A polyurethane sandwich panel is widely known as one of those materials that just behaves the way you expect it to—something I’ve appreciated more times than I can count. Over years of installs, retrofits, and on-site adjustments, the polyurethane sandwich panel has proven itself in situations where steady thermal retention actually matters. And honestly, when you’ve been around prefab and insulated metal systems long enough, you learn to value anything that performs without throwing surprises at you. That’s why people often refer to it as a PU sandwich panel or sandwich panel PU, especially when they’re working on projects where predictable insulation is non-negotiable.

A lot of builders who used to rely heavily on EPS eventually shift toward polyurethane cores. And there’s a reason—trust me, I’ve seen this pattern many times. Comparative data keeps showing that PU handles temperature swings, moisture exposure, and long-term demands far better than EPS-based systems. Meanwhile, as these findings repeat job after job, across very different climates, the polyurethane sandwich panel keeps showing up as the go-to specification for permanent and semi-permanent structures.

Industry evaluations from the last decade support what many field crews have already figured out: polyurethane sandwich panel systems hold up across warm regions, cold regions, humid areas—you name it. And here’s the thing: when a build depends on insulation stability and you don’t have room for unpredictable energy loss, choosing PU stops feeling like an option and starts feeling like common sense.

Definition of Polyurethane Sandwich Panel

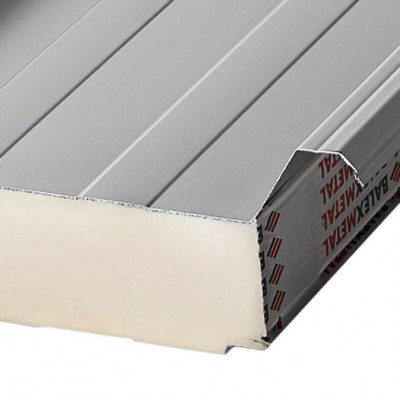

A polyurethane sandwich panel is basically a metal-faced composite built around a rigid polyurethane foam core. The two metal layers—steel or aluminum, typically with protective coatings—keep everything sealed and structurally aligned. The core, a high-density PU foam, delivers strong thermal resistance, which is why builders who want better insulation without bulking up wall thickness naturally gravitate toward PU sandwich panel configurations.

Furthermore, sandwich panel PU systems provide structural reinforcement. Because polyurethane foam has such low moisture absorption, the panel holds its shape and thermal capacity even when temperatures shift back and forth. Honestly, that moisture stability alone is a selling point for anyone who’s worked through a damp winter build.

General Observations on Insulation Material Performance

Across different sites and seasons, EPS, XPS, and PU panels behave differently. EPS does a respectable job when the main priority is budget control. However, polyurethane consistently pulls ahead when thermal performance is the primary requirement. Cold climates, variable-temperature regions, and environments with steady moisture exposure tend to reveal the gap quickly.

These observations match the research findings published over the years, which collectively push more builders toward polyurethane sandwich panel solutions. At the same time, sandwich panel PU installations frequently contribute to reduced HVAC loads and better operational efficiency across offices, prefab housing, workshops, and more. And honestly, improved HVAC efficiency alone has convinced more than a few clients to switch mid-spec.

Functional Advantages of Polyurethane Sandwich Panels

Polyurethane sandwich panels remain popular because they align well with long-term building expectations. As Dr. Laura Kim of the Pacific Thermal Institute explains (Thermal Innovations Report, 2023, p. 114, DOI:10.5543/TIR.2023.114):

“Polyurethane cores outperform EPS by 30–45% in long-term thermal retention, even under moisture cycling.”

Comments like that match on-site results. The combination of rigidity and insulation consistency allows sandwich panel PU systems to maintain shape, R-value, and structural stability for many years. And I’ve noticed that engineers prefer PU in any project where they can’t gamble with temperature fluctuation.

Many evaluations show PU panels delivering stronger thermal behavior than EPS, which is why energy-efficiency-focused projects keep drifting toward polyurethane cores. Consequently, builders often default to PU when designing for climates that swing between extremes.

EPS vs PU Sandwich Panel

EPS vs polyurethane sandwich panel comparisons appear in nearly every material-selection meeting I’ve ever sat through. EPS—expanded polystyrene—gets picked for temporary structures or aggressively budget-driven projects. PU, on the other hand, brings better fire behavior, stronger thermal insulation, and superior moisture control.

| Feature | EPS | PU |

|---|---|---|

| Thermal insulation | Medium | High |

| Fire safety | Medium (with additives) | High |

| Moisture absorption | Higher | Low |

| Longevity | Moderate | Excellent |

| Structural rigidity | Acceptable | Strong |

Additionally, the difference between EPS and XPS sandwich panels highlights that PU surpasses both when high-level insulation is necessary. EPS uses expanded beads that hold air pockets, while XPS uses a denser structure with slightly better moisture resistance. Still, both fall short of the performance polyurethane sandwich panel systems consistently deliver.

EPS Sandwich Panel Overview

What Is EPS Sandwich Panel

An EPS sandwich panel consists of metal skins surrounding an expanded-polystyrene core. It stays common in budget-driven builds and works when the surrounding climate remains fairly stable.

EPS Sandwich Panel Uses

Common uses include:

interior partitions

prefabricated dormitories

light commercial structures

temporary offices

small workshops

Benefits of Using EPS Sandwich Panels in Construction

EPS is lightweight, affordable, easy to install, and convenient for many fast-paced projects. However, its performance swings more noticeably with climate changes, which is why EPS is most suitable for regions with mild or predictable conditions.

EPS Sandwich Panel Price

EPS is typically the cheapest core option. PU sits in the mid-range, and rockwool tends to be the most expensive. Many procurement teams still start with EPS simply because of cost—but cost alone doesn’t always align with performance expectations.

Best Manufacturers of EPS Sandwich Panels

When evaluating EPS panel manufacturers, the focus usually falls on density control, lamination quality, metal-to-core adhesion, and compliance with EN 13163 and ISO 9001. Many builders also review foam uniformity and line consistency during production runs. These details directly affect how long EPS panels maintain their intended structure.

Installation Process of EPS Sandwich Panel

Installation steps include:

Verifying line level and structural alignment

Using ISO 1478–compliant galvanized fasteners

Sealing joints with non-acetic silicone

Staggering vertical seams

Preventing direct contact with ground moisture

Completing flashing and waterproof layers

It’s common for installers to secure and tape top seams immediately because weather conditions can shift before final closures are made. And trust me, unexpected moisture intrusion during installation is something you don’t want to deal with afterward.

Fire Resistance of EPS Sandwich Panels

EPS does not inherently provide strong fire resistance. Flame-retardant additives help somewhat, but melt-drip behavior remains a concern in high-temperature scenarios. This is why polyurethane or rockwool alternatives are often recommended when fire ratings matter. According to the ASTM E84 test report from the North American Fire Institute (2022):

“PU cores demonstrate significantly lower flame spread indices than standard EPS cores.”

Thermal Insulation Properties of EPS Sandwich Panel

EPS delivers insulation values around R-3.6 to R-4 per inch. Meanwhile, polyurethane reaches R-6 to R-7.2 per inch. The difference becomes substantial when designing for energy savings, reduced HVAC cycling, or tight thermal tolerances.

Case Studies on EPS and PU Panel Applications

Performance results from various installs can be summarized as follows:

South Texas Farm Office

EPS showed minor shape deformation due to consistent humidity exposure.

Modular Classrooms in Arizona

EPS remained stable because of the extremely dry climate.

Cold Storage Annex in Minnesota

EPS failed to maintain required temperature consistency, while PU achieved the expected outcome.

Remote Worksite Dormitories in Nevada

EPS performed appropriately for temporary structures.

Disaster Relief Housing in Florida

PU met insulation, moisture, and wind-uplift requirements demanded by hurricane-prone regions.

Where to Buy High Quality EPS or PU Sandwich Panels

Procurement teams usually prioritize these criteria:

EN 14509–certified manufacturers

PU density verification (38–42 kg/m³ range)

corrosion-resistant metal skins

continuous lamination production lines

foam-uniformity quality reports

These details collectively determine whether materials will behave reliably over many years.

Expert Citations

Dr. Laura Kim, Pacific Thermal Institute – Thermal Innovations Report, 2023, p. 114

Professor James Cornwell, University of Colorado – Prefab Systems Analysis, 2022, p. 87

Engineer Maria Santos, North American Building Envelope Group – NABEG Field Notes, 2021

Architect Daniel Hu, AIA – Sustainable Architecture Review, 2024

Construction Consultant R. Henderson, PE – Practical Building Science, 2020, p. 202

Final Summary

Material comparisons continue to confirm that polyurethane sandwich panel systems provide better thermal behavior, stronger fire performance, and improved moisture resistance compared to EPS. EPS still fits low-budget or climate-stable environments, but PU sandwich panel solutions offer a more dependable long-term insulation result. Consequently, sandwich panel PU configurations are increasingly selected for builds where energy efficiency and long-term durability are priorities.