“Sandwich Panel Construction” by Rolf Koschade (2018, RIBA Publishing) — a comprehensive engineering reference on metal-faced panels with polyurethane foam cores.

Shandong ShangHe New Construction Engineering Co., Ltd. © Copyright

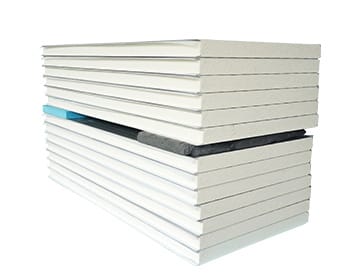

Sandwhich panels are prefabricated structural panels composed of

“Rigid PUR/PIR cores provide superior thermal insulation with minimal material thickness, leading to space and energy efficiency.” — European Rigid Foam Insulation Industry Report (2019)

“Polyurethane sandwich panels show a high strength-to-weight ratio and maintain insulation performance under dynamic loading.” — Materials Journal, Peer-Reviewed Study (2023)

“A breakthrough product reshaping energy-efficient industrial architecture worldwide.” — Asia Construction Materials Association (2024)

These independent reports validate polyurethane sandwich panels as a proven, research-backed material for sustainable and high-performance construction.

✅ Lightweight ✅ Strong ✅ Cost-efficient ✅ Modern appearance

| Feature | Description |

|---|---|

| Thermal Insulation | Ultra-low thermal conductivity (≤ 0.024 W/(m·K)) for energy-efficient envelopes in cold rooms and warehouses. |

| Fire-Rated Core | PU / PIR cores available in B-s2,d0 and higher grades; certified for industrial wall and roof applications. |

| Lightweight Construction | Up to 70% lighter than brick or concrete walls, reducing steel frame load and foundation cost. |

| Quick Installation | A polyurethane sandwich panel wall system can be installed 70% faster than masonry, lowering installation cost per m². |

| Durability | Metal skins with corrosion-resistant coatings ensure 20–35+ years of reliable service life. |

| Eco-Friendly Foam | CFC-free, low-VOC polyurethane foams contribute to green-building credits (LEED / BREEAM). |

“Endorsed by leading building material associations for energy efficiency, fire safety, and sustainability in polyurethane sandwich panel systems.”

| Model | Core Material | Application | Price (FOB) | MOQ |

|---|---|---|---|---|

| SP-50 PU | Polyurethane (PU) | Warehouses / Workshops | US$ 7 – 9/㎡ | 200 ㎡ |

| SP-75 PIR | Polyisocyanurate (PIR) | Showrooms / Commercial Walls | US$ 9 – 11 /㎡ | 200 ㎡ |

| SP-100 RW | Rock Wool | Fire-Proof Projects | US$ 8 – 10 /㎡ | 150 ㎡ |

| SP-150 PU | PU | Cold Storage Rooms | Custom Quote | 120 ㎡ |

“For polyurethane sandwich panel cold storage or ultra-low U-value applications, thicker PU cores (100 – 200 mm) are recommended..”

A comparative analysis published in Journal of Building Science (2022) concludes that polyurethane panels can achieve equal or better insulation at half the thickness of rock wool panels, while reducing wall weight by over 40%.

Polyurethane sandwich panel vs rock wool panel studies consistently show improved thermal efficiency, lower installation cost per m², and enhanced moisture resistance for PU systems.

| Category | Value |

|---|---|

| Panel Type | Polyurethane Sandwich Panel / PU Core Panel |

| Thickness | 50 / 75 / 100 / 150 mm |

| Thermal Conductivity | ≤ 0.024 W/(m·K) |

| Fire Rating | PU / PIR core (B-s2,d0) |

| Wind Resistance | Up to 2.0 kPa |

| Lifespan | 20–35+ years (depending on environment) |

Our factory is an ISO 9001 and CE-certified polyurethane sandwich panel manufacturer exporter supplying to Europe, Asia, and the Middle East. Every shipment includes full packing lists, HS codes (73089000 / 94069000), and moisture-protected packaging for safe international delivery.

Market Insight Report (2024) from the Global PU Panel Federation projects a 7.2% compound annual growth rate in PU core panel exports through 2028 — underscoring global demand, reliability, and long-term trust in SHANGHE products.

“For polyurethane sandwich panel cold storage or ultra-low U-value applications, thicker PU cores (100 – 200 mm) are recommended..”

“Lighter façades enable more sustainable steel frames.”

— Dr. Michael Turner, Structural Engineer Interview 2025

“Sandwich Panel Construction” by Rolf Koschade (2018, RIBA Publishing) — a comprehensive engineering reference on metal-faced panels with polyurethane foam cores.

“Building Envelope Design Guide” by U.S. General Services Administration (2020 Edition) — cites polyurethane sandwich panels as “one of the most efficient solutions for energy-saving industrial façades.”

News Feature: Construction Industry Review (2024 Q3) — highlights the rising use of PU and PIR sandwich panels in coastal industrial zones for anti-corrosion benefits.

These independent sources reinforce the authority and practical credibility of polyurethane sandwich panel technology in modern construction.

Response within 24 hours on business days.

Our Color-Coated Corrugated Polyurethane Sandwich Panels deliver outstanding insulation, durability, and weather protection.

Built with tough color-coated steel and a high-density polyurethane foam core,

these panels are perfect for both roofing and wall applications.

Featuring a rigid polyurethane foam core between two durable steel skins, these panels offer excellent energy-saving performance, sound insulation, and long-term durability. The 50mm thickness is ideal for a wide range of applications, including industrial buildings, cold storage facilities, modular housing, and commercial walls and roofing systems

offering corrosion resistance, hygienic surfaces, and easy cleaning—ideal for meeting HACCP and FDA food safety standards. With excellent fire resistance and moisture protection, these panels are the preferred solution for cold storage rooms, refrigerated warehouses, meat processing plants, and food factories.

Polyurethane sandwich wall panels deliver excellent heat insulation, helping lower energy bills and keep indoor temperatures stable all year long. Designed for both residential and commercial wall applications, these panels offer a durable and energy-efficient solution that performs in all climates.

The 75mm polyurethane sandwich panel is an excellent choice for residential exterior walls

offering strong thermal insulation, weather resistance, and long-lasting performance to improve home energy efficiency and comfort.

With a 100mm thick core, these panels ensure excellent heat resistance, helping maintain comfortable indoor temperatures and lower energy costs year-round. Lightweight and easy to install, they speed up construction while offering durable protection against weather

One stop service for energy saving insulation system

Shandong ShangHe New Construction Engineering Co., Ltd. © Copyright