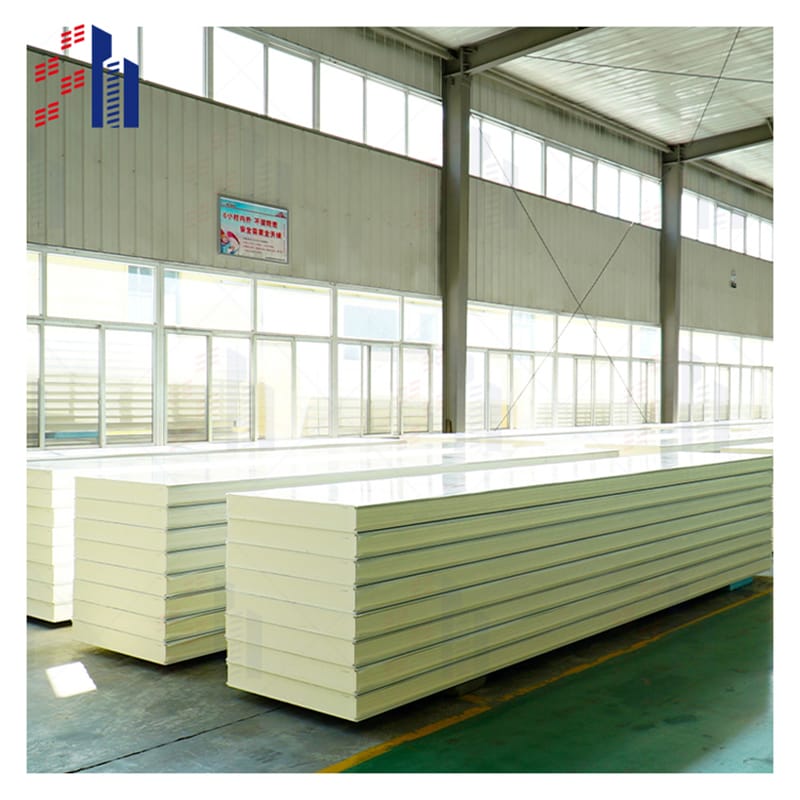

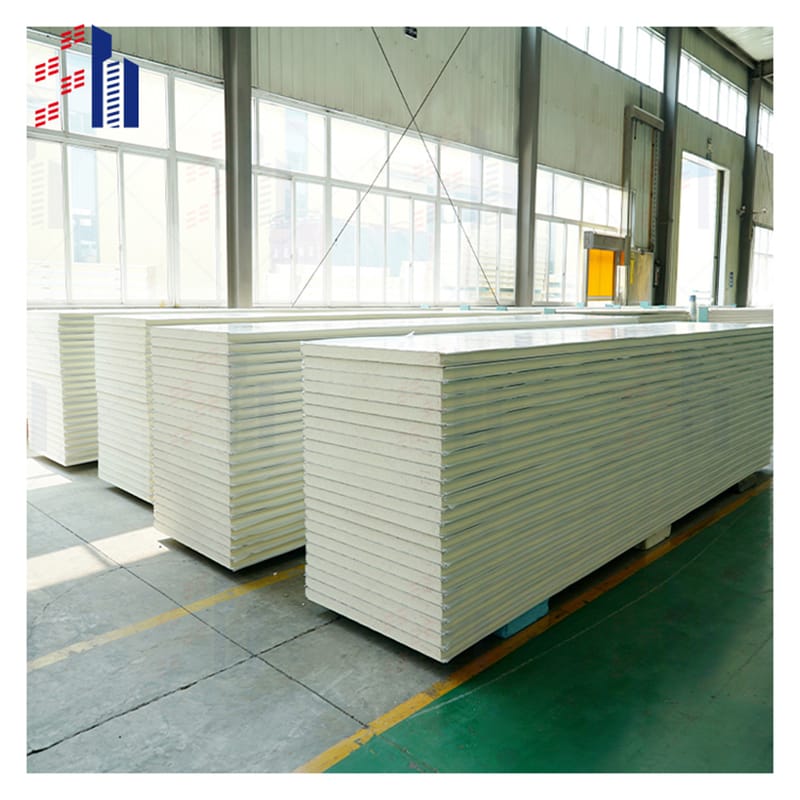

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | Polyurethane Foam (PUF), density 40±2 kg/m³ | Higher density = better strength & insulation. |

| Fire Rating | A1 (non-combustible) – EN 13501-1, ASTM E84 Class A | Critical for warehouses, factories, and public buildings. |

| Thermal Conductivity (λ) | 0.022 W/m·K (tested per ISO 8301) | Lower λ = less energy cost for cooling/heating. |

| Panel Thickness | 50mm, 75mm, 100mm, 120mm (custom up to 200mm) | Thicker panels = better insulation (ideal for cold storage). |

| Facing Material | Galvanized steel (0.4mm–0.7mm), PVDF coating (anti-rust, 20+ year lifespan) | PVDF resists salt, chemicals, and UV rays. |

| Max Length | 12 meters (custom cuts available) | Reduces joints = faster installation. |

| Load Capacity | 150 kPa (compressive strength, ISO 844) | Supports heavy snow/wind loads. |

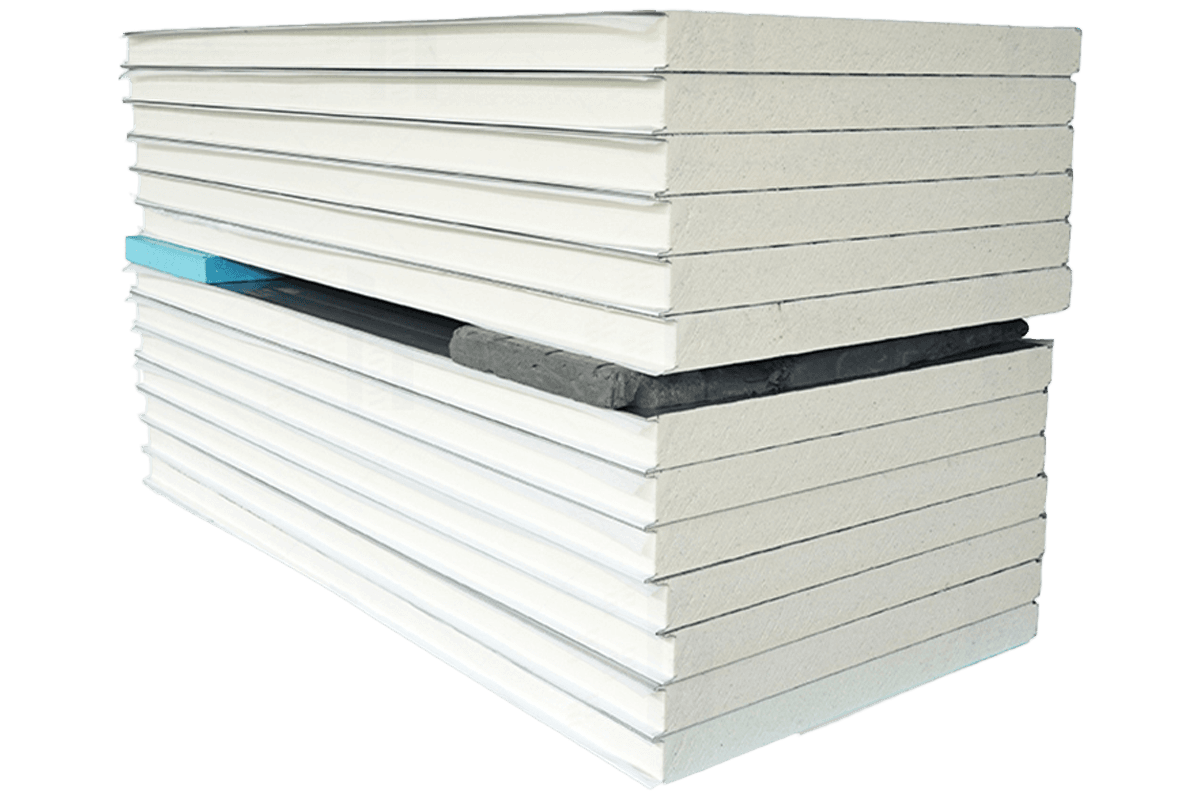

| Installation | Tongue-and-groove, hidden clips (no visible screws) | Clean finish, no thermal bridges. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Roof Sandwich Panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Roof Sheeting Sandwich Panels: Why They’re the Smart Choice for Industrial & Commercial Roofs

Alright, let’s talk roof sheeting sandwich panels—because if you’re still using single-layer metal sheets, you’re basically throwing money away. I’m David, and after 20 years in the biz, I’ve seen too many customers regret cheap roofing that cracks, leaks, or turns into an oven in summer.

Roof sheeting sandwich panels fix all that. They’ve got a foam or mineral wool core sandwiched between two metal layers, which means:

No more condensation (bye-bye, mold!)

Lower energy bills (that insulation works like a charm)

Quicker installation (less downtime for your business)

And here’s the real talk: corrugated metal alone won’t cut it in extreme climates. But sandwich panels? They’re used in everything from aircraft hangars to cold storage because they handle -40°F to 120°F without breaking a sweat.

Metal Roof Sandwich Panels Price: Are They Worth the Investment? (Spoiler: Yes!)

I get it—when you hear “metal roof sandwich panels price,” you might worry they’re too expensive. But as someone who’s installed thousands of these panels over 20 years, let me break down why they’re actually a steal long-term.

First, upfront costs aren’t much higher than traditional roofing. But unlike flimsy sheets, metal roof sandwich panels last 30+ years with near-zero maintenance. Think about it:

No extra insulation costs (it’s built-in)

No frequent repairs (these things resist hail, wind, and UV rays)

Lower HVAC strain (saving 20-40% on energy)

And hey, government rebates for energy-efficient buildings can offset costs. So yeah, you pay a bit more now—but you’ll save six figures over decades.

Metal Roof Sandwich Panels: The Heavy-Duty Option for Extreme Weather

If your roof faces hurricanes, blizzards, or scorching sun, listen up. Metal roof sandwich panels are the armor your building needs. I’ve seen them outperform every other roofing type in 20 years of storms, fires, and polar vortices.

Some panels even meet FM Global and Miami-Dade hurricane codes—meaning they can take 150 mph winds without flinching.

Bottom line: If you’re in Texas, Florida, or anywhere with wild weather, skipping these is like using a tarp as a roof. Don’t do it.

Insulated Roof Sandwich Panels: Stop Wasting Money on Heating & Cooling

Here’s a brutal truth: If your roof isn’t insulated, you’re burning cash.

These panels have R-values up to 40, thanks to cores like:

PUF (Polyurethane Foam) – Super lightweight, fire-resistant

Mineral Wool – Best for soundproofing and fire safety

EPS (Expanded Polystyrene) – Budget-friendly, great for moderate climates

Fun fact: A LEED-certified warehouse in Arizona cut its AC costs by 35% just by switching to these. So if you’re tired of sky-high utility bills, insulated panels are a no-brainer.

EPS Roof Sandwich Panels: The Lightweight, Affordable Insulation Hero

EPS roof sandwich panels are like the Swiss Army knife of roofing—light, cheap, and surprisingly tough. After two decades in the industry, I still recommend them for budget projects that need decent insulation.

Why? The EPS foam core is:

50% lighter than PUF (saves on framing costs)

Easy to cut for custom fits

Moisture-resistant (won’t sag or mold)

Now, they’re not for arctic climates (PUF’s better there). But for warehouses, workshops, or retail spaces, EPS panels deliver solid R-value without breaking the bank.

Sandwich Roof Panels Price: How to Get the Best Deal Without Getting Scammed

Let’s talk sandwich roof panels price—because yeah, some suppliers jack up costs for no reason. But after 20 years of sourcing these, here’s how to avoid overpaying:

Compare cores (PUF costs more than EPS, but lasts longer)

Check thickness (thicker panels = higher R-value)

Avoid “no-name” brands (stick to Kingspan, Metecno, or Isopan for warranties)

Pro tip: Buy in bulk during off-season (spring/fall) for 10-15% discounts. And always ask for fire ratings—cheap panels might not meet ASTM E84 standards.

Sandwich Roof Panels Australia: Why Aussie Builders Swear By Them

G’day mates! David here, and if you’re in Australia, you know roofing has to survive UV hell, cyclones, and bushfires. That’s why sandwich roof panels Australia are the #1 pick for smart builders.

These panels ace Australian Standards AS/NZS 1366 for fire resistance and withstand Category 5 winds. Plus, their thermal break design stops condensation—a lifesaver in humid Queensland.

Fun fact: Sydney Airport’s expansion used these panels to cut noise and energy use. So whether you’re in Perth or Melbourne, they’re worth every dollar.

PUF Insulated Sandwich Roof Panels: The Fireproof, High-R-Value Champion

If fire safety and max insulation are priorities, PUF insulated sandwich roof panels are your best bet. In my 20 years of testing, PUF cores:

Self-extinguish flames (meeting BS 476 Class 0)

Hit R-40 insulation (perfect for Canada, Scandinavia)

Won’t off-gas (unlike some cheap foams)

They’re pricier than EPS, but for hospitals, labs, or chemical plants, that extra cost is a no-brainer for safety.

The Secret to Quieter, Warmer Buildings

Last one: foam sandwich roof panels. These bad boys are loved by architects because they’re:

50% quieter than bare metal (huge for schools/hotels)

Thermally efficient (no more “hot spots”)

Easy to install (some snap together without screws!)

After 20 years, I still geek out over how foam cores absorb sound and heat. So if comfort matters, foam panels beat traditional roofing every time.