What Are 75mm Sandwich Panels

75mm sandwich panels are advanced composite building materials designed with a 75mm thick core made from high-performance insulation materials such as PUR (polyurethane), PIR (polyisocyanurate), EPS (expanded polystyrene), or mineral wool. This core is securely bonded between two durable outer skin layers, commonly steel, aluminum, or composite sheets, creating a strong, lightweight, and highly insulating panel.

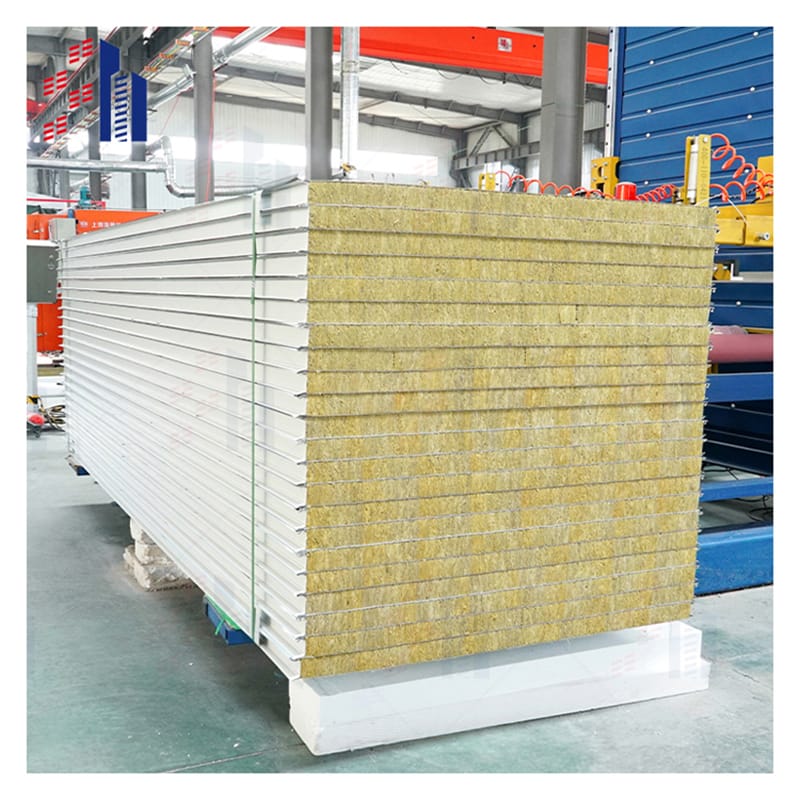

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Key Features of 75mm Sandwich Panels

- Lightweight but strong: The optimized thickness offers a high strength-to-weight ratio, making these panels easy to handle and install without compromising structural integrity.

- Excellent thermal insulation: The 75mm core delivers superior sandwich panel insulation, ideal for reducing energy costs in a variety of buildings.

- Versatile and durable outer skins: Available with steel or aluminum skins, these panels resist weather, corrosion, and wear.

Why Choose 75mm Thickness Compared to 50mm and 100mm

- Compared to 50mm panels: The 75mm thickness offers notably better thermal insulation and higher load-bearing capacity, making it a more reliable option for commercial and industrial buildings without significantly increasing weight or cost.

- Compared to 100mm panels: While 100mm panels provide even better insulation, the 75mm thickness strikes a perfect balance between efficiency, cost, and ease of installation — which explains why it is often the most popular choice for construction projects needing solid thermal and structural performance without overdoing material thickness.

In short, 75mm sandwich panels combine lightweight construction, strong insulation, and good durability, making them the preferred solution for many building applications across industrial, commercial, and residential sectors.

Benefits of Shanghe 75mm Sandwich Panels

Excellent Thermal Insulation and Energy Efficiency

Shanghe’s 75mm sandwich panels deliver superior thermal insulation, making them ideal for cold storage warehouses and commercial buildings. The core materials like PUR, PIR, EPS, and mineral wool provide a strong barrier against heat transfer. This cuts down on energy costs by maintaining consistent indoor temperatures, boosting overall energy efficiency for your facility.

Strong Structural Integrity for Industrial Use

These panels offer a high load-bearing capacity, supporting heavy industrial applications with ease. Their composite build balances lightweight design with toughness, ensuring your structure can withstand demanding environments without sacrificing strength.

Eco-Friendly and Sustainable Materials

Shanghe’s 75mm sandwich panels use eco-friendly materials that comply with green building standards. Choosing these panels helps reduce your project’s environmental impact by incorporating sustainable core options and recyclable skin materials, aligning with today’s push toward sustainable construction.

Easy Installation Saves Time and Money

Designed for quick and straightforward installation, these panels cut down on construction time and labor costs. Their standardized dimensions and lightweight nature mean less heavy equipment is needed, speeding up project timelines and reducing onsite workforce expenses.

Durable and Weather Resistant for Long Lifespan

Built to resist harsh weather conditions, Shanghe’s sandwich panels provide long-lasting durability. They stand up against moisture, UV exposure, and temperature fluctuations, ensuring your investment holds strong in diverse environments, from industrial zones to outdoor commercial spaces.

By choosing Shanghe’s 75mm sandwich panels, you get a product optimized for insulation, strength, sustainability, and ease of use — exactly what U.S. builders and facility managers need for efficient, reliable construction projects.

Applications of 75mm Sandwich Panels

75mm sandwich panels are highly versatile and widely used across various sectors due to their lightweight construction, strong insulation, and durability. Here are the top areas where these panels shine:

Industrial Use

- Warehouses and factories: Ideal for keeping environments controlled, 75mm panels provide excellent thermal insulation and structural strength, helping maintain energy efficiency while supporting heavy loads.

- Logistics centers: Their quick installation reduces downtime, and their insulation helps protect sensitive goods during storage and transit.

Commercial Buildings

- Shopping malls and retail spaces: The panels offer clean, modern finishes and sound insulation, making spaces comfortable for shoppers and employees alike.

- Office buildings: With their thermal efficiency, these panels reduce HVAC costs, creating a cost-effective commercial environment.

Residential Construction

- Prefabricated homes and modular buildings: 75mm panels are a smart choice for fast, reliable building that meets insulation standards, contributing to energy savings and quick project turnaround.

Specialized Facilities

- Cold storage and clean rooms: Rely on the superior thermal insulation of PUR, PIR, or EPS cores to maintain precise temperatures and hygiene standards.

- Agricultural facilities: From animal shelters to produce storage, these panels help create protected environments that extend shelf life and comfort.

Shanghe Project Highlight

At Shanghe, we recently completed a local warehouse project using our 75mm sandwich panels. The result was a structure that offered excellent thermal insulation, structural integrity, and quick assembly, cutting construction time by 30% compared to traditional building materials. This project is a testament to the practical benefits of choosing 75mm sandwich panels for your industrial or commercial projects.

By selecting Shanghe 75mm sandwich panels, you’re ensuring your project benefits from top-tier thermal insulation, eco-friendly materials, and durable construction, no matter the application.

Technical Specifications of Shanghe 75mm Sandwich Panel

When choosing 75mm sandwich panels for your project, it’s important to understand their technical details to ensure they meet your performance and regulatory needs. Shanghe’s panels offer a range of options tailored to diverse construction requirements, combining insulation efficiency, structural durability, and compliance with industry standards.

Core Materials Options

The 75mm core is available in several high-performance materials, each with unique benefits:

- PUR (Polyurethane) Core – Excellent thermal insulation with low thermal conductivity, ideal for energy-efficient buildings and cold storage.

- PIR (Polyisocyanurate) Core – Similar to PUR but with enhanced fire resistance and improved thermal properties.

- EPS (Expanded Polystyrene) Core – Lightweight and cost-effective, suitable for less demanding insulation needs.

- Mineral Wool Core – Provides superior fire resistance, sound insulation, and thermal stability, great for industrial and commercial applications.

Skin Material Choices

The outer layers provide structural strength and protection. Shanghe offers:

- Steel Skins – Durable, impact-resistant, ideal for industrial and commercial buildings.

- Aluminum Skins – Lightweight and corrosion-resistant, often used where aesthetics and longevity matter.

- Other Composites – Customized materials available for specialized projects requiring specific finishes or performance.

Dimensions and Customization

- Standard Thickness: 75mm core designed for an optimal balance of insulation and strength.

- Width and Length: Panels come in customizable sizes to fit any project scale, reducing waste and speeding installation.

- Custom Designs: Available to meet specific architectural or engineering requirements, including different facing profiles or edge configurations.

Fire Resistance and Insulation Ratings

Shanghe’s 75mm sandwich panels meet strict fire safety standards and deliver excellent thermal and acoustic performance:

- Fire Resistance: Depends on core type; mineral wool is non-combustible, PIR offers improved flame retardant properties, and PUR/EPS cores are tested for compliance with ASTM E84 and other relevant UL ratings.

- Thermal Conductivity: Core materials offer low lambda (λ) values, typically around 0.022 – 0.030 W/m·K, ensuring strong insulation for energy savings.

- Sound Insulation: Mineral wool core panels provide enhanced acoustic dampening, essential for noise control in commercial and residential use.

Compliance and Certifications

Shanghe 75mm sandwich panels comply with key international and local standards, ensuring reliability and suitability for U.S. construction projects:

- ISO Certifications: Ensuring quality management and consistent production standards.

- CE Marking: Confirming conformity with European safety, health, and environmental protection standards, useful for international projects.

- Local Building Codes: Panels are manufactured to meet or exceed U.S. building codes, including fire safety and energy efficiency regulations.

For detailed product specifications and ordering, explore Shanghe’s full range of foam core sandwich panels designed to fit various building needs efficiently and affordably.

Why Choose Shanghe for 75mm Sandwich Panels

When selecting 75mm sandwich panel for your project, Shanghe stands out for several important reasons that ensure quality, reliability, and value.

Proven Quality and Reliability

Shanghe’s panels go through rigorous mechanical, climatic, and chemical testing to meet strict durability standards. This means our panels consistently deliver high performance in insulation, structural strength, and weather resistance, making them a reliable choice for US industrial and commercial applications.

Competitive Pricing and Bulk Order Benefits

We understand project budgets matter. Shanghe offers competitive pricing without compromising quality. Plus, if you’re ordering in bulk for large projects, you benefit from additional cost savings and dedicated support to keep your costs manageable.

Efficient Local and Global Supply Chain

Fast delivery is critical on construction timelines. With a well-managed local and global supply chain, Shanghe ensures your 75mm sandwich panelarrive on time, no matter where your project is located in the United States. This reduces downtime and helps avoid costly delays.

Customization to Fit Your Needs

Every building has unique requirements. Shanghe provides tailored solutions, including different core materials (PUR, PIR, EPS, mineral wool), skin finishes (steel, aluminum), and panel dimensions. We work closely with you to meet specific project demands and local code requirements.

Dedicated Customer Support and Technical Guidance

Choosing the right panel is just the start. Shanghe offers technical guidance throughout your project—from selection and installation to maintenance. Our after-sales support team is always ready to help you solve challenges and ensure your panels perform over the long haul.

With Shanghe, you get a trusted partner providing high-quality, energy-efficient, and eco-friendly 75mm sandwich panel backed by proven expertise and service tailored to the needs of US customers.

How to Select the Right 75mm Sandwich Panel for Your Project

Choosing the right 75mm sandwich panel is key to getting the best performance and value for your building project. Here’s what you need to keep in mind:

Factors to Consider When Choosing 75mm Sandwich Panel

- Core Material: Decide based on your insulation needs, budget, and environment. The most common cores are PUR, PIR, EPS, and mineral wool.

- Application: Think about where and how the panels will be used—cold storage, industrial buildings, commercial spaces, or residential setups all have different requirements.

- Budget: Balance cost with performance. Some cores like PIR offer better fire resistance but can be pricier. EPS is more cost-effective but may lack in fire ratings.

- Environmental Conditions: Are you dealing with extreme weather, high humidity, or fire risk? Choose a panel core and skin that fits those local conditions.

Comparing Core Materials for 75mm Sandwich Panel

| Core Type | Thermal Insulation | Fire Resistance | Cost | Typical Uses |

|---|

| PUR | High | Moderate | Moderate | Cold storage, commercial roofs |

| PIR | Very High | High | Higher | Fire-sensitive areas, industrial |

| EPS | Moderate | Low | Low | Budget projects, interior walls |

| Mineral Wool | Moderate | Very High | Moderate | Fire protection, clean rooms |

Use this as a quick guide to match your project needs with the best core.

Tips for Customizing Panels with Shanghe

- Local Building Codes: Shanghe works closely with clients to ensure panels meet local U.S. building codes and regulations.

- Tailored Solutions: You can customize skin materials (steel, aluminum), panel dimensions, and core types to fit your project.

- Technical Support: Take advantage of Shanghe’s expert advice for specifics like thermal conductivity, fire ratings, or structural needs.

- Samples and Testing: Request samples or performance data upfront to verify compatibility with your site conditions.

By focusing on these factors and collaborating with Shanghe, you can choose the best 75mm sandwich panel insulation solution that’s efficient, compliant, and durable for your construction needs.

Installation and Maintenance Tips for 75mm Sandwich Panel

Step by Step Guide for Installing 75mm Sandwich Panels

Installing 75mm sandwich panels properly ensures maximum insulation, structural integrity, and durability. Follow these steps for a smooth installation process:

Prepare the Surface

Make sure the mounting surface is clean, level, and free of debris. Check for any structural issues that might affect panel alignment.

Measure and Plan Layout

Plan panel placement carefully to minimize cuts and overlaps. Ensure alignment with supporting structures like steel frames or purlins.

Handle Panels with Care

These panels are lightweight but can be damaged by rough handling. Use appropriate lifting equipment and avoid dragging panels on rough surfaces.

Secure Panels Correctly

Use compatible fasteners designed for sandwich panels to avoid damaging the core or skins. Fix panels tightly but avoid over-tightening, which can compress the insulation core.

Seal Joints and Edges

Apply approved sealants and gaskets at panel joints to maintain thermal performance and prevent moisture infiltration.

Check Alignment and Levels

Periodically check panel position and level during installation to prevent gaps and misalignments.

Complete Finishing Touches

Install flashings, trims, and accessories to protect edges and improve weather resistance.

Best Practices for Longevity and Performance

To get the most from your 75mm sandwich panel installation, keep these best practices in mind:

- Avoid exposing panels to extreme impacts during installation or handling.

- Maintain proper ventilation in enclosed spaces to prevent condensation buildup.

- Use compatible materials for fasteners and sealants to ensure chemical and thermal compatibility with PUR, PIR, or EPS cores.

- Follow local building codes and manufacturer guidelines strictly for safety and warranty protection.

Maintenance Cleaning Inspection and Repair Tips

Routine care helps extend the life of your sandwich panels and maintains their thermal insulation and structural strength:

- Regular cleaning: Wash panels periodically with mild soap and water to remove dirt, dust, and pollutants that can degrade the skin layers. Avoid abrasive cleaners or solvents.

- Inspection: Check for signs of damage such as dents, delamination, rust (in steel skins), or sealant failure at joints.

- Prompt repairs: Address minor issues like small cracks or sealant gaps quickly to prevent moisture penetration or insulation loss.

- Re-tighten fasteners every 6-12 months to keep panels secure and aligned.

- Protect edges and corners from mechanical wear or impact damage during routine inspections.

By following these installation and maintenance tips, you ensure your Shanghe 75mm sandwich panels deliver reliable performance, strong insulation, and a long lifespan – ideal for all kinds of commercial, industrial, and residential applications.

Environmental and Cost Benefits of 75mm Sandwich Panel

Energy Efficient Buildings and Reduced Carbon Footprint

Shanghe’s 75mm sandwich panels offer excellent thermal insulation, making buildings more energy-efficient. By maintaining stable indoor temperatures, these panels help reduce heating and cooling demands, significantly lowering energy consumption. This translates directly to a smaller carbon footprint—a big plus in today’s push for greener construction.

Cost Savings with Lower Energy Bills and Faster Construction

Using 75mm panels reduces energy expenses due to effective insulation. Buildings stay comfortable year-round without overworking HVAC systems, saving money month after month. Plus, these panels are lightweight and easy to install, which means faster construction times and lower labor costs. The result? Quicker project completion and overall budget savings for your commercial or industrial builds.

Support for Sustainable Construction and Green Certifications

Shanghe’s sandwich panels align well with sustainable building practices. Many of our 75mm panels include eco-friendly core materials like PUR, PIR, or mineral wool, which meet green building standards. Choosing these panels can help with LEED, ENERGY STAR, or other green certification goals by reducing energy demand and using responsible materials.

In , Shanghe’s 75mm sandwich panels provide a solid combination of environmental friendliness and cost-effectiveness, making them an ideal choice for US-based projects focused on performance, savings, and sustainability.