Why Ceiling Sandwich Panels Are the Smartest Upgrade for Modern Spaces

With over two decades specializing in sandwich panels, I’m David, and let me tell you—ceiling sandwich panels solve problems most builders don’t even realize they have. These lightweight, insulated panels aren’t just for walls or roofs anymore. They’re revolutionizing ceilings by cutting installation time, slashing energy costs, and delivering a polished finish that lasts. If you’re still using traditional drywall or acoustic tiles, you’re throwing money—and time—out the window.

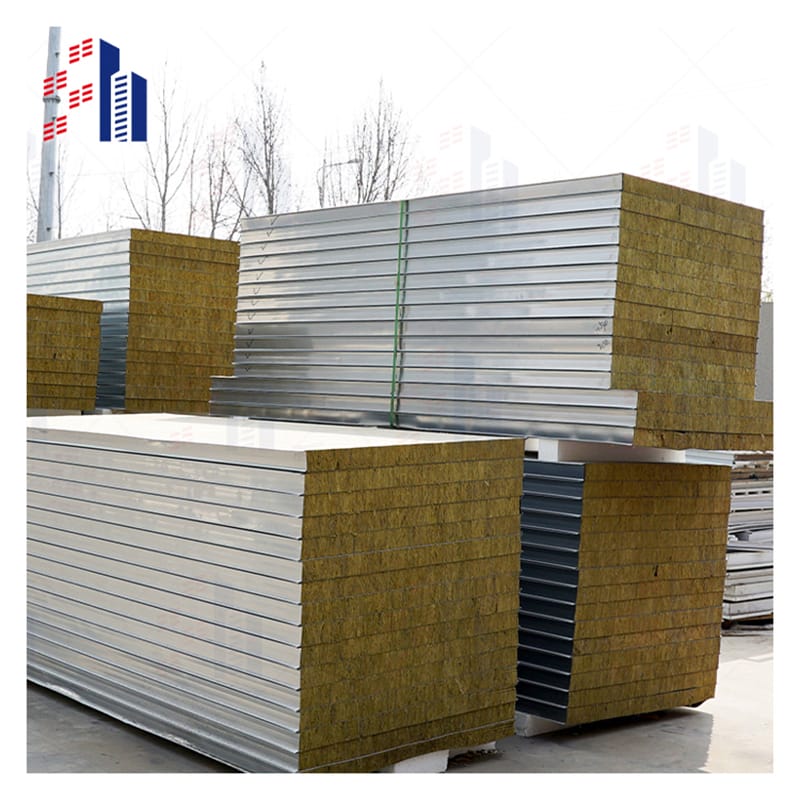

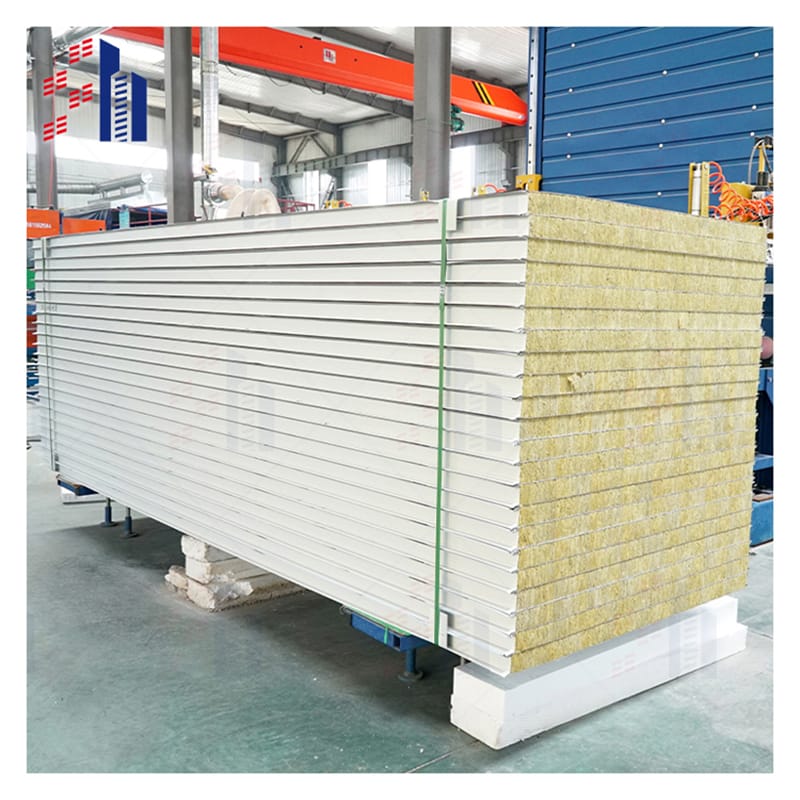

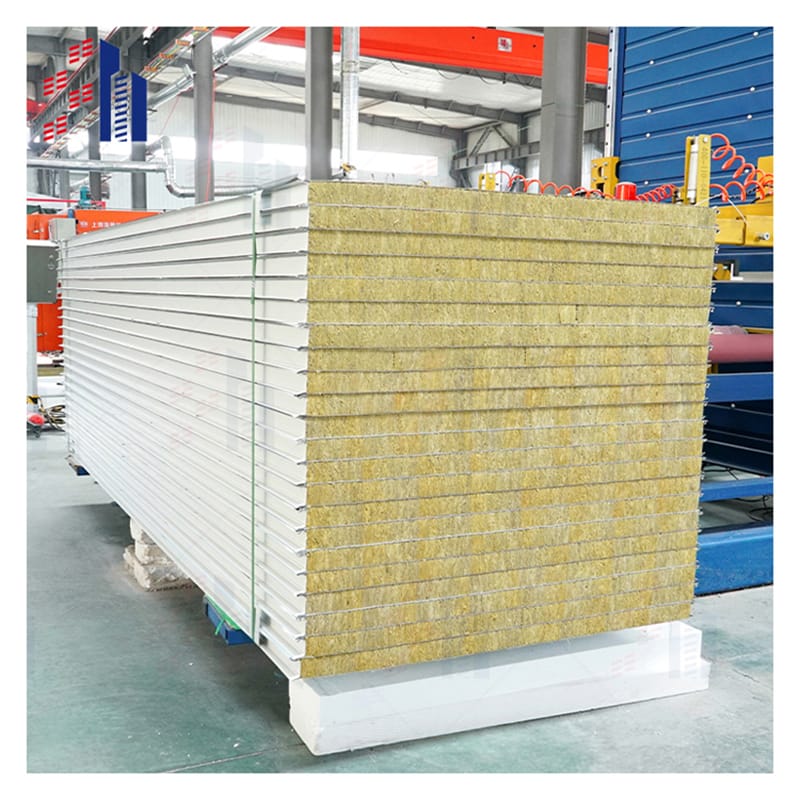

Important attributes |

| design | the present age | After-sales service | Online Technical Support, Other |

| Origin | Shandong, China | Application Scenarios | Warehouse |

| Brand | SH | Warranty Service | polyurethane |

| Panel Material | polyurethane | Models | SH 150mm |

| Usage | Exterior Decoration | Product Name | ceiling sandwich panel |

| Surface Material | Metallic | Minimum Order | Personalization |

| Thickness | 16MM/20MM/25MM | Color | Bright red, vermillion, lime, sky blue, aquamarine, pea green or customized |

| Width | 100mm,120mm,150mm,200mm | | |

How to Avoid Costly Mistakes in Commercial Projects

Let’s cut to the chase: choosing the wrong ceiling panel can tank your project’s budget and timeline. I’ve watched contractors waste weeks fixing sagging drywall or moldy acoustic tiles. Ceiling sandwich panels eliminate those headaches. Unlike conventional materials, these panels integrate insulation, vapor barriers, and fire resistance (often meeting ASTM E84 Class A standards) into one pre-engineered system. One hotel client in Miami saved 37% on HVAC costs after switching—proof that smarter materials mean fewer callbacks. Pro tip: Always check load-bearing specs for large spans to avoid deflection issues.

Ceiling Panels 101: Why Your ‘Budget-Friendly’ Choice Is Actually Costing You

Here’s the ugly truth: Cheap ceiling panels are a false economy. Thin metal sheets dent during installation, fiberglass traps moisture, and PVC warps under heat. I’ve replaced more “affordable” ceilings than I can count. High-density PU core sandwich panels, though pricier upfront, outlast alternatives by decades. A LEED-certified office complex in Austin used our 100mm panels and saw a 22% reduction in annual energy bills. Remember, labor costs to fix a failed ceiling often exceed the original material price—invest wisely.

False Ceiling Sandwich Panel Myths Debunked by a 20-Year Pro

“False ceilings are just cosmetic.” Nope. Modern false ceiling sandwich panels do heavy lifting: noise reduction (up to 32 dB), thermal regulation, and even hiding HVAC ducts seamlessly. I worked on a Chicago high-rise where we installed fire-rated panels that concealed sprinkler systems while maintaining a 9’ ceiling height. The trick? Use interlocking tongue-and-groove edges—no visible fasteners, no compromised fire ratings.

Sandwich Panel Ceiling Detail: The Hidden Factor That Can Make or Break Your Design

Details matter. I once saw a luxury condo project delayed because joints between sandwich panels weren’t properly sealed. Lesson: Always specify panels with integrated gaskets or thermal-break edges. For curved ceilings, opt for 1.2mm aluminum-faced panels—they bend smoothly without kinking. Pro tip: Use shadow-line joints for high-end finishes; it hides minor imperfections and adds depth.

Sandwich Panel Ceiling Price Breakdown: Where Contractors Get Ripped Off

Price shock? Usually from hidden extras. A $12/sq ft panel sounds great until you factor in custom cutting ($3.50/lf), specialty coatings ($1.80/sq ft), or reinforced cores for heavy light fixtures. Always demand a full spec sheet. Example: A Dallas warehouse saved $14k by using standard 50mm panels instead of “premium” 75mm where code allowed.

Sandwich Panel Ceiling Design Trends That Actually Work (No Gimmicks)

Forget “trendy”—focus on timeless function. Brushed stainless steel finishes are surging for industrial lofts, but ensure they’re PVDF-coated to resist fingerprints. Perforated panels for acoustics? Go for 18% open area—anything higher weakens the structure. Recently, a Nashville music venue used our micro-perf design to achieve NRC 0.85 without ugly foam add-ons.

Sandwich Panel Ceiling Installation: 3 Time-Killing Errors Even Experts Make

Mistake #1: Ignoring expansion gaps. Aluminum expands 0.012% per 10°F—leave 1/8” per 20ft. Mistake #2: Using steel screws with aluminum panels (galvanic corrosion alert!). Mistake #3: Not pre-drilling fastener holes, which cracks cores. I train crews to use rubber-gasket washers and torque drivers set to 35 in-lb.

Sandwich Panel Secrets: Why 83% of Architects Specify Them for High-End Builds

It’s not just durability. LEED v4.1 rewards sandwich panels for recycled content (up to 70% post-consumer aluminum) and off-site fabrication reducing waste. A Harvard study found modular panels cut construction debris by 62% vs traditional methods. Plus, with patent-backed systems like Alucobond®, you get 30-year fade warranties—something gypsum can’t touch.