Caseta Panel Sandwich: The Ultimate Solution for Durable, Customizable Prefab Buildings

If you’re looking for a strong, insulated, and hassle-free structure, a Caseta panel sandwich is your best bet. These prefab units are built with high-quality sandwich panels—two rigid layers with an insulating core—making them perfect for worksites, storage, or even backyard offices. Unlike traditional construction, they’re quick to install, energy-efficient, and fully customizable.

What makes them stand out? Well, they’re weatherproof, fire-resistant (often meeting LEED-certified standards), and built to last decades. No more dealing with rotting wood or rusting metal sheds. Plus, since they’re prefabricated, you avoid the mess and delays of on-site building. Whether you need a workshop, garden shed, or temporary site office,

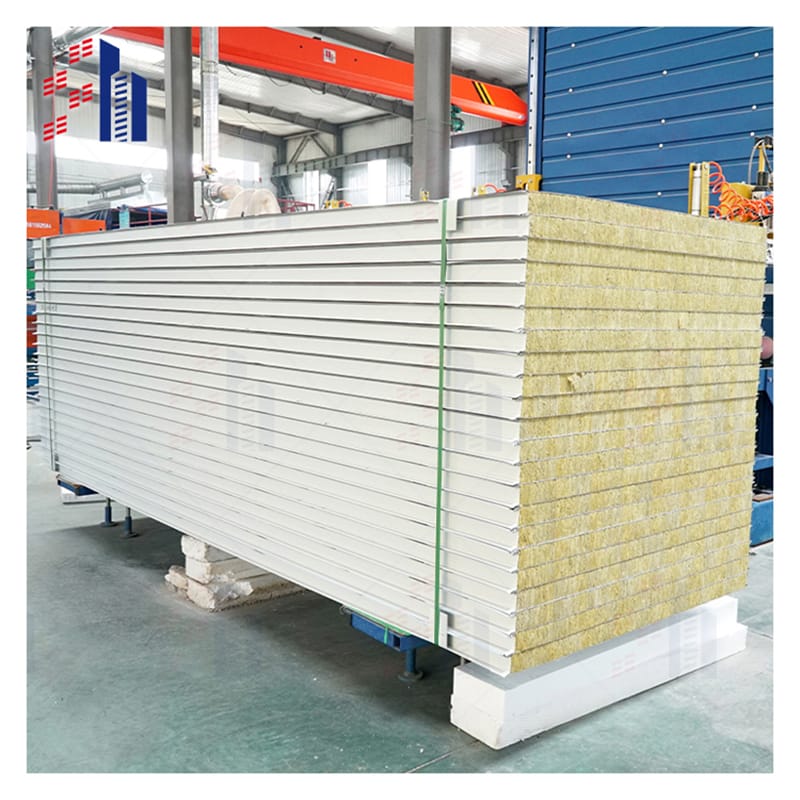

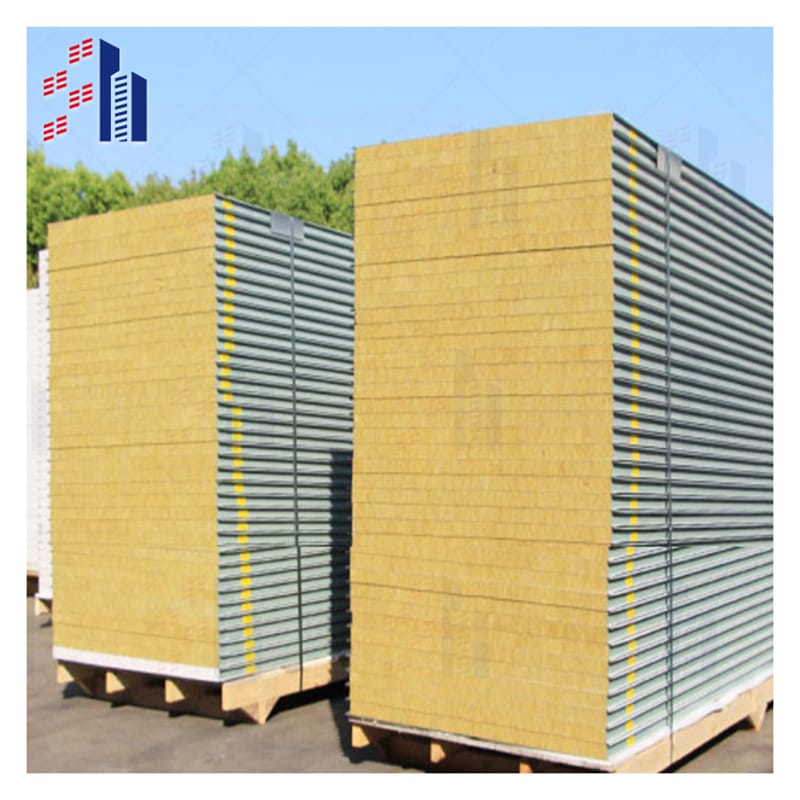

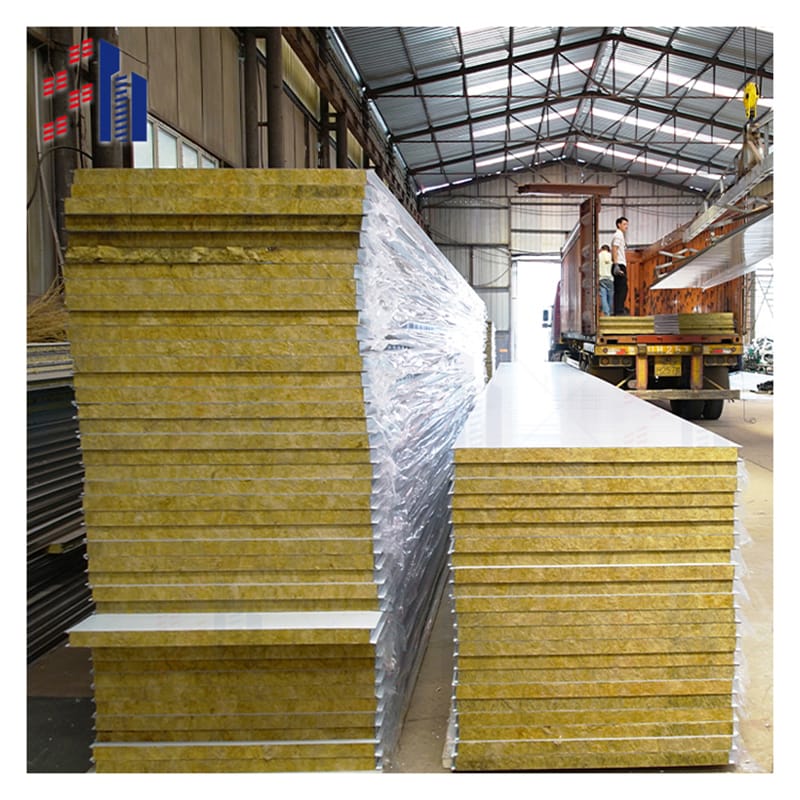

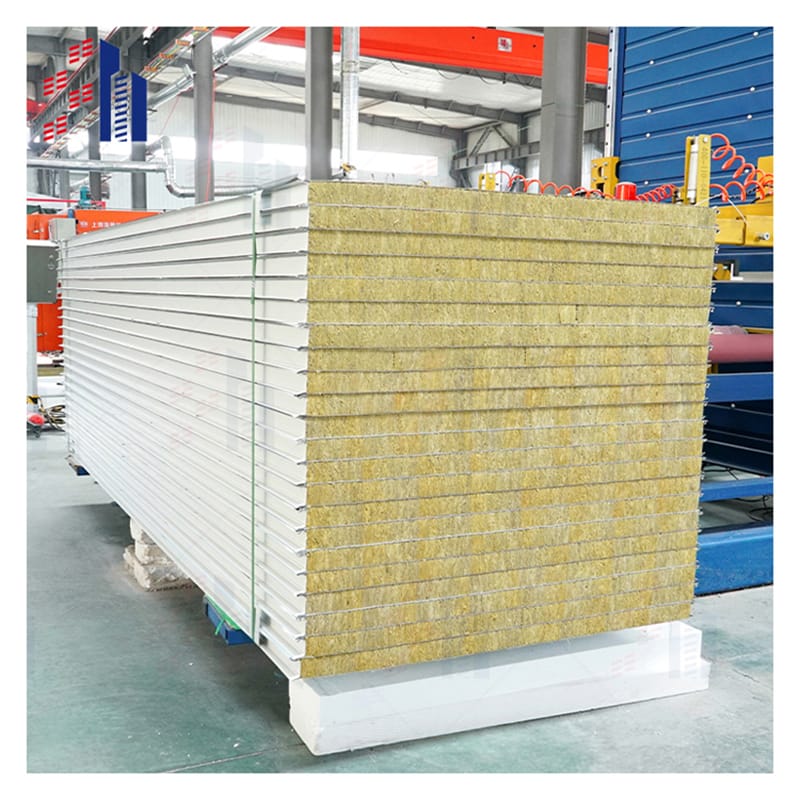

Customers visit the factory

Installation details

Key Specifications

| Parameter | Details | Why It Matters |

| Core Material | PIR Foam (Best R-value) • Rockwool (Fireproof) • EPS (Budget) | PIR saves 40% on heating bills vs. EPS. |

| Thickness | 50mm • 75mm • 100mm • 120mm (Customizable) | 100mm = Best for year-round living. |

| Fire Rating | A1 (Non-combustible) – EN 13501 / ASTM E84 Class A | Required for US/Canada modular home permits. |

| R-Value | Up to R-6.5 per inch (PIR core) | Beats fiberglass insulation (R-3.2). |

| Load Capacity | 150 kPa (Supports rooftop solar panels) | Critical for snow-heavy regions. |

| Panel Width | 1,150mm (Standard) • Up to 1,200mm (Custom) | Wider panels = Fewer seams, faster install. |

| Surface Options | Galvanized Steel • PVDF Coated • Woodgrain | PVDF resists coastal salt corrosion. |

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | 3D Cementitious Sandwich Panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

Caseta Panel Sandwich a Medida: Get a Perfect Fit for Your Space (No Wasted Room!)

Tired of prefab sheds that almost fit but leave awkward gaps? A Caseta panel sandwich a medida (custom-built) solves that. These aren’t one-size-fits-all boxes—they’re tailored to your exact dimensions, whether you need a narrow toolshed or a sprawling backyard studio.

Here’s the deal: You give the measurements, and the panels are precision-cut off-site. No hacking away at materials or compromising on space. Need an extra window? A reinforced floor? Done. Custom builds also mean better insulation (no drafts!) and cleaner finishes (no ugly seams). It’s like a bespoke suit for your backyard—just way more heavy-duty.

Caseta Prefabricada Panel Sandwich: Assemble in Hours, Not Weeks (Zero Construction Hassle)

If the thought of weeks of construction noise and debris makes you cringe, a Caseta prefabricada panel sandwich is your shortcut. These arrive as pre-cut, pre-insulated panels—just bolt them together, and boom, your structure is up. No waiting for cement to dry or carpenters to show up.

Why’s this a game-changer? Time = money. A traditional shed might take a month; a prefab Plus, since panels are factory-made, quality is consistent (no warped wood or weak spots). Perfect for emergency site offices, pop-up retail spaces, or even a last-minute guest room.

Caseta Jardín Panel Sandwich: The Stylish, No-Rot Upgrade Your Backyard Deserves

That old wooden garden shed? It’s one rainy season away from mold city. A Caseta jardín panel sandwich swaps rot and pests for sleek, low-maintenance durability. The sandwich panels resist moisture, UV rays, and even pests (termites hate these things).

But it’s not just tough—it’s aesthetic. Modern designs mimic wood or metal finishes, so your shed doesn’t stick out like an eyesore. Add French doors, skylights, or even a green roof. Unlike flimsy plastic units, this won’t crack in winter or bake into a sauna come summer.

Caseta con Panel Sandwich: Why Build from Scratch When You Can Snap It Together?

Let’s be real: Traditional construction is a money pit. A Caseta con panel sandwich skips the headaches—no masons, no lumber deliveries, no surprise costs. The panels arrive ready to assemble, like a giant, ultra-strong LEGO set.

The perks? Faster, cheaper, and smarter. The insulated core slashes energy bills (great for heated workshops), and the steel/aluminum skins shrug off storms. Even better, disassembly is a breeze—move it, expand it, or sell it later. No rubble, no regrets.

Caseta Desmontable Panel Sandwich: Take It with You When You Move (Yes, Really!)

Renting? Relocating often? A Caseta desmontable panel sandwich goes where you go. Unlike fixed structures, these unbolt into lightweight panels for easy transport. No abandonment guilt or demolition fees.

Ideal for contractors, event vendors, or military families. Set it up as a site office this month, a lakeside cabin next year. The airtight seals prevent drafts, and the rigid panels won’t sag like tents or trailers. Portable and professional-grade.

Caseta Hecha con Panel Sandwich: How Factories Build Smarter Than On-Site Crews

Ever seen a construction crew cut corners? A Caseta hecha con panel sandwich avoids that—every panel is factory-tested for fit and strength before shipping. That means no wonky walls or leaky joints.

Precision engineering matters. Think airplane or car manufacturing—controlled conditions beat outdoor guesswork. The result? Tighter insulation, straighter walls, and zero wasted materials. Even the wiring/plumbing slots are pre-mapped.

Caseta de Obra Panel Sandwich: The Temporary Office That Outlasts the Job Site

Temporary shouldn’t mean flimsy. A Caseta de obra panel sandwich gives construction crews a dust-proof, weatherproof HQ that’s tougher than trailers. Heavy machinery vibration? No cracks. Pouring rain? No leaks.

Bonus: These often qualify for LEED points (sustainable materials + energy efficiency). At project end, relocate it—no demolition waste. Cheaper than leasing a mobile unit, sturdier than a Portakabin.

Construir Caseta Panel Sandwich: DIY It Without the Usual Disasters

Think you need a contractor? Nope. With a kit Caseta panel sandwich, you can DIY like a pro. The panels slot together with basic tools, and manuals are IKEA-level clear.

Key perks: No foundation needed (gravel or slabs work), no special permits (usually), and no skill gaps—just follow the numbered steps. YouTube tutorials cover the rest. Even first-timers get it done in a weekend.

Kit Caseta Panel Sandwich: Everything in One Box (Even the Screws!)

Nothing kills a DIY project like missing parts. Open the box, and you’re 100% ready.Why this rocks: No last-minute hardware runs, no mismatched panels. Kits often include optional add-ons (solar roof hooks, shelving mounts). Just add coffee and a buddy to lift the heavy bits. Done by sundown.