What Are Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels are advanced composite materials consisting of two aluminum alloy sheets bonded to a lightweight foam core. This structure combines the rigidity and durability of aluminum with the lightweight and insulating properties of foam, making them ideal for a wide range of industrial and commercial applications.

Customers visit the factory

Installation details

Key Specifications

| Parameter | Specification | Why It Matters |

|---|

| Face Material | 6-12mm Fiber Cement Board (Density: 1.6g/cm³) | Thinner = lighter weight; Thicker = higher impact resistance. |

| Core Material | Mineral Wool (A1 Fireproof) or PIR Foam (B1 Fire-rated) | A1 = No burning; B1 = Lightweight + insulation. |

| Fire Rating | ASTM E136 (U.S.) / EN 13501-1 (EU) / GB 8624 (China) – Class A1 | Required for high-rises, hospitals, and factories. |

| Thermal Conductivity (λ) | 0.038 W/m·K (Mineral Wool) / 0.022 W/m·K (PIR) | Lower λ = Better insulation (cuts HVAC costs). |

| Load-Bearing Capacity | Up to 150 kPa (Compressive Strength) | Handles heavy wind/snow loads for roofs and walls. |

| Water Resistance | ≤0.5% Water Absorption (ASTM C1185) | No swelling or mold in humid climates. |

| Size Options | Standard: 1220x2440mm / Custom: Max 4000mm length, 50-200mm thickness | Fits modular construction needs. |

| Surface Finish | Smooth, Woodgrain, or Custom Coating (Fade-resistant) | Aesthetic flexibility for architects. |

| Installation | Tongue-and-Groove or Aluminum Rail System | No specialized tools needed; 50% faster than brick. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

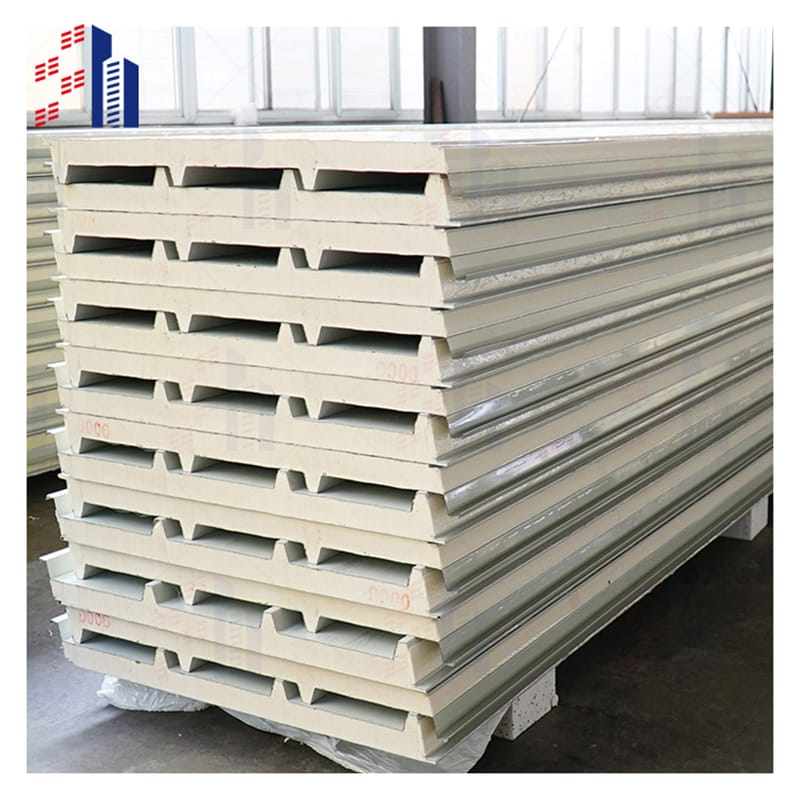

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | Sandwich Panel Uae |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Structure and Definition

These panels typically feature two outer layers of high-quality aluminum alloy, such as grades 3003 or 5052, which provide structural strength and corrosion resistance. Sandwiched between these sheets is a foam core made from materials like polyurethane (PU), extruded polystyrene (XPS), or polyethylene terephthalate (PET). This core is responsible for reducing the panel’s weight while offering thermal and acoustic insulation benefits.

Types of Foam Cores

Understanding the core material is essential to selecting the right aluminum foam sandwich panel. There are two main types of foam cores:

- Closed-cell foam core

- Highly dense structure with sealed cells

- Provides excellent thermal insulation

- Superior moisture and fire resistance

- Common in energy-efficient building applications and harsh environments

- Open-cell foam core

- Porous structure with interconnected cells

- Enhanced sound absorption capabilities

- Less dense, resulting in lower weight but reduced waterproofing

- Ideal for noise reduction in transportation and industrial settings

Manufacturing Processes

The performance of aluminum foam sandwich panels depends heavily on the manufacturing technique used to bond the foam core and aluminum sheets. Shanghes employs two primary bonding methods:

- Ex-situ bonding

- Pre-formed foam core panels are bonded externally to aluminum sheets using adhesives or mechanical fasteners.

- Allows for high flexibility in panel thickness and material combinations.

- Common for customized designs and retrofit projects.

- In-situ bonding

- Foam core is created directly between aluminum sheets during production, often using chemical foaming agents.

- Results in a seamless bond with enhanced structural integrity.

- Preferred for high-strength applications requiring precise dimensional control.

Both methods ensure strong adhesion, maintaining the panel’s durability and lightweight properties while meeting industry standards for safety and performance.

Shanghes aluminum foam sandwich panels deliver a perfect balance between lightweight design and high structural performance thanks to their advanced foam core technology and superior aluminum alloy facings. Whether for construction, transportation, or industrial use, understanding the materials and manufacturing behind these panels is key to maximizing their value in your projects.

Key Features and Benefits of Shanghes Aluminum Foam Sandwich Panels

Shanghes aluminum foam sandwich panels stand out for their outstanding performance and versatility, making them a top choice for many industries across the U.S. Here’s why these lightweight aluminum panels deliver exceptional value:

Lightweight with High Strength-to-Weight Ratio

Our panels combine two durable aluminum alloy sheets with a lightweight foam core, offering a superior strength-to-weight ratio. This makes them ideal for weight-sensitive applications such as transportation, aerospace, and modern construction, where lowering dead weight can improve fuel efficiency and reduce costs without compromising strength.

Excellent Thermal Insulation

Thanks to their foam core, Shanghes aluminum foam sandwich panels provide outstanding heat resistance and energy efficiency. Whether for building facades or refrigerated truck bodies, these panels help maintain stable temperatures, cutting down HVAC costs and improving overall insulation performance.

Superior Sound Absorption

Noise reduction is crucial in environments like industrial facilities, transportation, and commercial buildings. Our panels deliver effective sound absorption, reducing unwanted noise and creating quieter, more comfortable spaces without adding bulk.

Reliable Fire Resistance

Shanghes aluminum sandwich panels meet stringent fire safety standards, offering fireproof protection suitable for fire-prone settings. This ensures safer environments in construction, industrial facilities, and transportation sectors where fire resistance is non-negotiable.

Outstanding Corrosion Resistance

Built to withstand harsh weather and corrosive environments, these panels feature durable aluminum alloys and eco-friendly foam cores resistant to moisture, rust, and chemical exposure. This durability makes them perfect for outdoor use, coastal areas, and industrial applications.

Customizable Finishes and Sizes

To suit different projects and design preferences, Shanghe offers a range of custom finishes including wood grain, stone textures, and various RAL colors. Panels come in multiple thicknesses and sizes, allowing easy integration into architectural designs, transportation builds, or industrial equipment.

By combining these key features, Shanghes aluminum foam sandwich panels provide a balanced solution that meets the demands of U.S. customers looking for lightweight, durable, and versatile composite sandwich panels. Whether you’re tackling construction projects, transportation needs, or industrial enclosures, these panels deliver performance with style and reliability.

Applications of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels are highly versatile and used across many industries thanks to their lightweight, strength, and thermal insulation properties. Here’s a breakdown of key applications where these panels make a real impact:

Construction and Architecture

Ideal for building facades, interior partitions, roofing, and cold storage facilities, these panels offer excellent thermal insulation and corrosion resistance. Their fire-resistant nature also contributes to safer building envelopes, while customizable finishes (wood grain, stone) fit various aesthetic needs.

Transportation and Vehicle Manufacturing

In refrigerated trucks, RVs, train interiors, and aerospace components, aluminum foam sandwich panels reduce vehicle weight without compromising durability. This helps improve fuel efficiency and enhances insulation for temperature-sensitive cargo or passenger comfort. For example, Shanghe’s panels have been successfully used to upgrade refrigerated truck bodies, significantly improving thermal performance and energy savings during transit.

Industrial Equipment and Soundproofing

Panels are perfect for equipment enclosures and factory soundproofing, helping reduce noise pollution and protect machinery from harsh environments. Their sound absorption qualities create quieter workplaces, critical in industrial settings.

Military and Aerospace

In military and aerospace uses, the panels provide energy absorption for protective structures like armor or landing gear. Their lightweight yet sturdy design helps meet strict safety and performance standards, contributing to improved impact resistance and overall vehicle stability.

Case Study: Refrigerated Truck Enhancement

A refrigerated truck outfitted with Shanghe’s aluminum foam sandwich panels experienced:

- Improved thermal insulation, reducing cooling system workload

- Lower overall vehicle weight, boosting fuel efficiency

- Enhanced structural integrity for longer service life

This real-world example highlights how Shanghe’s aluminum foam sandwich panels deliver durable, efficient, and practical solutions for temperature-controlled transportation.

Using aluminum foam sandwich panels lets you benefit from lightweight strength, thermal and acoustic insulation, plus fire and corrosion resistance—all tailored to your project’s unique demands. Whether for construction, transport, or industrial uses, Shanghe offers reliable panels designed to perform in the toughest U.S. environments.

Why Choose Shanghes Aluminum Foam Sandwich Panels

When it comes to aluminum foam sandwich panels, Shanghes stands out for a reason. Here’s why our panels are the right choice for your next project:

Premium Materials for Reliable Performance

We use high-quality aluminum alloys like 3003 and 5052 paired with eco-friendly foam cores such as PU, XPS, and PET. This ensures not only strength and durability but also an environmentally responsible product—important for sustainable building and manufacturing.

Advanced Manufacturing for Precision and Strength

Our production process uses vacuum compression bonding combined with CNC precision cutting, giving you panels that fit perfectly and deliver consistent performance. This advanced tech keeps the core bonded tightly to the aluminum sheets, preventing delamination and enhancing structural integrity.

Customization to Fit Your Needs

Every project is unique, and we offer custom sizes, thicknesses, and surface finishes including PVDF coatings, anodized layers, and popular textures like wood grain or stone. You can select from a wide range of RAL colors as well, making it easy to match any aesthetic or functional requirement.

Certified to Meet Industry Standards

Shanghes panels comply with international certifications including ISO quality management and fire safety standards. This gives you peace of mind knowing the panels meet or exceed the benchmarks for safety, durability, and environmental responsibility.

Competitive Pricing and Reliable Delivery

We balance premium quality with competitive prices and make sure your orders arrive on time, backed by solid customer support. This reliability makes us a top choice among manufacturers and contractors in the U.S. market.

Choosing Shanghes means getting lightweight aluminum foam core panels that combine strength, insulation, and style—all backed by trusted quality and service.

Technical Specifications of Aluminum Foam Sandwich Panels

Our aluminum foam sandwich panels come with a wide range of specifications to meet different project needs across the U.S. market. Here’s a clear guide to their technical details and customization options.

Standard Dimensions

- Thickness: 10mm up to 120mm, offering flexibility for lightweight to heavy-duty applications

- Width: 800mm to 2600mm, suitable for large facade panels or smaller interior sections

- Length: Up to 12 meters, allowing for large-scale construction or transport paneling without joints

Core Materials

We use several core options, each tailored for different performance needs:

| Core Material | Description | Key Properties |

|---|

| PU (Polyurethane) | Closed-cell foam | Strong thermal insulation, lightweight |

| XPS (Extruded Polystyrene) | Rigid closed-cell foam | High compressive strength, moisture resistant |

| PET (Polyethylene Terephthalate) | Eco-friendly recycled foam | Good insulation, recyclable |

| PVC (Polyvinyl Chloride) | Lightweight foam core | Fire-resistant, durable |

Additional core materials are available on request to suit specific industrial or environmental requirements.

Aluminum Grades and Surface Treatments

- Aluminum Alloys: Primarily 3003 and 5052 grades, known for excellent corrosion resistance and strength.

- Surface Finishes:

- PVDF coatings for long-lasting color retention and UV protection

- Anodized treatments for enhanced corrosion resistance

- Embossing options to add texture or patterns

- Custom RAL color matching to fit design needs, including wood grain and stone finishes

Performance Comparison of Core Materials

| Core Type | Density (kg/m³) | Thermal Insulation (W/m·K) | Weight (lbs/ft²) | Fire Resistance |

|---|

| PU | 35-80 | 0.022-0.028 | Light to moderate | Moderate |

| XPS | 30-50 | 0.029-0.034 | Moderate | High |

| PET | 40-70 | 0.035-0.040 | Moderate | Good |

| PVC | 40-70 | 0.035-0.040 | Moderate | Very High |

Weights and insulation values vary depending on panel thickness and density chosen.

With these detailed specs and customization options, you can pick the right aluminum foam core panel to balance weight, strength, thermal performance, and appearance for your construction, transportation, or industrial application.

How to Select the Right Aluminum Foam Sandwich Panel for Your Project

Choosing the perfect aluminum foam sandwich panel means balancing your project’s needs with the panel’s core features. Here’s a straightforward guide to help you make the best choice.

Consider Your Application and Environment

- Where will the panel be used?

Panels for building facades or roofing need different properties than those used in transportation or industrial enclosures. - Exposure conditions:

If your project faces harsh weather, moisture, or corrosive environments, prioritize panels with strong corrosion resistance and durable aluminum grades like 5052. - Thermal and acoustic needs:

For insulation or soundproofing, consider panels with foam cores known for thermal insulation and sound absorption like PU or PET.

Match Core Material to Project Demands

- PU foam offers lightweight and excellent insulation—ideal for construction and refrigerated transport.

- XPS foam has high compressive strength and moisture resistance, great for cold storage and outdoor use.

- PET foam is eco-friendly and good for sound absorption in industrial or commercial applications.

- PVC foam is fire-resistant, suitable for fire-sensitive areas or aerospace.

Aluminum Thickness and Grade

- Thicker aluminum sheets provide higher strength and durability but add weight—perfect for heavy-duty applications.

- Thinner sheets reduce weight, improving fuel efficiency in transport or aircraft parts but may sacrifice some strength.

- Common aluminum alloys include 3003 for general use and 5052 for enhanced corrosion resistance.

Budget and Size Requirements

- Define your budget early, balancing cost versus performance. Higher-grade foam cores and aluminum alloys come at a premium but deliver longer lifespan and better performance.

- Standard panel sizes range from 10-120 mm thickness, widths of 800-2600 mm, and lengths up to 12 meters—custom sizes are available if needed.

Use Shanghe’s Expert Consultation Services

If you’re unsure which panel fits your project best, Shanghe’s team offers tailored advice based on your application, environment, and budget. They can help you pick the right core material, aluminum grade, and finish to ensure optimal performance.

Key takeaways when selecting aluminum foam sandwich panels:

- Match core materials to insulation, weight, and fire requirements

- Choose aluminum thickness based on strength and environmental exposure

- Align size and budget before ordering

- Leverage expert consultation for customized solutions

This approach guarantees you get high-quality, durable, and efficient aluminum foam sandwich panels that precisely fit your project’s demands.

Environmental Benefits and Sustainability of Aluminum Foam Sandwich Panels

Recyclable Materials for a Greener Future

Shanghe’s aluminum foam sandwich panels are made using highly recyclable aluminum alloys paired with environmentally friendly foam cores like PET. Both materials can be processed and reused, cutting down on landfill waste and reducing the need for virgin raw materials. This makes our panels a smart choice for eco-conscious projects across the U.S.

Enhanced Energy Efficiency

Our panels offer excellent thermal insulation, which helps keep buildings cooler in the summer and warmer in the winter. This reduces reliance on heating and cooling systems, leading to lower energy bills and decreased carbon footprints. For homeowners and businesses alike, this means not only savings but also a positive step toward sustainability.

Commitment to Eco-Friendly Manufacturing

Shanghe prioritizes green manufacturing practices throughout production. We use energy-efficient processes, minimize waste, and carefully select materials that reduce environmental impact without compromising quality. This commitment helps ensure you receive a durable, sustainable product designed for long-term performance.

Why It Matters for U.S. Customers

- Use of recyclable aluminum and PET foam cores aligns with growing U.S. regulations and incentives for sustainable building materials.

- Improved energy efficiency supports green building certifications such as LEED and ENERGY STAR.

- Durable and corrosion-resistant panels reduce the need for frequent replacements, cutting down on resource consumption over time.

By choosing Shanghe aluminum foam sandwich panels, you’re investing in a product that delivers reliable performance and helps protect the environment — making it a win-win for your projects and the planet.

Aluminum Foam Sandwich Panels FAQ

What is the Lifespan of Aluminum Foam Sandwich Panels

Shanghe’s aluminum foam sandwich panels are built to last. Depending on the application and environment, they typically offer a lifespan of 25 to 50 years. The durable aluminum skins combined with corrosion-resistant foam cores like PU, XPS, or PET ensure long-term stability even in harsh outdoor or industrial settings.

Are Shanghe Panels Fireproof

Yes, Shanghe’s aluminum foam sandwich panels meet stringent fire safety standards. The foam cores used, particularly those rated for fire resistance, alongside aluminum’s natural non-combustible qualities, make these panels fireproof and suitable for safety-critical environments such as commercial buildings and transportation.

Can Panels be Customized with Specific Colors or Patterns

Absolutely. We offer extensive customization options including:

- RAL color matching for any shade you need

- Decorative finishes like wood grain or stone patterns

- Multiple surface treatments such as PVDF coating or anodizing

This lets you match the panels to your project’s aesthetic while keeping core technical advantages intact.

How Do Aluminum Foam Sandwich Panels Compare to Honeycomb Panels

Both are lightweight composite panels, but key differences include:

| Feature | Aluminum Foam Sandwich Panel | Honeycomb Panel |

|---|

| Core Structure | Closed or open-cell foam (PU, XPS, PET) | Honeycomb-shaped aluminum or paper |

| Impact Absorption | Excellent energy absorption, ideal for safety | Good but generally less impact resistant |

| Thermal Insulation | Superior thermal insulation thanks to foam core | Lower thermal resistance |

| Sound Absorption | High noise dampening due to foam | Minimal sound absorption |

| Weight | Slightly heavier but offers better strength | Ultra-light but less rigidity |

| Customization | Wide range of finishes and thicknesses | Limited finishes and core types |

Choose aluminum foam sandwich panels when you need better insulation, durability, and impact resistance, especially in the U.S. market where building codes and standards are strict.

How to Order Aluminum Foam Sandwich Panels from Shanghe

Ordering is straightforward and customer-friendly:

- Request a Quote: Visit our website or email us your project specs.

- Consultation: Our team helps select the best panel type, thickness, core material, and finish based on your needs.

- Custom Sample: We provide samples to confirm color and texture.

- Place Your Order: We handle bulk orders and custom sizes with reliable lead times.

- Shipping: Global shipping with tracking and customer support ensures your panels arrive on time.

Contact us via phone, email, or live chat to get started on your aluminum foam sandwich panel project today.

For any project requiring lightweight aluminum panels with strong fireproof, thermal insulation, and customizable options, Shanghe’s aluminum foam sandwich panels provide a proven, eco-friendly solution made to last in the U.S. market.

Contact Shanghe for Aluminum Foam Sandwich Panel Solutions

When you’re ready to buy aluminum foam sandwich panels or need professional advice, Shanghe is here to help. Whether you want to request a quote, schedule a consultation, or explore our full product catalog, we make the process simple and straightforward.

How to Reach Shanghe

You can easily inquire about custom aluminum foam sandwich panel options, get pricing, or ask about technical specs directly through any of these channels.

Our Service and Shipping

- Global Shipping: We ship aluminum foam core panels across the United States and worldwide, ensuring fast and reliable delivery no matter your location.

- Customer Support: Our knowledgeable team is available to assist you with product selection, customization, and troubleshooting so your project runs smoothly.

Why Choose Shanghe for Aluminum Foam Sandwich Panels

- Quick responses to inquiries and detailed product information

- Flexibility with sizes, finishes, foam types, and aluminum grades

- Support for eco-friendly and energy-efficient solutions

- Competitive pricing with no compromise on quality

For any questions or to place your order, contact Shanghe today and experience the convenience and reliability of working with a top aluminum foam sandwich panel manufacturer tailored for the US market.