2 Hour Fire Rated Sandwich Panel: The Ultimate Protection Your Building Needs

When it comes to fire safety in construction, every second counts. That’s why a 2 hour fire rated sandwich panel is a game-changer—it gives you crucial extra time to evacuate and minimize damage. Unlike standard panels, these are rigorously tested to withstand extreme heat for two full hours, making them ideal for high-risk areas like industrial facilities, hospitals, and commercial buildings. And let’s be real—no one wants to cut corners when lives and property are at stake.

So, how do these panels work? They’re built with fire-resistant cores, often rockwool or mineral wool, sandwiched between metal layers. This isn’t just some basic insulation; it’s engineered to slow fire spread, reduce smoke, and maintain structural integrity longer. Plus, many of these panels are LEED-certified, meaning they’re not just safe—they’re also eco-friendly.

If you’re in the UAE, Australia, Saudi Arabia, or Qatar, you know local fire codes are no joke. A 2 hour fire rated sandwich panel isn’t just a smart choice—it’s often required by law in critical applications. And while some might worry about cost, think about this: What’s the price of safety? Because when fire strikes, you don’t get a second chance.

Customers visit the factory

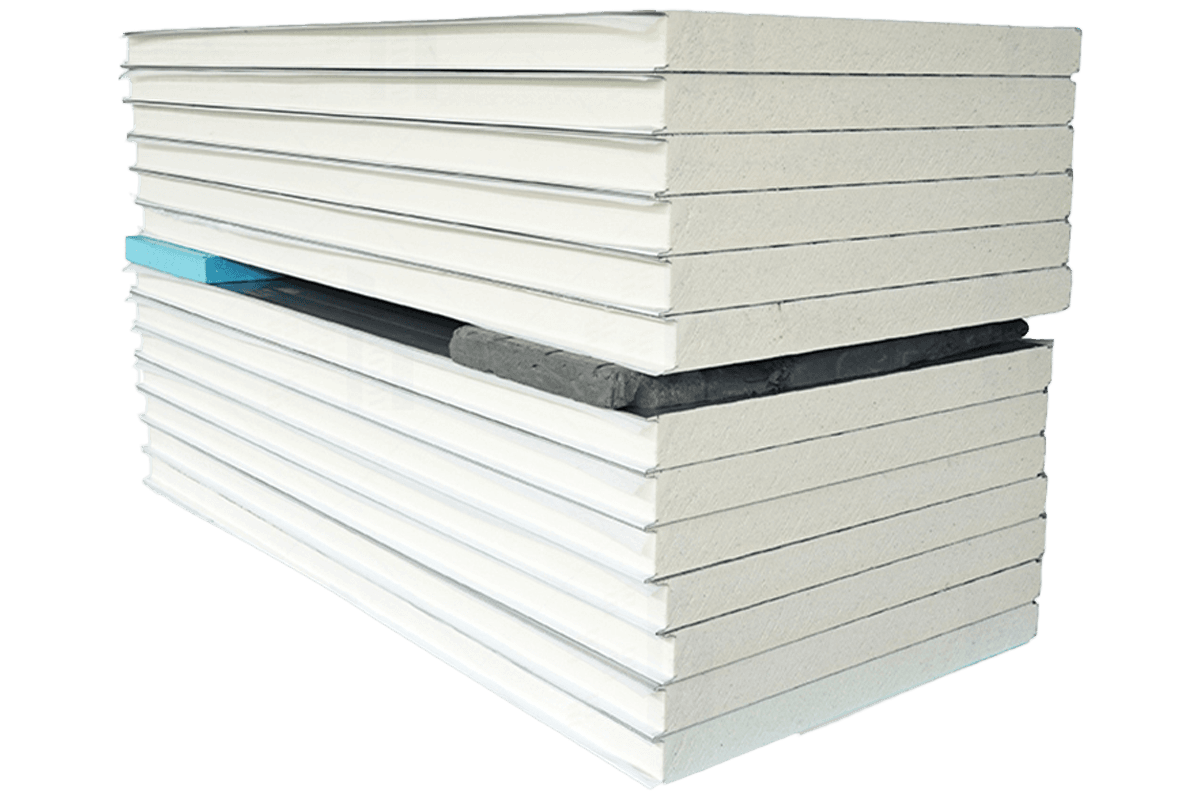

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

| Core Material | High-density PU foam (150kg/m³) / Mineral wool (for fireproofing) | Lighter than solid wood, better insulation |

| Facing Layers | 3mm Oak/Birch veneer or HDF (water-resistant coating optional) | Natural wood look, scratch-resistant |

| Panel Thickness | 30mm, 50mm, 80mm (customizable up to 120mm) | Thicker = better insulation for cold climates |

| Fire Rating | Class B (EN 13501), Class A optional (with mineral wool core) | Meets EU/US building codes |

| Load Capacity | Up to 250kg/m² (static load) | Safe for walls, floors, and ceilings |

| Thermal Conductivity | 0.022 W/m·K (PU core) / 0.038 W/m·K (mineral wool) | Reduces heating/cooling costs by ~30% |

| Moisture Resistance | Swelling <0.5% (72hrs, humidity 95%) | No mold, lasts longer in wet climates |

| Custom Sizes | Max. 4m length, 1.2m width (larger sizes consult us) | Fits most designs without wasteful cutting |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | wood sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Fire Rated Sandwich Panel UAE: Meeting Strict Safety Standards Without Compromise

In the UAE, where skyscrapers and high-risk facilities dominate the skyline, fire safety isn’t optional—it’s mandatory. A fire rated sandwich panel UAE builders trust must comply with strict Civil Defense regulations, and guess what? Not all panels make the cut.

The best panels here use non-combustible rockwool cores and are tested under extreme conditions. Why? Because in a place where summer temps soar, heat resistance is everything. And let’s not forget—UAE fire codes demand real performance, not just paperwork.

So if you’re sourcing panels here, don’t settle for weak links. Go for certified, high-performance fire rated sandwich panels—because when it comes to safety, “good enough” isn’t good enough.

Fire Rated Sandwich Panel Saudi Arabia: Built for Extreme Conditions

Saudi Arabia’s construction boom is unstoppable—but with massive projects come massive fire risks. That’s why a fire rated sandwich panel Saudi Arabia developers use must handle more than just flames. Think sandstorms, extreme heat, and heavy structural loads.

The best panels here combine fire resistance (1 or 2 hour ratings) with durable metal facings that won’t warp under pressure. And since Saudi regulations are tightening, cutting corners means failed inspections—or worse, disasters.

Bottom line? If you’re building in KSA, fire safety isn’t just a feature—it’s a necessity. Choose panels that actually perform when it matters most.