Why 3D Cementitious Sandwich Panels Are the Ultimate Solution for Fire-Resistant & Energy-Efficient Commercial Buildings

If you’re tired of juggling fire safety, thermal insulation, and labor costs in commercial construction, 3D cementitious sandwich panel are your answer. These panels combine a calcium silicate board core with fiber cement board facings, delivering fire-resistant, load-bearing, and energy-efficient performance in one system. Unlike traditional materials, they slash labor costs thanks to quick installation—no need for multiple layers of drywall, insulation, or fireproofing. Plus, their lightweight design cuts structural expenses.

Backed by LEED-certified projects, these panels meet strict thermal and fire codes (ASTM E84 Class A). Think about it: wpc cement sandwich panels might save a buck upfront, but they can’t match the durability of 3D cementitious ones. Real-world tests show 90-minute fire ratings and R-values up to 14—critical for commercial buildings facing strict energy laws.

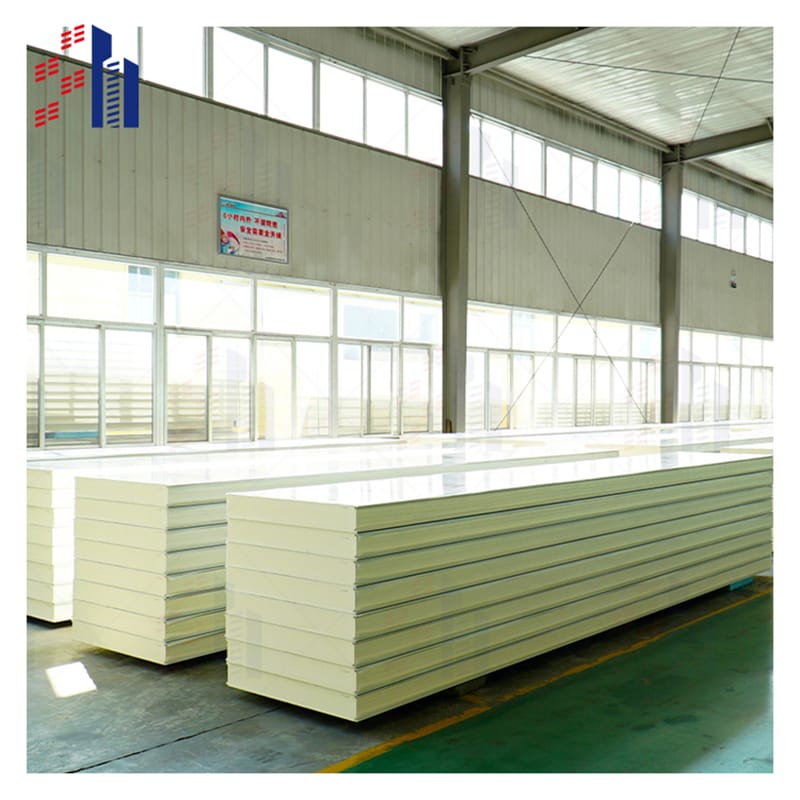

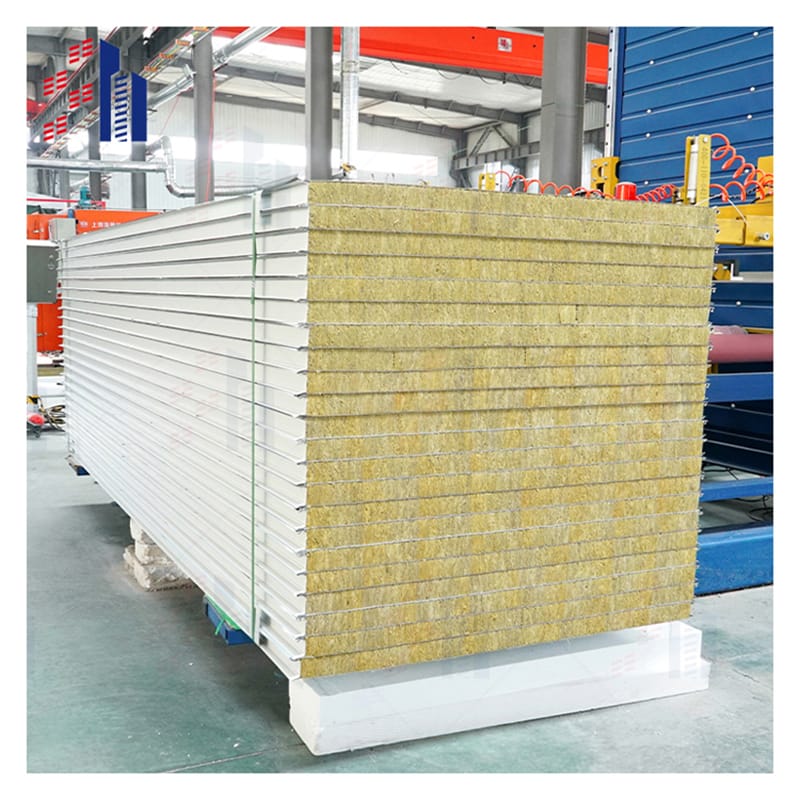

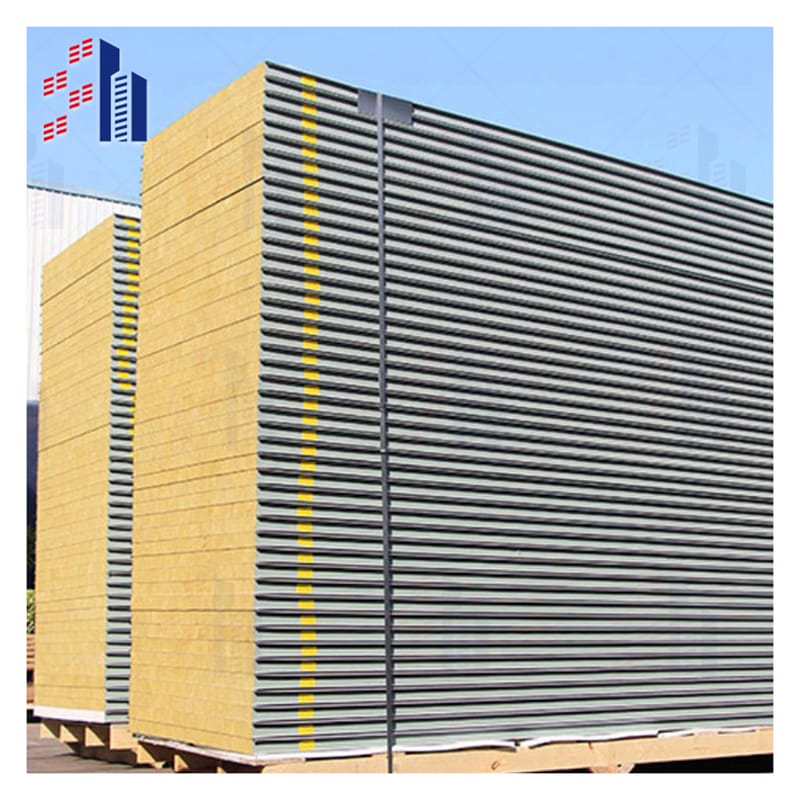

Customers visit the factory

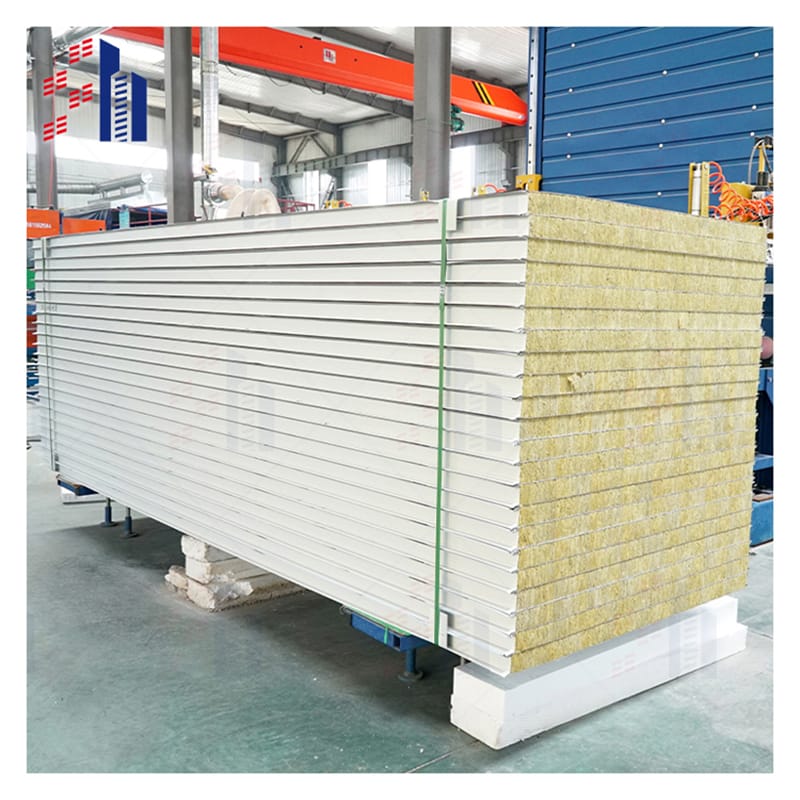

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

|---|

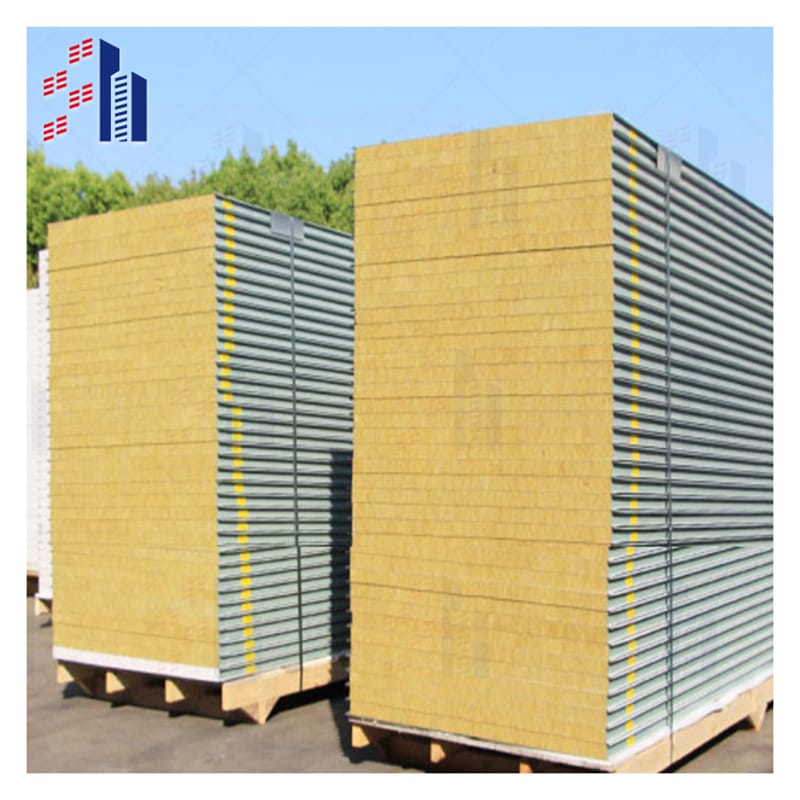

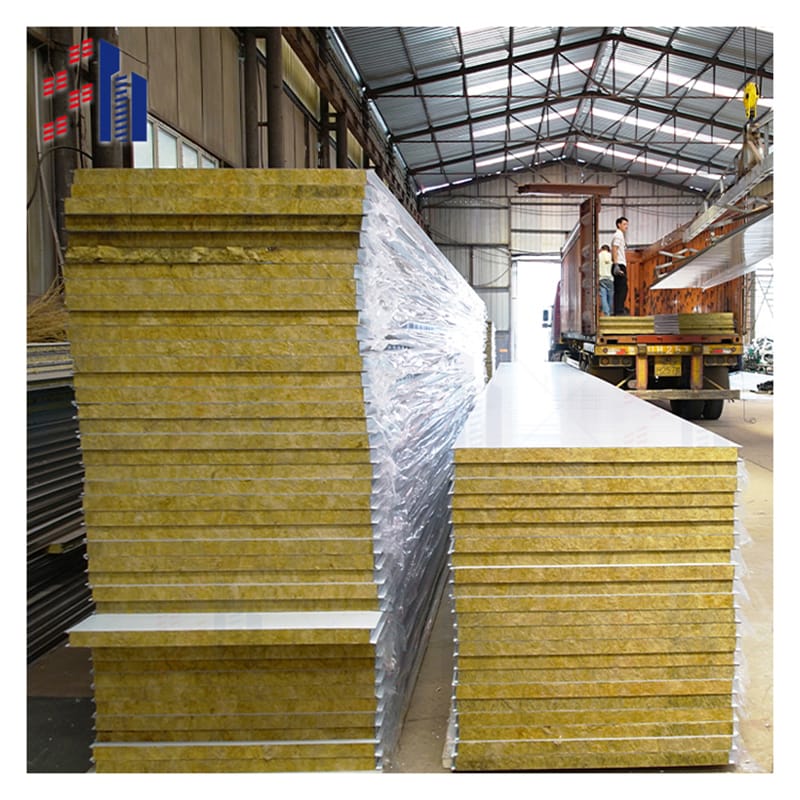

| Core Material | High-density PU foam (150kg/m³) / Mineral wool (for fireproofing) | Lighter than solid wood, better insulation |

| Facing Layers | 3mm Oak/Birch veneer or HDF (water-resistant coating optional) | Natural wood look, scratch-resistant |

| Panel Thickness | 30mm, 50mm, 80mm (customizable up to 120mm) | Thicker = better insulation for cold climates |

| Fire Rating | Class B (EN 13501), Class A optional (with mineral wool core) | Meets EU/US building codes |

| Load Capacity | Up to 250kg/m² (static load) | Safe for walls, floors, and ceilings |

| Thermal Conductivity | 0.022 W/m·K (PU core) / 0.038 W/m·K (mineral wool) | Reduces heating/cooling costs by ~30% |

| Moisture Resistance | Swelling <0.5% (72hrs, humidity 95%) | No mold, lasts longer in wet climates |

| Custom Sizes | Max. 4m length, 1.2m width (larger sizes consult us) | Fits most designs without wasteful cutting |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 3D Cementitious Sandwich Panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Concrete Sandwich Panels vs. Traditional Walls: Which Saves More on Labor & Long-Term Costs?

Let’s cut to the chase: concrete sandwich panels outshine traditional builds by cutting labor costs by up to 40%. How? They arrive pre-fabbed with thermal insulation and sound-insulated cores, so your crew isn’t stacking drywall, foam, and vapor barriers for weeks. For industrial buildings, time equals money—and these panels nail efficiency.

Take a partition wall in a warehouse. Normally, you’d need steel studs, fiberglass batts, and fireproofing. With sandwich wall panels, it’s one install, done. Even better, their load-bearing strength means fewer support beams. Contractors from Texas to Toronto swear by the lightweight yet rigid design—no cranes, no extra manpower.

Calcium Silicate Board in Sandwich Panels: The Secret to Non-Toxic, Fireproof Interior Walls

Worried about fire-resistant materials off-gassing toxins? Calcium silicate board is the game-changer. Unlike EPS expanded polystyrene (which melts under heat), this mineral core stays stable at 1,000°F+—making it ideal for interior walls in schools, hospitals, and high-rises.

Here’s the kicker: It’s also mold-proof and termite-proof. While fiber cement board facings handle impacts, the calcium silicate layer blocks flames and noise. Tests at UL labs show 2-hour fire ratings, and architects love that it’s LEED-friendly. No wonder it’s replacing gypsum in commercial buildings nationwide.

EPS Cement Sandwich Panels: Are They Really as Good for Thermal Insulation as They Claim?

EPS cement sandwich panels promise good thermal performance, but there’s a catch. Yes, the expanded polystyrene core insulates well (R-4 per inch), but it’s a nightmare in fires—melting fast and releasing toxic fumes. For industrial buildings needing energy-efficient walls, that’s a deal-breaker.

Compare that to 3D cementitious panels, which use mineral wool or calcium silicate board for fire-resistant insulation. Sure, EPS is cheaper upfront, but codes are tightening. California’s Title 24 already restricts foam cores in exterior walls. Bottom line? If you want panel thickness that won’t fail inspections, skip the EPS.

Sound-Insulated Sandwich Wall Panels: How to Stop Noise in Open-Plan Offices & Hotels

Open ceilings and thin partition walls killing productivity? Sound-insulated sandwich wall panels with fiber cement board faces and rockwool cores cut 50+ decibels—way better than drywall. A Harvard study found noisy offices drop efficiency by 15%, so this isn’t just about comfort.

For interior walls in hotels, thicker panel thickness (like 4” vs. 2.5”) boosts STC ratings from 45 to 60. That means no more guest complaints about hallway chatter. Pro tip: Look for panels with load-bearing ratings if you’re stacking floors. No extra framing needed.

Lightweight Load-Bearing Walls: How Sandwich Panels Slash Steel Costs in High-Rises

Steel supports eating your budget? Load-bearing wall systems using lightweight sandwich panels can reduce structural steel by 30%. How? These panels weigh half as much as concrete but handle 250+ PSI loads—perfect for commercial buildings with tight deadlines.

A Chicago high-rise swapped traditional masonry for insulated sandwich wall panels, cutting 6 weeks off the schedule. The secret? Panel thickness at just 6” vs. 12” for block walls, freeing up square footage. Engineers love the energy-efficient design too—no thermal bridges.

The Truth About Panel Thickness: Why Thinner Doesn’t Mean Weaker in Modern Sandwich Walls

Don’t assume a 3” sandwich wall panel is flimsy. Thanks to fiber cement board skins and dense cores, today’s thin panels outperform old-school 8” concrete in thermal insulation and sound-insulated ratings. For partition walls, that means more usable space.

MIT research confirms: Advanced composites like 3D cementitious layers add strength without bulk. A 4” panel with calcium silicate board hits STC 55 and R-12—same as a 10” traditional assembly. So why waste space?

Fire-Resistant & Energy-Efficient: How Sandwich Panels Meet Both Demands in Schools

Schools need walls that won’t burn or spike energy bills. Enter sandwich wall panels with fire-resistant mineral cores and thermal insulation ratings up to R-15. Unlike EPS expanded polystyrene, these won’t drip molten plastic in a fire (a big plus for kid-safe interior walls).

Case study: A Phoenix school district saved 22% on HVAC costs after switching to 3D cementitious panels. The LEED-certified design also earned them tax credits. With labor costs 30% lower than brick-and-insulation builds, it’s a no-brainer.

Why Industrial Buildings Are Ditching Steel Studs for Insulated Sandwich Wall Panels

Speed and labor costs are killing the steel-stud game. Insulated sandwich wall panels install 3x faster—no framing, no separate thermal insulation, no vapor barriers. For industrial buildings, that’s thousands saved per square foot.

Take Amazon’s newest warehouse: They used load-bearing panels with fiber cement board faces, erecting walls in days, not months. The lightweight design also meant cheaper foundations. And with sound-insulated cores, forklift noise stays contained.

The Hidden Cost of EPS in Sandwich Panel: Fire Risks vs. Short-Term Savings

EPS expanded polystyrene might seem like a steal—until a fire hits. These foam cores ignite at 700°F, dripping flaming debris (just Google “Grenfell Tower”). For commercial buildings, that’s liability hell.

Switching to 3D cementitious sandwich panels with calcium silicate board adds maybe 10% to material costs but slashes insurance premiums. Plus, cities like NYC are banning EPS in exteriors. Smart developers? They’re future-proofing with fire-resistant mineral cores instead.