What Are 4 cm Sandwich Panels

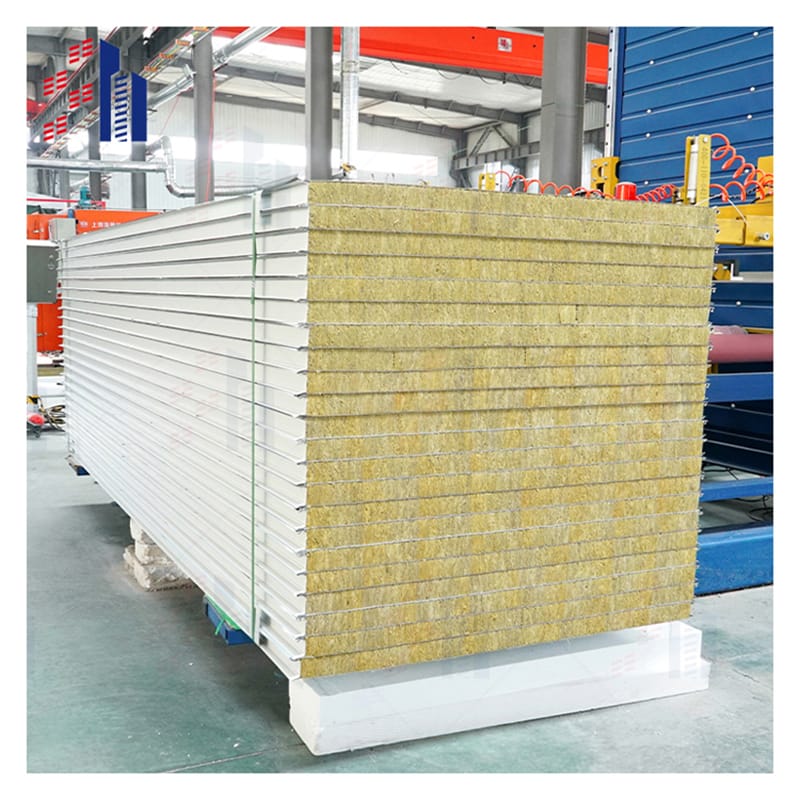

4 cm sandwich panels are building materials made of two strong outer skins bonded to a lightweight core. This layered structure creates a panel that is both sturdy and insulated without adding extra weight. The outer skins provide durability and protection, while the core offers thermal insulation and strength.

The 4 cm thickness hits a sweet spot for many construction needs. It’s thick enough to provide good insulation and structural support but still thin and light enough for easy handling and faster installation. This makes 4 cm panels ideal for applications where space is limited or where lightweight materials are a priority.

At Shanghe, our 4 cm sandwich panels commonly use cores like polyurethane (PUR), expanded polystyrene (EPS), rock wool, or glass wool. The outer skins are usually made from steel, aluminum, or fiberglass, depending on the project requirements. This combination ensures a balance of strength, insulation, and fire resistance tailored to your building needs.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification (Metric) | U.S. Standard | Why It Matters |

|---|

| Core Material | PIR (Polyisocyanurate) | ASTM E84 Class A | Stops fires + cuts cooling costs by 40% |

| Fire Rating | A1 (Non-combustible) | UL 94 V-0 | Meets NYC high-rise codes – no toxic smoke |

| Thickness | 50mm, 75mm, 100mm | – | 100mm = -40°F freezer compliance (ASHRAE) |

| Thermal Conductivity (λ) | 0.022 W/m·K | R-6.5 per inch | Beats fiberglass (R-3.7) – cheaper long-term |

| Panel Strength | 150 kPa compressive | ASTM C165 | Walkable roof loads (25 psf) – no dents |

| Custom Sizes | Up to 40ft x 4ft | – | Fewer seams = faster install + better insulation |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | steel foam sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Features of Shanghe’s 4 cm Sandwich Panels

Shanghe’s 4 cm sandwich panels are designed with a lightweight build, making them perfect for cutting down on structural weight without sacrificing strength. This helps reduce the load on your building’s framework, which can save you money on support materials and foundation work.

When it comes to thermal insulation, these panels perform well thanks to core materials like polyurethane (PUR) that offer low thermal conductivity—around 0.28 W/mK. This means they keep indoor temperatures steady, helping you save on heating and cooling costs year-round.

Durability is another strong point. Shanghe’s panels resist moisture, corrosion, and other environmental factors, so they hold up well in different weather conditions. Plus, there are fire-resistant options available, giving you extra peace of mind for safety and compliance with local building codes.

Installation is straightforward and fast. The panels are designed for easy handling and quick assembly, which means less labor time and lower construction costs. Whether you’re working on a new build or a retrofit, these panels help keep your project on schedule and budget.

Applications of 4 cm Sandwich Panels

4 cm sandwich panels are versatile and fit well in many building projects across the U.S. Here’s where they shine:

Residential Construction

These panels work great for walls, roofs, and floors in homes. Their lightweight nature makes installation easier, and the thermal insulation helps keep energy bills down by maintaining indoor temperatures.

Commercial Buildings

For warehouses, offices, and retail spaces, 4 cm sandwich panels provide a strong, durable shell. They’re perfect for creating quick, energy-efficient structures that meet modern building codes.

Industrial Use

In cold storage facilities, factories, and cleanrooms, these panels help maintain strict temperature controls and hygiene standards. Their fire-resistant options add an extra layer of safety for industrial environments.

Specialized Applications

Lightweight and easy to install, 4 cm sandwich panels are ideal for mobile homes, modular buildings, and temporary structures. They offer flexibility without sacrificing durability or insulation.

Whether you’re building a new home, upgrading a commercial space, or setting up an industrial facility, Shanghe’s 4 cm sandwich panels deliver reliable performance tailored to your needs.

Benefits of Choosing Shanghe’s 4 cm Sandwich Panels

Shanghe’s 4 cm sandwich panels offer real value for your building projects. Here’s why they stand out:

Energy Efficiency

These panels provide excellent thermal insulation, helping to reduce heating and cooling costs. That means your energy bills stay lower, and your space stays comfortable year-round.

Cost-Effectiveness

Thanks to their lightweight design and easy installation, Shanghe’s panels cut down on labor and material costs. You get strong, durable walls and roofs without breaking the budget.

Sustainability

Shanghe uses eco-friendly materials and manufacturing processes, so these panels support greener building practices. Choosing them helps reduce your project’s environmental impact.

Customization

Every project is different. Shanghe offers customizable options for core materials, skin finishes, and sizes, so you get panels tailored to your specific needs.

Compliance

These panels meet global standards for safety, fire resistance, and performance. You can trust they’ll pass inspections and keep your building up to code.

With Shanghe’s 4 cm sandwich panels, you get energy savings, cost control, green building benefits, flexibility, and reliable quality—all in one package.

Technical Specifications of Shanghe’s 4 cm Sandwich Panels

Shanghe’s 4 cm sandwich panels come with a precise 40 mm thickness, making them ideal for a balance of insulation and lightweight design. The core materials include polyurethane (PUR), expanded polystyrene (EPS), rock wool, or glass wool—each offering different levels of thermal insulation and fire resistance to fit your project needs.

The outer skins are made from durable materials like steel, aluminum, or fiberglass, providing strength and protection against weather and wear. For example, PUR cores offer a thermal conductivity around 0.28 W/mK, helping keep energy costs down.

Panels come in standard sizes but can be customized to fit unique building requirements. They’re lightweight too—EPS panels weigh roughly 10 kg per square meter, making handling and installation easier.

All panels meet strict testing standards to ensure quality, durability, and safety, giving you peace of mind for your construction projects.

Why Choose Shanghe for 4 cm Sandwich Panels

Shanghe stands out for its strict quality control, putting every 4 cm sandwich panel through mechanical and climatic tests to ensure they hold up in real-world conditions. This means you get reliable, durable panels built to last.

With a strong global reach, Shanghe supports customers not just in Asia-Pacific and Europe but also offers local support tailored to the U.S. market. Whether you need technical advice or quick delivery, help is always nearby.

Their panels come with certifications that meet international standards, reflecting Shanghe’s commitment to innovation and customer satisfaction. You can trust their products for safety, performance, and sustainability.

Ready to improve your building project? Contact Shanghe today for quotes or samples and see how their 4 cm sandwich panels can fit your needs.

Comparing 4 cm Sandwich Panels to Other Thicknesses

When choosing sandwich panels, thickness matters. A 4 cm sandwich panel strikes a balance between lightweight design and decent insulation, but how does it compare to thinner or thicker options?

- Compared to 2 cm panels: Thinner panels like 2 cm are lighter and easier to handle, making them great for temporary or lightweight structures. However, they offer less thermal insulation, which can increase energy costs in the long run.

- Compared to 10 cm panels: Thicker panels provide superior insulation and better soundproofing, ideal for colder climates or industrial uses. But they add more weight and cost more to install and transport.

Trade-offs to consider

- Weight vs Insulation: 4 cm panels are lighter than 10 cm options, reducing the structural load and installation effort. But they don’t insulate as well, so they’re best for moderate climates or where space is limited.

- Cost vs Performance: Thicker panels cost more upfront but can save energy over time. Thinner panels save on initial costs but might require extra heating or cooling.

Real-world examples

- In residential projects across the U.S., 4 cm panels are popular for walls and roofs where moderate insulation is sufficient without adding too much weight.

- For cold storage or industrial buildings, 10 cm panels are preferred to maintain strict temperature control.

- Temporary or mobile units often use 2 cm panels for easy transport and quick setup.

Choosing the right thickness depends on your project’s insulation needs, budget, and structural limits. For more detailed options, check out Shanghe’s range of thermal insulation sandwich panels and polyurethane sandwich panels.

Installation Tips for 4 cm Sandwich Panels

Getting your 4 cm sandwich panels installed right makes all the difference in performance and durability. Here are some straightforward tips to keep in mind:

Ensure Proper Alignment

Make sure panels line up evenly to avoid unnecessary stress or gaps. Misalignment can lead to weak spots and reduce insulation efficiency.

Use Appropriate Adhesives or Fasteners

Choose fasteners or adhesives designed for sandwich panels. This helps keep the panels secure without damaging the outer skins or core.

Account for Thermal Expansion

Panels expand and contract with temperature changes. Leave a small gap or use flexible joints to prevent buckling or warping over time.

Refer to Installation Guides or Support

Always check Shanghe’s detailed installation manuals or reach out to their support team. Proper guidance ensures your project stays on track and meets quality standards.

Following these tips helps you get the most out of your 4 cm sandwich panels, ensuring a smooth, efficient build that lasts.