Why Are Foam Cored Aluminium Sandwich Panels Perfect for Cold Storage?

Foam cored aluminium sandwich panels excel in cold storage because their polyurethane (PU) or PIR cores trap heat like a thermos. These panels can cut energy bills by 30% in LEED-certified facilities—Walmart uses them for freezer warehouses. The aluminium sheets add rust-proof durability, even in humid environments.

Need fire safety? Some foam cores blend fire retardants to pass ASTM E84 tests. Whether you pick 50mm or 100mm thickness, foam balances cost and insulation. Architects love them for eco-friendly offices, too—stylish and functional.

Aluminum Composite Panels vs. Aluminium Sandwich Panels: Which Is Stronger?

Aluminum composite panels (ACPs) have a plastic core, making them lightweight for signs or facades. But aluminium sandwich panels use robust cores like mineral wool or foam, ideal for structural jobs like airport roofs. MIT studies show sandwich panels handle wind loads twice as well as ACPs.

For fireproofing, sandwich panels with non-combustible cores (like those in Dubai Metro) outperform ACPs. If you need durability over decor, sandwich panels with 3mm aluminium sheets are the clear winner.

Do Fire-Resistant Aluminium Sandwich Panels Really Stop Flames?

Yes! Fire-resistant aluminium sandwich panels use mineral wool cores that withstand 1,000°C+ flames for 2+ hours—certified by EN 13501 Class A2. They’re mandatory in high-rises like the Burj Khalifa to prevent fire spread.

Though 20% pricier than PE core panels, they slash insurance costs and meet strict codes. Pair them with 2mm aluminium sheets for extra strength. For schools or hospitals, skipping these is a safety gamble.

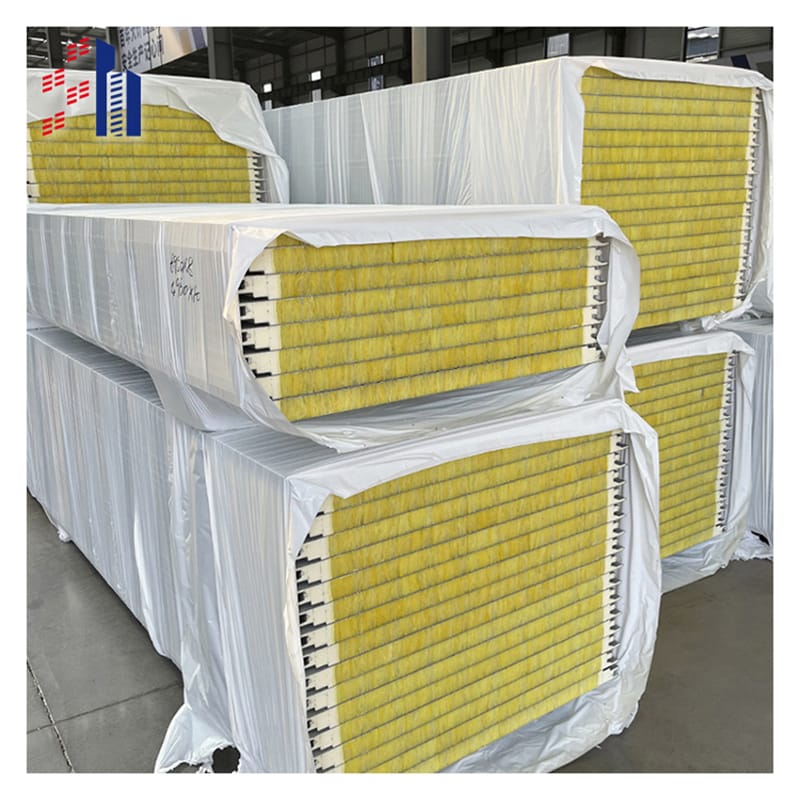

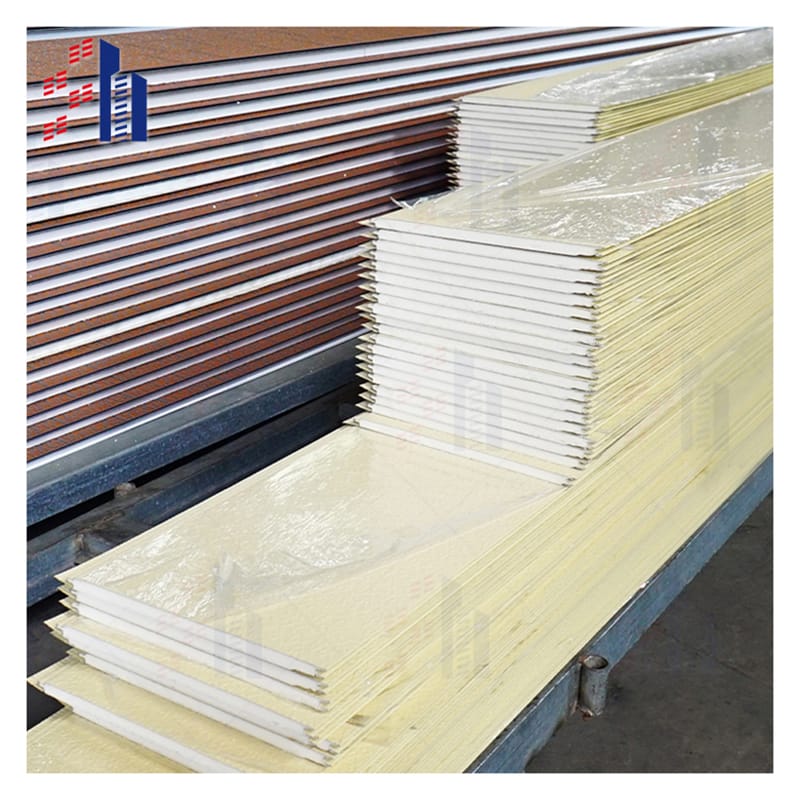

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | metal sandwich panel |

| Panel Material | Metal | Models | SH 150mm pu |

| Usage | Exterior Decoration | Product Name | aluminium sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

How Thick Should Your Aluminium Sandwich Panels Be? (MM Thick Guide)

MM thickness depends on your project: 30-50mm for interior walls, 100mm+ for Arctic warehouses. NASA’s labs use 120mm PE core panels to block extreme temps. LEED projects often require 80mm+ for max energy savings.

Thicker panels (e.g., 150mm) cost more but reduce heating bills by 40%. For fireproofing, mineral cores need at least 50mm to hit UL 94 ratings. Always consult an engineer—overdoing thickness wastes money.