How Composite Panels Revolutionize Modern Construction

Composite panels are changing the game in construction, offering a blend of durability and design flexibility. Unlike traditional materials, aluminum composite panels (ACPs) combine lightweight aluminum sheets with core layers like polyethylene (PE), creating structures that resist warping and weathering. For example, LEED-certified projects often use ACPs for their energy efficiency and recyclability. Architects love how these panels maintain their finish for decades, even in coastal areas prone to salt spray. Whether it’s a skyscraper or a retail store, composite panels deliver high performance without sacrificing aesthetics.

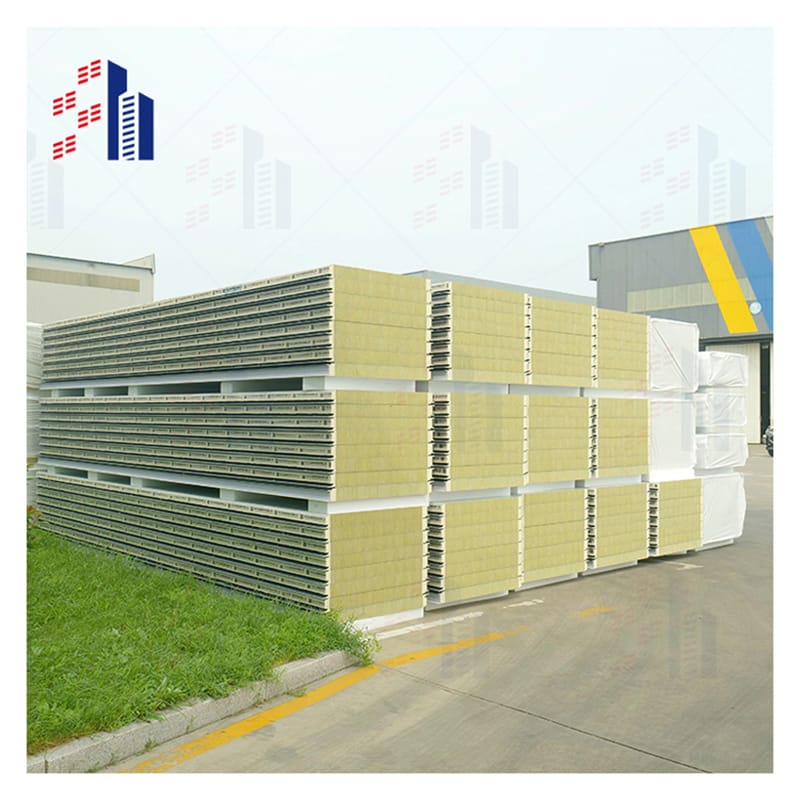

The Hidden Strengths of Sandwich Panel Technology

Sandwich panels aren’t just layers of material—they’re engineered for maximum strength. At their core, materials like mineral wool or PE foam act as insulators, while aluminum sheets on the outside handle heavy loads and harsh weather. Think of them as the “safety net” of building exteriors. A 2021 study by MIT highlighted how sandwich panel designs reduce energy costs by up to 30% in commercial buildings. From airport hangars to cold storage facilities, these panels are built to outperform single-layer alternatives.

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | metal sandwich panel |

| Panel Material | Metal | Models | SH 150mm pu |

| Usage | Exterior Decoration | Product Name | aluminum sandwich panels |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Why High-Quality Aluminum Panels Are Worth Every Penny

High-quality aluminum sandwich panels are an investment, not an expense. Cheap imitations might save money upfront, but they crack or fade under UV exposure. Premium panels, like those with a PVDF coating, stay vibrant and dent-resistant for over 20 years. Take the Burj Khalifa—its façade uses top-tier aluminum composite materials to withstand Dubai’s extreme heat. For projects where longevity matters, cutting corners isn’t an option.

Weather-Resistant Aluminum: Survival Gear for Buildings

If your building faces hurricanes, blizzards, or scorching sun, weather-resistant aluminum panels are a must. These panels use a patented alloy (like AluGuard™) to prevent oxidation and fading. In Miami, where hurricanes are routine, contractors swear by their ability to handle 150 mph winds without bending. Plus, their powder-coated finishes repel moisture, making mold and rust a non-issue.

Corrosion-Resistant Panels: The Secret to Long-Lasting Facades

Saltwater, acid rain, and pollution eat through ordinary metals—but not corrosion-resistant aluminum composite panels. Brands like Alucobond® use a chromium treatment to create a barrier against chemical damage. The Sydney Opera House, exposed to ocean air daily, relies on similar tech to keep its iconic look. For factories or coastal homes, these panels are like a built-in insurance policy.